ZM6 alloy spectrum standard material ratio method

A standard material and spectral technology, which is applied in the field of ZM6 alloy spectral standard material ratio, can solve the problem of narrow chemical composition range, achieve the effect of accurate and objective data and eliminate deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

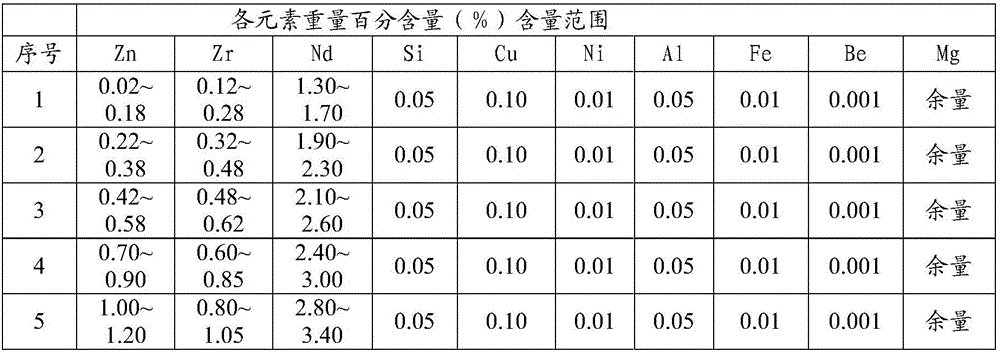

[0095] Proportion the ZM6 magnesium alloy spectral standard substance, which is divided into 5 gradients, and its composition is shown in the following table:

[0096]

[0097] The specific ratio method is as follows:

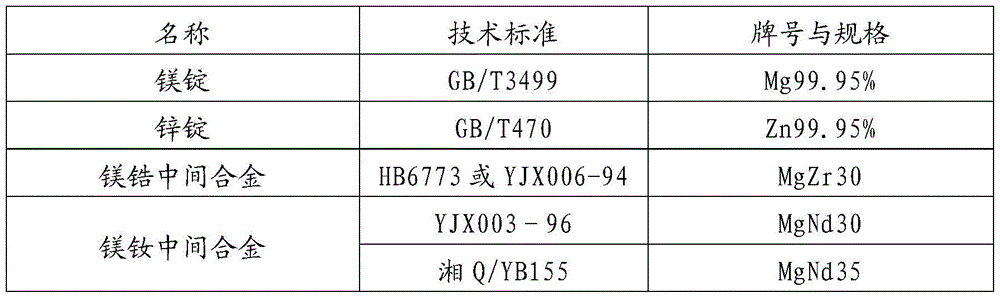

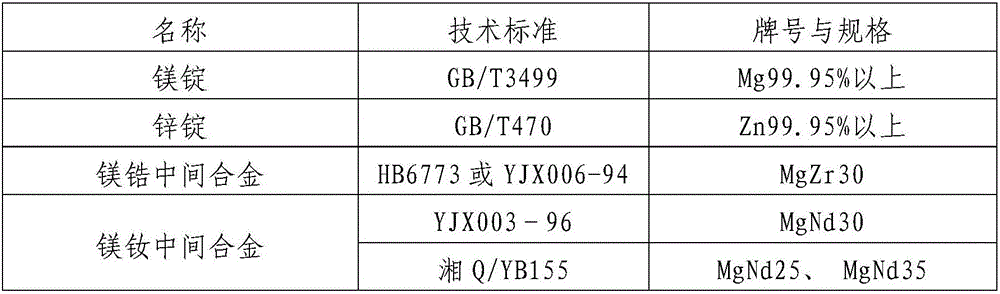

[0098] 1. Material selection

[0099] According to the following table for raw material selection:

[0100]

[0101] 2. Material preparation

[0102] 1) cutting the magnesium ingot into strips of 10mm×10mm;

[0103] 2) Cut the magnesium-zirconium master alloy into 12 small alloy parts on average, inspect and record the content of Zr in each part;

[0104] 3) Cut the master alloy of magnesium and neodymium into 12 small alloy parts on average, inspect and record the content of Nd in each part;

[0105] 4) remelting and casting the zinc ingot into thin slices of 15mm×15mm×2mm;

[0106] 5) Cut the small material of magnesium-zirconium master alloy into strips of 10mm×10mm with a pneumatic pick;

[0107] 6) breaking each part of the magnesium-neodymium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com