Patents

Literature

64results about How to "Shorten the cantilever length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

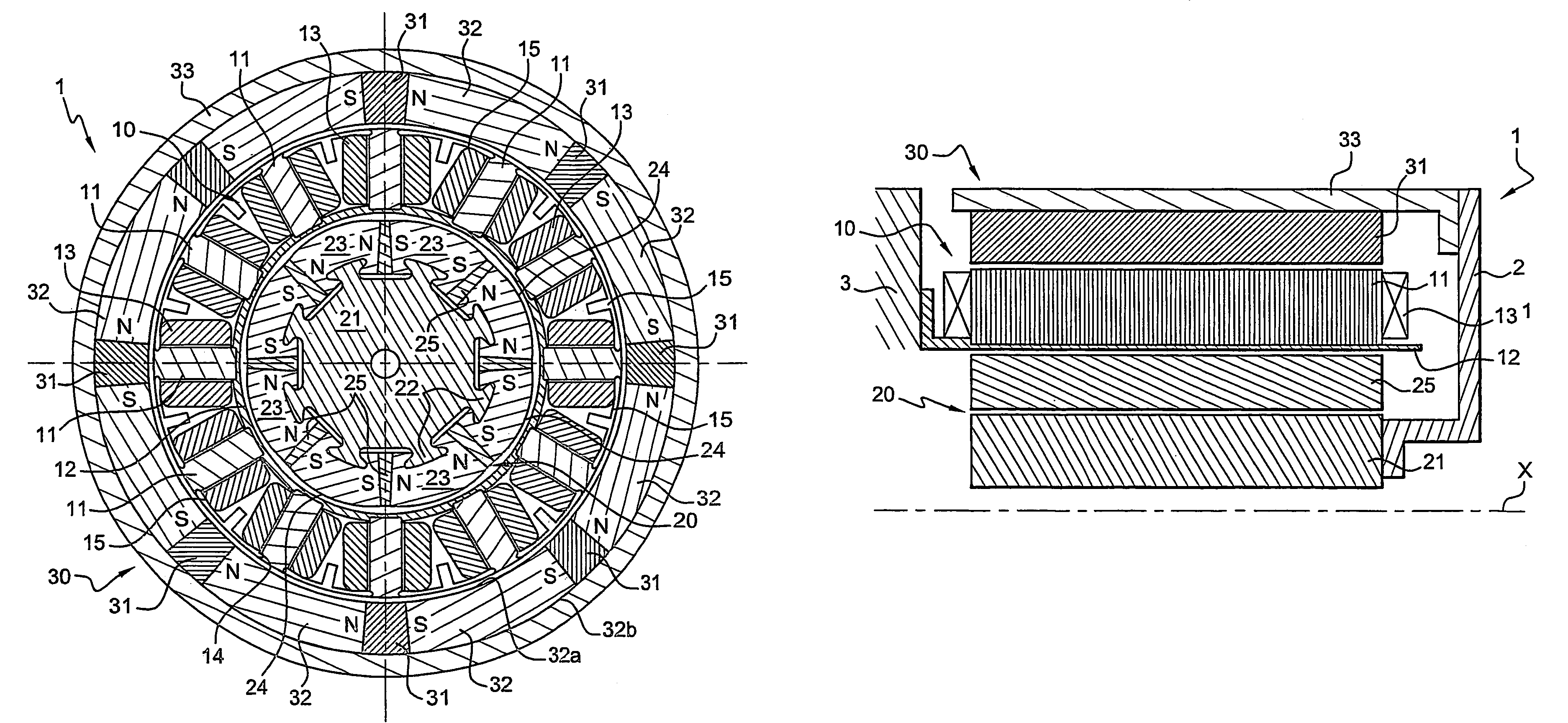

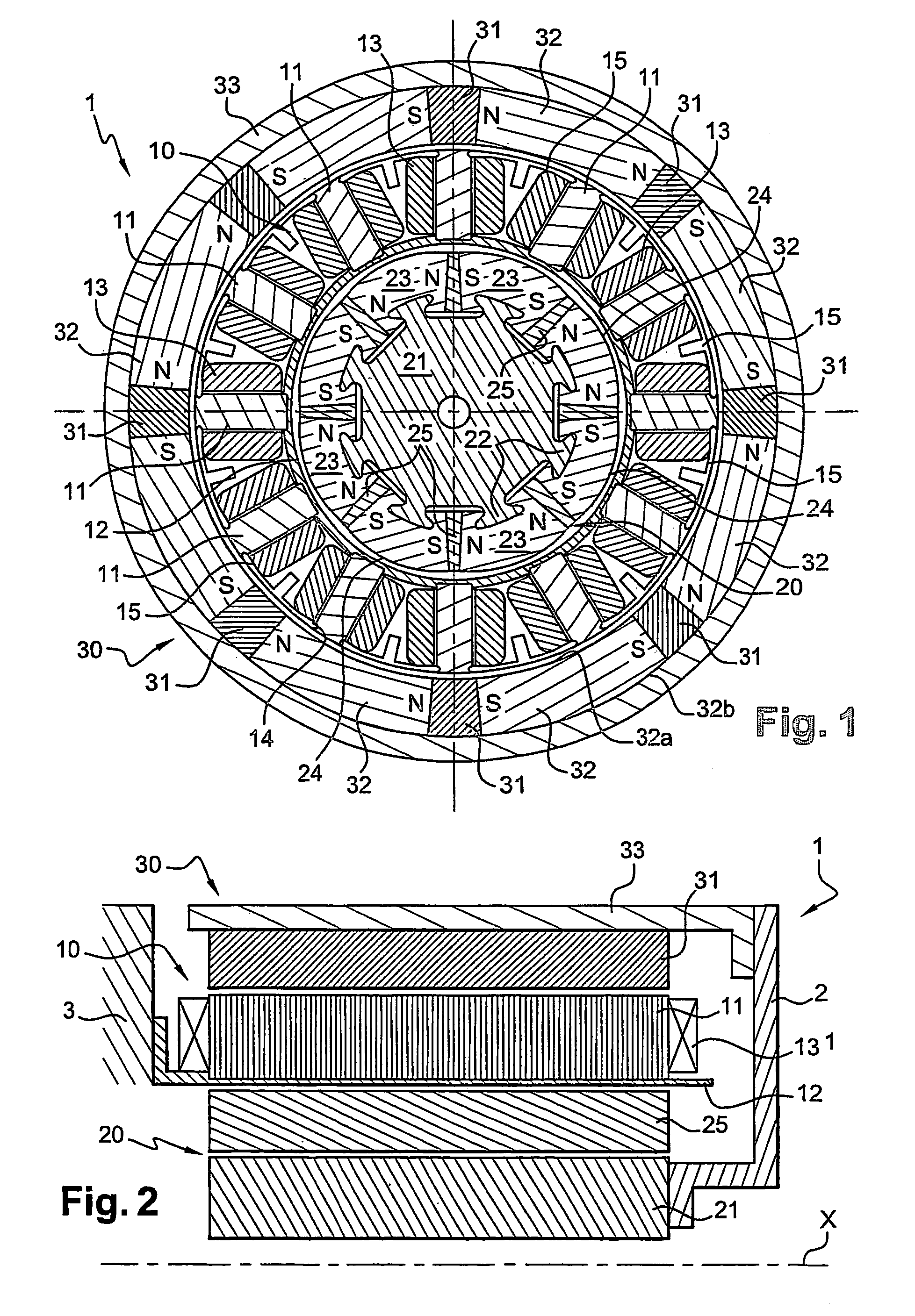

