Intelligent lifting hook, monitoring system and using method of intelligent lifting hook

A lifting hook and intelligent technology, applied in the direction of load hanging components, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve the problem of unable to automatically collect loads, etc., to prevent production accidents , the data is objective and accurate, and the effect supported by reliable data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following embodiments are combined with the accompanying drawings to explain the structure, composition and use (work) of the intelligent lifting hook monitoring system of the present invention and the intelligent lifting hook ) method is described in detail.

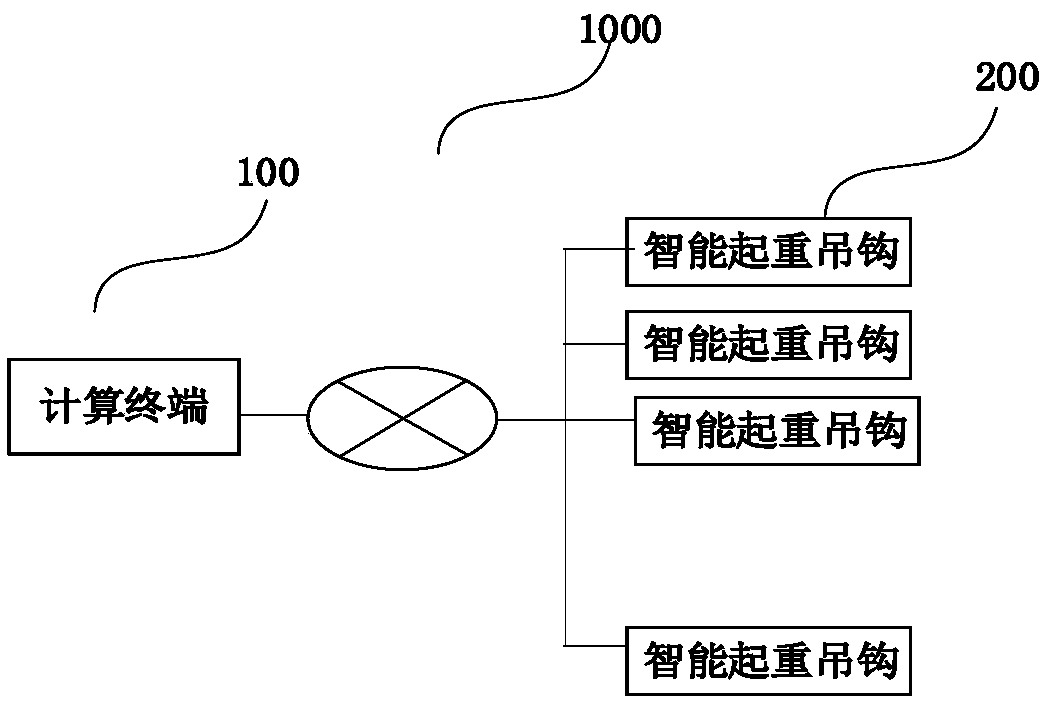

[0053] figure 1 It is a composition diagram of the intelligent lifting hook monitoring system in the embodiment of the present invention.

[0054] Such as figure 1 As shown, the intelligent lifting hook monitoring system 1000 is used to analyze the efficacy of each intelligent lifting hook, including at least one intelligent lifting hook 100 and at least one computing terminal connected in communication with the intelligent lifting hook 100 200. In this embodiment, the two are connected through a wireless network for communication.

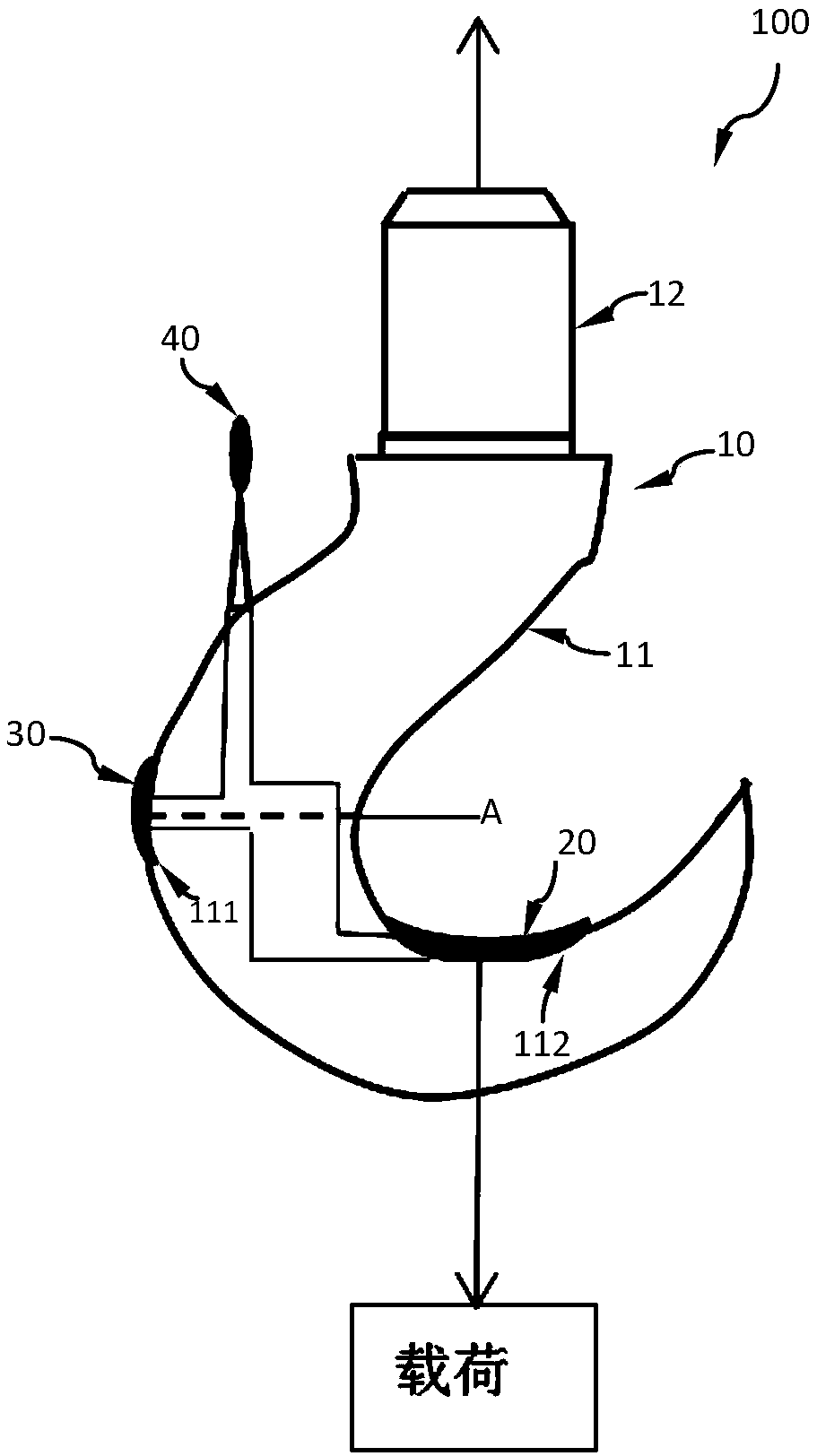

[0055] figure 2 It is a structural schematic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com