Patents

Literature

32results about How to "Data is accurate and objective" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

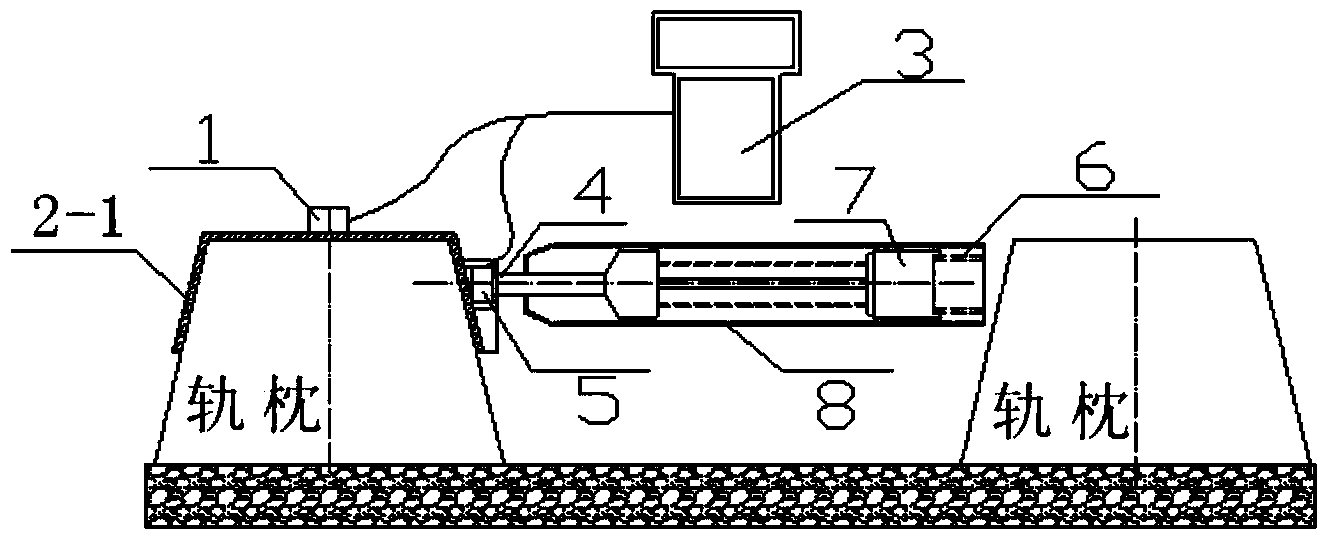

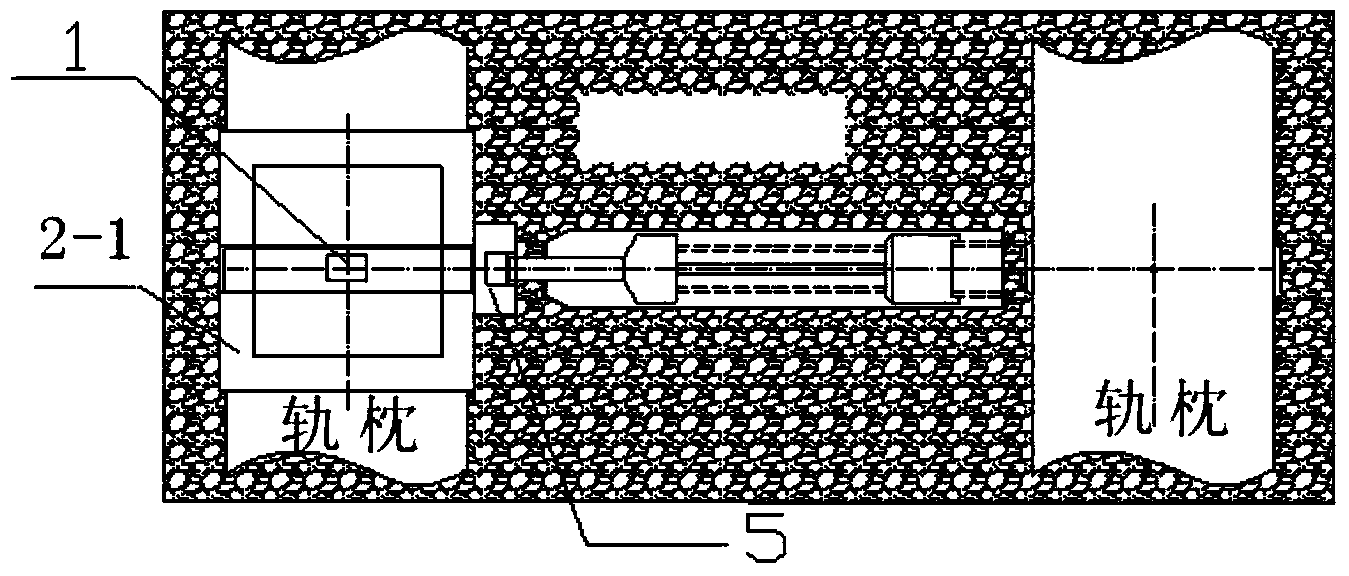

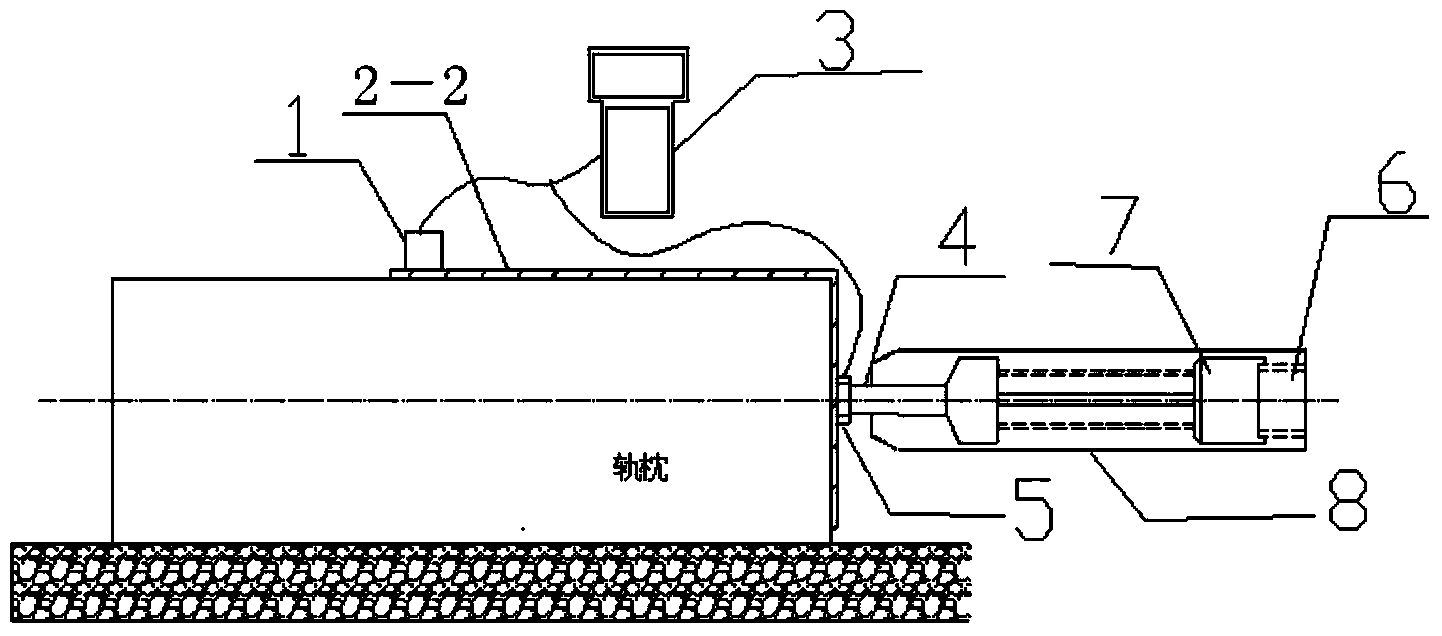

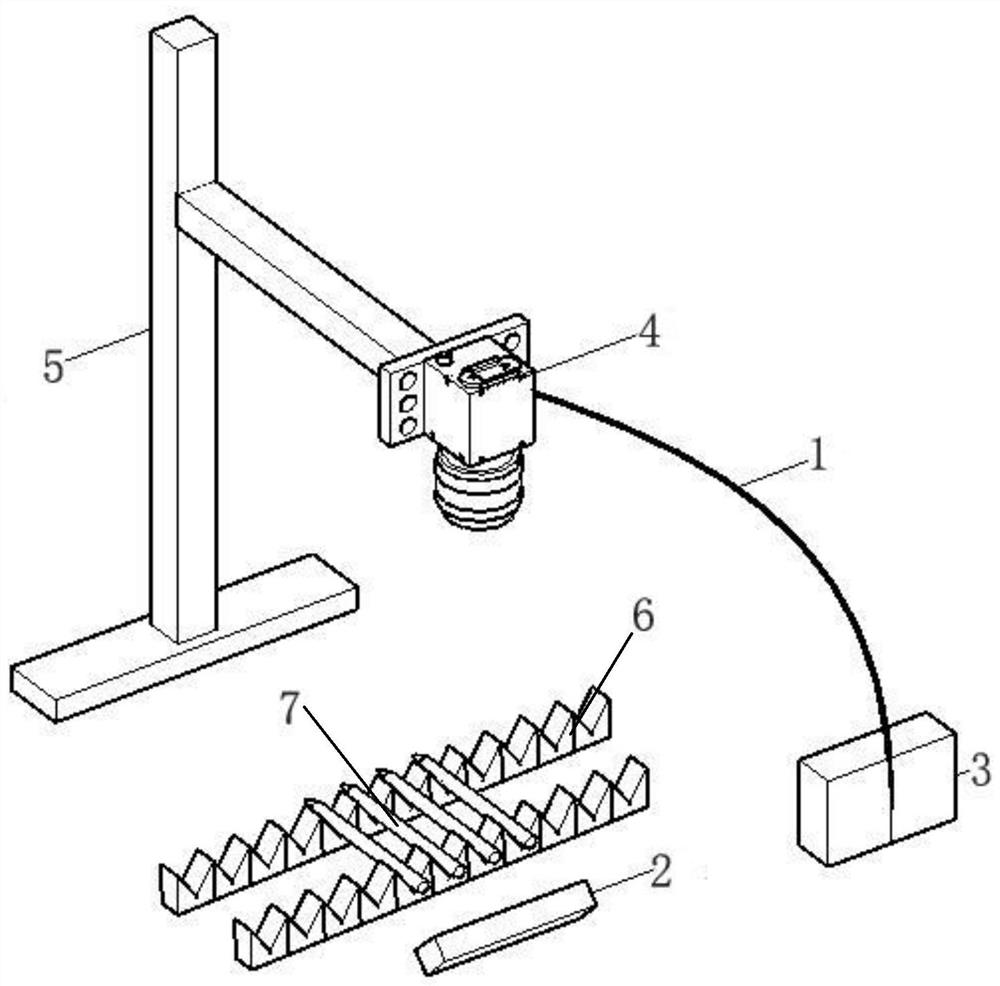

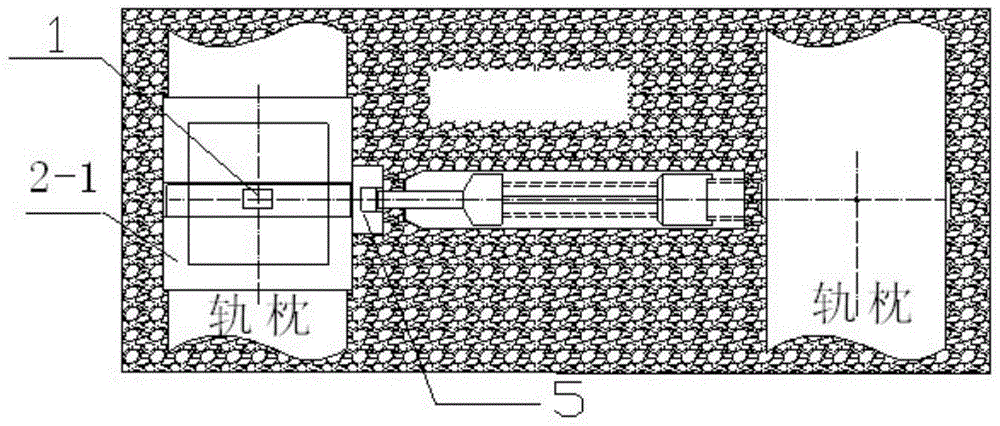

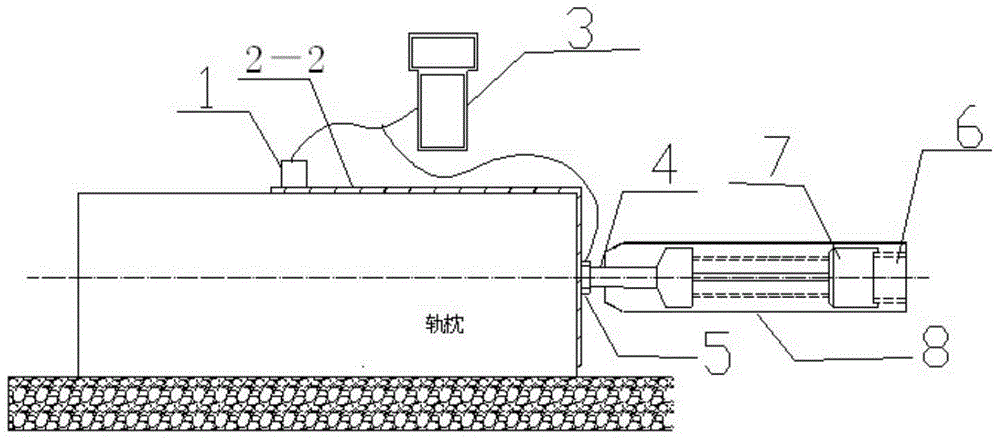

Sleeper longitudinal-transverse resistance dynamic detector and detecting method

ActiveCN103630283AReduce labor intensityThe instrument is lightweightApparatus for force/torque/work measurementTester deviceEngineering

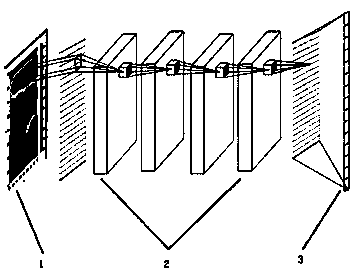

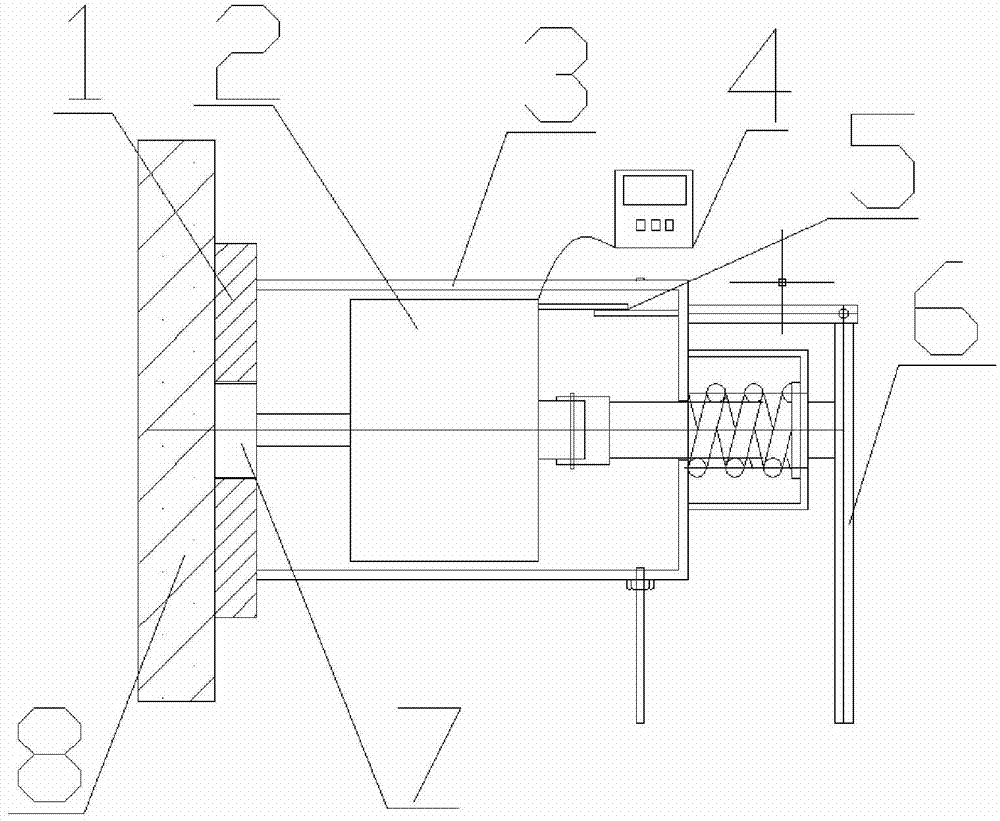

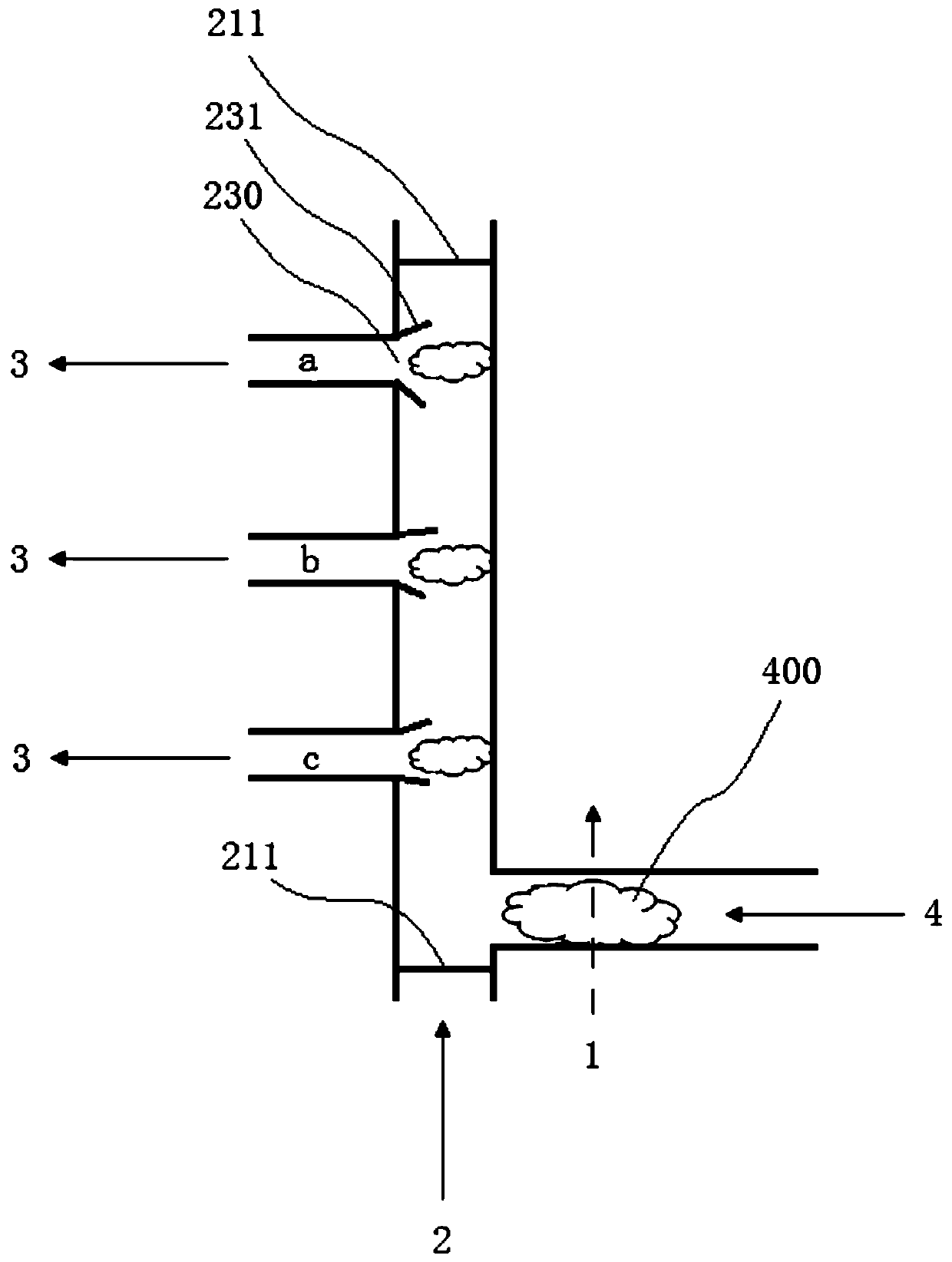

The invention discloses a sleeper longitudinal-transverse resistance dynamic detector and detecting method. The detector comprises a loading device, a sleeper longitudinal-transverse bearing device and an electronic testing device. The end of the loading device is provided with an impact head. An impact hammer and a spring augmenter are disposed inside the impact head. The electronic testing device comprises a force sensor and an acceleration or displacement sensor, wherein the force sensor and the acceleration or displacement sensor are respectively connected with a tester mainframe. The acceleration or displacement sensor is disposed on the upper portion of the sleeper longitudinal-transverse bearing device. The force sensor is disposed on the side of the sleeper longitudinal-transverse bearing device. The detector capable of dynamically detecting sleeper longitudinal and transverse resistance is light, convenient to use, simple to operate, simple to mount, accurate and objective in data, and capable of automatically printing and saving detecting results, labor intensity of detecting personnel is lowered, and detecting efficiency is increased.

