Blade polishing-grinding machining method based on neural network

A neural network and neural network model technology, applied in the field of blade polishing and grinding based on neural network, can solve problems such as affecting the accuracy of data and difficult to ensure the processing quality, so as to improve the recognition ability and accuracy, improve the accuracy, The effect of objective and accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

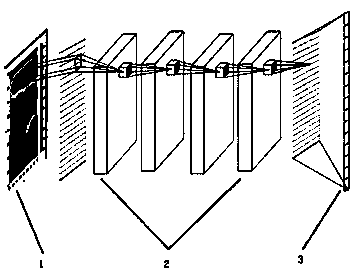

[0029] The technical solution will be further described below in conjunction with specific implementation methods and accompanying drawings.

[0030] A method for blade polishing and grinding based on a neural network, comprising: obtaining blade machining allowance information; using historical data to train a neural network model; determining processing parameters through a neural network model according to the machining allowance, and performing online processing; The parameters are uploaded to the database and the neural network model is updated.

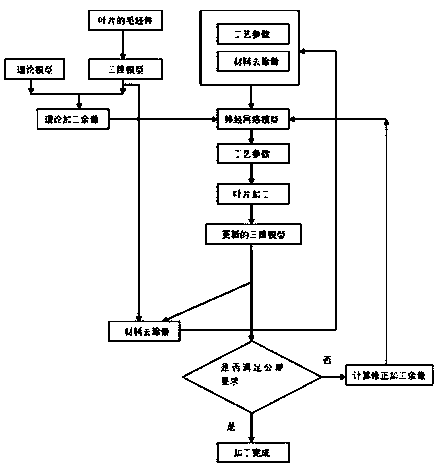

[0031] see figure 1 , including the following steps:

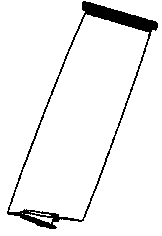

[0032] Step 1: Reconstruct the blade through reverse technology to obtain a 3D model (such as figure 2 As shown), by comparing the three-dimensional model with the feature points on the theoretical model of the blade, adjusting and making the coordinate systems of the two models coincide, so as to calculate the theoretical machining allowance of the blade.

[0033] The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com