Method for quickly starting polymerization reaction in alpha-olefin gas-phase fluidized bed reactor

A gas-phase fluidized bed and polymerization reaction technology, which is applied in the field of rapid start-up of α-olefin gas-phase fluidized bed reactor polymerization reaction, can solve the problem of unseen α-olefin rapid start-up method, unfavorable energy saving and consumption reduction, slow polymerization reaction, etc. problems, to achieve the effect of saving energy, reducing consumption, improving product market competitiveness, and avoiding production accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

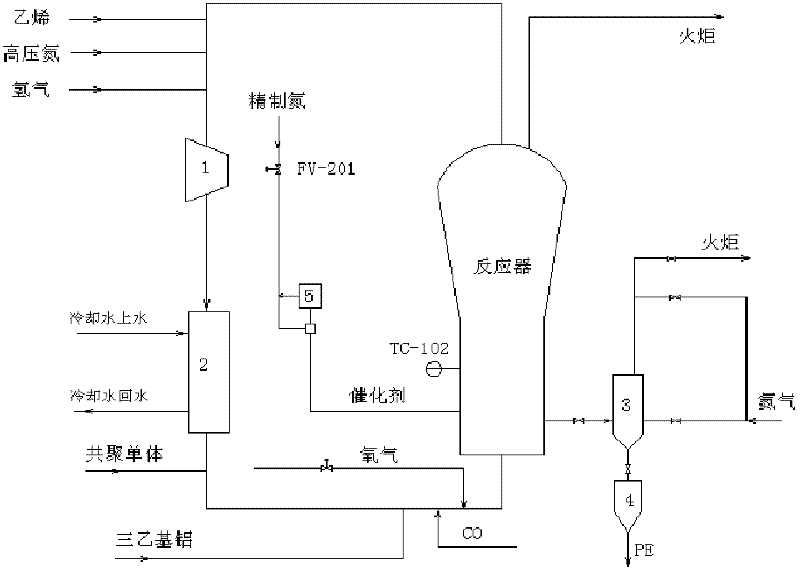

Image

Examples

Embodiment 1

[0066] Example 1 Production of high-density polyethylene by using α-olefin gas-phase fluidized-bed reactor polymerization quick start method

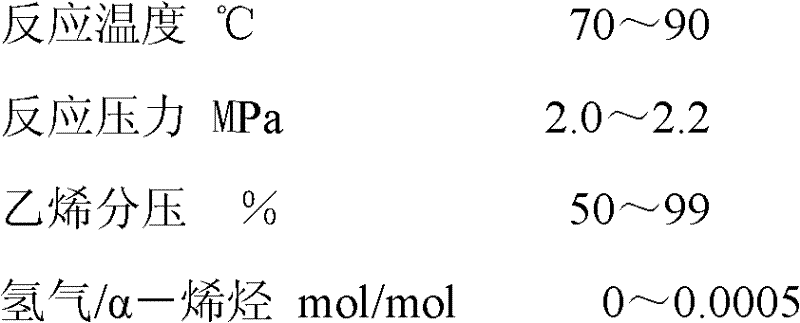

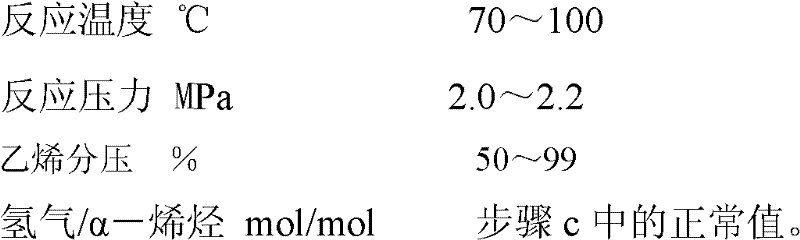

[0067] After using nitrogen and ethylene to replace the trace amount of water in the gas-phase fluidized bed reactor, the metallocene catalyst is first used to initiate the polymerization reaction, and then switch to the conventional chromium-based catalyst polymerization reaction system, and stop adding the metallocene catalyst at the same time. into a conventional ethylene gas phase fluidized bed reactor for polymerization. Production of high-density polyethylene. Including the following steps:

[0068] ① replacement

[0069] a. Nitrogen replacement: after bed installation, control the nitrogen pressure to 0.7MPa~1.1MPa, and raise the temperature of the system to 85°C~88°C; according to the replacement method of the prior art, replace until the water content of the system is ≤5ppm;

[0070] b. Ethylene replacement: After nitrogen r...

Embodiment 2

[0085] During the development and production of chromium-based catalyst products in the full-density pilot plant of Qilu Plastic Factory, if the S-2 chromium-based catalyst does not react for 2 hours and the ash content exceeds 0.06%, it is very dangerous, and the bed has to be replaced in serious cases. Because the discharge port of the pilot plant is designed to be 50mm, if the replacement does not cut the bottom, the reaction will be established by catalyst accumulation and detoxification. Once the catalyst reacts, it is easy to agglomerate, and the agglomeration is difficult to be brought out by the discharge, resulting in the reaction not going on. You can only park and change beds.

[0086] Start the polymerization reaction according to the method and steps of Example 1, save about 1 ton of ethylene every time you start up, and save about 16 hours of start-up time.

Embodiment 3

[0088] When the HDPE unit of Qilu Plastic Factory was started up, there was also the situation that the S-2 chromium catalyst did not react for a long time. The normal response was 4 hours, and the response was 10 hours long. The ethylene emission was 4-5t / h, so the material consumption was also very high.

[0089] Start the polymerization reaction according to the method and steps of Example 1, save about 50 tons of ethylene every time you start up, and save about 10 hours of start-up time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com