Owner:CHINA RAILWAY FIFTH SURVEY & DESIGN INST GRP

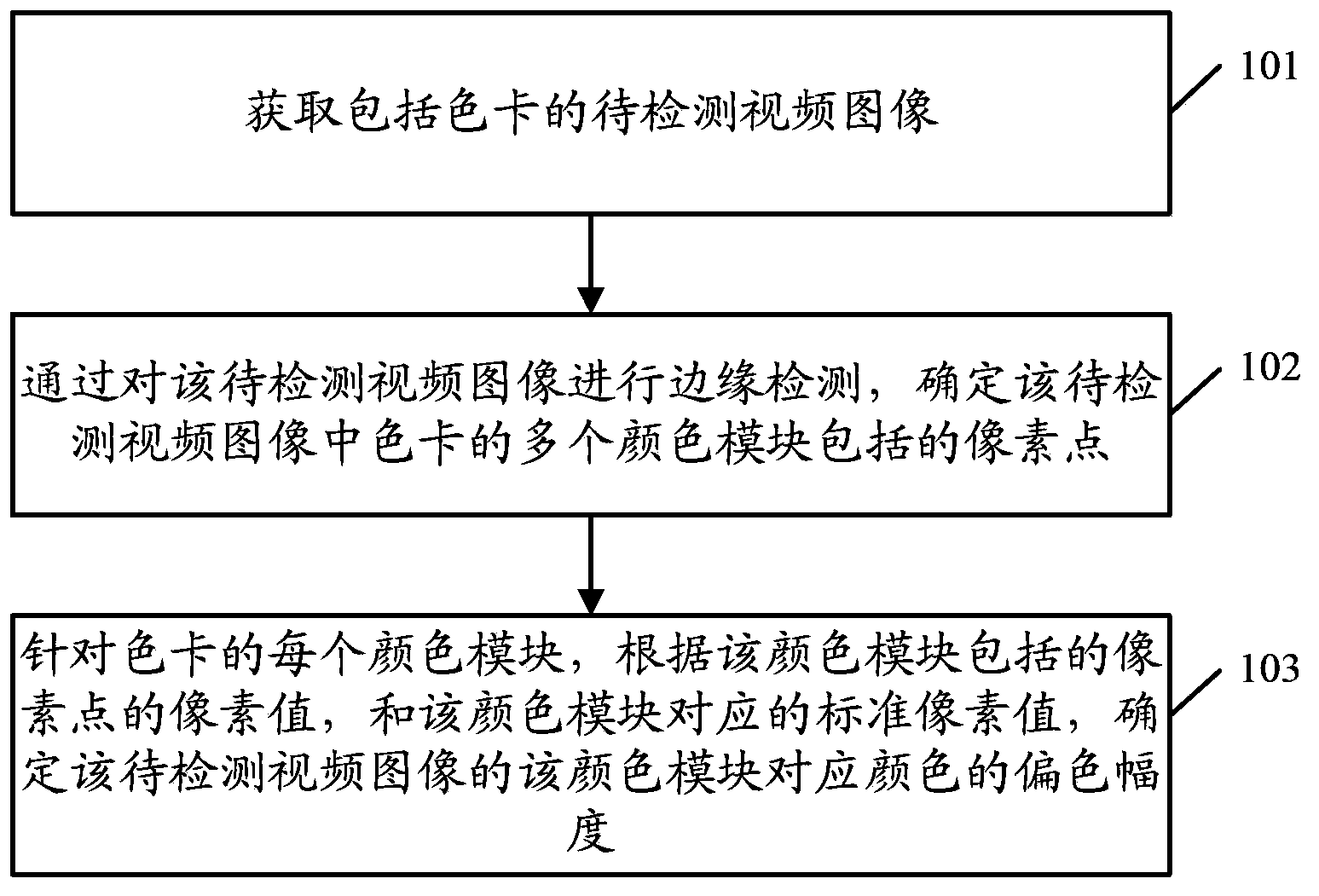

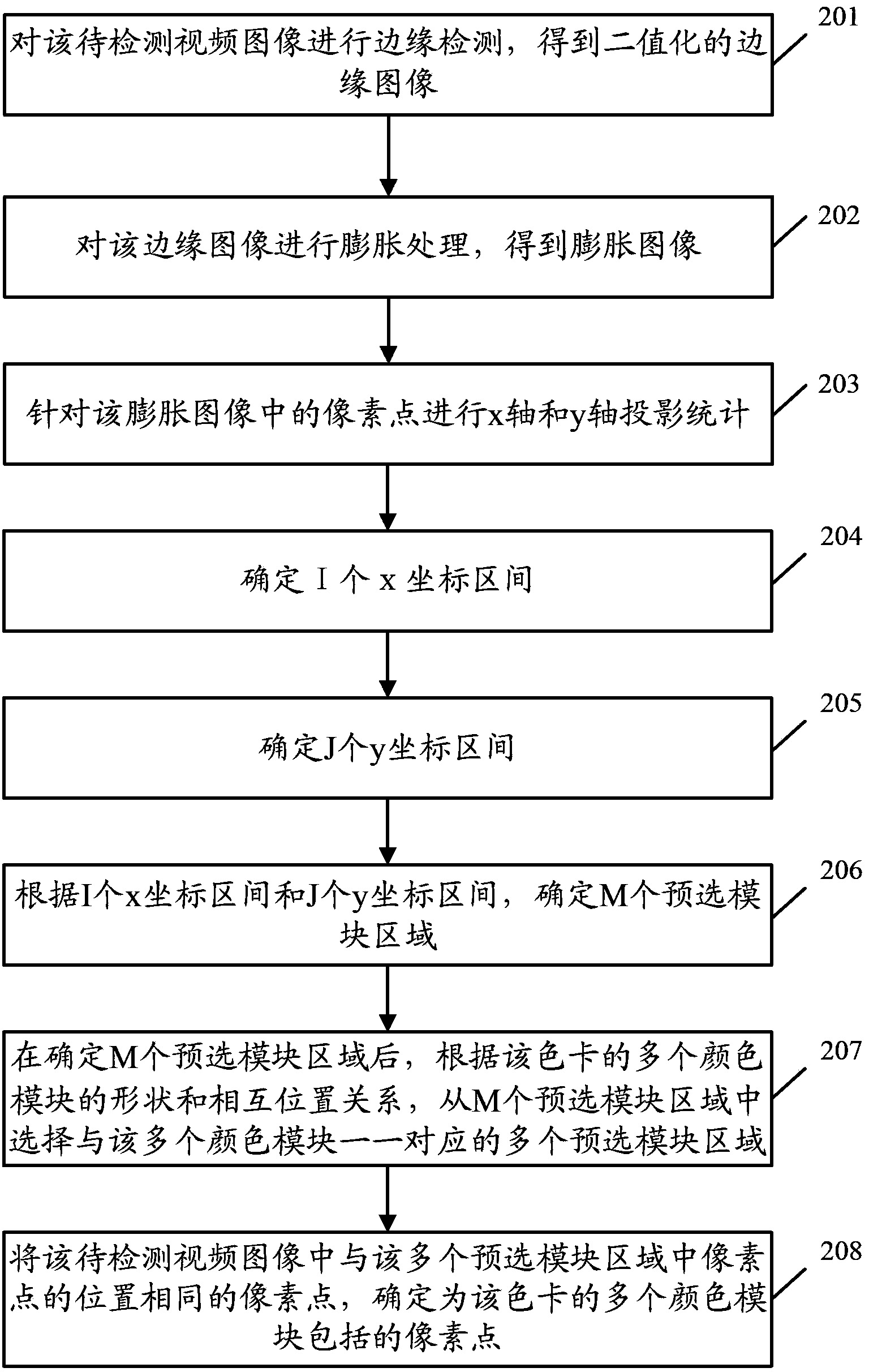

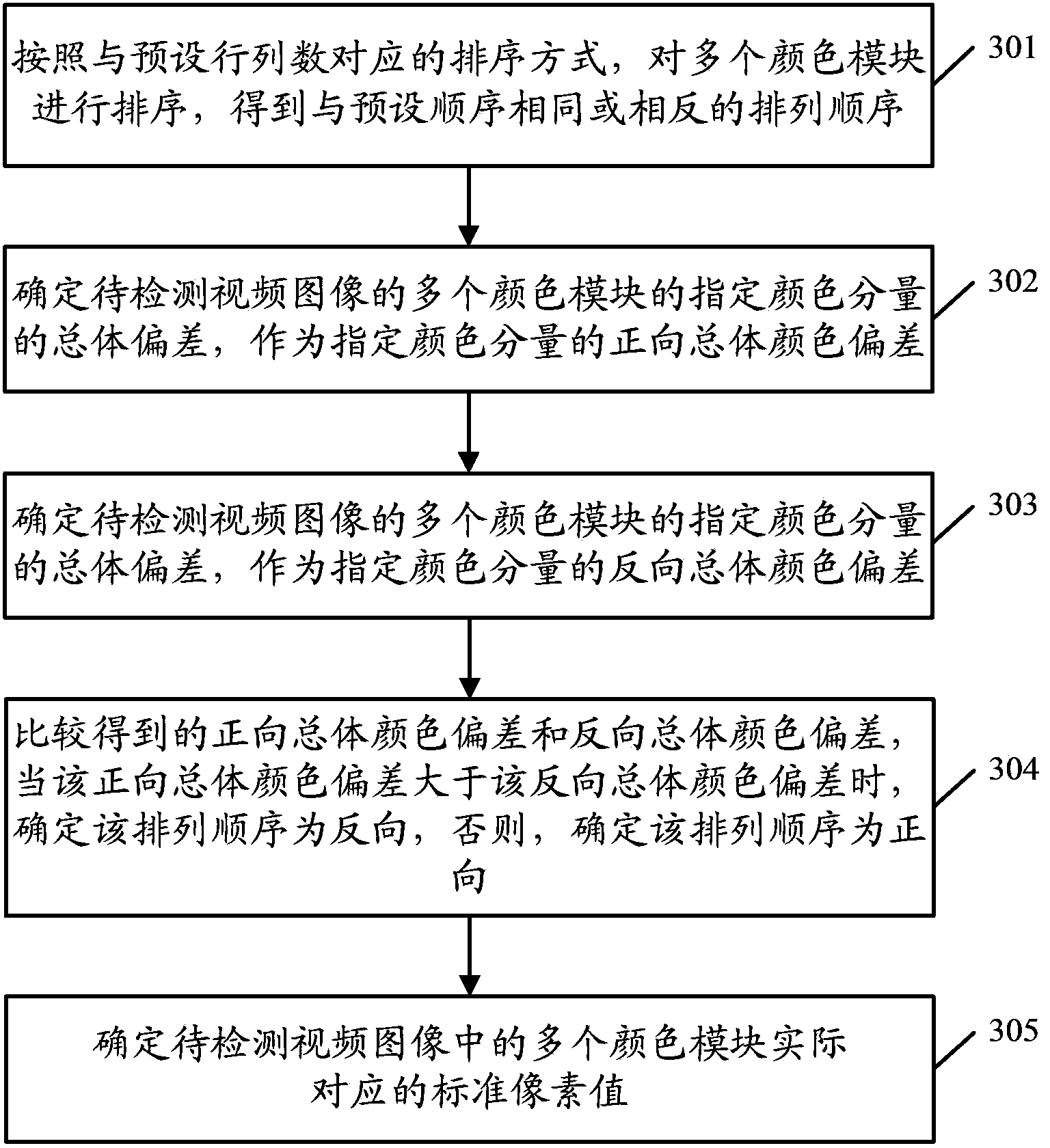

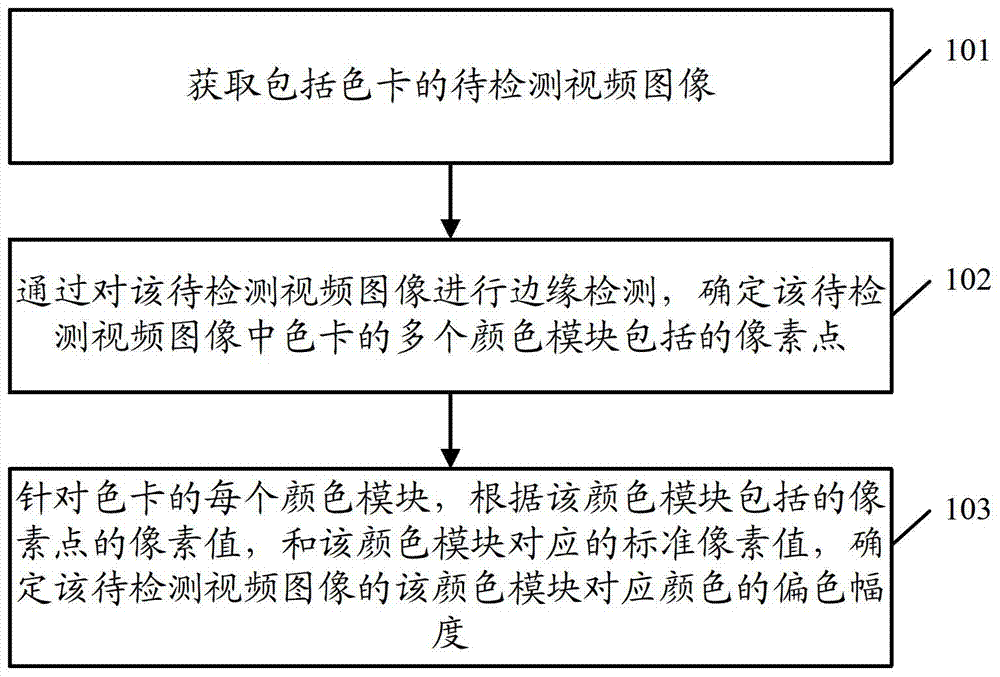

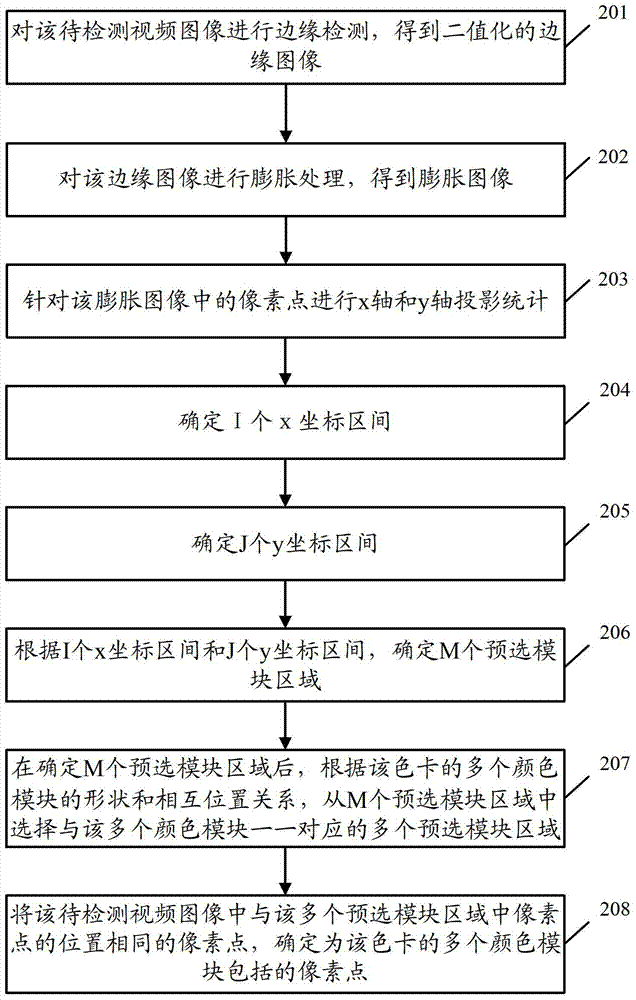

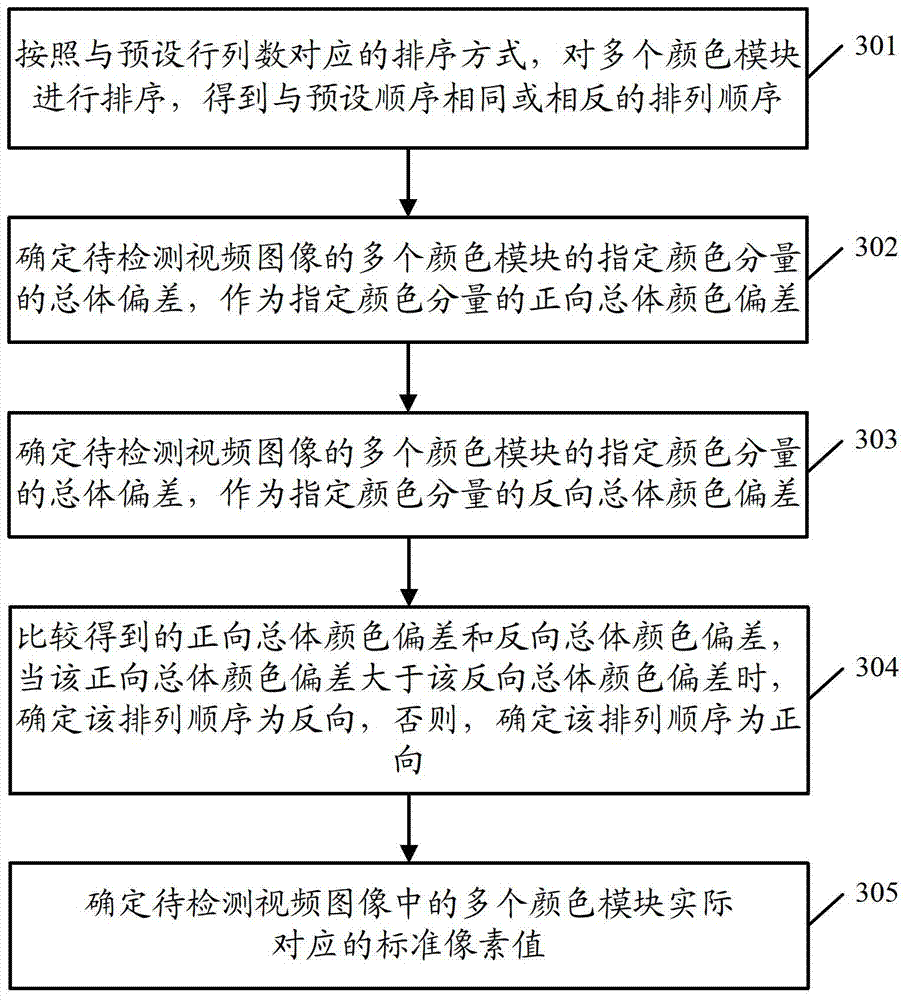

Video image color cast detection method and device

ActiveCN104346817AReduce the influence of human subjective factorsImprove detection efficiencyImage enhancementImage analysisEdge detectionColour cast

The invention discloses a video image color cast detection method and device. The method comprises the steps that a video image including a color card is acquired; edge detection is performed on the video image to be detected so that pixel points included by multiple color modules of the color card in the video image to be detected are confirmed; and color cast amplitude of colors corresponding to the color modules of the video image to be detected is confirmed according to the pixel points and pixel values included by the color modules and standard pixel values corresponding to the color modules by aiming at all the color modules of the color card. Compared with methods and the devices in the prior art, color cast amplitude of the video image is automatically detected via application of the method and the device so that the whole detection process is high in detection efficiency, data are objective and accurate and detection speed is high.

Owner:ZHEJIANG DAHUA TECH CO LTD

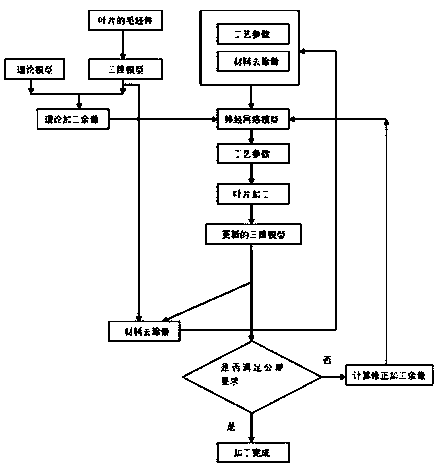

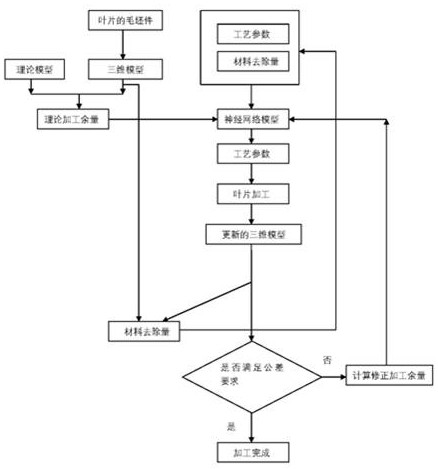

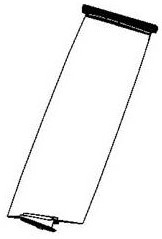

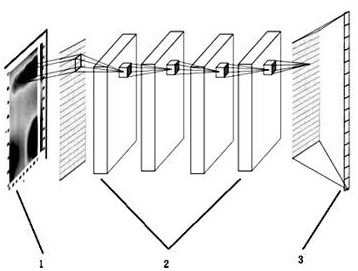

Blade polishing-grinding machining method based on neural network

ActiveCN109732450AREACTIVE SURFACE CONTACTData is accurate and objectiveBelt grinding machinesNeural architecturesMaterial removalNetwork model

The invention relates to a blade polishing-grinding machining method based on a neural network. A blank part of a blade is scanned and measured by a measuring device, information is transferred to computer software so as to obtain a reconstructed three-dimensional model, the reconstructed three-dimensional model is compared with feature points on a theoretical model, adjustment is conducted, coordinate systems of the reconstructed three-dimensional model and the theoretical model coincide, and thus the theoretical machining allowance of the blade is calculated. A neural network model is trained with historical data, thereby being capable of recognizing machining technological parameter configurations under different theoretical machining allowances. The theoretical machining allowance of the blade is input to the neural network model, and machining technological parameters of blade machining are calculated by the neural network model and are used for polishing-grinding machining. The machined blade is scanned and measured, information is transferred to the computer software to obtain an update model, the update model is compared with the three-dimensional model before machining, and the material removal quantity of the blade is calculated. If the size of the machined blade meets the tolerance requirement, machining is completed.

Owner:CHONGQING UNIV OF TECH

Environment monitoring system based on Internet of Things

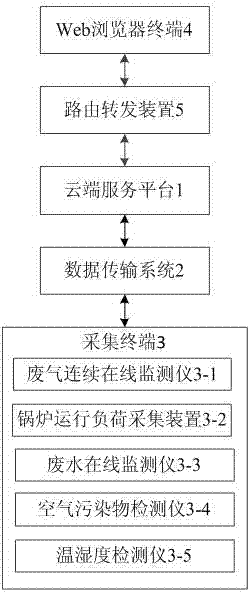

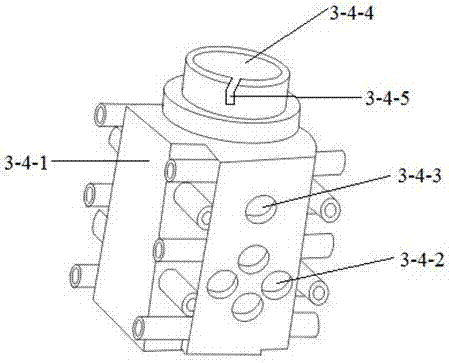

PendingCN107454172AImprove continuitySave manpower and material costsMeasurement devicesTransmissionWeb browserAmbient data

The invention provides an environment monitoring system based on Internet of Things. The system herein includes a cloud service platform, a data transmission system, an acquisition terminal and a Web browser terminal. The acquisition terminal uploads the acquired all kinds of environment data to the data transmission system. The data transmission system is intended for aggregating all kinds of data which is uploaded by the acquisition terminal to monitoring data, and uploading the monitoring data to the cloud service platform through the internet. The cloud service platform is intended for receiving and saving the monitoring data which is uploaded by the data transmission system. The Web browser terminal is intended for accessing the cloud service platform through the internet, and checking the monitoring data which is acquired by the acquisition terminal. According to the invention, the system, by uploading the self working states of the acquisition terminal and the environment monitoring data that are uploaded, enables a user to in timely find the problems of devices, and is conductive to the correctness of determining data and maintenance of the system.