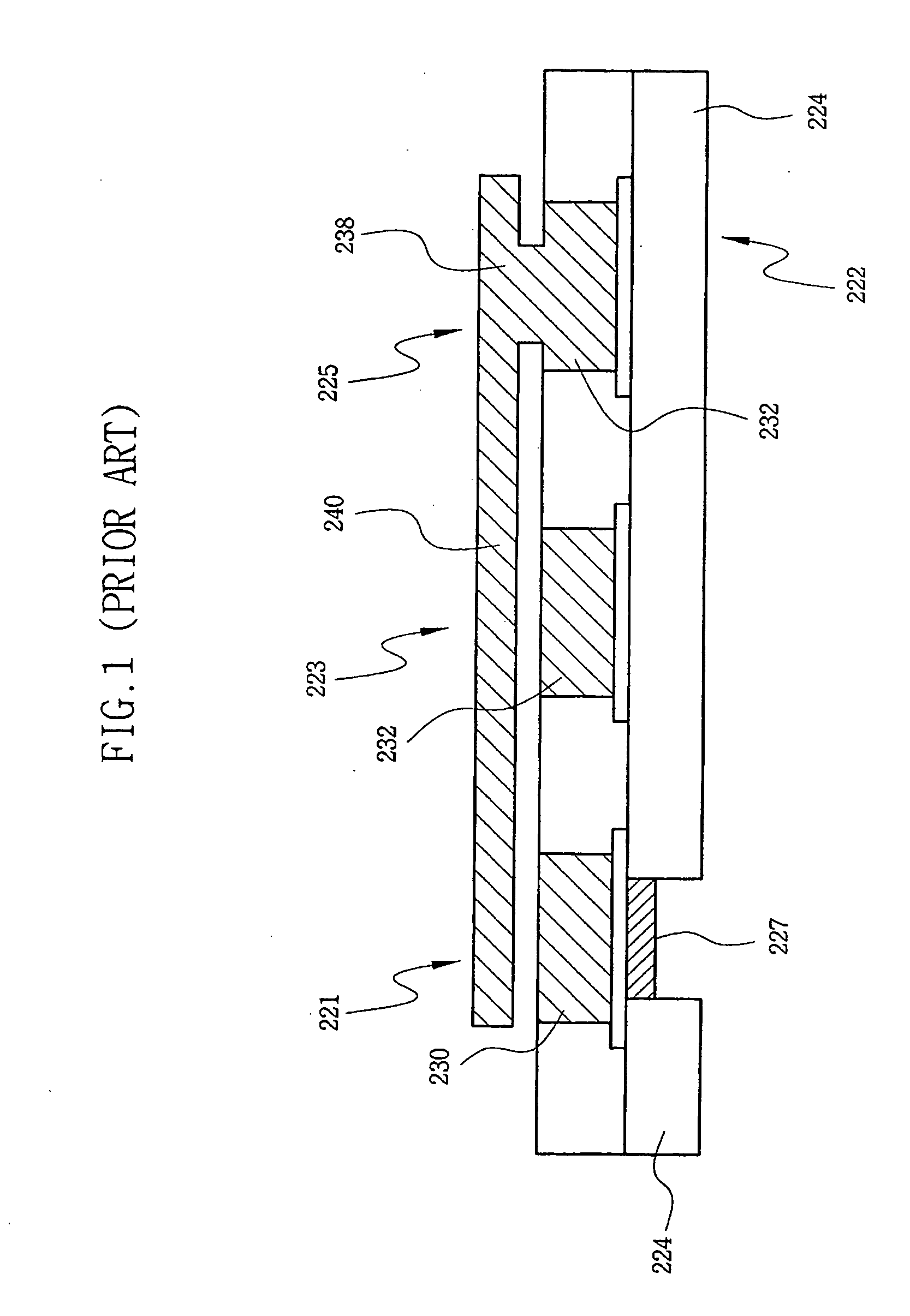

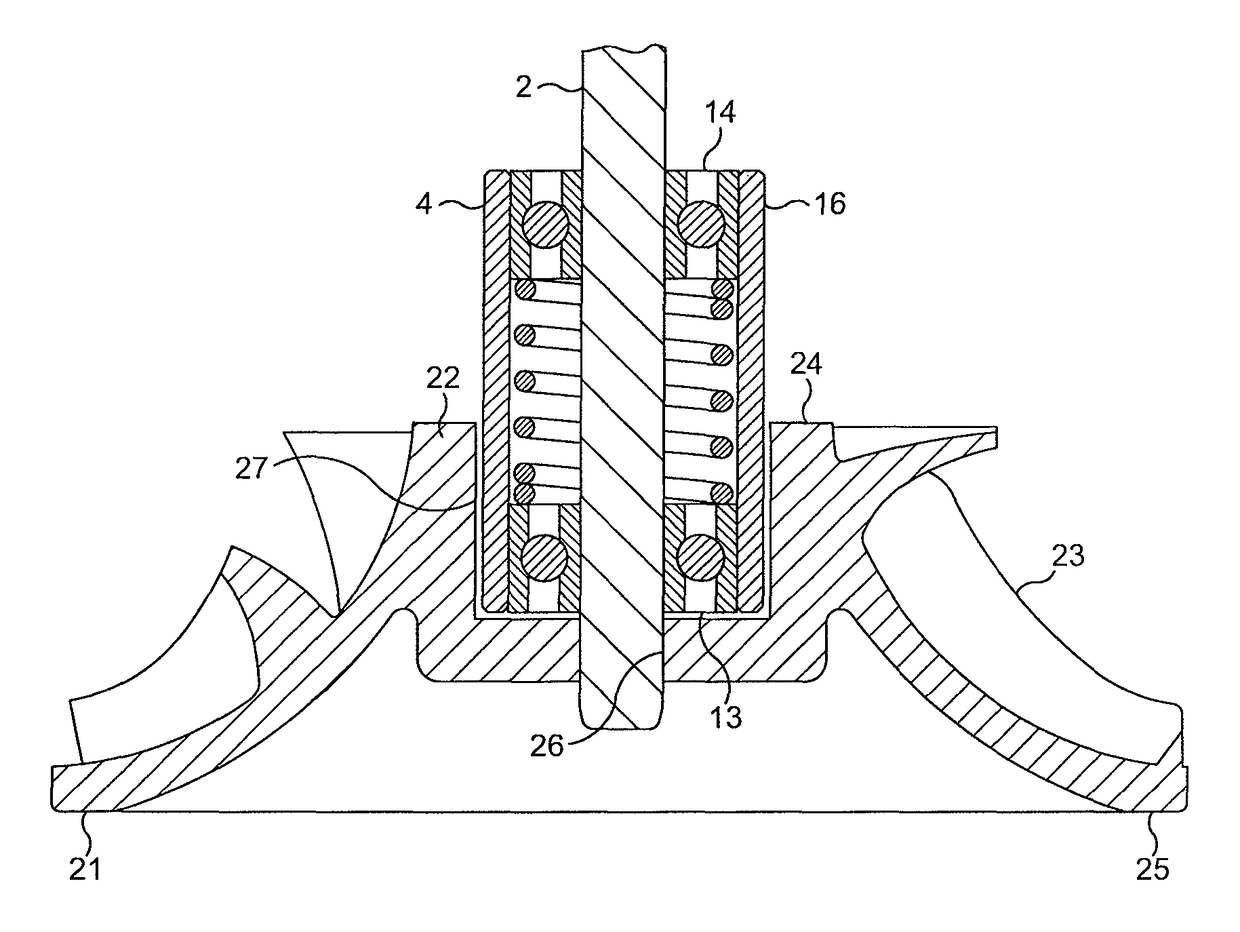

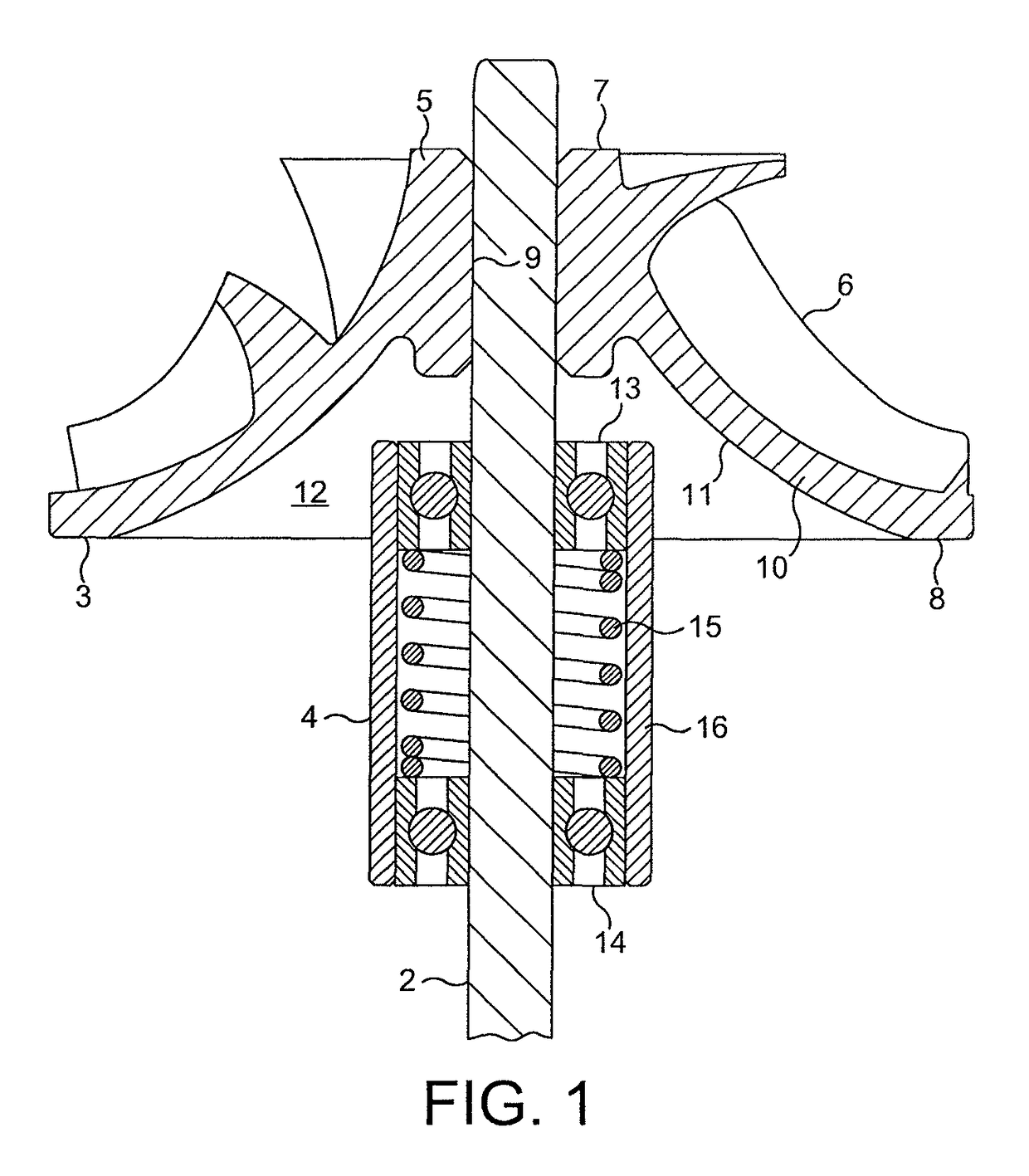

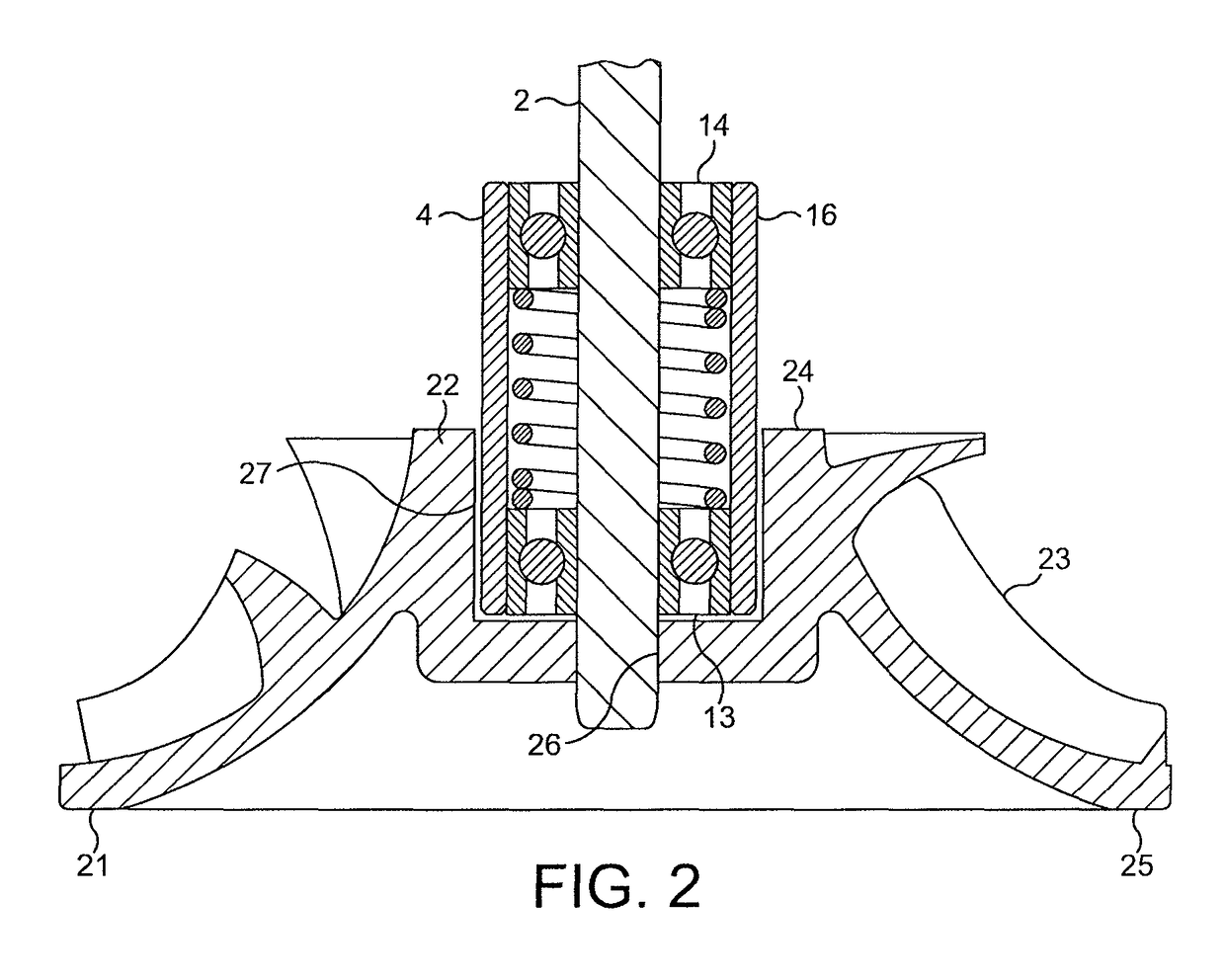

Rotary electric machine comprising a stator and two rotors

InactiveUS7250702B2Shorten the cantilever lengthDuplicate structureMagnetic circuit rotating partsElectric machinesElectric machineFlux concentration

The invention relates to an electric machine comprising a stator (10, 40) provided with a plurality of teeth (11, 41), each tooth supporting at lest one individual coil (13, 46, 47), an external rotor (30) which is radially arranged outside the stator and provided with constant magnets, an internal rotor (20) radially arranged inside the stator, provided with constant magnets and connected to the external rotor (30). At least one of the external (30) and internal (20) rotors is disposed in a flux concentration.

