Metal circular workpiece detection device and using method thereof

A detection device and a technology for circular workpieces, which are used in measurement devices, instruments, sorting, etc., can solve the problems of high detection cost, low detection efficiency, and large equipment occupation area, and achieve accurate and objective data, reasonable and ingenious design, and detection. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

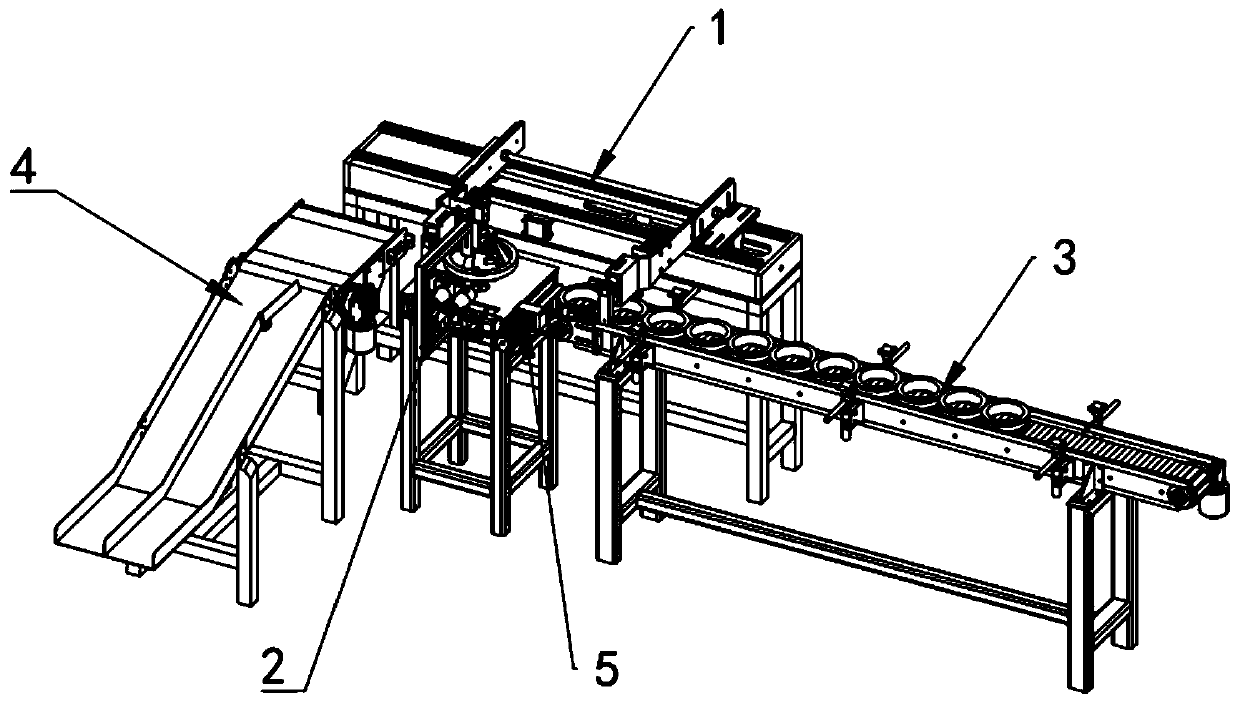

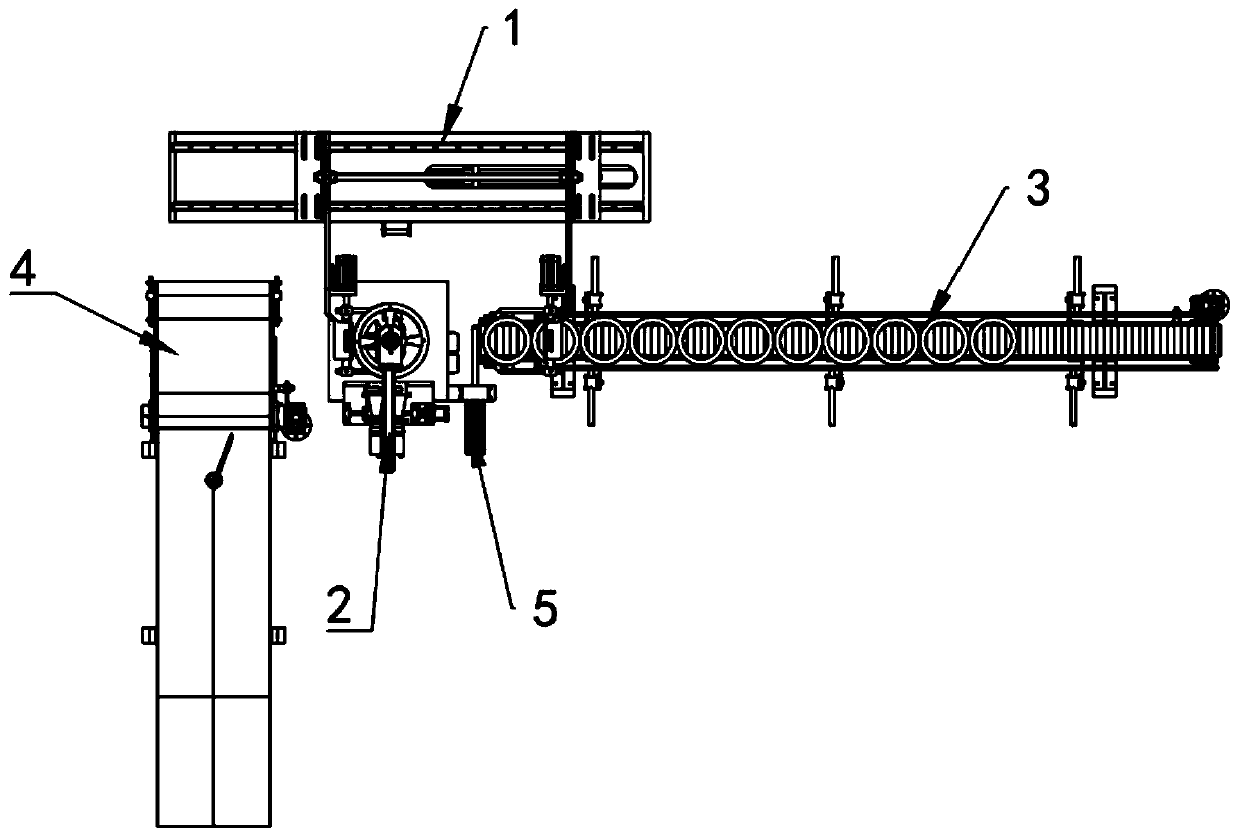

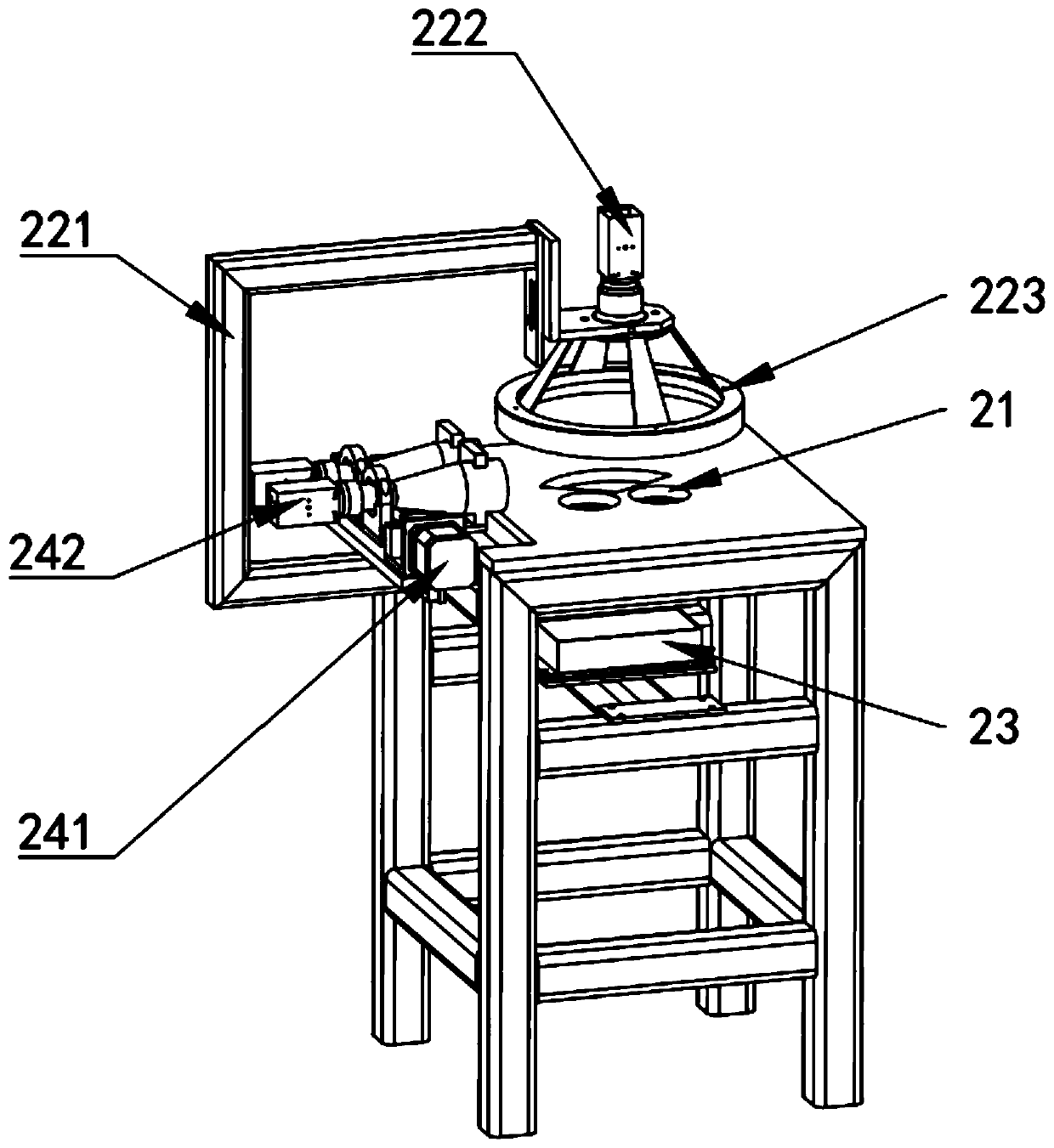

[0030] Example: see Figure 1 to Figure 7 , a metal circular workpiece detection device provided in this embodiment, which includes a detection device 2 and a grasping device 1 arranged beside the detection device 2, the detection device 2 includes a workpiece fixing seat 21, which is respectively arranged on the The roundness detection mechanism above and below the workpiece fixing seat 21, the CCD detector 23 and the flaw detection device arranged on one side of the workpiece fixing seat 21, the grasping device 1 includes The driving device and the feeding gripper mechanism 11 and the unloading gripper mechanism 12 respectively movably arranged on the driving device, the loading gripper mechanism 11 and the unloading gripper mechanism 12 are fixed corresponding to the workpiece Seat 21 is provided.

[0031] see Figure 4 to Figure 5The feeding gripper mechanism 11 includes a gripper mount 111 movably arranged on the driving device, a second cylinder 117 laterally disposed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com