Owner:海南钧瑞科技有限公司

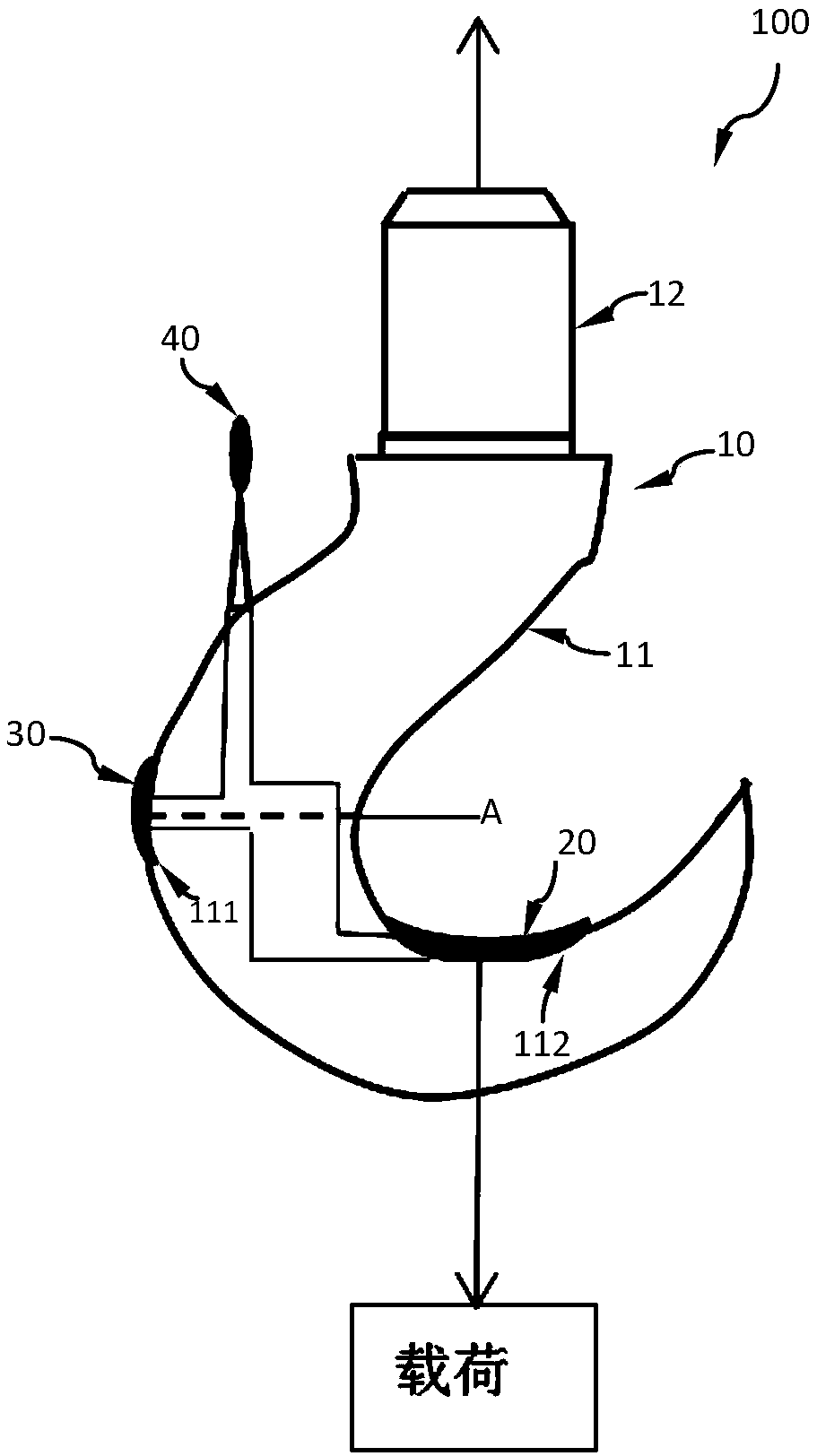

Intelligent lifting hook, monitoring system and using method of intelligent lifting hook

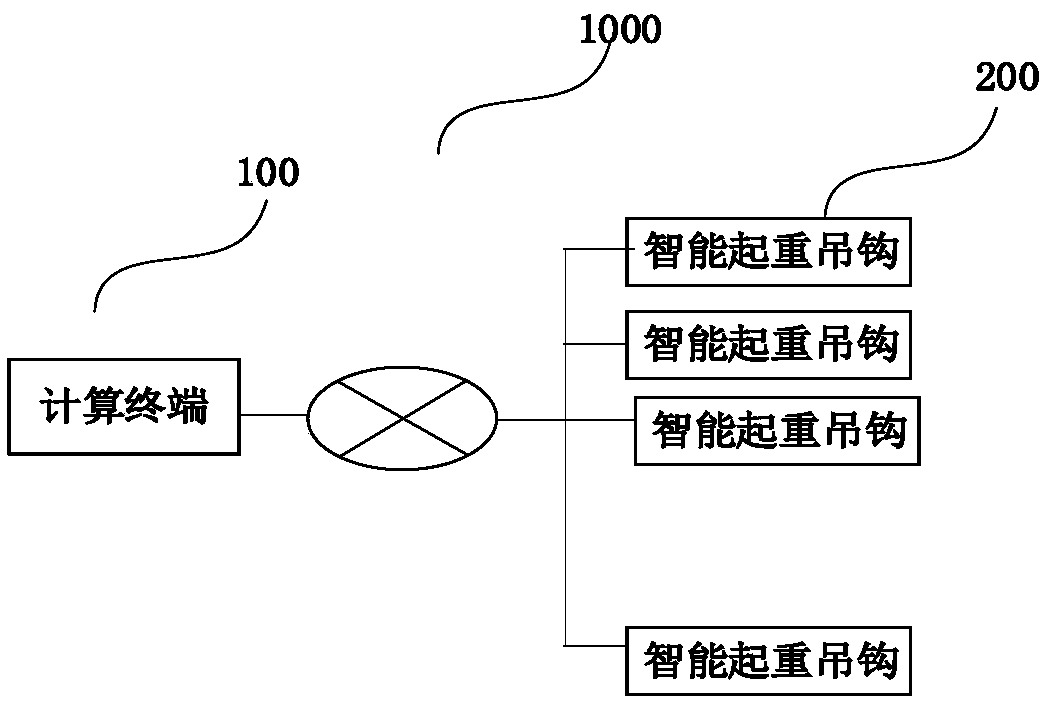

PendingCN108750926AAvoid production accidentsRealize intelligenceBatteries circuit arrangementsPiezoelectric/electrostriction/magnetostriction machinesMonitoring systemComputer terminal

An intelligent lifting hook comprises a lifting hook body, a power supply unit, a strain measurement unit and a data transmission unit, wherein the lifting hook body is provided with a bent hook partfor hooking and lifting loads, and the outer side wall of the bent hook part is provided with an installation sunken part; the power supply unit is arranged on the lifting hook body and used for supplying power; the strain measurement unit is fixedly installed on the installation sunken part, connected with a power supply unit circuit and used for measuring the strain borne by the bent hook part;and the input end of the data transmission unit is connected with a strain measurement unit circuit so that a strain signal can be received, and the output end of the strain measurement unit is in communication connection with an external computing terminal so that the stain signal can be transmitted to the computing terminal. The intelligent lifting hook is connected with the external computing terminal so that whether the lifting hook is overloaded, and whether the stress of the lifting hook is within the safety range or not can be controlled and monitored, production accidents caused by damage to the lifting hook or overload are prevented, and through strain changing, compared with the actual workload of a certain external intelligent lifting hook, intelligentization of a common liftinghook is achieved. Meanwhile, the invention further provides a monitoring system and a using method of the intelligent lifting hook.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

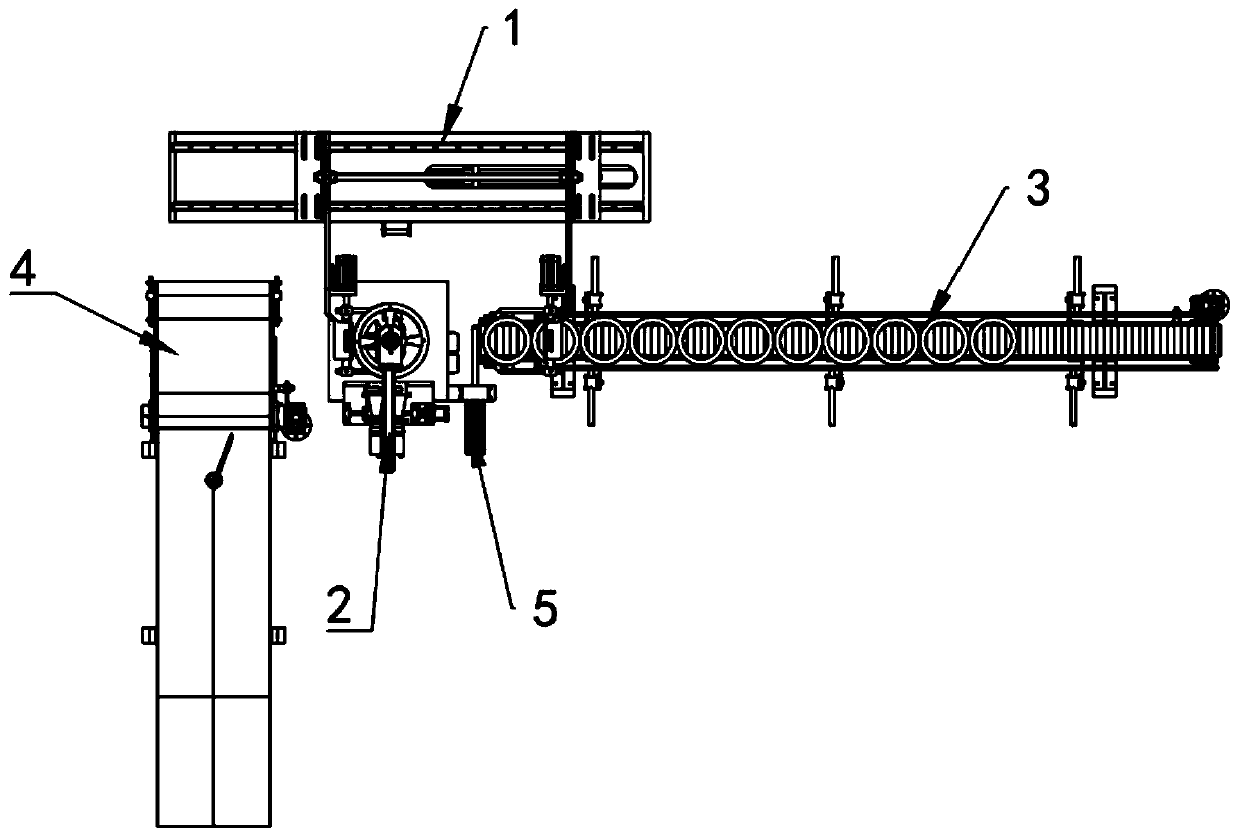

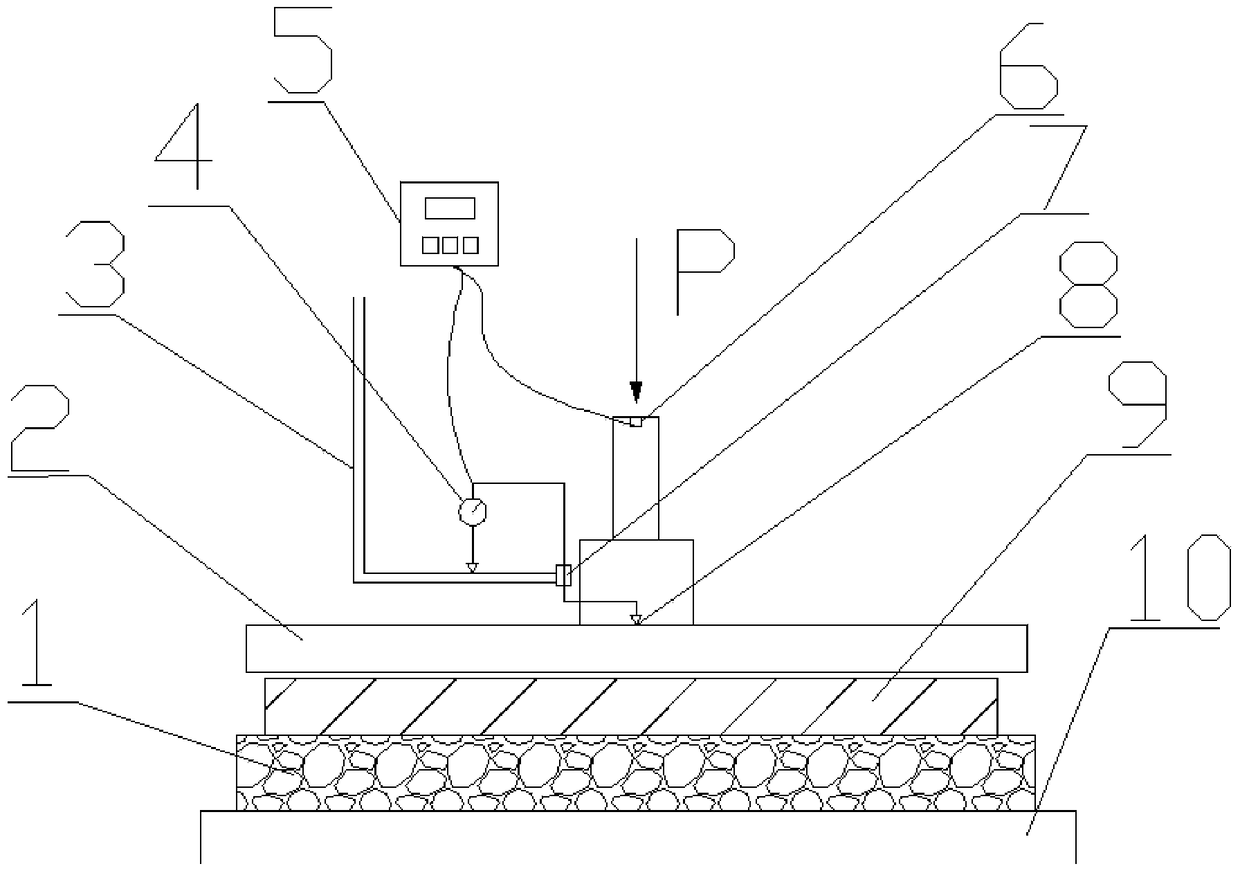

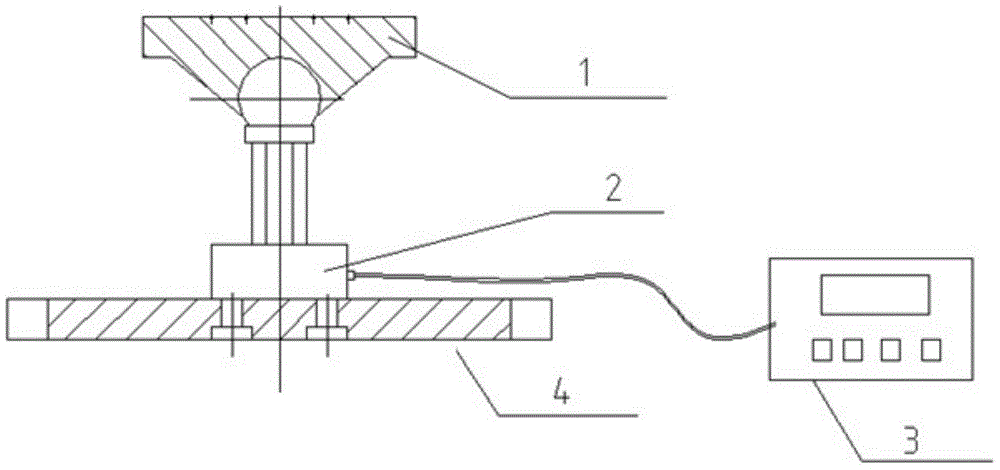

Automatic testing and early-warning device for track plate displacement

InactiveCN104727195AEasy to operateData is accurate and objectiveMeasuring apparatusDisplay deviceTester device

The invention discloses an automatic testing and early-warning device for track plate displacement. A formwork is arranged between a track plate and a concrete base. The track plate is provided with a grouting hole and an observation hole. A magnetic gauge stand is fixed to the side face of the formwork, a universal support arm is arranged on the magnetic gauge stand, a displacement detection device is fixed to the end of the universal support arm, a probe of the displacement detection device makes perpendicular contact with the top face and / or the side face of the track plate, and the displacement detection device is connected with a tester host through a connecting wire. The tester host is provided with a recording device, a display device and a printing device, and further provided with an early-warning sound or lamplight prompt device. The automatic testing and early-warning device can automatically detect the floating amount or sinking amount of the track plate during filled layer grouting, is convenient to use, easy to operate and easy and convenient to install, data are accurate and objective, the detection result can be automatically displayed, early-warned, printed and stored, the labor intensity of plate type ballastless track filling layer pouring construction staff is lowered, and efficiency is improved.

Owner:CHINA RAILWAY FIFTH SURVEY & DESIGN INST GRP

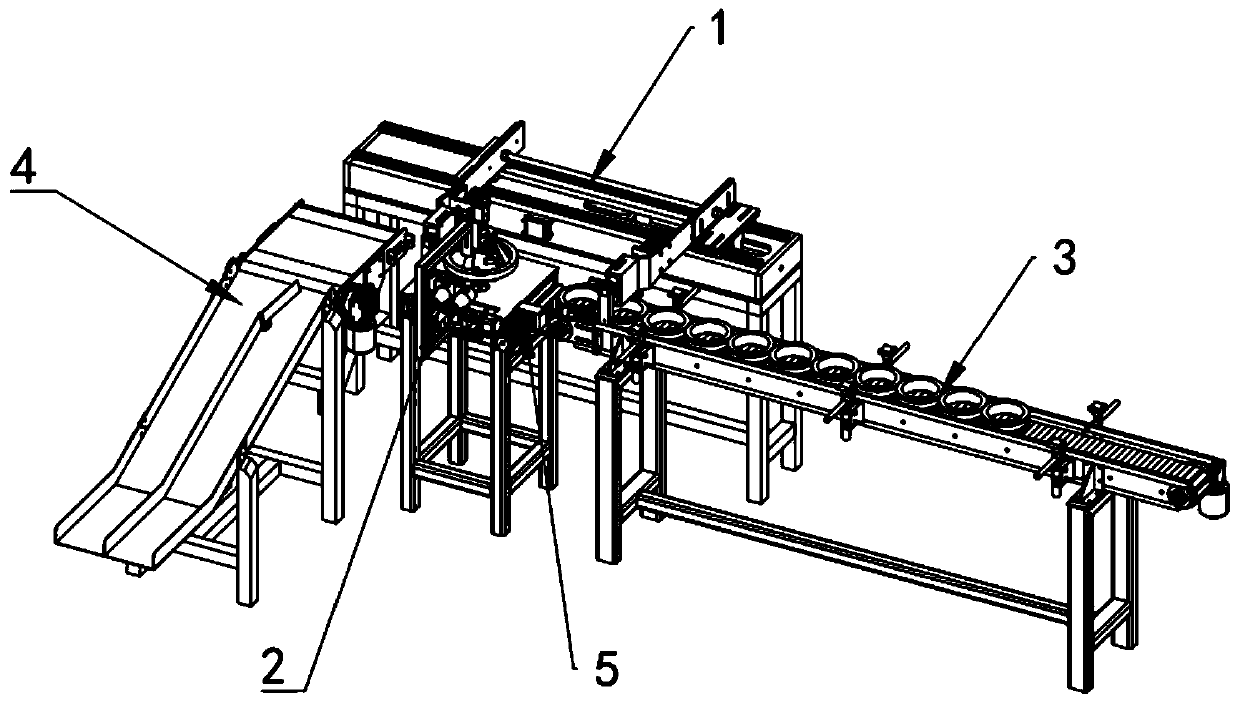

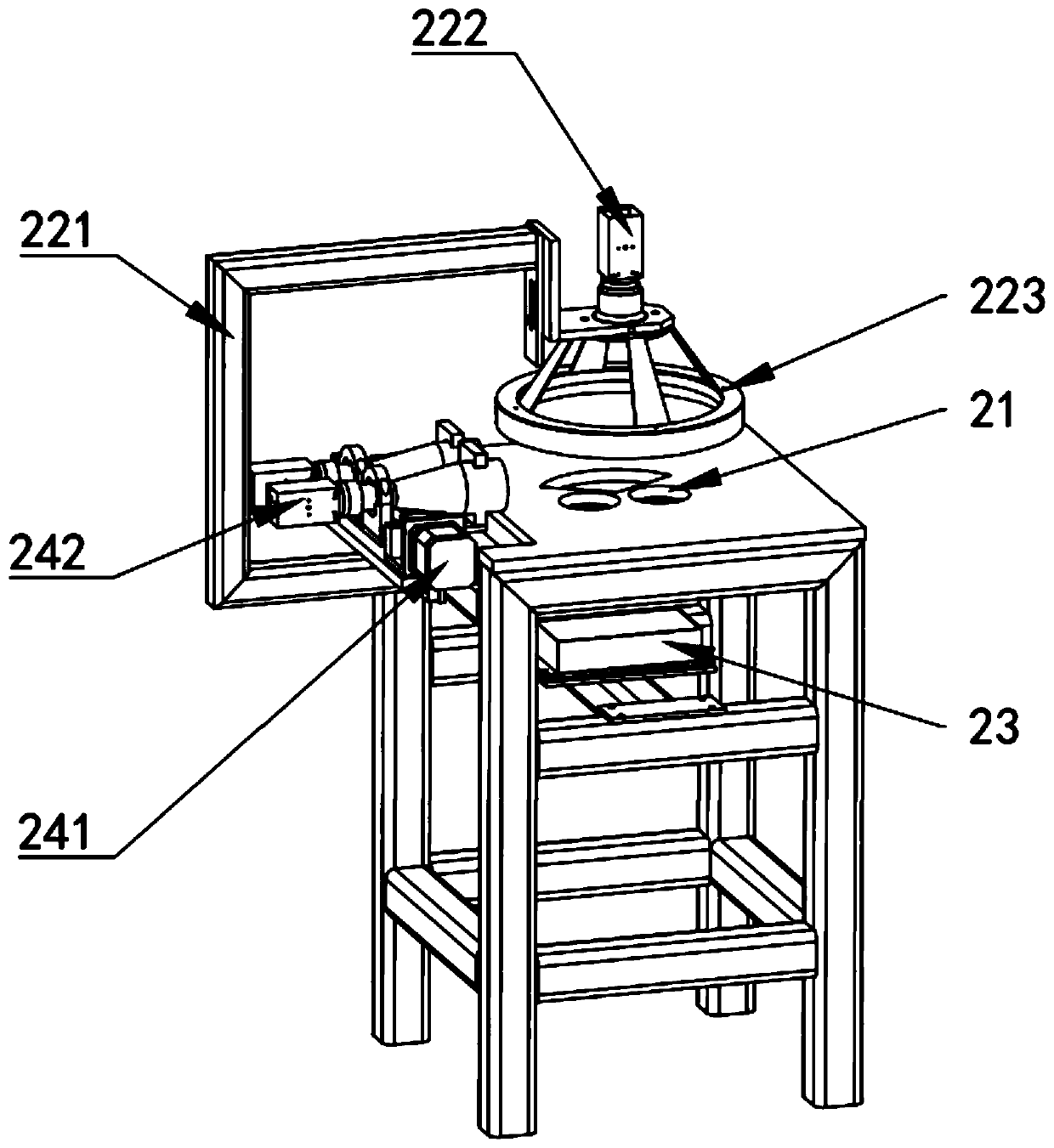

Metal circular workpiece detection device and using method thereof

PendingCN109909172AIngenious and reasonable designReal-time detection and monitoringMeasurement devicesSortingBiochemical engineeringMetal

The invention discloses a metal circular workpiece detection device. The metal circular workpiece detection device comprises a detection device and a grasping device arranged next to the detection device. The detection device comprises a workpiece fixing seat, a roundness detection mechanism, a CCD detector and a flaw detection device, wherein the roundness detection mechanism and the CCD detectorare separately arranged above and below the workpiece fixing seat, and the flaw detection device is arranged on one side of the workpiece fixing seat. The grasping device comprises a driving device arranged on one side of the workpiece fixing seat, a feeding grasping mechanism and a discharging grasping mechanism, the feeding grasping mechanism and the discharging grasping mechanism are arrangedseparately and movably on the driving device, and the feeding grasping mechanism and the discharging grasping mechanism are arranged corresponding to the workpiece fixing seat. The invention further discloses a using method of the metal circular workpiece detection device. According to the metal circular workpiece detection device and the using method thereof, the design is reasonable and ingenious, the process of feeding, detection and discharging can be realized automatically, the real-time detection and monitoring of a workpiece is carried out, the detection effect is good, the detection speed and efficiency are high, the data is accurate and objective, the metal circular workpiece detection device is suitable for detecting the workpieces of various sizes, and a wide range of applications is achieved.

