Automatic testing and early-warning device for track plate displacement

A technology of automatic test and early warning device, applied in the direction of track, track maintenance, road, etc., can solve the problem of time-consuming and laborious reading, floating or offset of the track board, inability to observe the floating and offset of the track board, etc. Easy to operate, accurate and objective data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

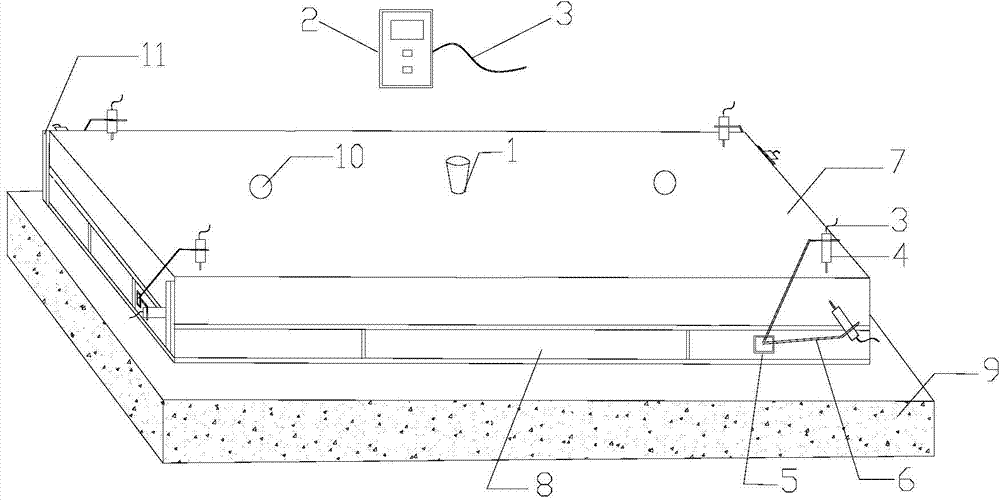

[0032] Such as figure 1 As shown, before pouring, 4 magnetic table bases are placed around the support layer template under the track plate, and each magnetic table base includes 2 universal support arms. Place 8 displacement sensors on the universal support arm respectively, so that 4 are perpendicular to the top surface of the track plate, and 4 are perpendicular to the side of the track plate. Each displacement sensor contact is in contact with the track plate, and the sensor contact is adjusted to keep it in the middle of the sensor range (positive and negative displacements can be detected at this time). Each displacement sensor is connected with the tester host through wires. In the host program of the tester, clear the indications of all displacement sensors to zero.

[0033] During perfusion, as the perfusion volume increases, the track plate rises and shifts, and the main unit of the tester can display it in real time. When the track board floats or the offset is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com