Stiffened joint-crossing plate based bridge deck jointless expansion device and construction method thereof

A technology of telescopic device and seam-spanning plate, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of increased impact of heavy vehicles, application limitations, and service life impact, etc. It is easy to guarantee the processing accuracy and low construction cost , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

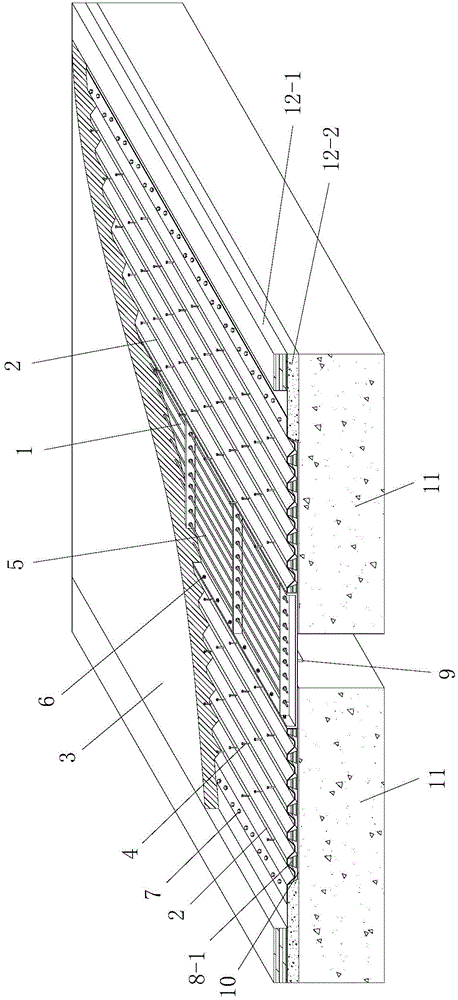

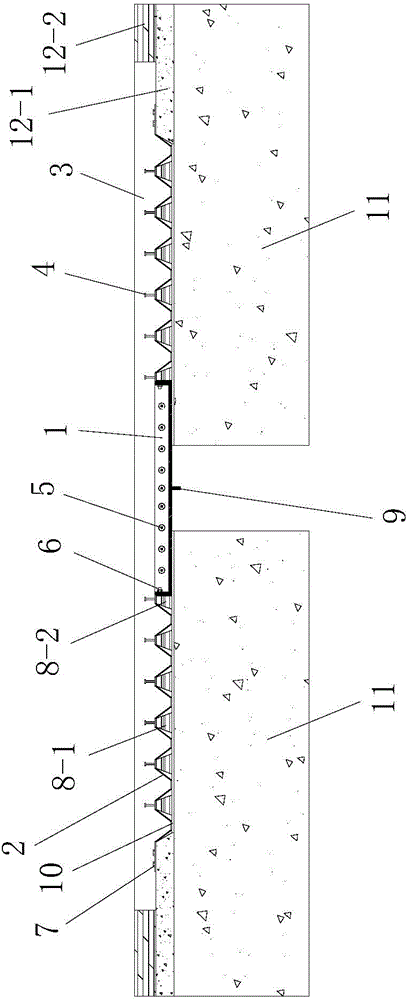

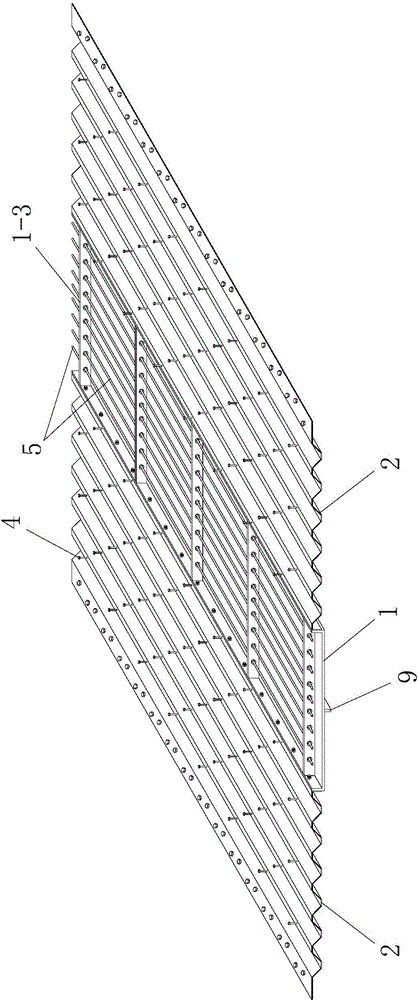

[0074] Such as figure 1 , figure 2 The shown bridge deck seamless expansion device based on stiffening type span slabs includes a prefabricated expansion assembly and an expansion joint filling layer 3 filled above the prefabricated expansion assembly. The prefabricated expansion assembly is laid on the On the expansion joints left between the front and rear adjacent beam sections 11 of the bridge main girder; Sections 11 are laid out from front to back along the longitudinal bridge direction, and bridge deck pavement structures are laid on each beam section 11; A reserved installation slot is formed for the installation of the prefabricated telescopic assembly, the longitudinal length of the reserved installation slot is greater than the distance between the two adjacent beam sections 11, and the beam section 11 is located in the The section below the reserved installation groove is the exposed section of the main beam, and the sliding layer 10 is laid on the exposed secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com