Owner:东莞市旭高精密金属制品有限公司

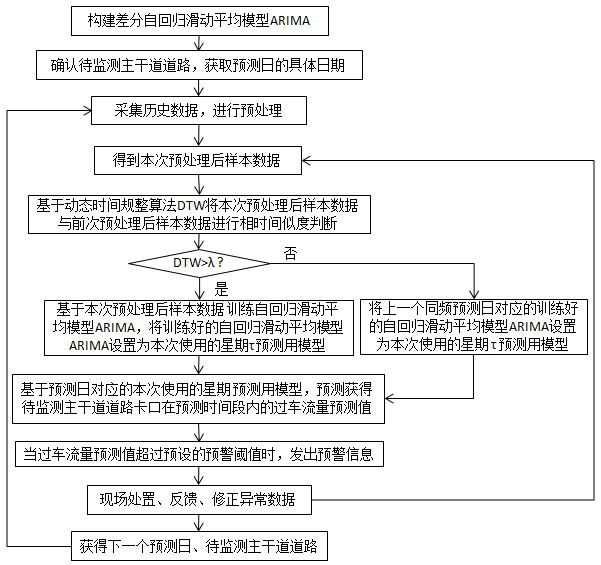

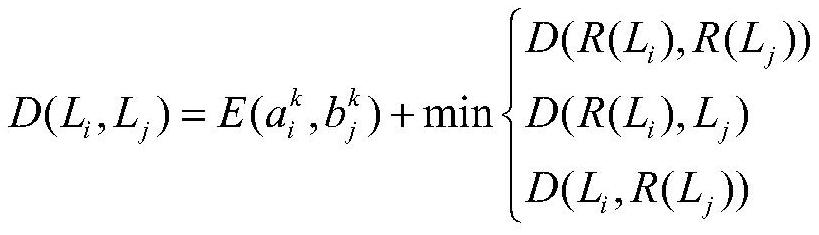

Checkpoint flow early warning method based on mobile police affairs

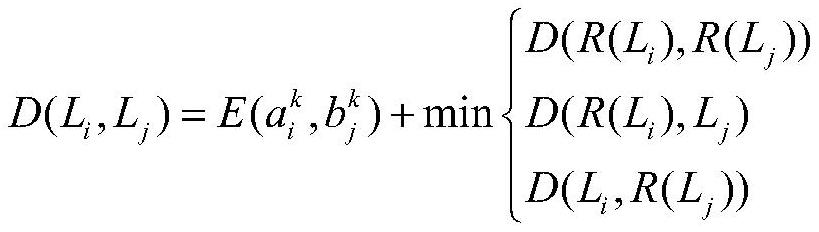

InactiveCN112330074AReduce training frequencyData is accurate and objectiveForecastingComplex mathematical operationsTraffic forecastSimulation

The invention provides a Checkpoint flow early warning method based on mobile police affairs, which can ensure that traffic polices can discover abnormal road sections in time, simplify the configuration process of Checkpoint flow early warning parameters by the traffic polices, and further ensure that the traffic polices can optimize Checkpoint distribution points and improve the operation and maintenance level of Checkpoint equipment. In the technical scheme of the invention, the traffic flow of the prediction day is predicted through the differential autoregressive moving average model ARIMA, and the traffic police can receive the early warning information before the traffic abnormality occurs once the traffic abnormality occurs by setting the early warning threshold, so that the traffic police can arrive at an abnormal place in time, and the problem is solved in time; based on historical data, a differential autoregressive moving average model ARIMA is established for a main trunkroad to be monitored on the basis of each day of a week, and it is ensured that a traffic flow passing predicted value predicted by the differential autoregressive moving average model ARIMA conformsto the characteristics of the peak value and valley value of the Checkpoint daily flow of each day in urban life.

Owner:TRAFFIC MANAGEMENT RES INST OF THE MIN OF PUBLIC SECURITY

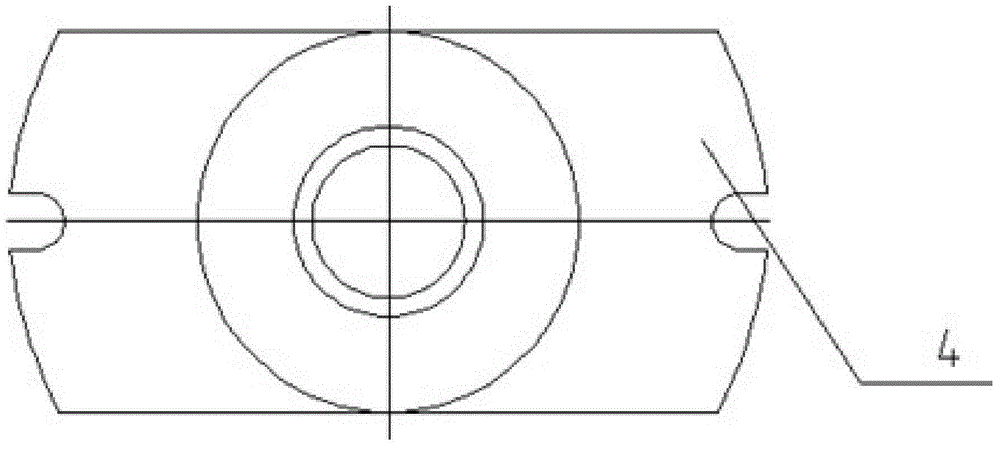

Ballastless track slab downward filling layer strength detection device

ActiveCN104713782AImprove construction qualityEasy to useMaterial strength using tensile/compressive forcesUltimate tensile strengthInstrumentation

The invention discloses a ballastless track slab downward filling layer strength detection device which comprises a sensor shell fixed on a sensor base, wherein a pressure sensor is arranged in the sensor shell; a through hole is formed in the middle of the sensor base; a pressure head is arranged at the front end of the pressure sensor and is arranged in the through hole; a pressurization device is arranged at the rear end of the pressure sensor; the pressure sensor is connected with a displacement sensor; the pressure sensor and the displacement sensor are electrically connected with a tester host; the sensor base is used for being fixed on the side surface of a ballastless track slab downward filling template; and the pressure head is contacted with the ballastless track slab downward filling layer. The device is light in instrument, convenient to use, easy to operate, high in detection speed, and accurate and objective in data, the detection result can be automatically printed and stored, and the construction quality of the ballastless track slab downward filling layer is improved.

Owner:CHINA RAILWAY FIFTH SURVEY & DESIGN INST GRP

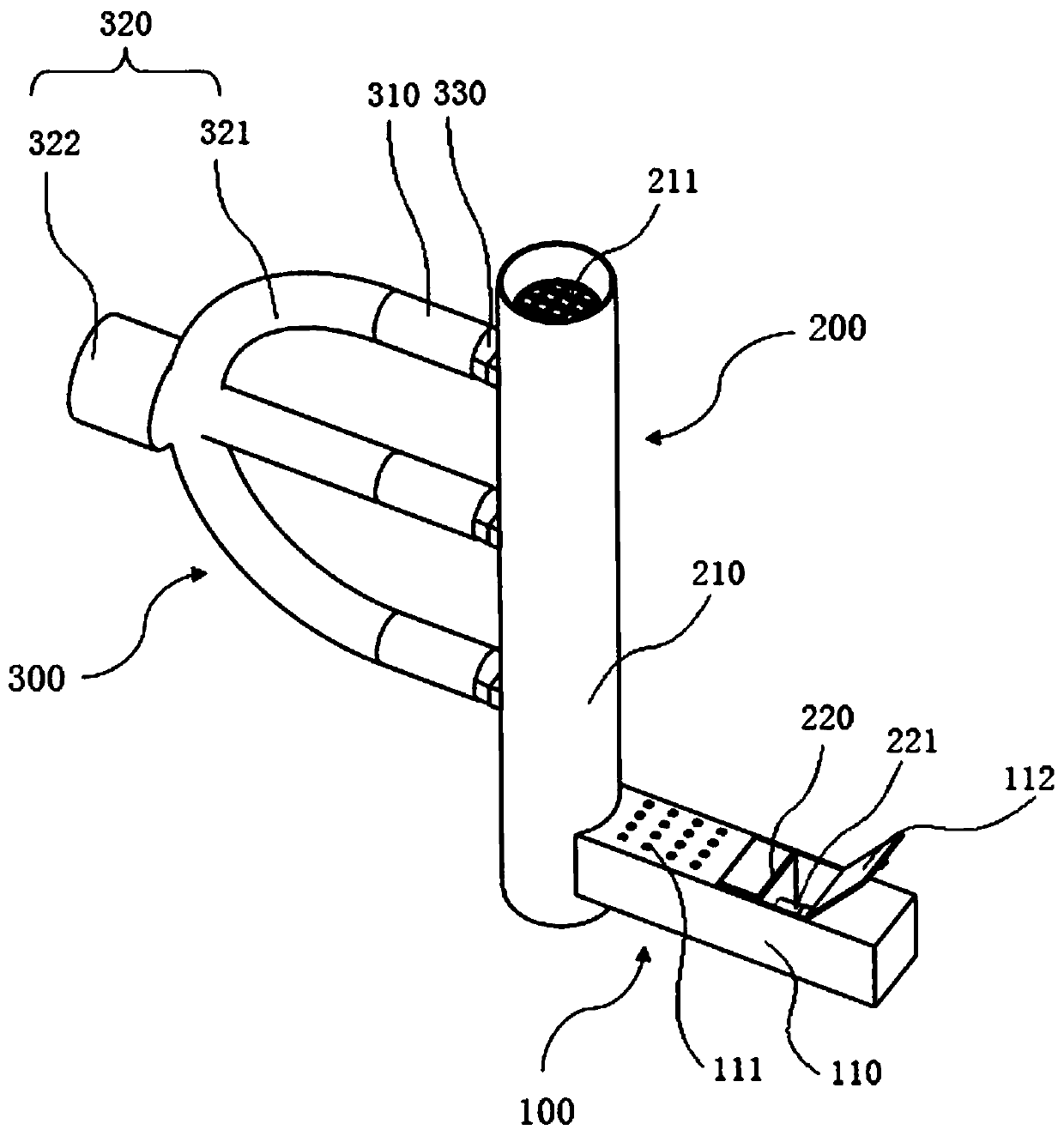

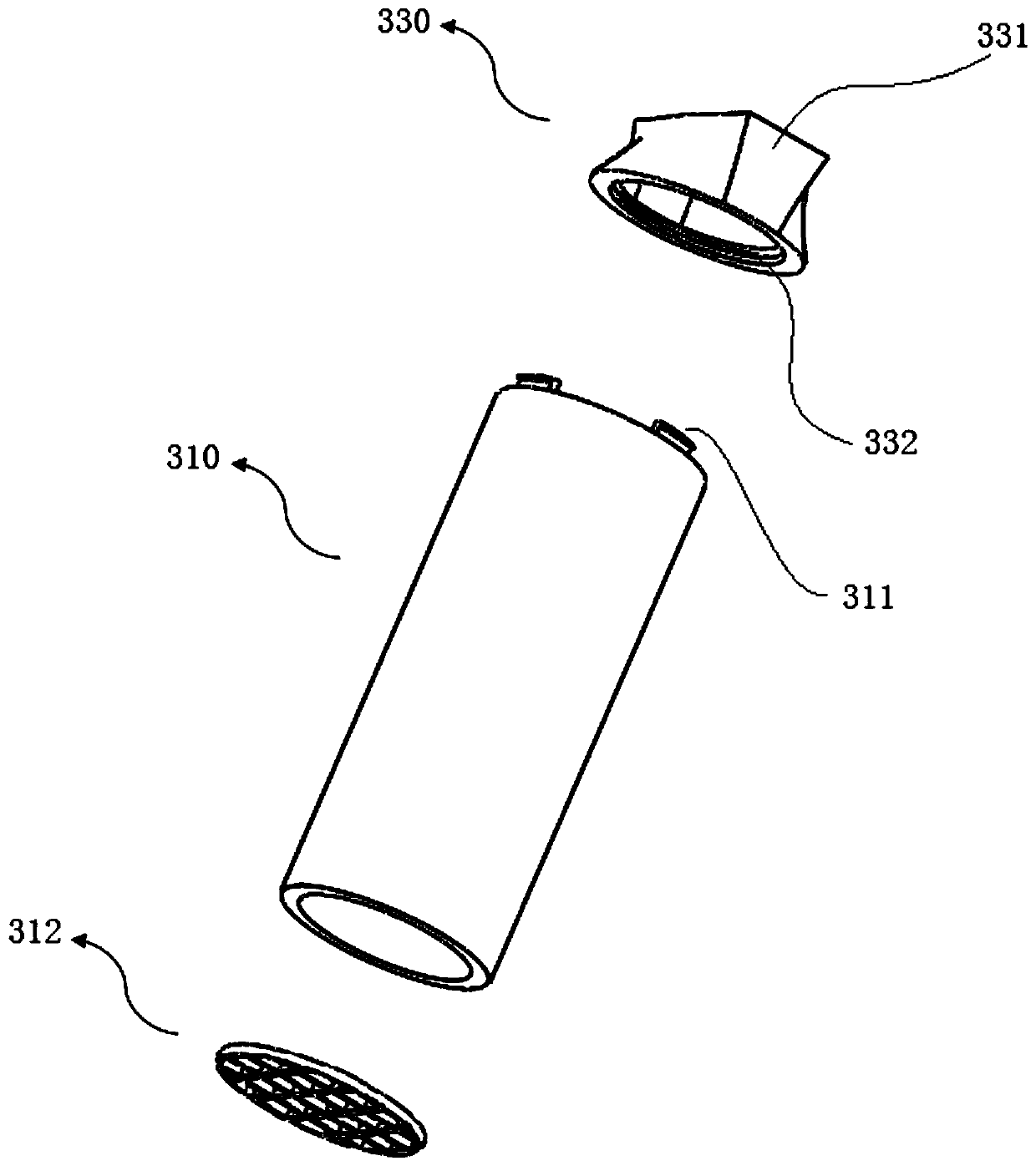

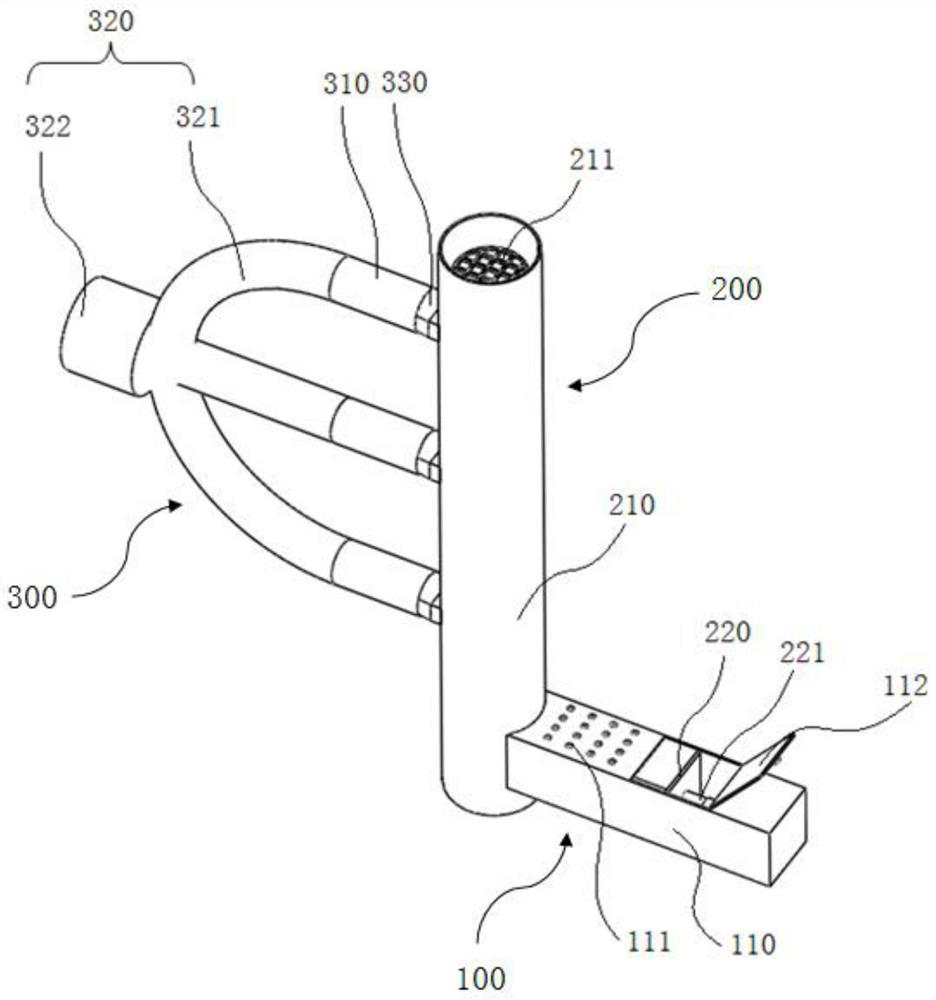

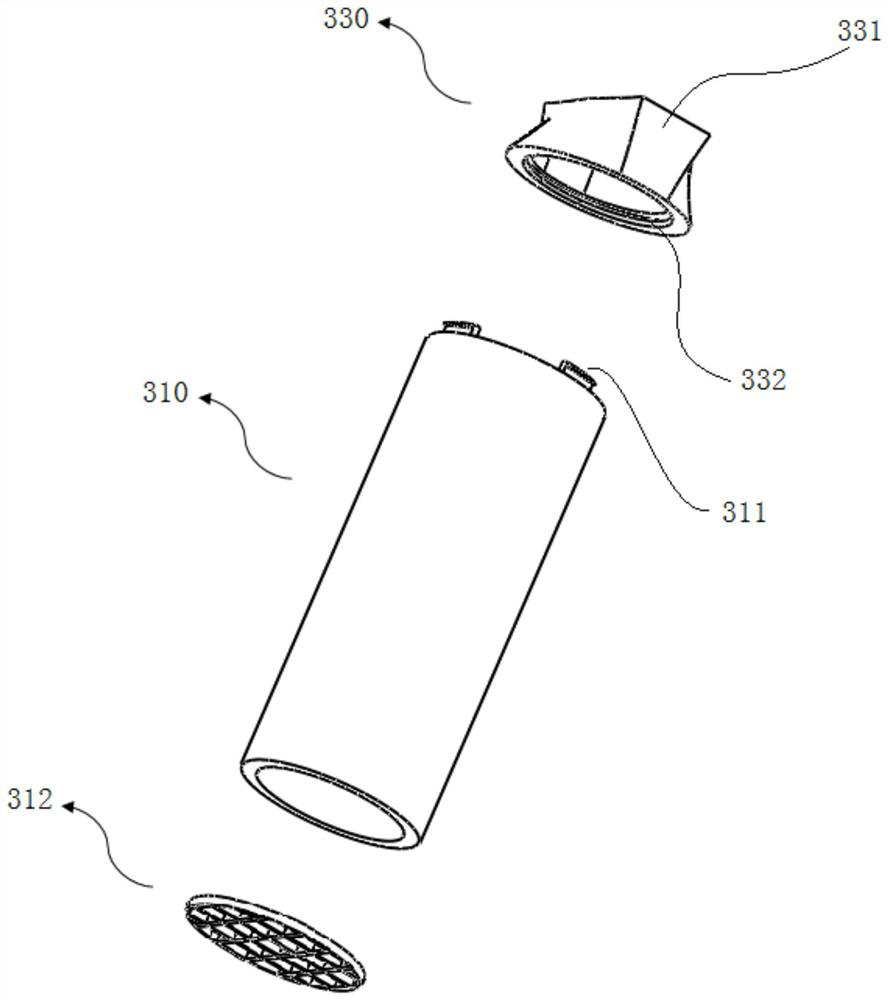

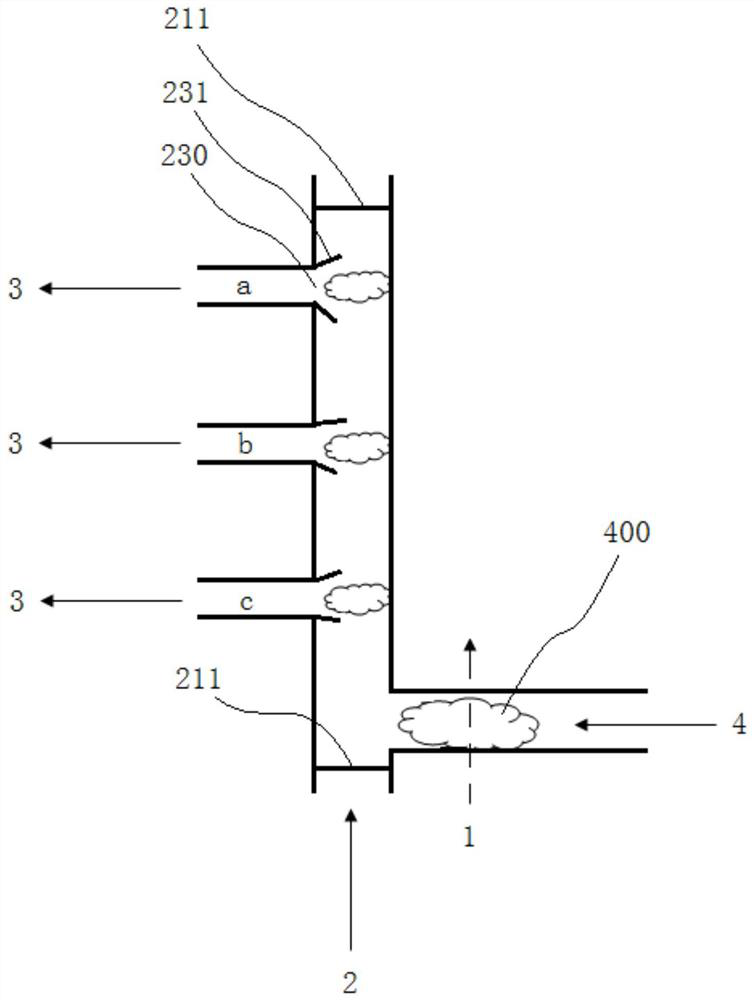

Down feather component and content detection system, and down feather quality detection method

ActiveCN111172629AEasy to sort and collectReduce manual screeningFibre cleaning/opening by air draught arrangementsFibre cleaning/opening machinesStructural engineeringMechanical engineering

The invention discloses a down feather component and content detection system which comprises a pretreatment device, an air classification device and a collecting device which are sequentially connected, wherein the pretreatment device comprises a horizontally-placed pretreatment cylinder, and first airflow moves from the interior of the pretreatment cylinder to the outside through ventilation holes; the air classification device comprises a vertically-arranged screening barrel, an electrostatic eliminator arranged at the bottom of the screening barrel and a push plate; the side face of the lower portion of the screening barrel communicates with the pretreatment barrel; a plurality of outlets are formed in the side wall of the screening barrel in the height direction of the screening barrel; down feather is blown into the screening barrel by second airflow to be stable at a certain height; the collecting device comprises a collecting part and an exhaust pipe which communicate with theoutlet; and the third airflow moves along the collecting part and the exhaust pipe in sequence from the screening drum. According to the method, the down feather components are classified and detectedaccording to the weight difference between the down feather components, manual screening is reduced, the workload is reduced, the subjective influence of people is avoided, and data is more objectiveand accurate.

