Gas extraction method using phase change material to assist liquid nitrogen to crack and extraction system

A phase change material and gas extraction technology, applied in gas discharge, mining equipment, mining fluid, etc., can solve the problems of hindering gas extraction, slow melting of coal seam ice, etc., to achieve smooth and efficient discharge, smooth efficiency, and ingenious and reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

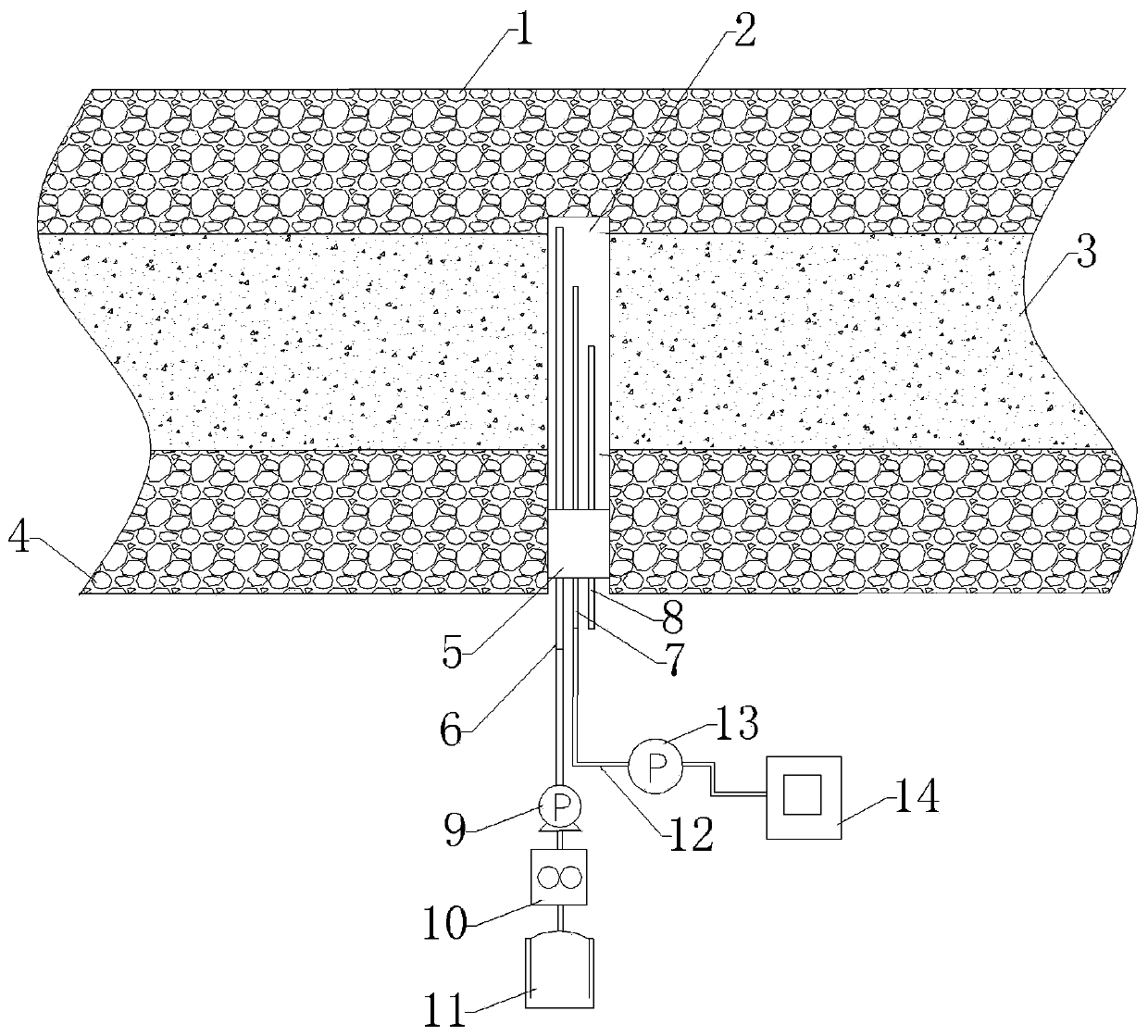

[0028] Such as figure 1 A gas extraction method using phase change materials to assist liquid nitrogen fracturing is shown, which is characterized in that it includes the following steps:

[0029] 1) drilling a drainage hole 2 in the coal seam 3;

[0030] 2) To establish a drainage system, first extend the steel pipe 6 for inputting the phase change material into the extraction hole 2, then extend the liquid nitrogen pipe 7 for inputting liquid nitrogen into the extraction hole 2, and then insert the The gas drainage pipe 8 extends into the interior of the drainage hole 2; after the steel pipe 6, the liquid nitrogen pipe 7 and the gas drainage pipe 8 are connected, the drainage hole 2 is finally sealed with a hole sealer 5;

[0031] 3) Coal seam fracturing Turn on the liquid nitrogen pump 13, inject liquid nitrogen into the extraction hole 2, and use the low-temperature liquid nitrogen to freeze the coal seam 3 and cause fracturing;

[0032] 4) To heat the coal seam, turn on...

Embodiment 2

[0044] A drainage system for gas extraction from coal seams assisted by liquid nitrogen fracturing with phase change materials, comprising a drainage hole 2 arranged on a coal seam 3, a hole sealing device 5 is arranged in the drainage hole 2, and a steel pipe is additionally arranged 6. The liquid nitrogen pipe 7 and the gas extraction pipe 8 pass through the hole sealer 5 and extend into the extraction hole 2. The outer end of the steel pipe 6 is connected to the storage bin 11, and the outer end of the liquid nitrogen pipe 7 is connected to the Liquid nitrogen tank14.

[0045] In the specific implementation process, after the steel pipe 6, the liquid nitrogen pipe 7 and the gas extraction pipe 8 are inserted into the extraction hole 2 in advance, a hole sealing device 5 is installed outside the extraction hole 2 to seal the hole. Simultaneously, the inner ends of the steel pipe 6, the liquid nitrogen pipe 7 and the gas extraction pipe 8 are arranged in the extraction hole 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com