Sleeper Longitudinal and Transverse Resistance Dynamic Tester and Test Method

A technology for lateral resistance and sleepers, which is applied to the dynamic detection instrument and detection of lateral resistance, and the longitudinal field of sleepers. It can solve the problems of disturbance of the ballast bed and slow detection speed, etc., and achieve the effects of reducing labor intensity, light and handy instruments, and accurate and objective data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

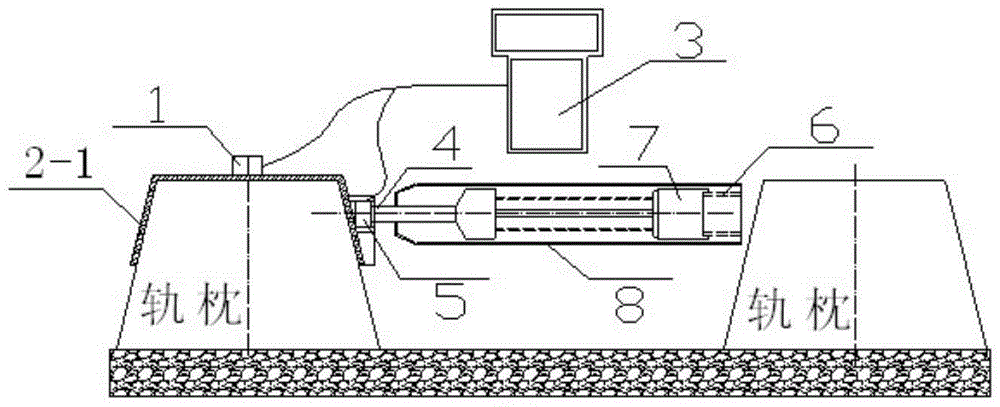

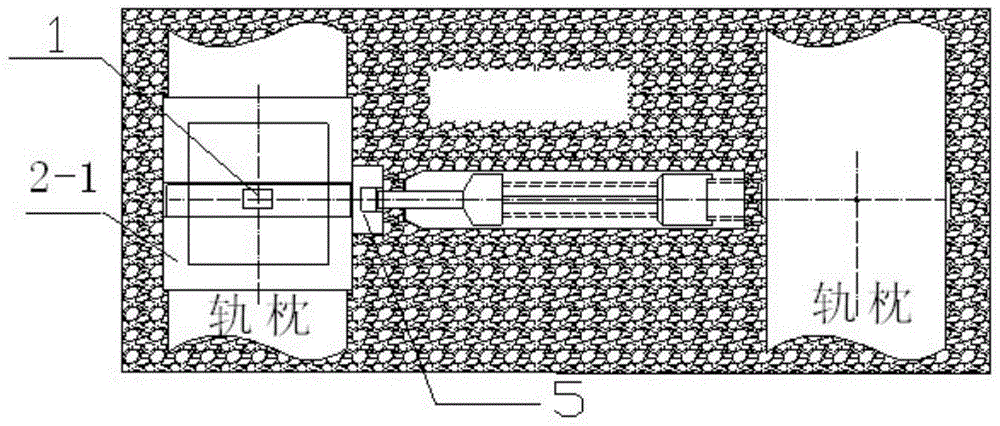

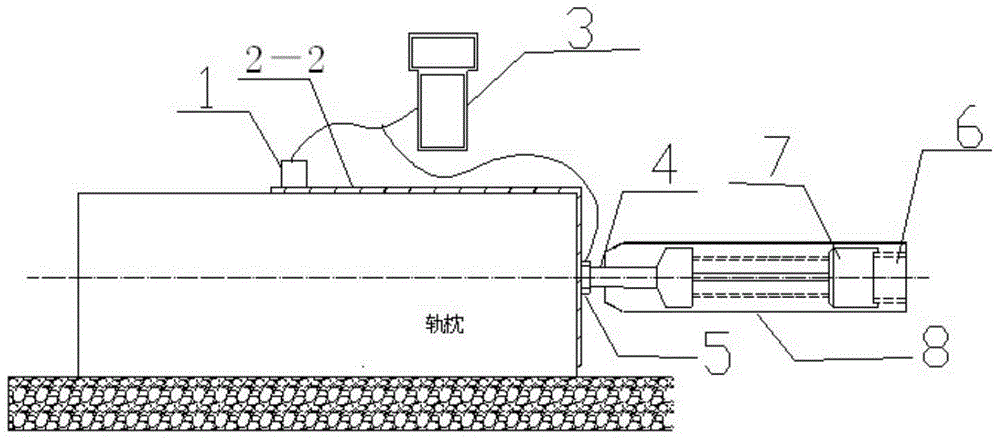

[0043] Such as Figure 1a , Figure 1b , figure 2 As shown, before the test, place the longitudinal and transverse bearing devices 2-1 and 2-2 of the sleeper on the upper or side of the sleeper, place the acceleration or displacement sensor 1 on the upper part of the bearing device, and place the force sensor 5 on the side of the bearing device to fix , the tester host 3 is connected to the acceleration or displacement sensor 1 and the force sensor 5 respectively. During the test, the loading device 8 is held in hand, and a dynamic load is applied horizontally to the position of the force sensor, and the force sensor transmits the force to the sleeper through the bearing device, so that the sleeper is displaced. The dynamic load value and the resulting displacement change are measured by the force sensor 5 and the acceleration or displacement sensor 1 respectively, and the measured signal is transmitted to the tester host 3 through the cable, and the tester host 3 automatica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com