Owner:SUZHOU FIBER EXAMINATION INST

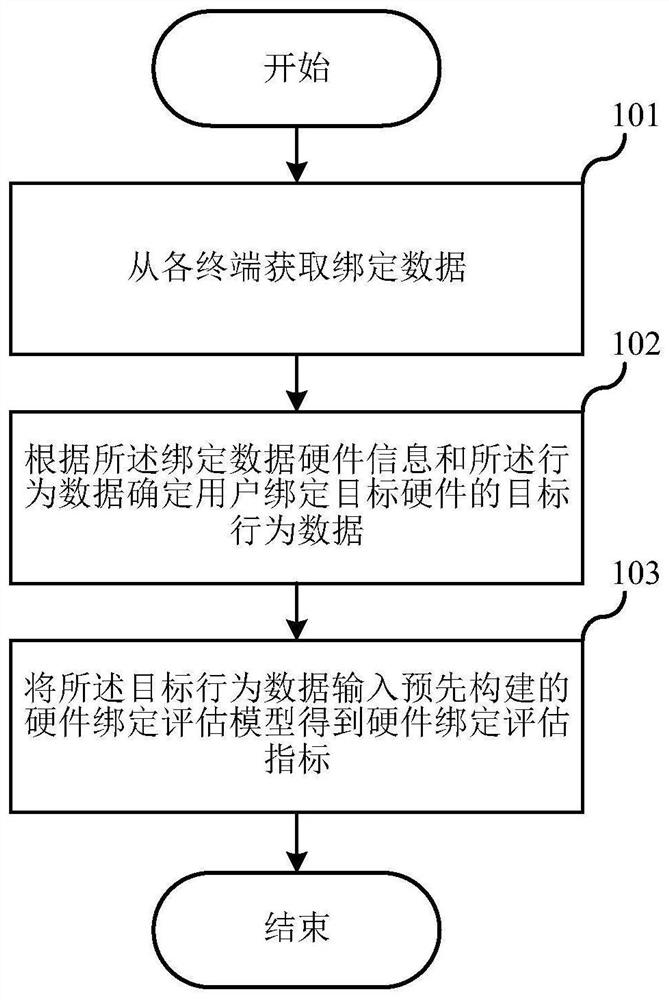

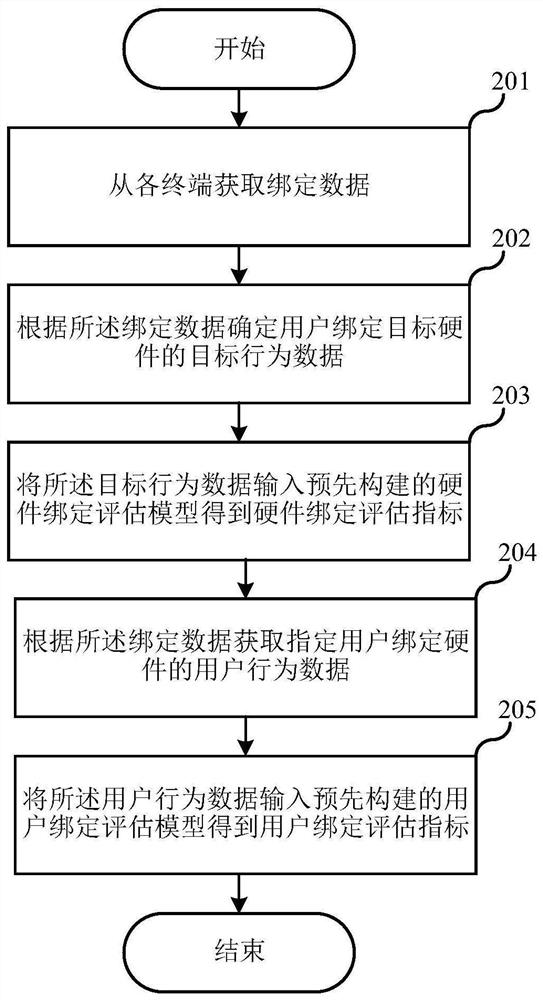

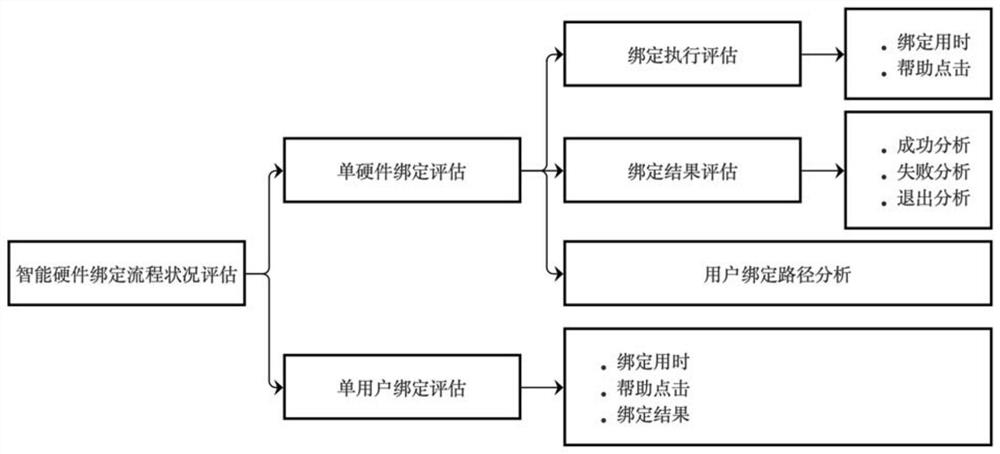

Binding process evaluation method and device, server and storage medium

PendingCN112036666AData is accurate and objectiveReduce demandForecastingOffice automationCollections dataEvaluation result

The embodiment of the invention relates to the technical field of IT application, in particular to a binding process evaluation method and device, a server and a storage medium. The method comprises steps of acquiring binding data from each terminal, the binding data including behavior data of each user for binding hardware and hardware information of the bound hardware; determining target behavior data of binding target hardware by a user according to the binding data; inputting the target behavior data into a pre-constructed hardware binding evaluation model to obtain a hardware binding evaluation index; wherein the hardware binding evaluation model is used for carrying out statistics on target behavior data, and the hardware binding evaluation index is used for evaluating a hardware binding process. The binding data is obtained from the terminal, so that the information is objective and accurate, a large number of statistical samples from different users can be obtained, the requirements for data collection manpower and time resources are reduced, the binding process evaluation result of the users can be quickly obtained based on hardware binding evaluation model evaluation, andthe evaluation period is effectively shortened.

Owner:CHINA MOBILEHANGZHOUINFORMATION TECH CO LTD +1

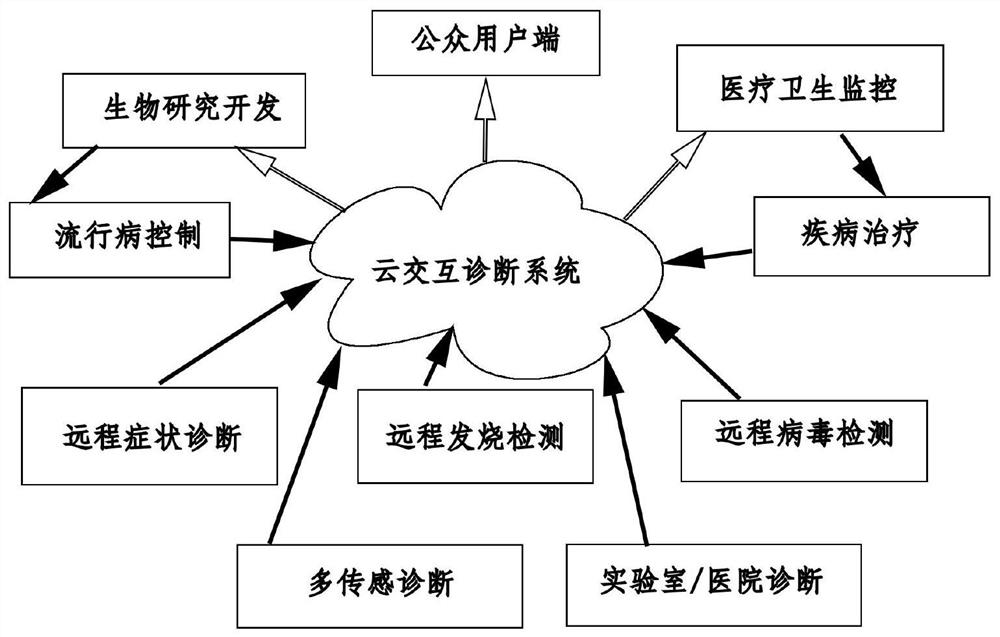

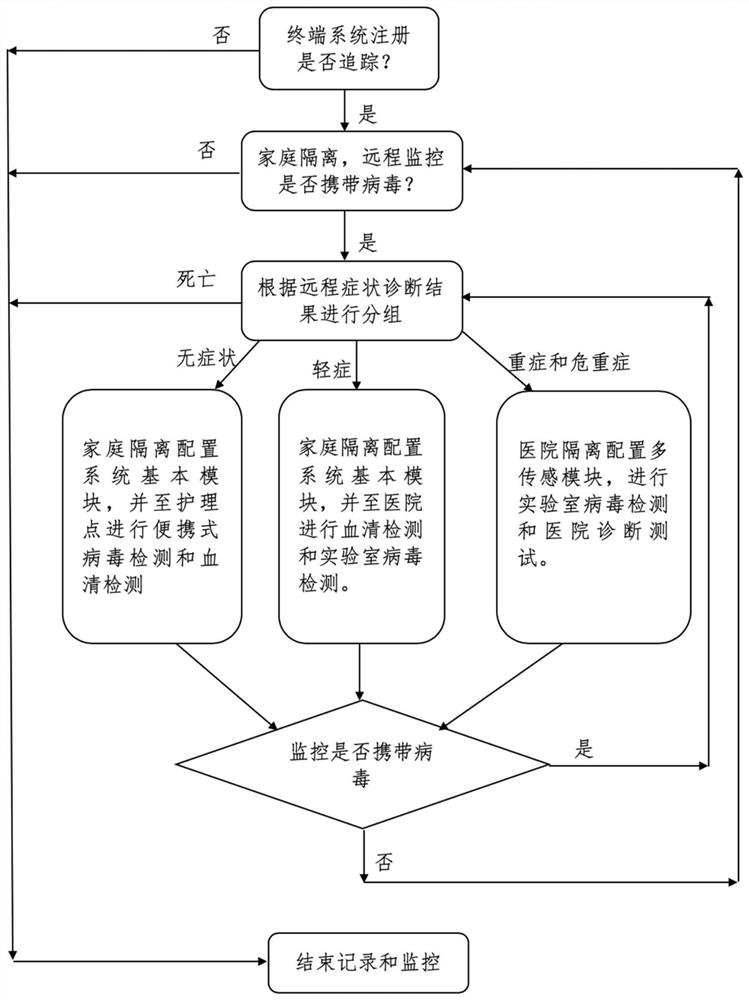

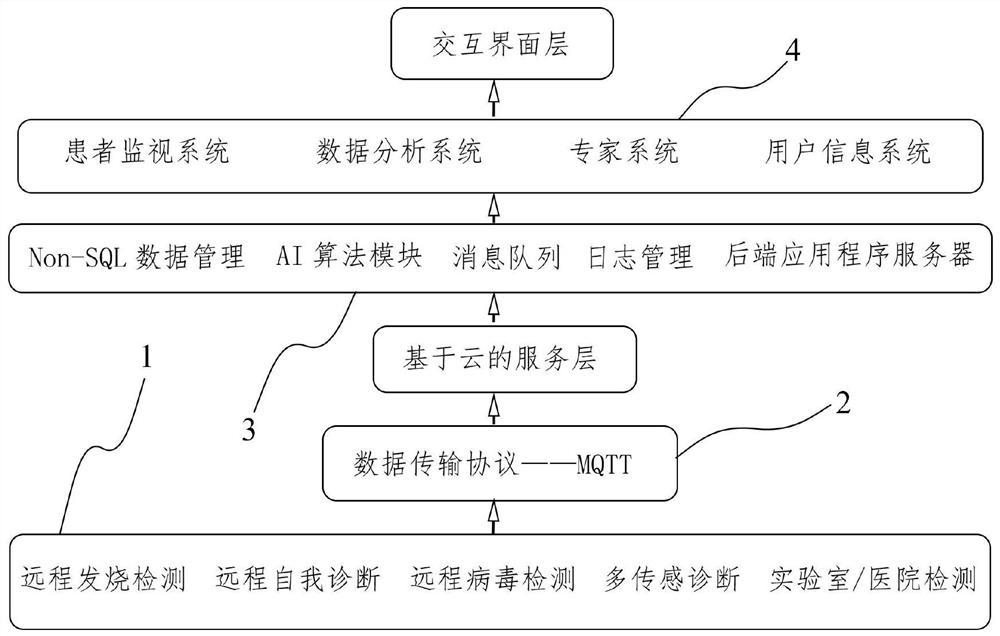

Intelligent multi-channel disease diagnosis system based on cloud technology and method thereof

PendingCN114078600AReduce flowProtect medical resourcesEpidemiological alert systemsMedical automated diagnosisDiseaseMedicine

The invention provides an intelligent multi-channel disease diagnosis system based on the cloud technology and a method thereof. The system comprises a remote symptom diagnosis module, a remote fever detection module, a remote virus detection module, a multi-sensor diagnosis module, a laboratory / hospital diagnosis module and a cloud interaction diagnosis system used for establishing terminal communication and conducting modeling analysis. The remote virus detection module comprises a wearable virus detection module and a portable virus detection module, and the cloud interaction diagnosis system analyzes and processes data uploaded from each module and provides various data services; and the invention further provides a method for performing graded treatment and monitoring on infectious diseases through the disease diagnosis system. According to the technical scheme provided by the invention, the problems in the prior art that the infectious disease risk is possibly caused by artificial close-range infectious disease virus detection and the infectious disease data cannot be tracked, opened and shared in real time are solved by utilizing the combination of a cloud technology platform and wearable virus detection equipment and a multi-channel diagnosis technology.

Owner:联合数字健康有限公司

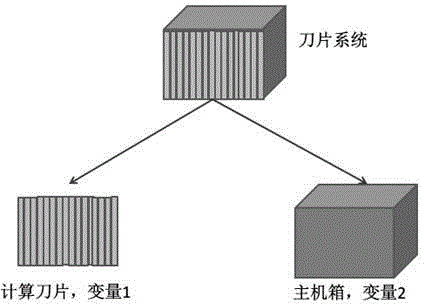

Simple power consumption assessment method of blade server

InactiveCN104142880AData is accurate and objectiveIncreased data requirementsHardware monitoringEnergy efficient computingButt jointComputer module

The invention provides a simple power consumption assessment method of a blade server. According to most blade servers, connectors are used for achieving butt joint of all composing modules. Different from a method of measuring and assessing AC ends and DC ends of traditional servers, the characteristic that a grouped measuring mode is combined with the operation mode of sharing a power source by blade servers is utilized, grouped measuring and average measuring are combined to conveniently carry out project power consumption quick assessment, and the data requirement of user machine room matched construction is better met.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

