Drive assembly of pulsator washing machine

A drive assembly and washing machine technology, applied to other washing machines, washing devices, textiles and paper making, etc., can solve the problems of inconvenient processing, high suction noise, high manufacturing cost, etc., and achieve light overall weight, lower sound, and lower energy consumption consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

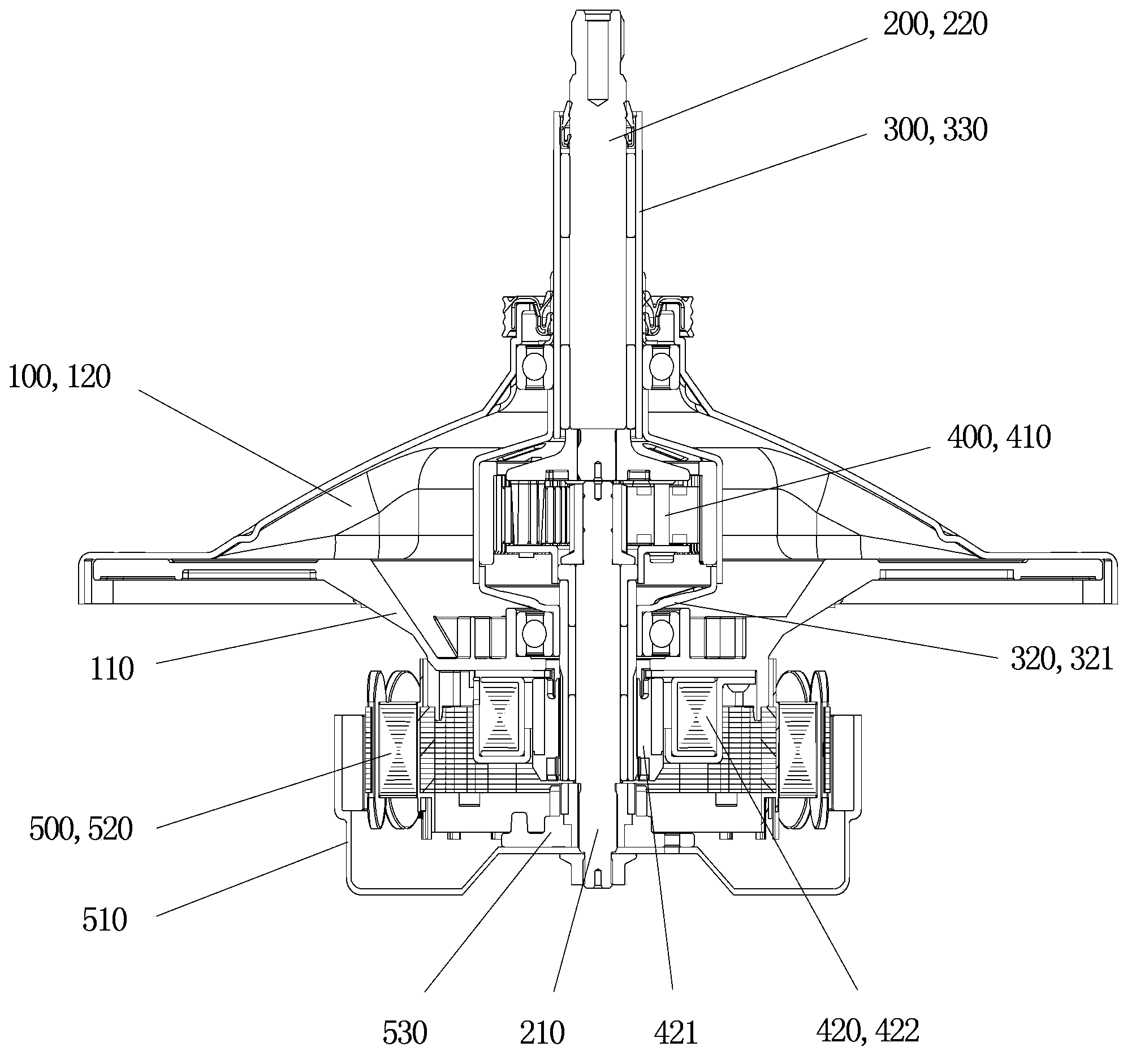

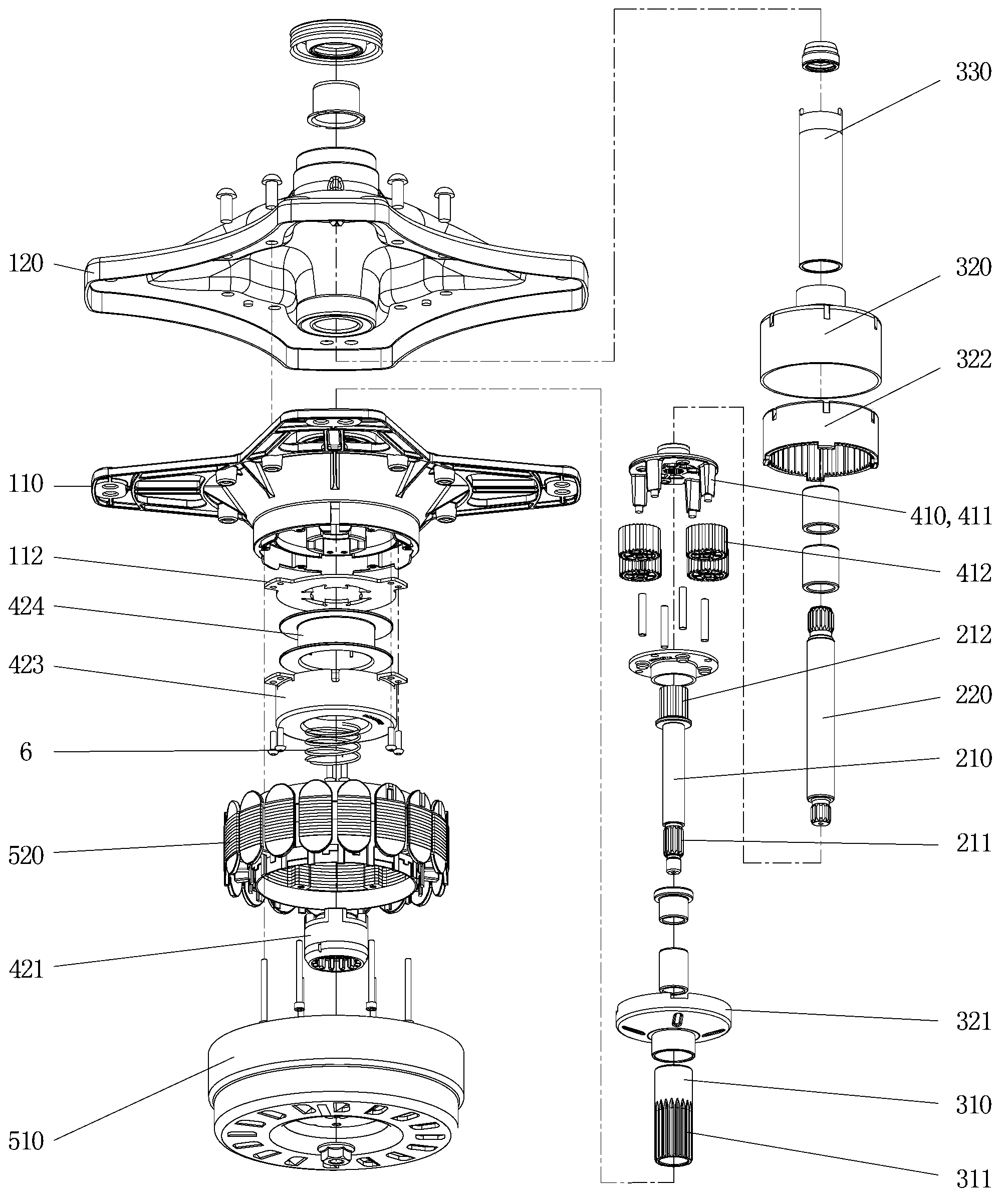

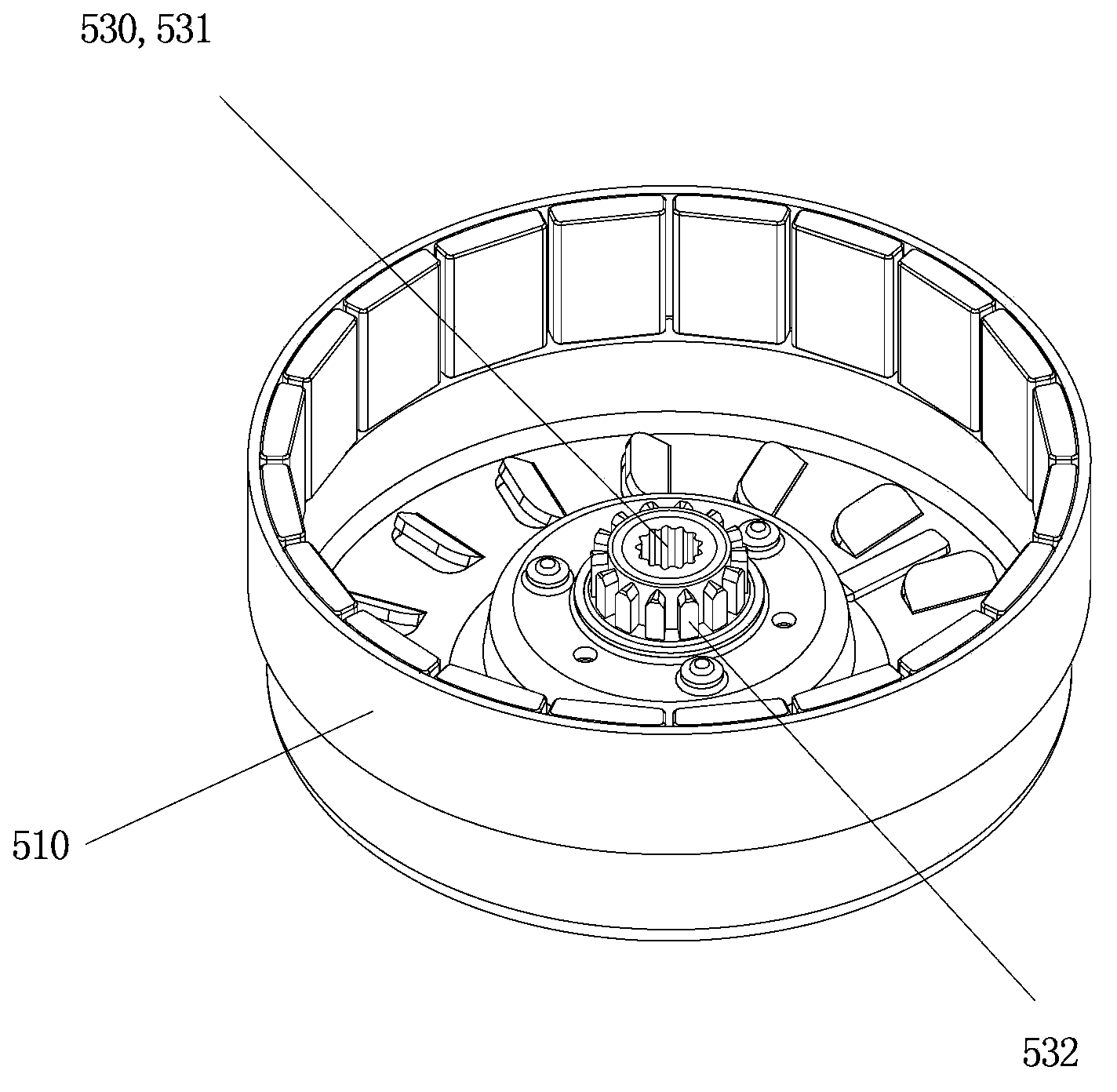

[0037] See Figure 1 to Figure 6 , the present invention has an installation tray 100, on which a main shaft 200 and a shaft sleeve 300 sleeved on the main shaft 200 are rotated, and a deceleration electromagnetic clutch mechanism 400 is provided between the main shaft 200 and the shaft sleeve 300, and a drive is provided at the bottom of the main shaft 200. Mechanism 500; the deceleration electromagnetic clutch mechanism 400 is an electromagnetic clutch planetary gear deceleration electromagnetic clutch mechanism, with a planetary gear assembly 410 and an electromagnetic clutch assembly 420, and the drive mechanism 500 is an outer rotor direct drive motor with a rotor 510 and a stator 520, The stator 520 is fixedly connected to the installation tray 100, and the rotor 510 is fixedly connected to the main shaft 200; the installation tray 100 has a stator installation plate 110 and an upper cover 120, and the stator installation plate 110 is fixedly connected to the stator 520 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com