Owner:MOTEURS LEROY SOMER

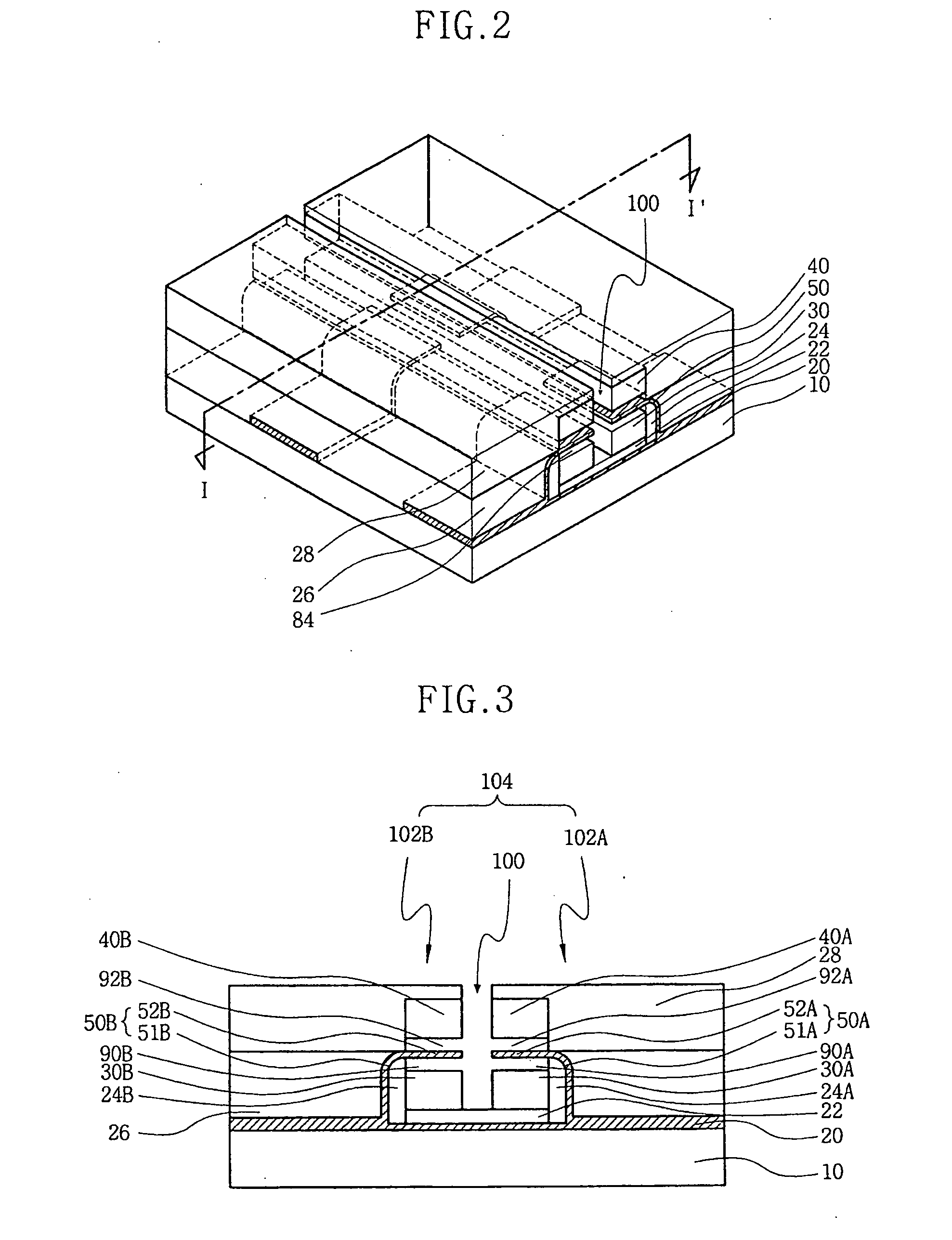