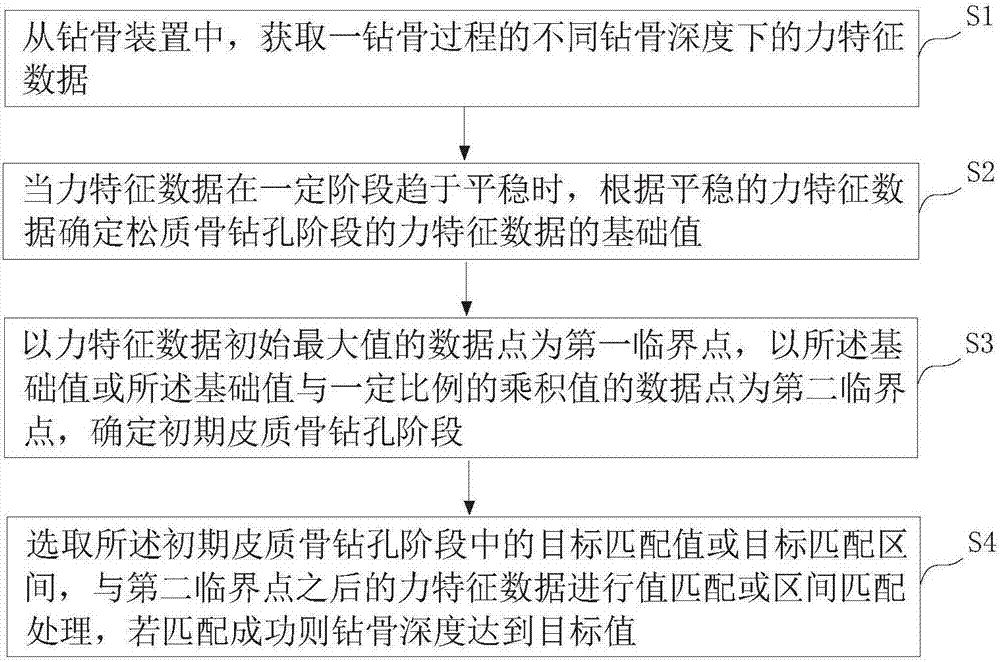

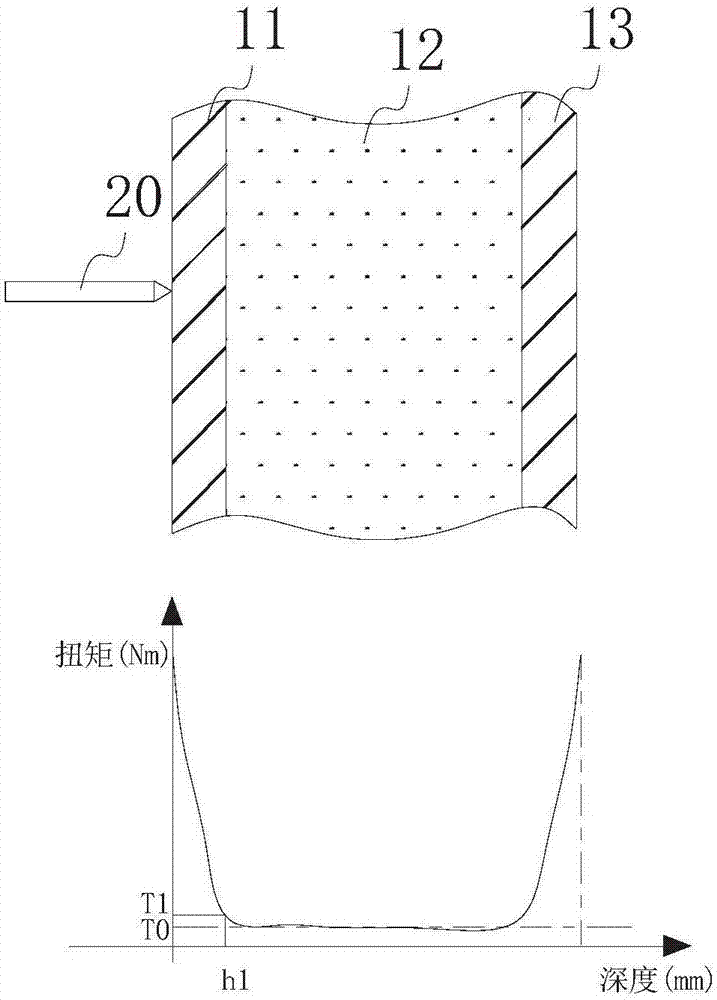

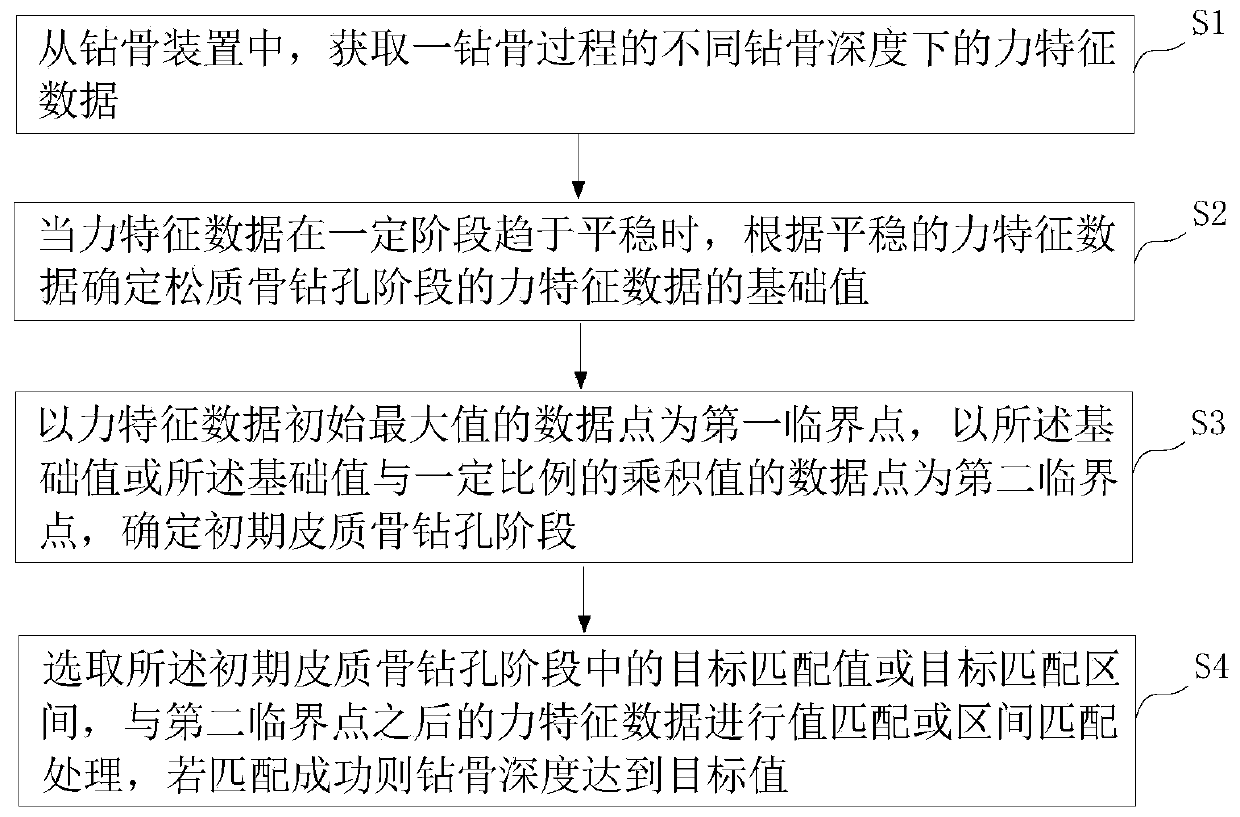

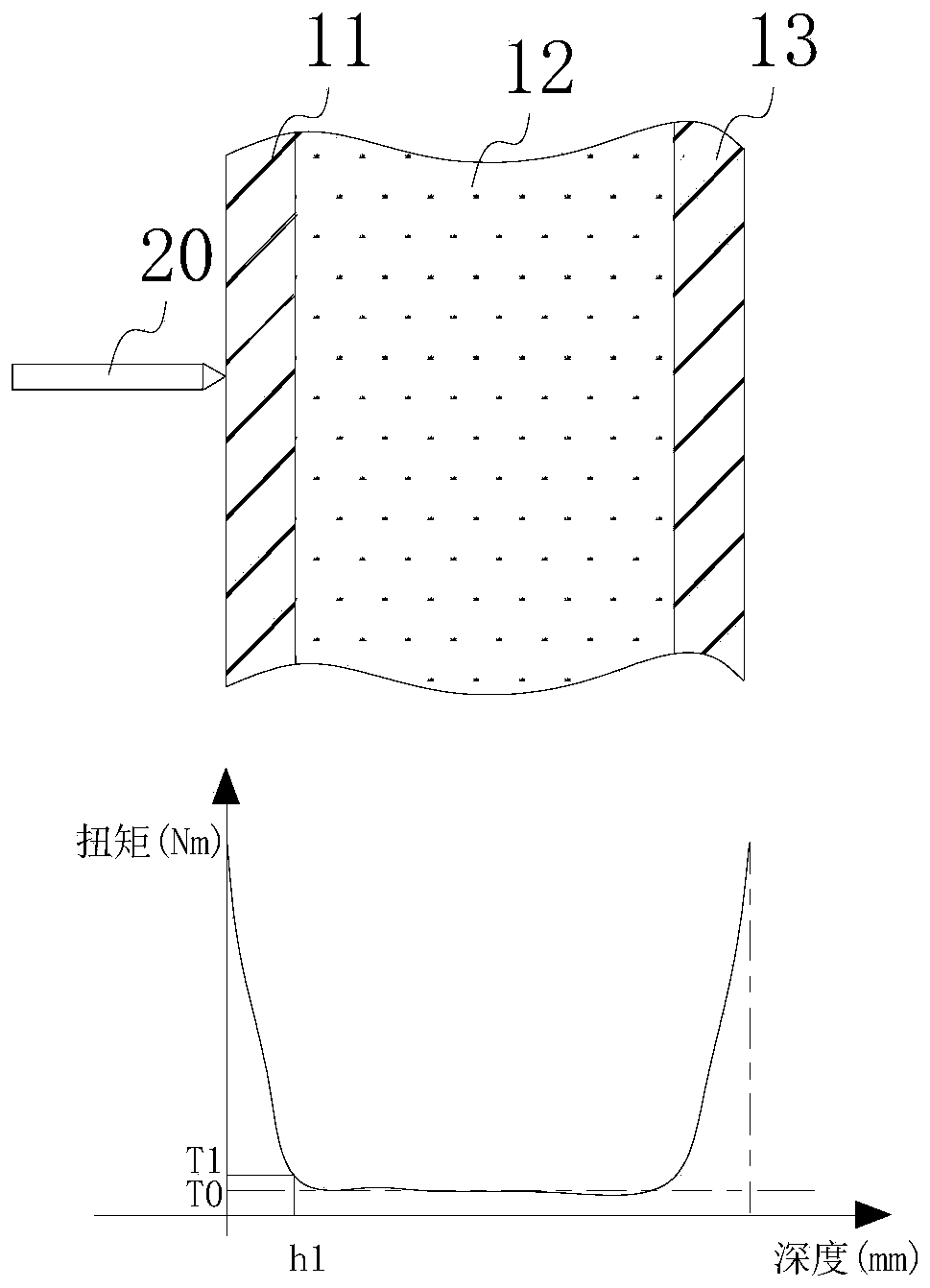

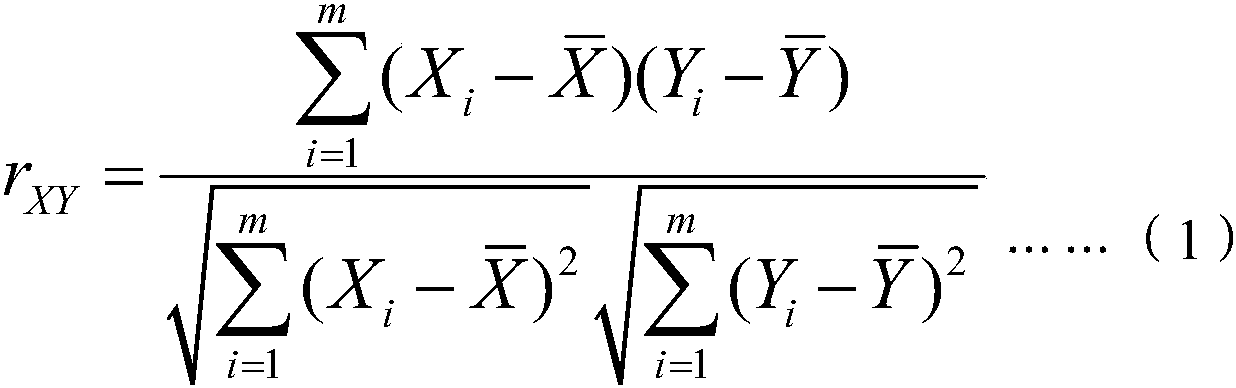

Bone drilling depth judging method and system

ActiveCN107092788AAbandon subjective judgmentData is accurate and objectiveMedical equipmentSpecial data processing applicationsStress conditionsBone Cortex

The invention discloses a bone drilling depth judging method and system. The method comprises the following steps of: S1, obtaining force characteristic data under different bone drilling depths in a bone drilling process; S2, when the force characteristic data tends to be stable in a certain stage, determining a basic value of the force characteristic data in a cancellous bone drilling stage according to the stable force characteristic data; S3, determining a preliminary cortical bone drilling stage by taking a data point with a force characteristic data initial maximum value as a first critical point and taking a data point of the basic value or a product value having a certain proportion with the basic value as a second critical point; and S4, selecting a target matching value or a target matching interval in the preliminary cortical bone drilling stage, carrying out value matching or interval matching on the target matching value or the target matching interval and the force characteristic data after the critical point, and if the matching succeeds, considering that the bone drilling depth achieves a target value. According to the method and system disclosed by the invention, the fact whether the target depth is achieved can be judged according to stress condition, and the result is more objective and correct.

Owner:SHANGHAI INNOMOTION

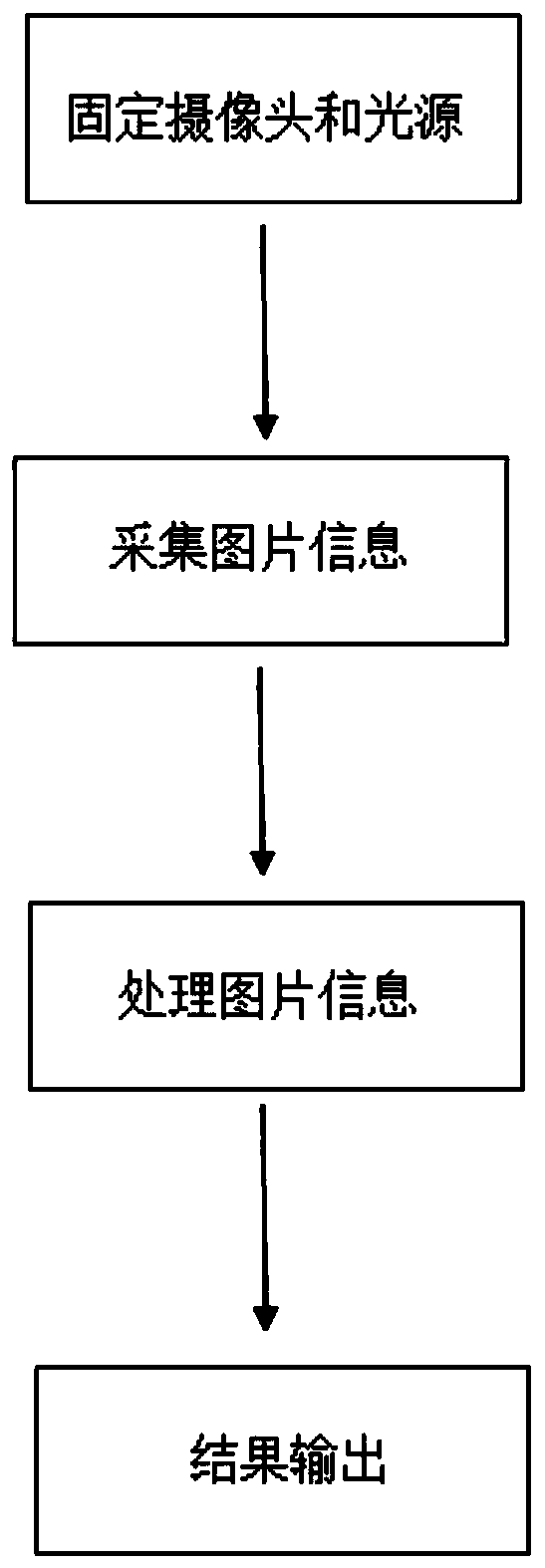

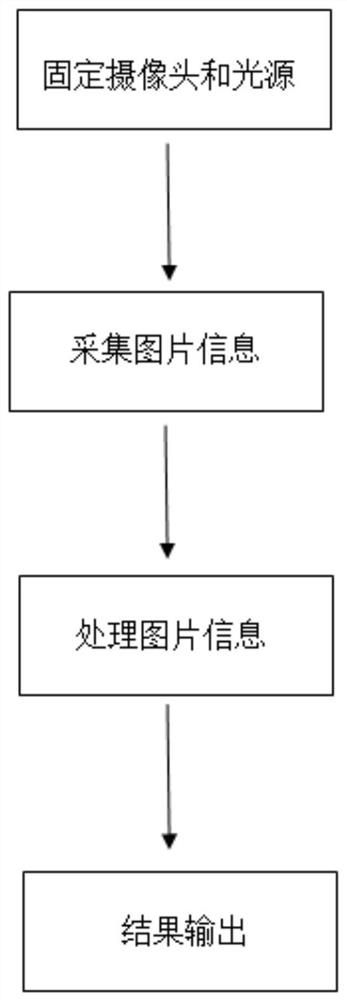

Refill tail oil length automatic detection method and system

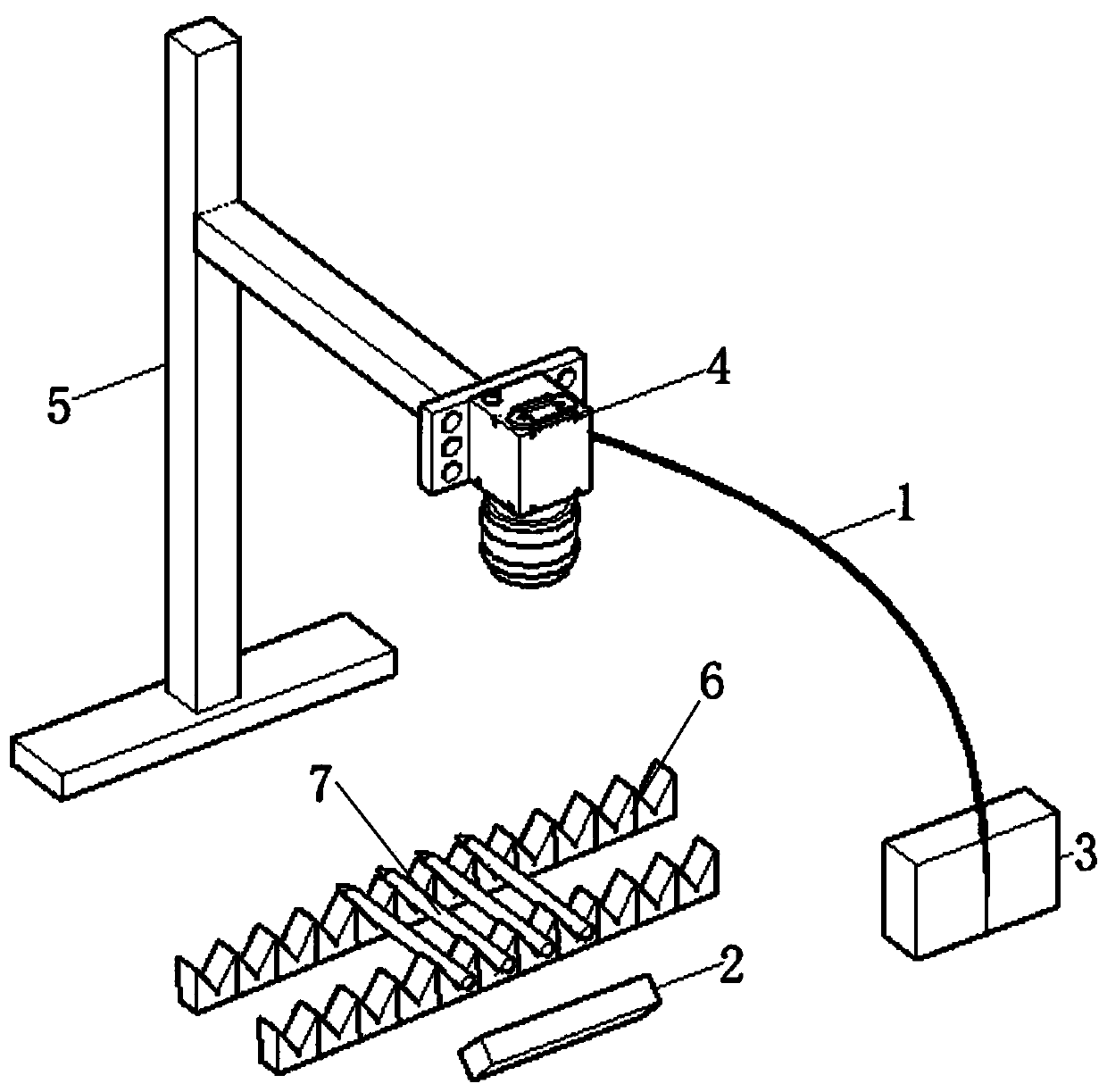

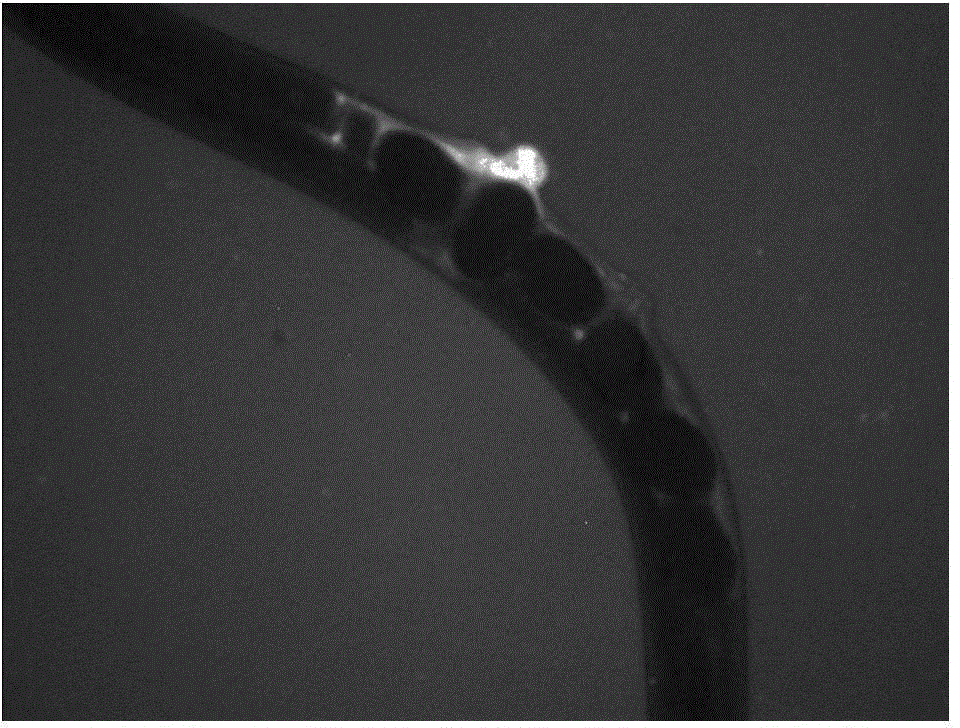

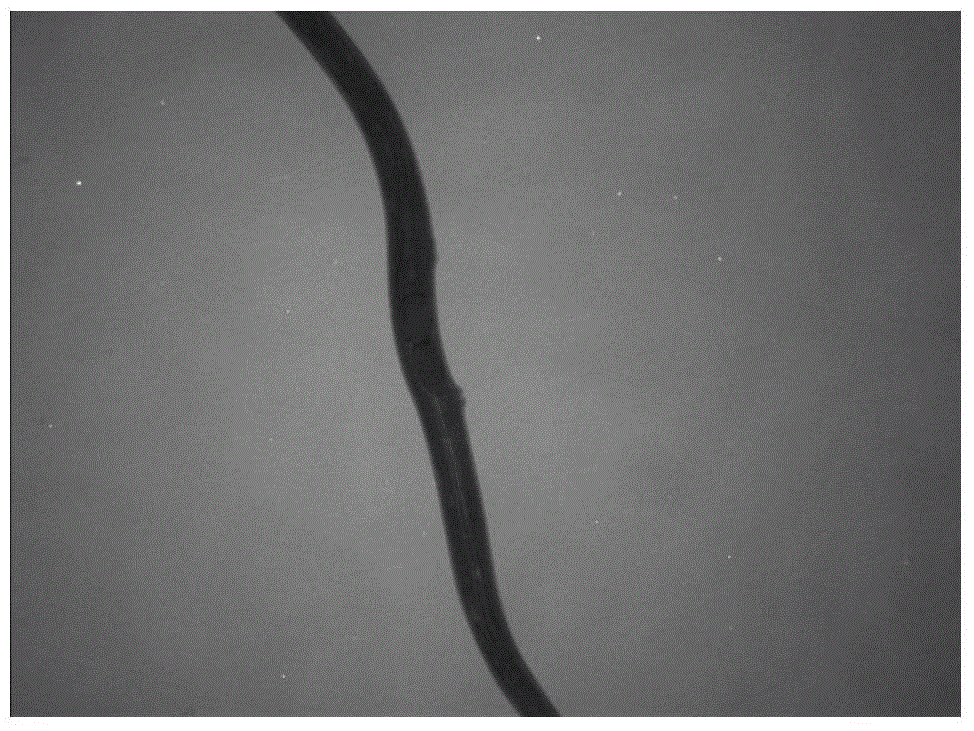

ActiveCN111141746AReduce labor intensityThe instrument is lightweightOptically investigating flaws/contaminationUsing optical meansPattern recognitionImaging processing

The invention relates to a refill tail oil length automatic detection method and system in the field of stationery manufacturing and detection. The detection device involved in the method comprises adata transmission line, a light source, an industrial personal computer, an image acquisition device, a support and a refill transmission device used for transmitting a detected refill. The method comprises the following steps of: sequentially fixing the positions of the image acquisition device and the light source, collecting image information, processing the image information and performing binarization processing on the image through a grayscale image processing system, and outputting a result, setting a standard tail oil length range by referring to the sample refill, outputting a logic value '1' when the length is within an effective range, outputting a logic value '0' when the length is not within the range, outputting an 'invalid' value when the image is not detected, repeating thesteps, then retaining the refill with the output logic result '1', and removing the refill with the output logic result '0'. By using the method, the detection accuracy and the detection efficiency can be remarkably improved.

