Diffusion tube type rectangular flow meter

A rectangular flowmeter and tube-type technology, applied in the field of flowmeters, can solve the problems of low long-term work stability and reliability, small range ratio, large permanent pressure loss, etc., and achieve long-term work stability and high reliability. Improved service life and reduced flow fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

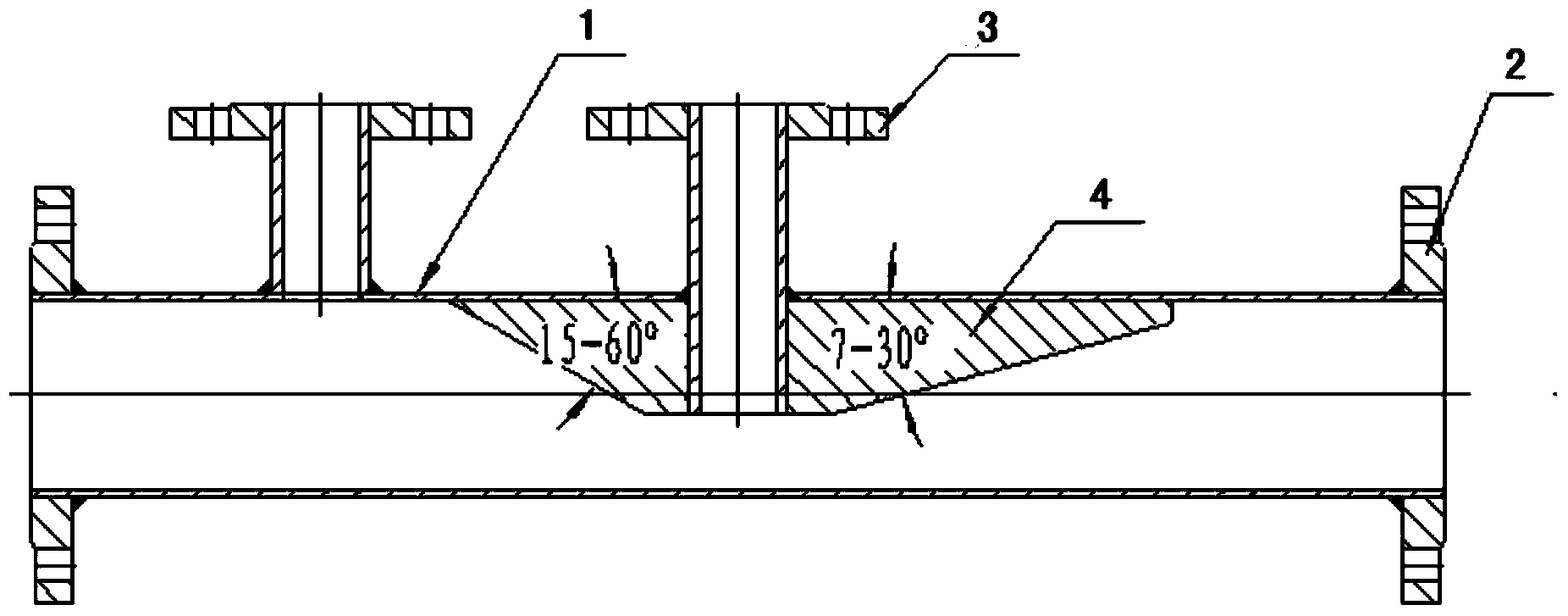

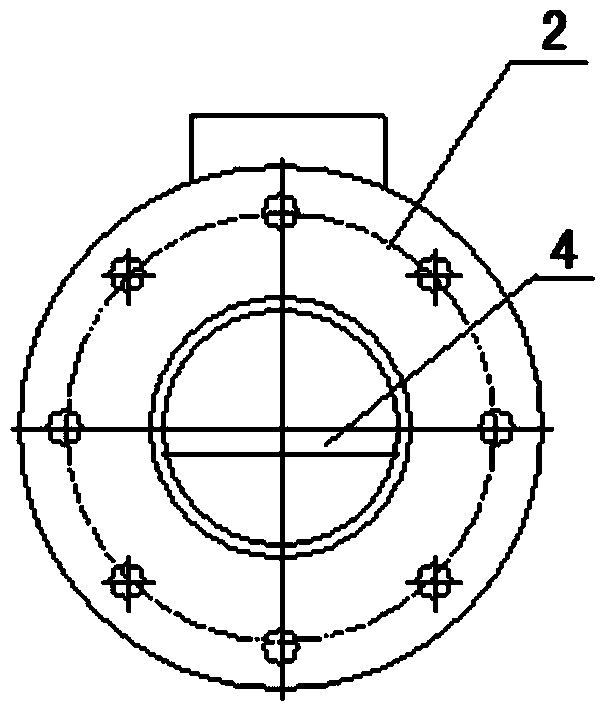

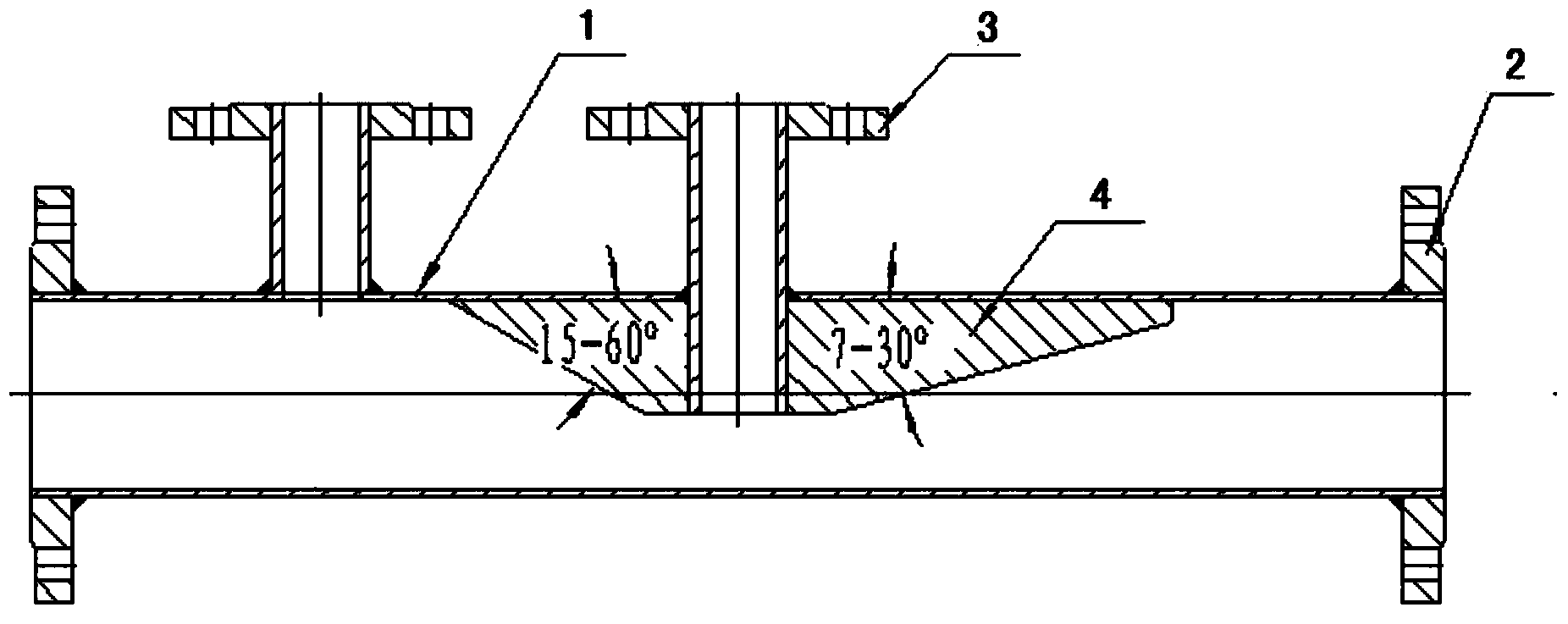

[0019] A diffuser tube type rectangular flowmeter, including a measuring tube 1 and a body flange 2 welded at both ends of the measuring tube 1, a pair of pressure-taking flanges 3 are welded in the axial direction of the measuring tube 1, such as figure 1 and 3 As shown: a trapezoidal throttling piece 4 is arranged in the measuring tube 1 under the pressure taking flange 3 .

[0020] The cross-sectional shape of the trapezoidal throttling member 4 is circular, and the front projection is an inverted trapezoid with a large upper part and a smaller lower part. The two acute angles of the trapezoidal shape are 15-60° and 7-30° respectively. hole.

[0021] Such as figure 2 and 4 Shown: the cross section of the measuring tube 1 is circular or square.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com