Refill tail oil length automatic detection method and system

An automatic detection and refill technology, applied in measuring devices, optical testing flaws/defects, instruments, etc., can solve the problems of inaccurate detection, low work efficiency, low efficiency, etc., achieve accurate and objective data, reduce labor intensity, improve The effect of detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

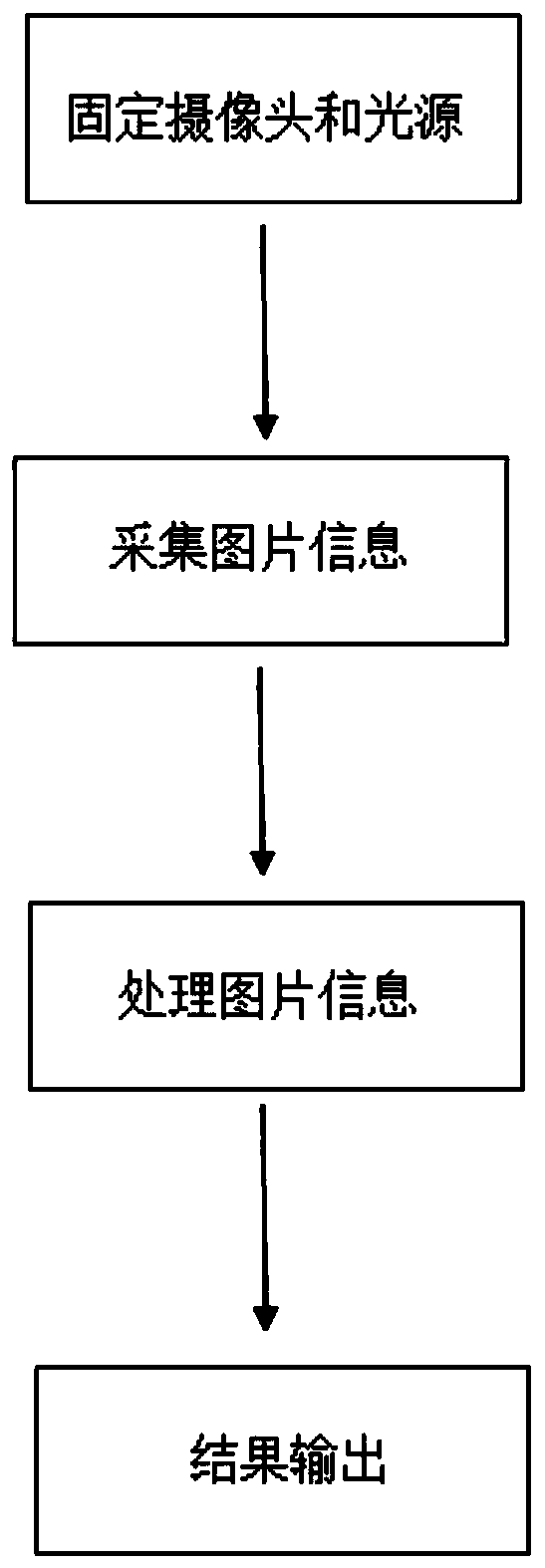

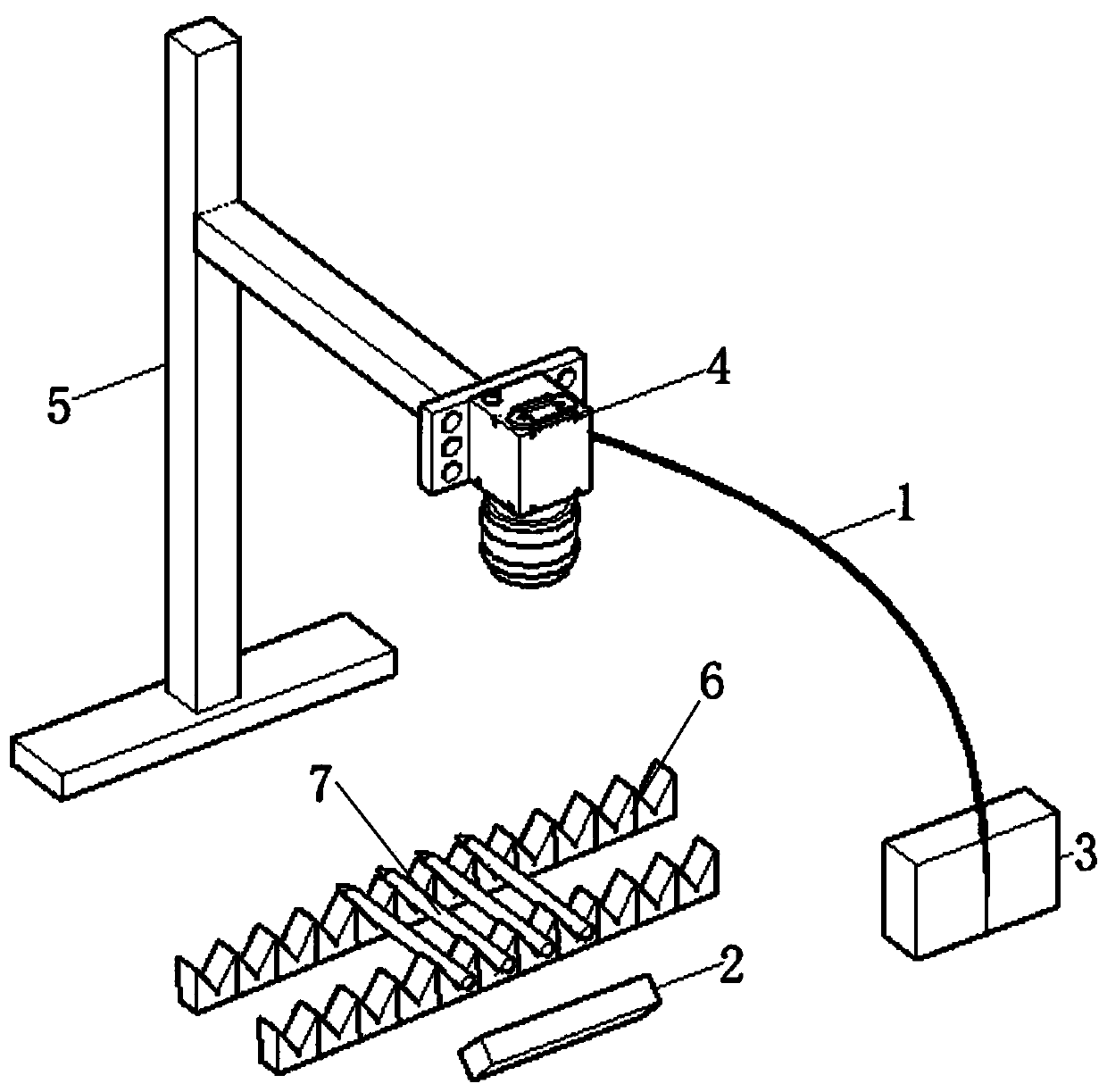

[0022] Attached below Figure 1-3 The specific embodiments further illustrate the method for automatically detecting the length of the refill tail oil of the present invention.

[0023] Such as figure 2 As shown, the detection device involved in this method includes a data transmission line 1, a light source 2, an industrial computer 3, an image acquisition device 4, a bracket 5, and a pen core transmission device 6 for transmitting the pen core 7 to be detected.

[0024] The above-mentioned pen core transmission device (conveyor belt) 6 is signally connected to the image acquisition device 4, and the pen core transmission device 6 generates a transmission trigger signal at the same time to start the shooting action of the image acquisition device 4 to speed up the shooting efficiency.

[0025] The image acquisition device 4 is set as a grayscale image acquisition device, including a CCD camera and a lens. The image acquisition device 4 is provided with a lens with a focal length of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com