Owner:SHANGHAI UNIV OF ENG SCI

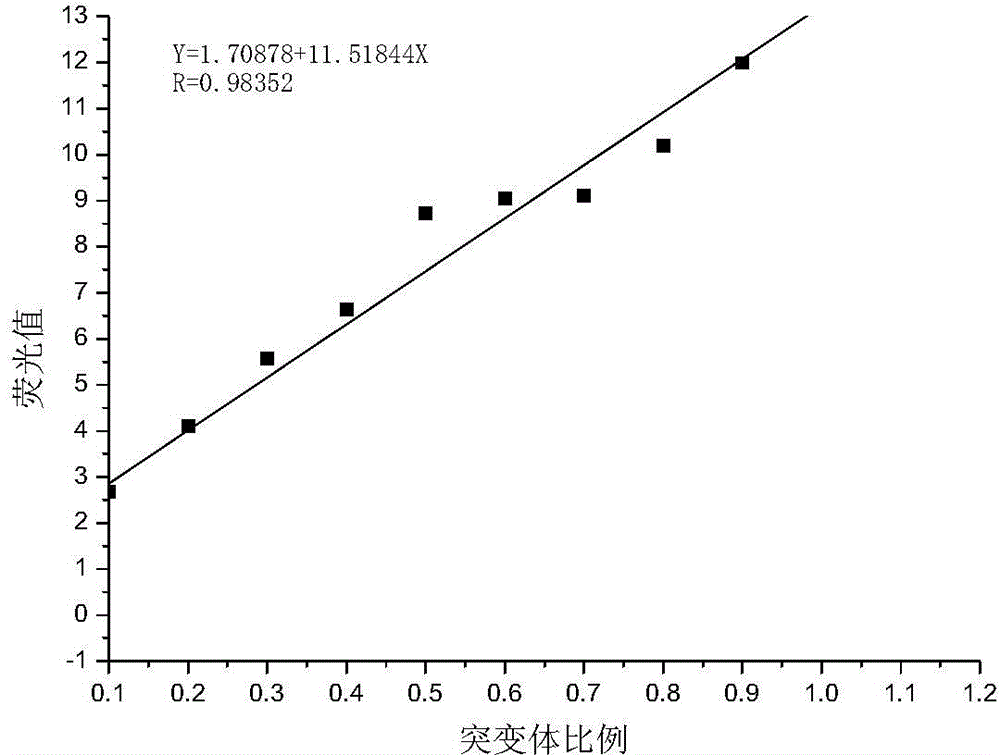

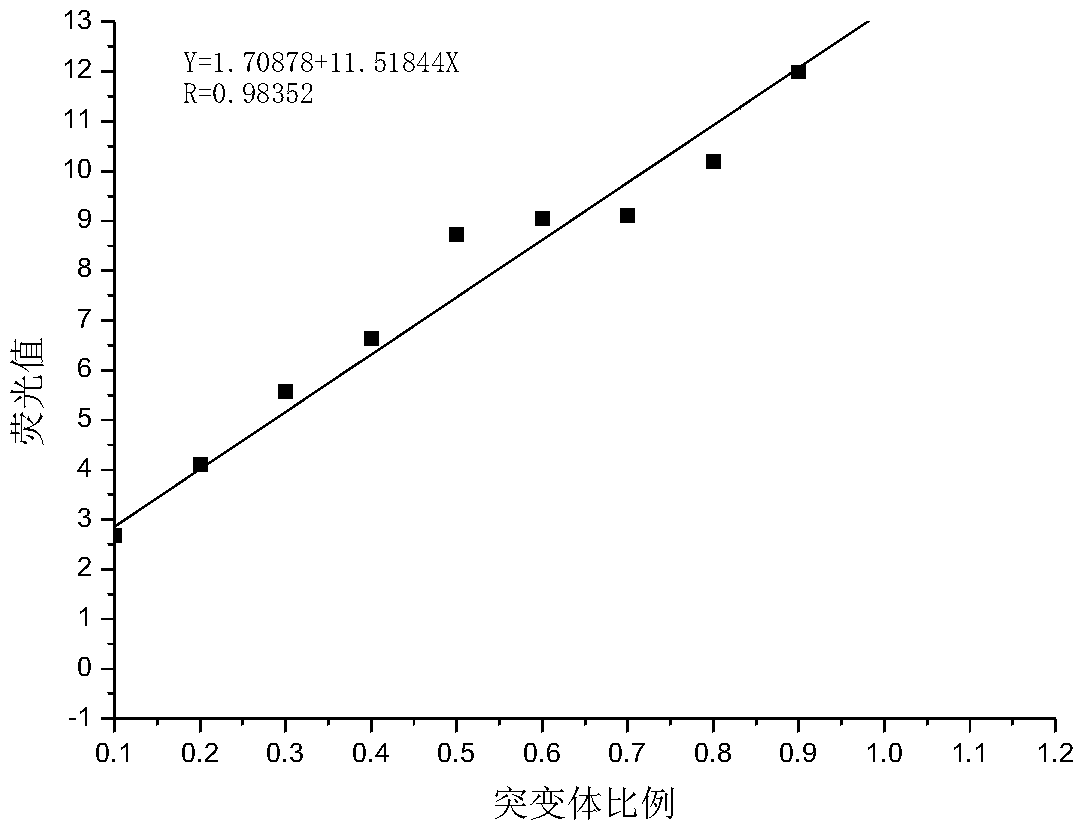

Drug screening kit

InactiveCN105738585AEnables high-throughput screeningEasy to operateFluorescence/phosphorescenceTesting medicinal preparationsEscherichia coliHigh flux

The invention discloses a drug screening kit and a use method thereof, and belongs to the technical field of biological detection. The kit comprises Caenorhabditis elegans, a Caenorhabditis elegans medium, Escherichia coli and a dye. Different dyeing effects of the dye 2',7'-dichlorodihydrofluorescein diethyl ester on a mutant and wild Caenorhabditis elegans are used to realize rapid, efficient and accurate simple-operation and high-flux screening of effective antitumor drugs, so the time and the cost of general research and development workers of antitumor drugs are saved.

Owner:杨同玥

A down component and content detection system, and down quality detection method

ActiveCN111172629BEasy to sort and collectReduce manual screeningFibre cleaning/opening by air draught arrangementsFibre cleaning/opening machinesAir separationMechanics

The invention discloses a down component and content detection system, which comprises a pretreatment device, a winnowing device and a collection device which are connected in sequence; The inside moves to the outside; the winnowing device includes a vertically arranged sub-screen cylinder, a static eliminator arranged at the bottom of the sub-screen cylinder, and a push plate. The side of the lower part of the sub-screen cylinder communicates with the pretreatment cylinder, and the 1. A number of outlets are arranged along its height direction, and the second air flow blows the down to a stable height in the sub-sieve cylinder; the collection device includes a collection part and an air extraction pipe connected to the outlet, and the third air flow passes from the sub-sieve cylinder along the collection part, Pumping tube movement. The invention classifies and detects the components of the down by using the weight difference between the components of the down, reduces manual screening, lightens the workload, avoids subjective influence of people, and makes the data more objective and accurate.

Owner:SUZHOU FIBER EXAMINATION INST

Antitumor drug screening kit and use method thereof

ActiveCN105738329BEnables high-throughput screeningEasy to operateFluorescence/phosphorescenceEscherichia coliNematode

The invention discloses an antitumor medicine screening kit and a using method thereof, and belongs to the technical field of biomedicine. The kit comprises caenorhabditis elegans, a nematode culture medium, escherichia coli and dye. An objective of screening effective antitumor medicines rapidly, efficiently and accurately with simple operation and a high throughout is achieved by utilizing different dyeing effects of the dye that is 2',7'-dichlorofluorescein diacetate on mutants and wild type caenorhabditis elegans, thus saving time and the cost for personnel researching and developing antitumor medicines.

Owner:甘肃药业集团科技创新研究院有限公司

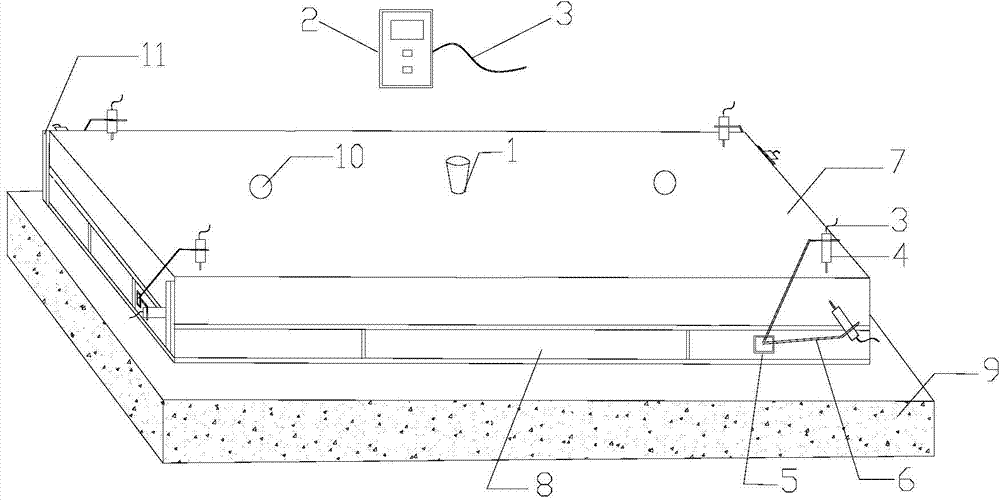

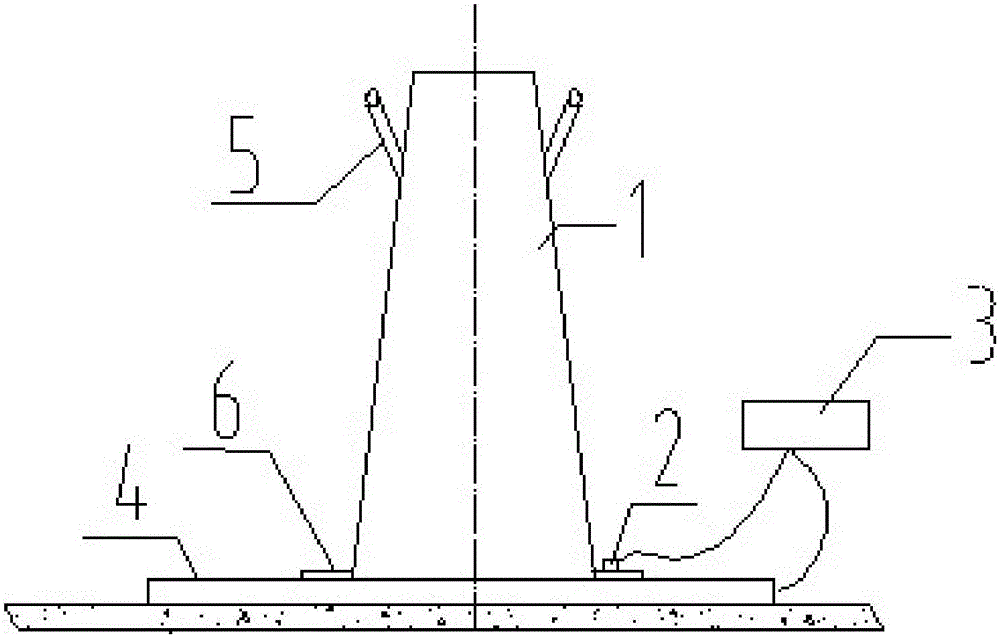

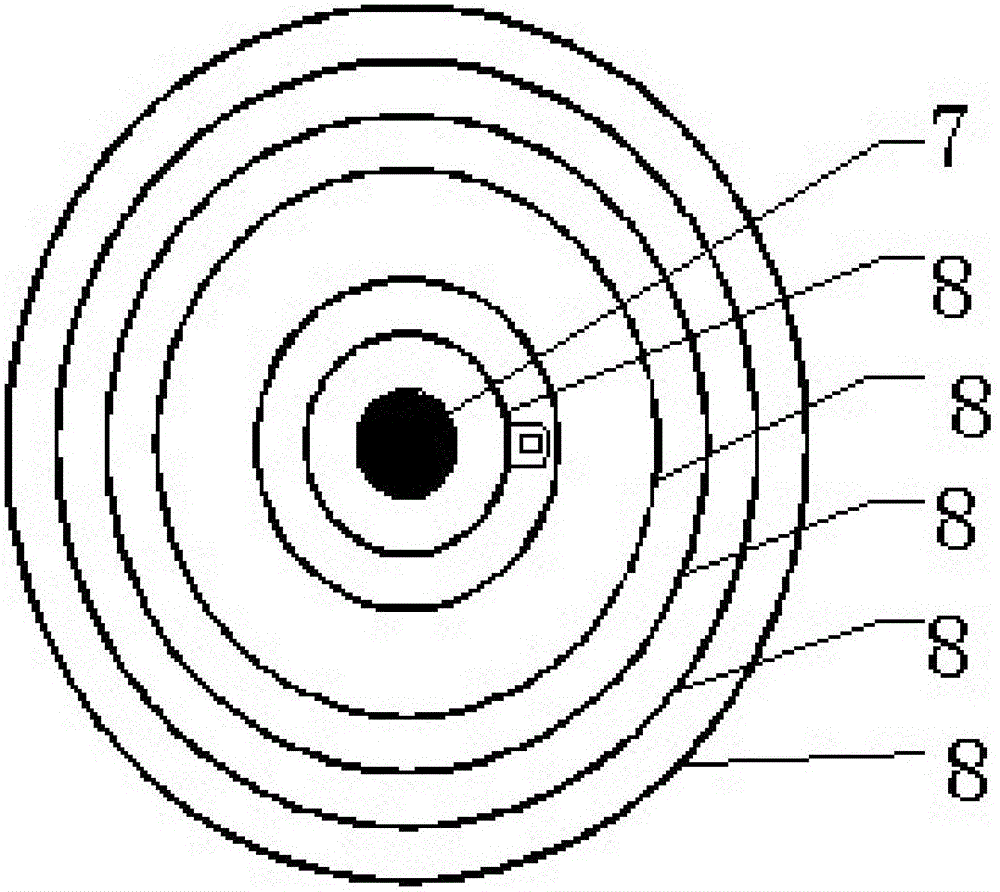

Self-compacting concrete expansion time automatic test device

ActiveCN103823047BEasy to useEasy to operateMaterial testing goodsRound tableAutomatic test equipment

The invention discloses an automatic self-compacting concrete expanding time testing device. The automatic self-compacting concrete expanding time testing device comprises a concrete slump cylinder comprising a round-table-type steel cylinder; the round-table-type steel cylinder is arranged on the middle part of a base plate; the center of the base plate is provided with a metal circle center; the base plate is provided with a plurality of concentric metal circular rings marked with different diameters around the metal circle center; the upper part of the round-table-type steel cylinder is provided with a handle, and the lower part of the round-table-type steel cylinder is provided with a pedal plate; the pedal plate is internally provided with a limit switch; the limit switch and the metal circular rings are respectively connected with an electronic testing device by leads. The automatic self-compacting concrete expanding time testing device can automatically test the time for the self-compacting concrete mixture expansion degree to reach the set diameter, is convenient to use, and is simple to operate, and has accurate and objective data.

Owner:CHINA RAILWAY FIFTH SURVEY & DESIGN INST GRP CO LTD

A kind of blade polishing processing method based on neural network

ActiveCN109732450BREACTIVE SURFACE CONTACTData is accurate and objectiveBelt grinding machinesNeural architecturesInformation transmissionMaterial removal

The invention relates to a neural network-based blade polishing processing method, which scans and measures the hairy parts of the blade through a measuring device and transmits the information to the computer software to obtain a reconstructed three-dimensional model, and compares it with the characteristic points on the theoretical model Make a comparison, adjust and make the coordinate systems of the two models coincide, so as to calculate the theoretical machining allowance of the blade; use historical data to train the neural network model, so that the neural network model can identify the processing under different theoretical machining allowances Process parameter configuration; input the theoretical machining allowance of the blade into the neural network model, and the neural network model calculates the processing parameters of the blade processing for polishing; scan and measure the processed blade and The information is transmitted to the computer software to obtain an updated model, which is compared with the three-dimensional model before processing and the material removal amount of the blade is calculated; if the size of the blade after processing meets the tolerance requirements, the processing is considered complete.

Owner:CHONGQING UNIV OF TECH

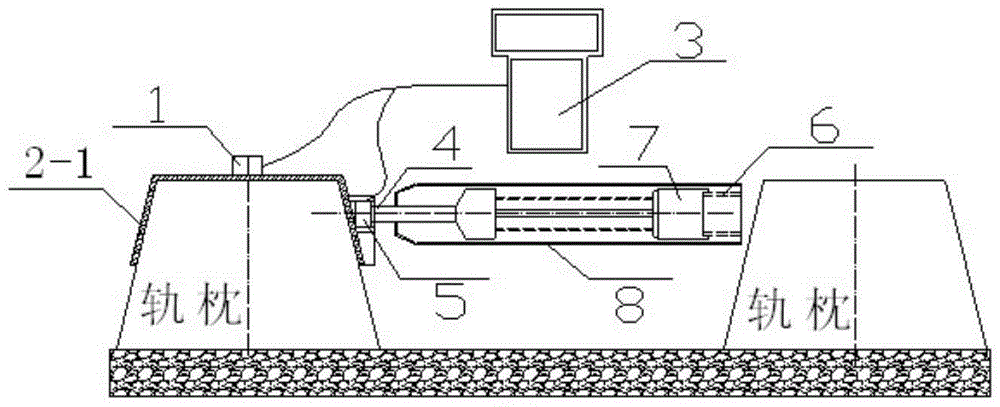

Automatic detection device for static stiffness of elastic backing plate under sleeper

ActiveCN104977212BEasy to operateThe detection process is fastMaterial strength using tensile/compressive forcesTest sampleData acquisition

Owner:CHINA RAILWAY FIFTH SURVEY & DESIGN INST GRP CO LTD

Method and system for judging bone drilling depth

ActiveCN107092788BAbandon subjective judgmentData is accurate and objectiveMedical equipmentStress conditionsBone Cortex

The invention discloses a bone drilling depth judging method and system. The method comprises the following steps of: S1, obtaining force characteristic data under different bone drilling depths in a bone drilling process; S2, when the force characteristic data tends to be stable in a certain stage, determining a basic value of the force characteristic data in a cancellous bone drilling stage according to the stable force characteristic data; S3, determining a preliminary cortical bone drilling stage by taking a data point with a force characteristic data initial maximum value as a first critical point and taking a data point of the basic value or a product value having a certain proportion with the basic value as a second critical point; and S4, selecting a target matching value or a target matching interval in the preliminary cortical bone drilling stage, carrying out value matching or interval matching on the target matching value or the target matching interval and the force characteristic data after the critical point, and if the matching succeeds, considering that the bone drilling depth achieves a target value. According to the method and system disclosed by the invention, the fact whether the target depth is achieved can be judged according to stress condition, and the result is more objective and correct.