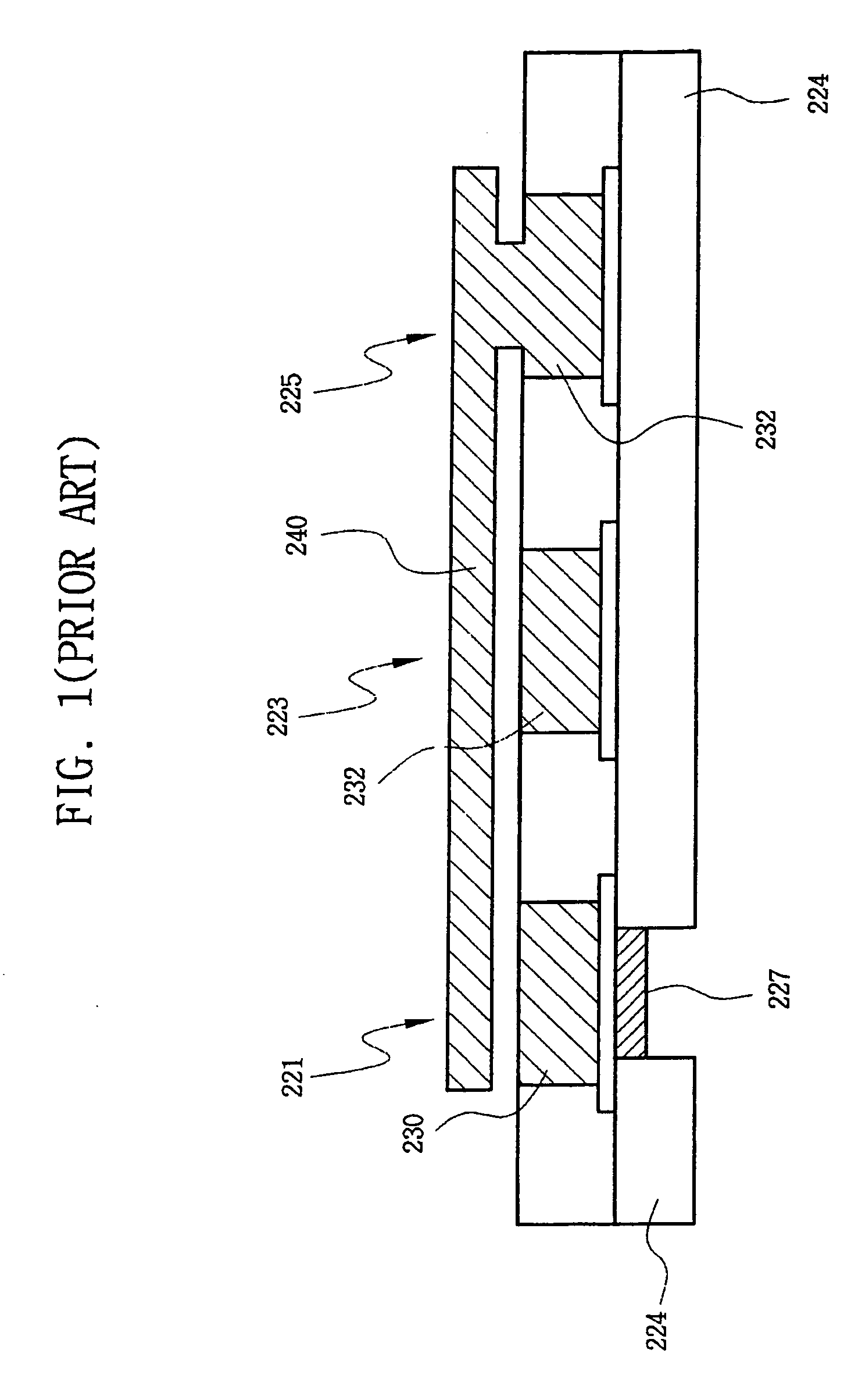

