Ballastless track slab downward filling layer strength detection device

A ballastless track, strength testing technology, applied in the direction of applying stable tension/pressure to test material strength, etc., can solve the problem that it is difficult to accurately reflect the strength and deviation of the filling layer under the ballastless track slab on site, and it is difficult to accurately and objectively inspect the ballastless track The strength of the filling layer under the slab and other problems can be solved, and the detection speed is fast, the instrument is light and handy, and the effect of improving the construction quality is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

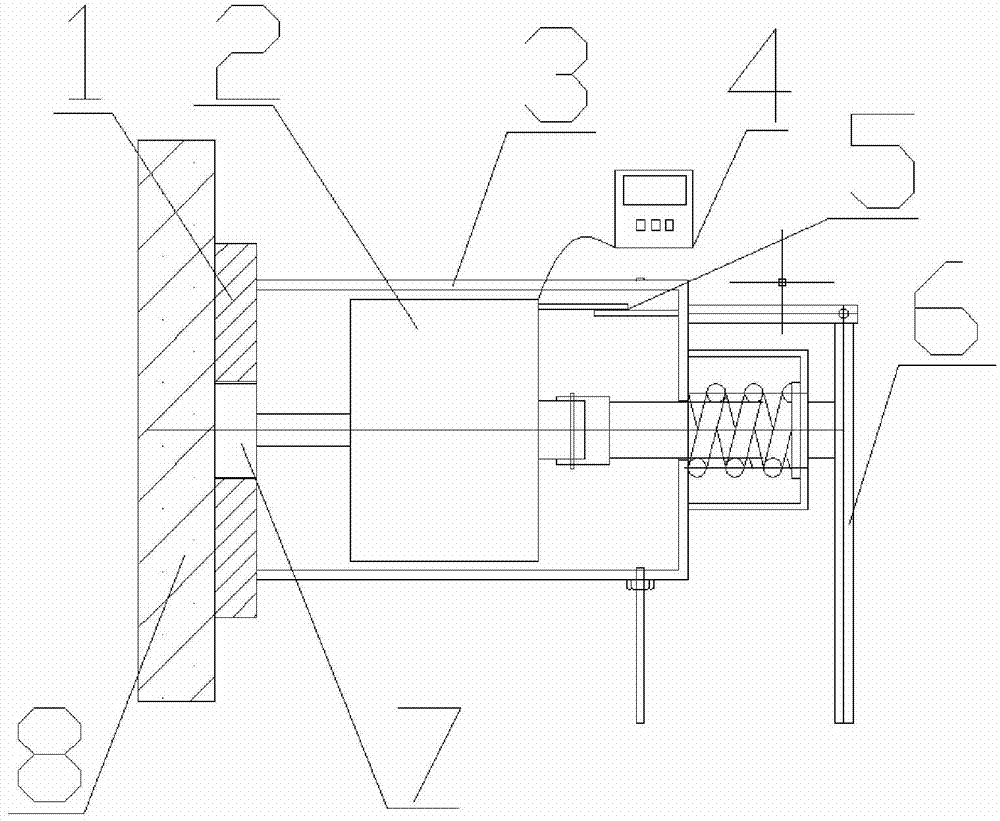

[0023] like figure 1 As shown, when the filling material is poured, the strength detection device for the filling layer under the ballastless track slab is installed on the side of the formwork through the sensor base, and a certain pressure is applied to the filling material through the pressure device, and measured by the pressure sensor and the displacement sensor. The compressive strength of the filling material under certain deformation conditions is automatically calculated and displayed by the host of the tester.

[0024] After the test, the host of the tester can print the stored test data on site.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com