Owner:SHANGHAI INNOMOTION

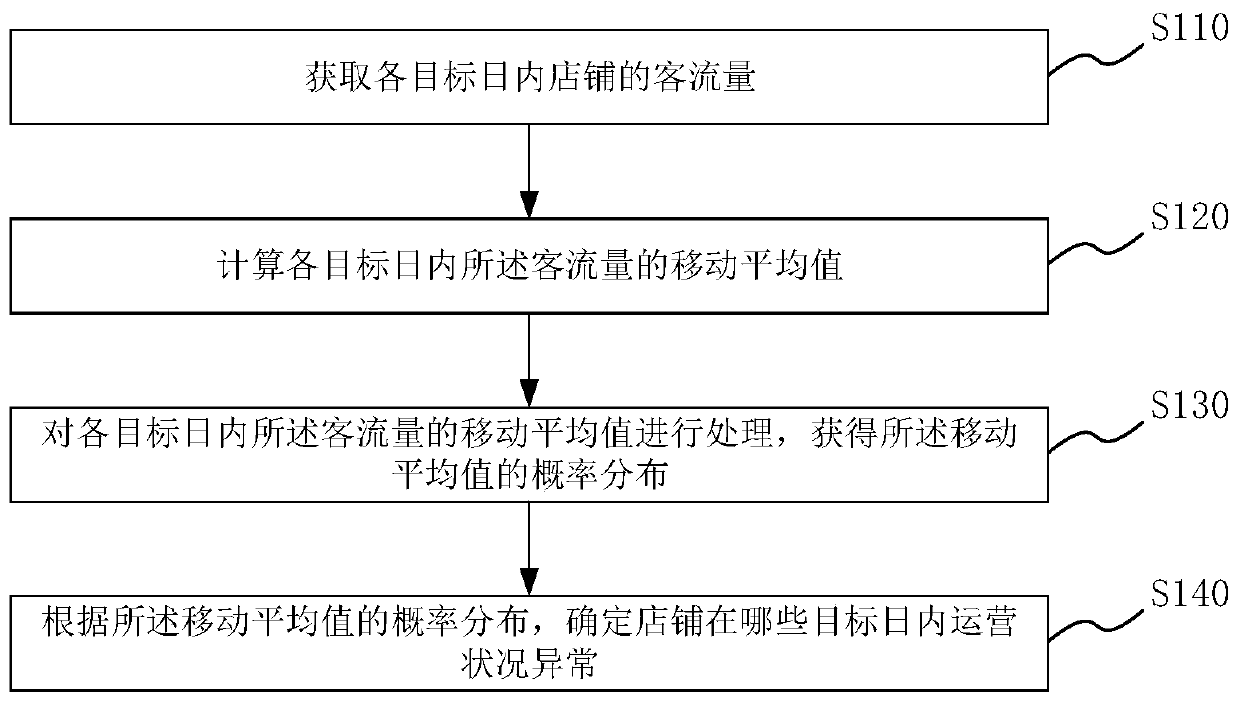

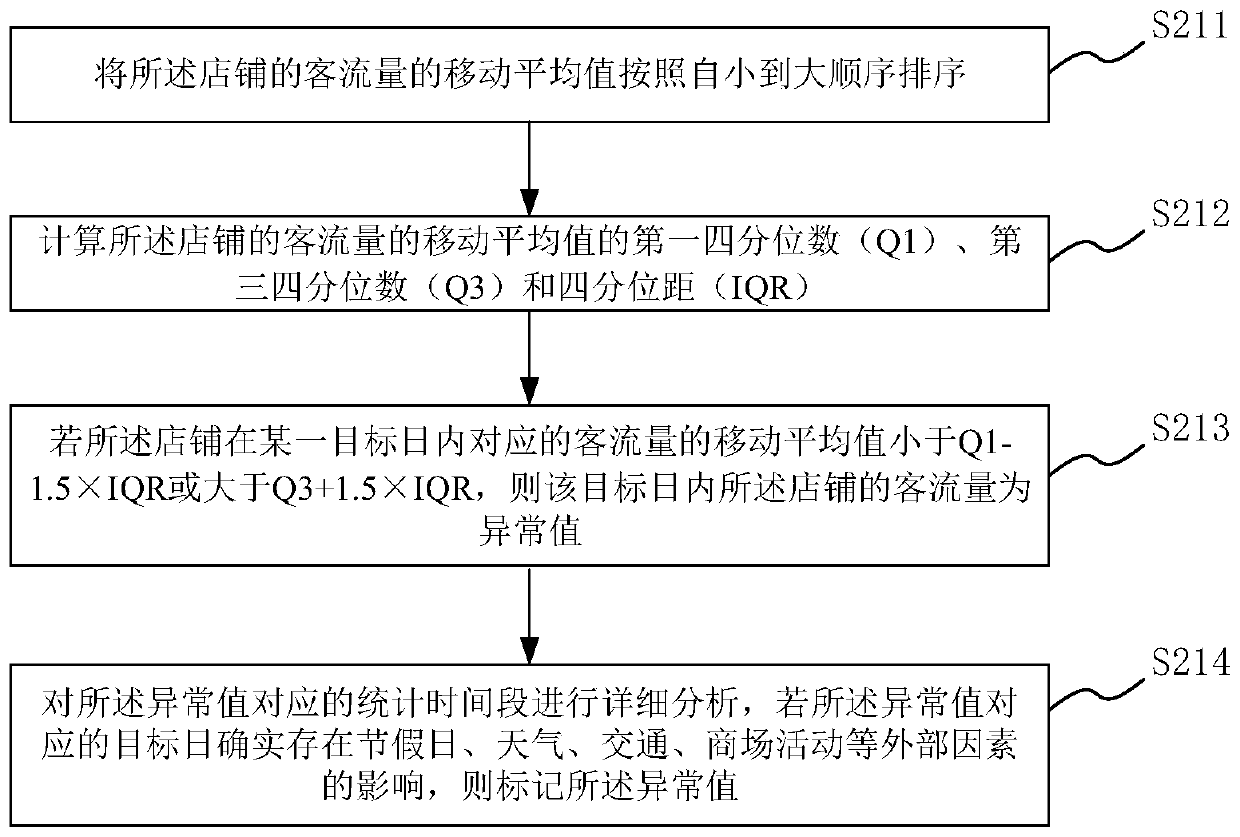

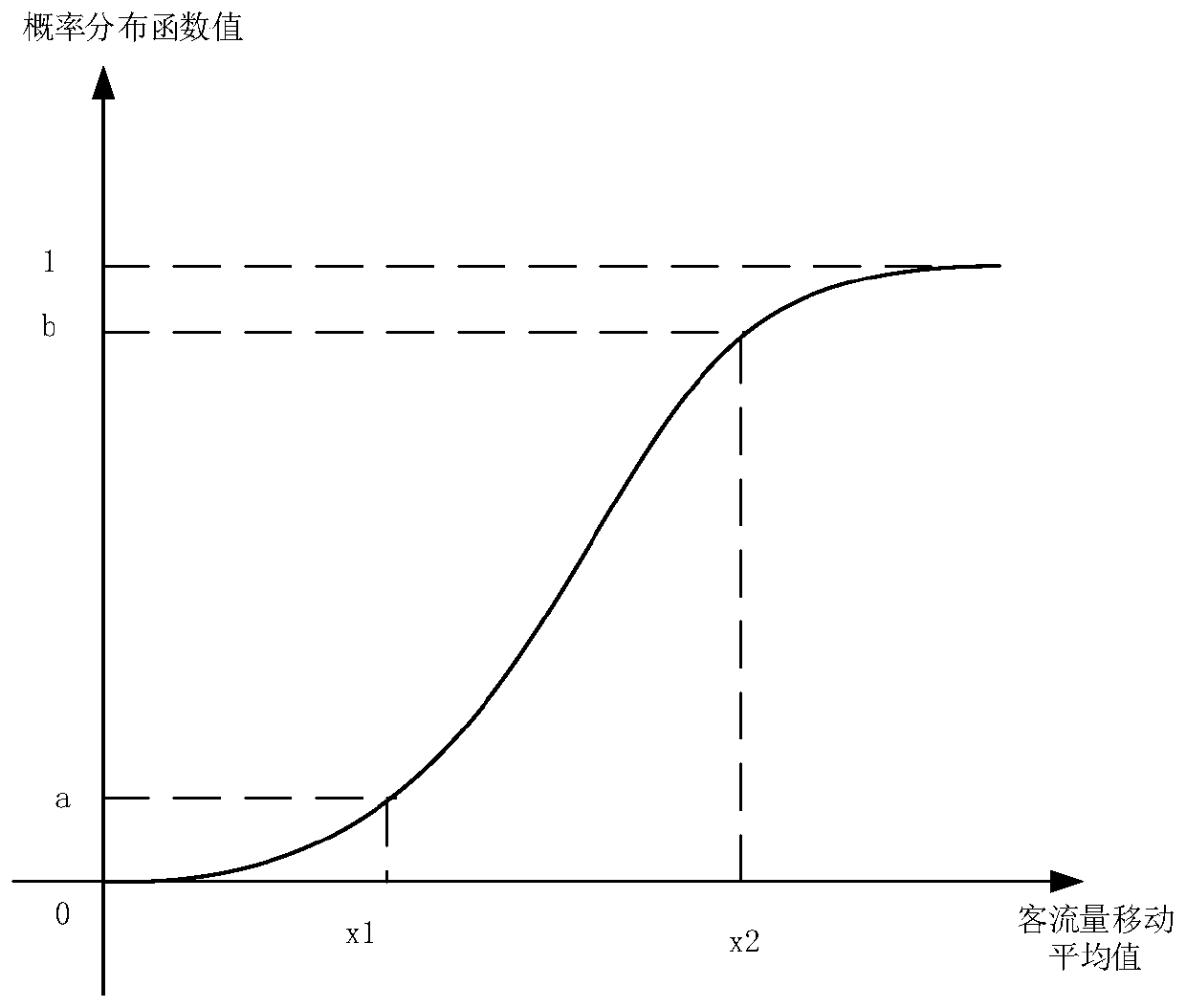

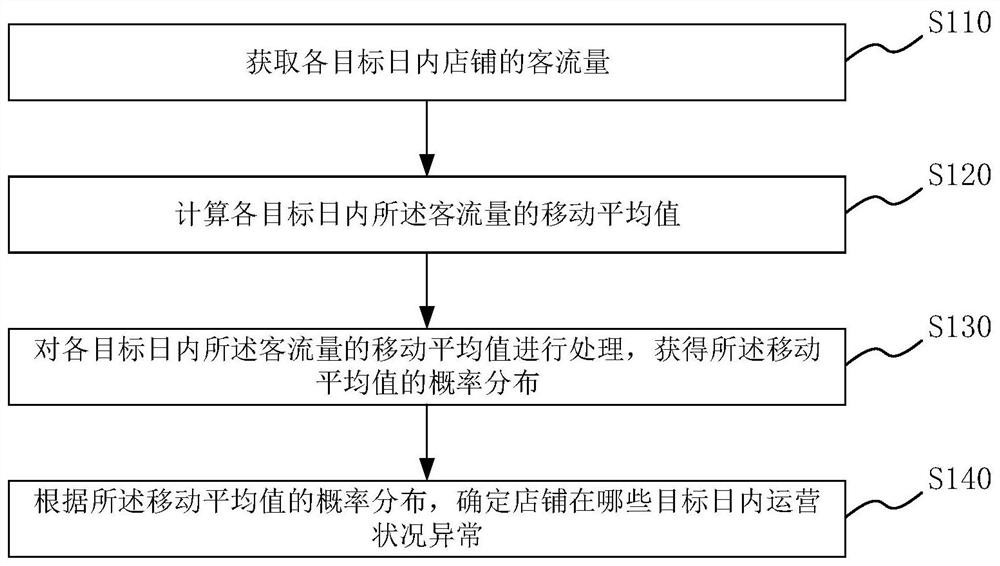

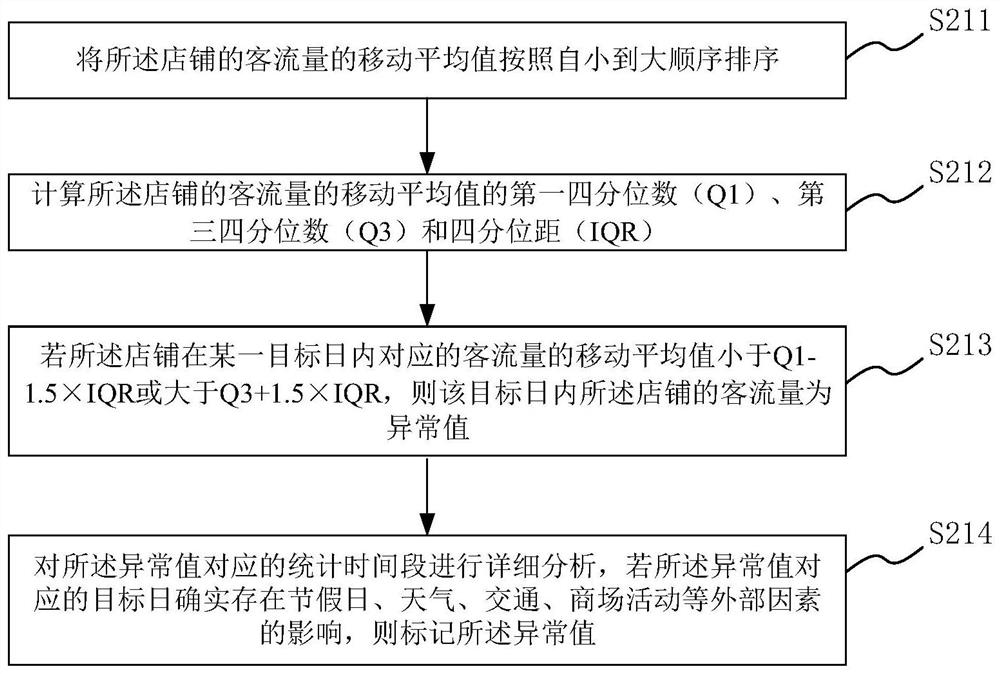

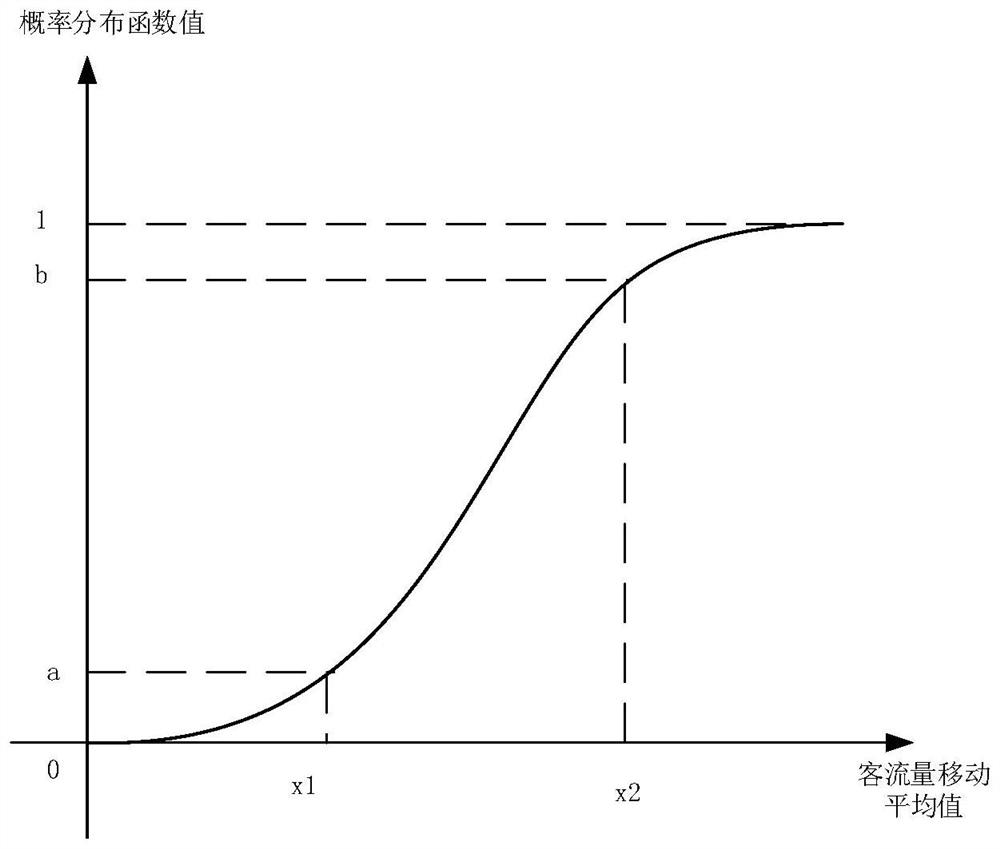

Shop operation condition judgment method and system, medium and equipment

ActiveCN110597875AImprove management efficiencyData is accurate and objectiveDigital data information retrievalCharacter and pattern recognitionDaily operationMoving average

The invention provides a shop operation condition judgment method and system, a medium and equipment. The shop operation condition judgment method comprises the steps of obtaining passenger flow volumes of shops in each target day; calculating a moving average value of the passenger flow volume in each target day; processing the moving average value of the passenger flow volume in each target dayto obtain probability distribution of the moving average value; and according to the probability distribution of the moving average value, determining which target daily operation conditions of the store are abnormal. According to the shop operation condition judgment method, an operator or a manager is allowed to directly obtain the shop operation condition analysis result, a large amount of manpower participation is not needed, and the shop management efficiency is improved.

Owner:汇客云(上海)数据服务有限公司

A video image color cast detection method and device

ActiveCN104346817BReduce the influence of human subjective factorsImprove detection efficiencyImage enhancementImage analysisVideo imageColor chart

Owner:ZHEJIANG DAHUA TECH CO LTD

Method, system, medium and equipment for judging store operating conditions

ActiveCN110597875BImprove management efficiencyData is accurate and objectiveDigital data information retrievalCharacter and pattern recognitionMoving averageManagement efficiency

The present invention provides a method, system, medium and equipment for judging store operating conditions. The method for determining the business status of the store includes: obtaining the passenger flow of the store in each target day; calculating the moving average of the passenger flow in each target day; processing the moving average of the passenger flow in each target day to obtain the moving average. The probability distribution of the average value; according to the probability distribution of the moving average value, determine which target days the store operates abnormally. The method for determining the operating status of a store allows the operator or manager to directly obtain the analysis results of the operating status of the store without requiring a large amount of human participation, thereby improving the management efficiency of the store.

Owner:汇客云(上海)数据服务有限公司

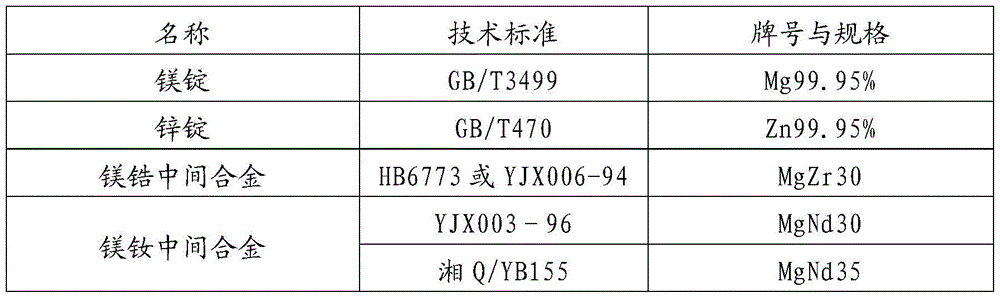

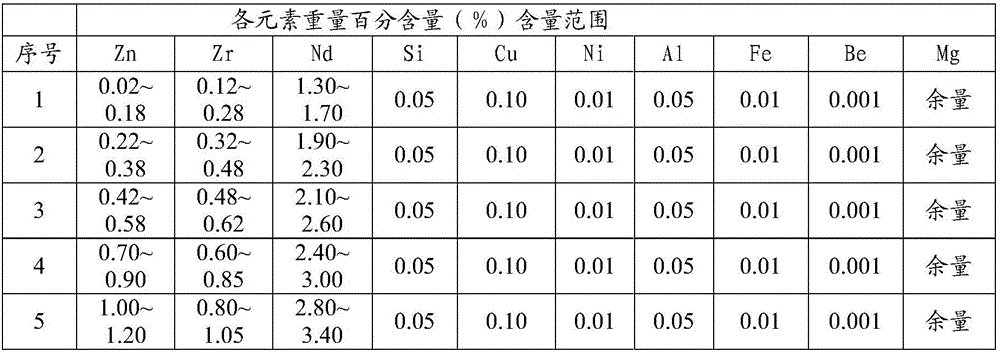

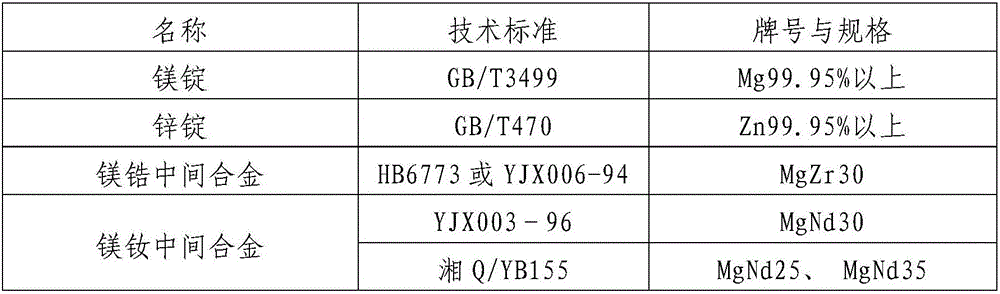

ZM6 alloy spectrum standard material ratio method

ActiveCN104122129BMeet the requirements of rapid chemical analysis in front of the furnaceEliminate biasPreparing sample for investigationMetallurgyMaterials science

The invention relates to a method for proportioning ZM6 magnesium alloy spectral standard substances. According to the proportion table, according to the content of each element in the raw material and the total weight of the alloy, the weight of the raw materials in each gradient is calculated, and each gradient is formulated according to the calculation results. Compare. The invention can eliminate the deviation of the final result caused by the different element content in each position of the raw material, the calculated data is accurate and objective, and the product can completely meet the requirement of rapid chemical analysis on the alloy before furnace through actual production.

Owner:HARBIN DONGAN ENGINE GRP

A method and system for automatic detection of the length of pen refill tail oil

ActiveCN111141746BReduce labor intensityThe instrument is lightweightOptically investigating flaws/contaminationUsing optical meansAlgorithmImage manipulation

The invention relates to a method and system for automatic detection of the length of pen refills and tails in the field of stationery manufacturing and detection. The method includes the following steps: sequentially fixing the image acquisition device and the position of the light source; collecting picture information; Refer to the sample refill to set the standard tail oil length range. If the length is within the valid range, it will output a logical value of "1". If the length is not within the range, it will output a logical value of "0". If no image is detected, it will output an "invalid" value. Then keep the refill whose output logic result is "1", and remove the refill whose output logic result is "0". Using this method, the detection accuracy and detection efficiency can be significantly improved.

Owner:SHANGHAI UNIV OF ENG SCI

Parameter detection device for surface vibration compaction tester

InactiveCN104614237AEasy to operateThe detection process is fastStrength propertiesClassical mechanicsData acquisition

The invention discloses a parameter detection device for a surface vibration compaction tester. The parameter detection device comprises two parts, namely a force detection device and a data acquisition and processing device, wherein the force detection device comprises a force carrying plate, a force sensor and a base plate which are connected in sequence from top to bottom; the upper surface of the force carrying plate is in direct contact with a steel rammer of the surface vibration compaction tester; the force sensor is connected with the data acquisition and processing device; the lower part of the force carrying plate is connected with the force sensor through a ball hinge; the force sensor is used for detecting parameters such as the surface static pressure, the vibration frequency and the excitation force. The parameter detection device has the advantages of being convenient to use, simple to operate, high in detection speed, accurate and objective in data, and capable of automatically printing and storing a detection result, and the test accuracy is improved.

Owner:CHINA RAILWAY FIFTH SURVEY & DESIGN INST GRP

Sleeper Longitudinal and Transverse Resistance Dynamic Tester and Test Method

ActiveCN103630283BReduce labor intensityThe instrument is lightweightApparatus for force/torque/work measurementEngineeringDynamic resistance

The invention discloses a sleeper longitudinal-transverse resistance dynamic detector and detecting method. The detector comprises a loading device, a sleeper longitudinal-transverse bearing device and an electronic testing device. The end of the loading device is provided with an impact head. An impact hammer and a spring augmenter are disposed inside the impact head. The electronic testing device comprises a force sensor and an acceleration or displacement sensor, wherein the force sensor and the acceleration or displacement sensor are respectively connected with a tester mainframe. The acceleration or displacement sensor is disposed on the upper portion of the sleeper longitudinal-transverse bearing device. The force sensor is disposed on the side of the sleeper longitudinal-transverse bearing device. The detector capable of dynamically detecting sleeper longitudinal and transverse resistance is light, convenient to use, simple to operate, simple to mount, accurate and objective in data, and capable of automatically printing and saving detecting results, labor intensity of detecting personnel is lowered, and detecting efficiency is increased.

Owner:CHINA RAILWAY FIFTH SURVEY & DESIGN INST GRP CO LTD

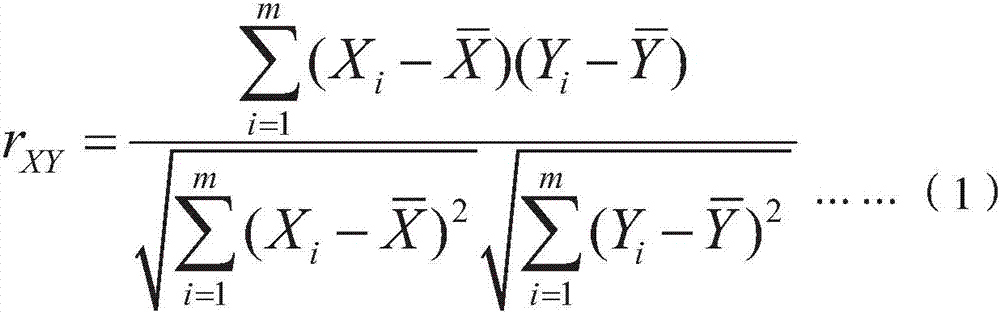

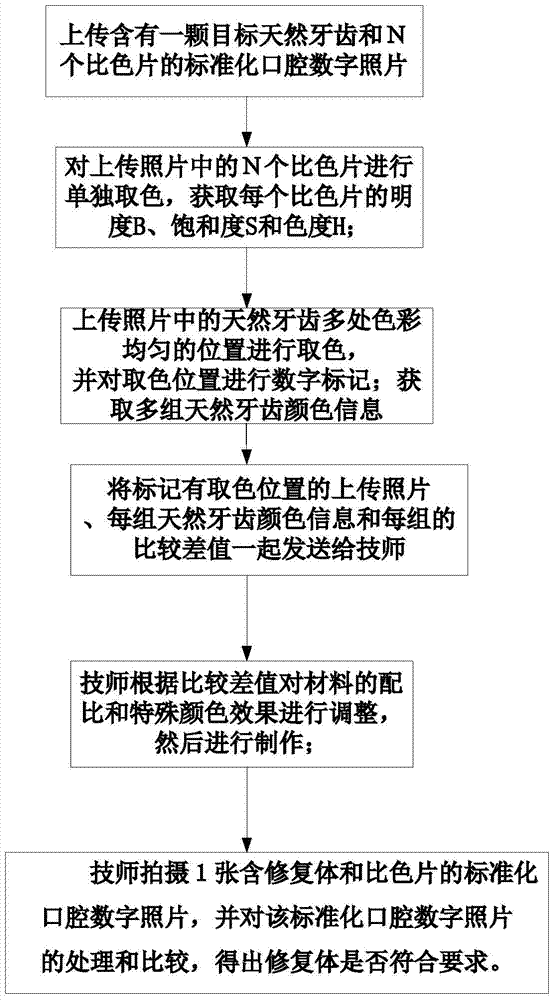

Dental digital colorimetric method based on digital photos and hsb color system

The invention discloses a digital colorimetric method for oral cavity based on digital photos and HSB color system. The present invention firstly uploads a standardized oral digital photo containing a target natural tooth and N color comparison sheets, and then independently picks the color of the N color comparison sheets in the uploaded photo, and at the same time picks the color of the natural teeth evenly; screens out The color comparison sheet closest to the natural tooth, and the calculated comparison difference ΔB, ΔS, ΔH; the technician adjusts the ratio of the material and the special color effect according to the comparison difference ΔB, ΔS, ΔH, and then makes it; After the prosthesis is made, a standardized oral digital photo will be taken, and then through the processing and comparison of the standardized dental digital photo, the obtained prosthesis will be compared with the color information of the color chart to determine whether the prosthesis meets the requirements. The present invention is capable of measuring the color of any region of the tooth without being limited to the size and shape of the tooth surface.

Owner:范翌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com