Automatic detection device for static stiffness of elastic backing plate under sleeper

An automatic detection device and the technology of the elastic backing plate, applied in the direction of applying stable tension/pressure to test the strength of the material, can solve the problem that it is difficult to accurately reflect the compression of the elastic backing plate under the pillow, and achieve automatic calculation and storage of the detection results. The effect of convenient operation and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

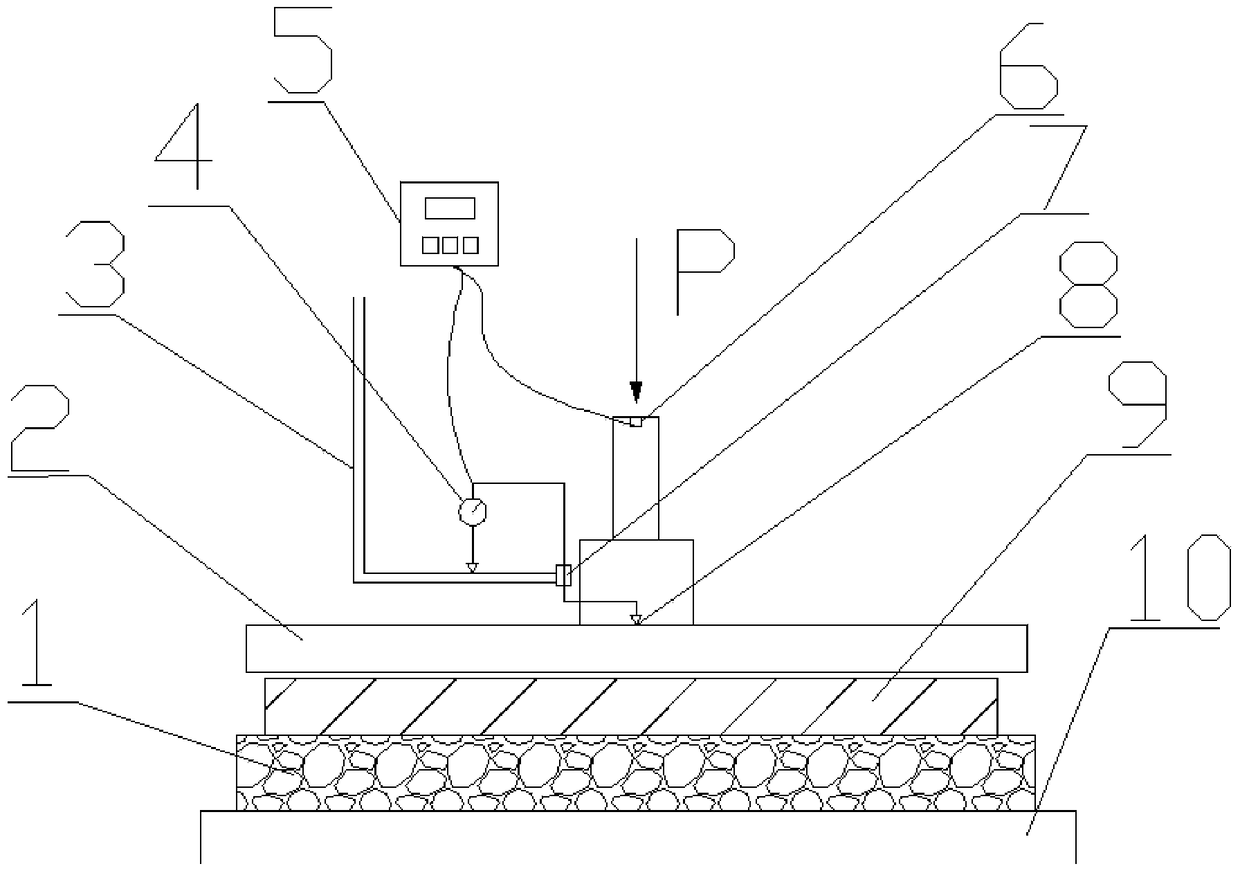

[0034] Such as figure 1 As shown, its working principle is:

[0035] When using the automatic detection method and device for the static stiffness of the elastic backing plate under the sleeper to detect the elastic backing plate under the sleeper, the tested sample 9 is placed above the ballast backing plate 1, and the loaded steel plate 2 is used to pressurize the tested sample 9 , measure the compression amount of the sample 9 through the compression amount acquisition device. When the loaded steel plate 2 pressurizes the sample 9, the sample 9 is deformed, and the data acquisition and processing device 5 measures the compression amount of the sample 8 under the load of 20kpa and 80kpa through the displacement sensor 4, and automatically calculates the amount of compression of the sample 8 under the sleeper. Static stiffness of elastic backing plate sample 8.

[0036] The load applied by the loading device can be controlled by the data acquisition and processing device 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com