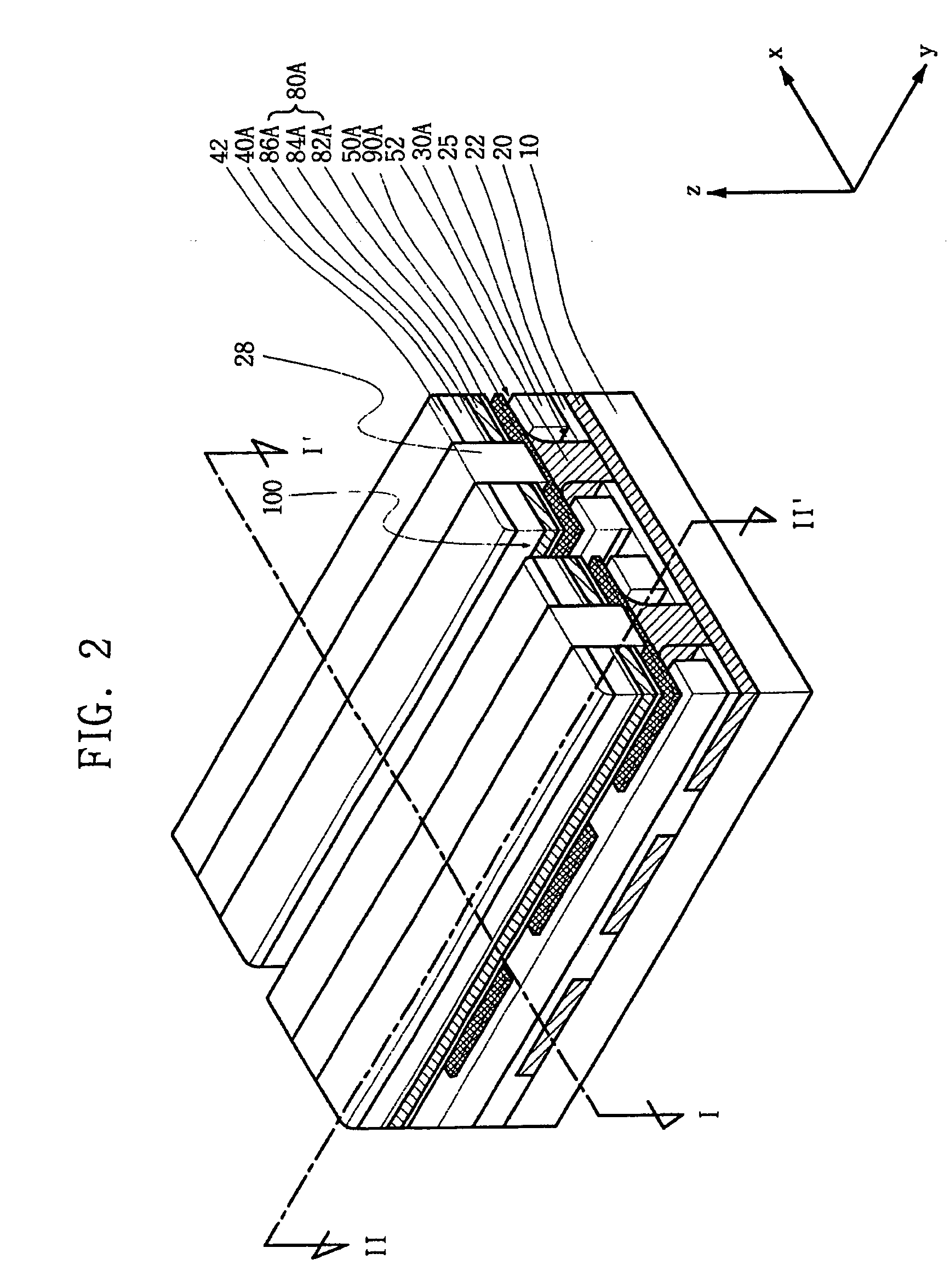

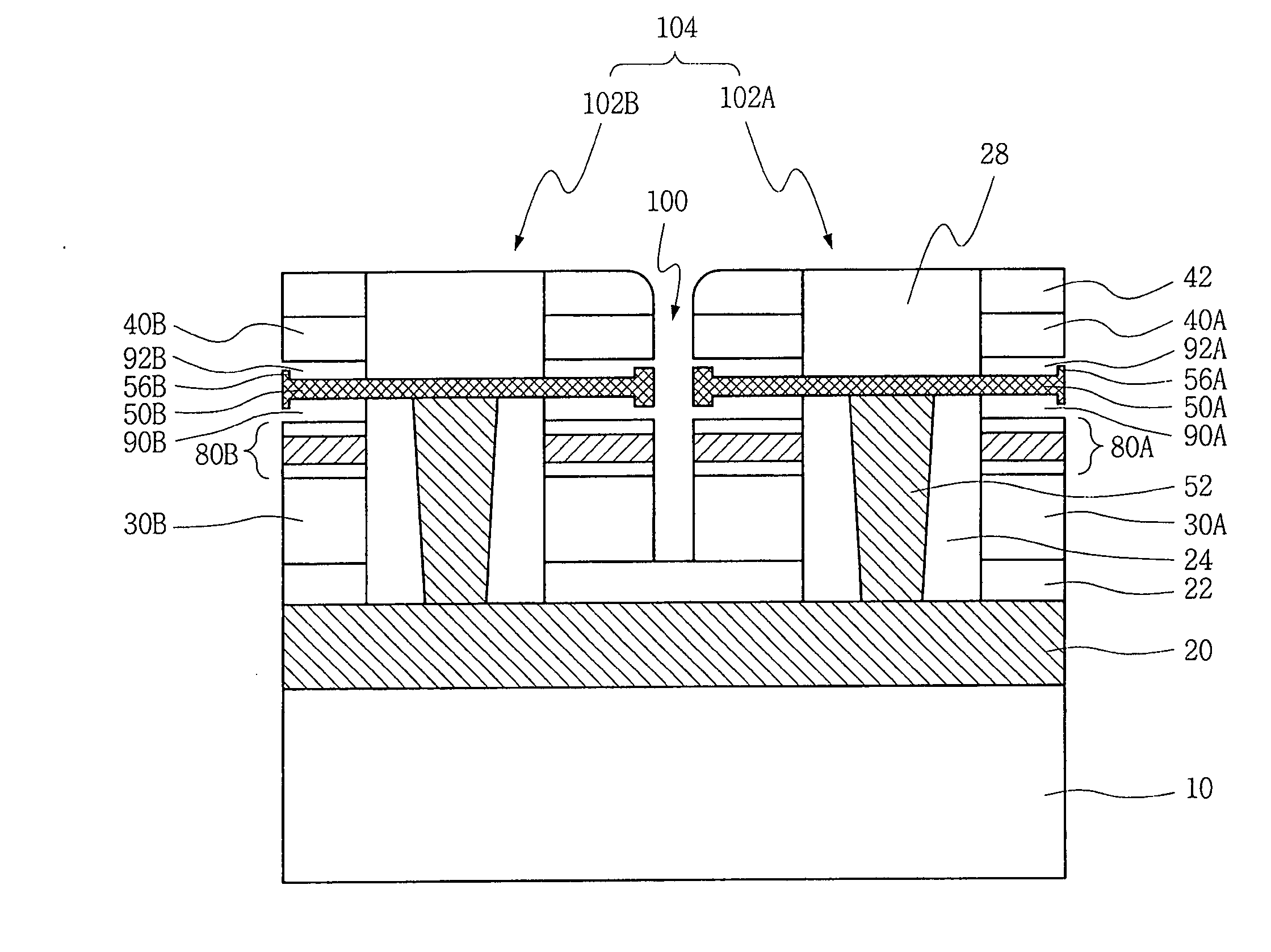

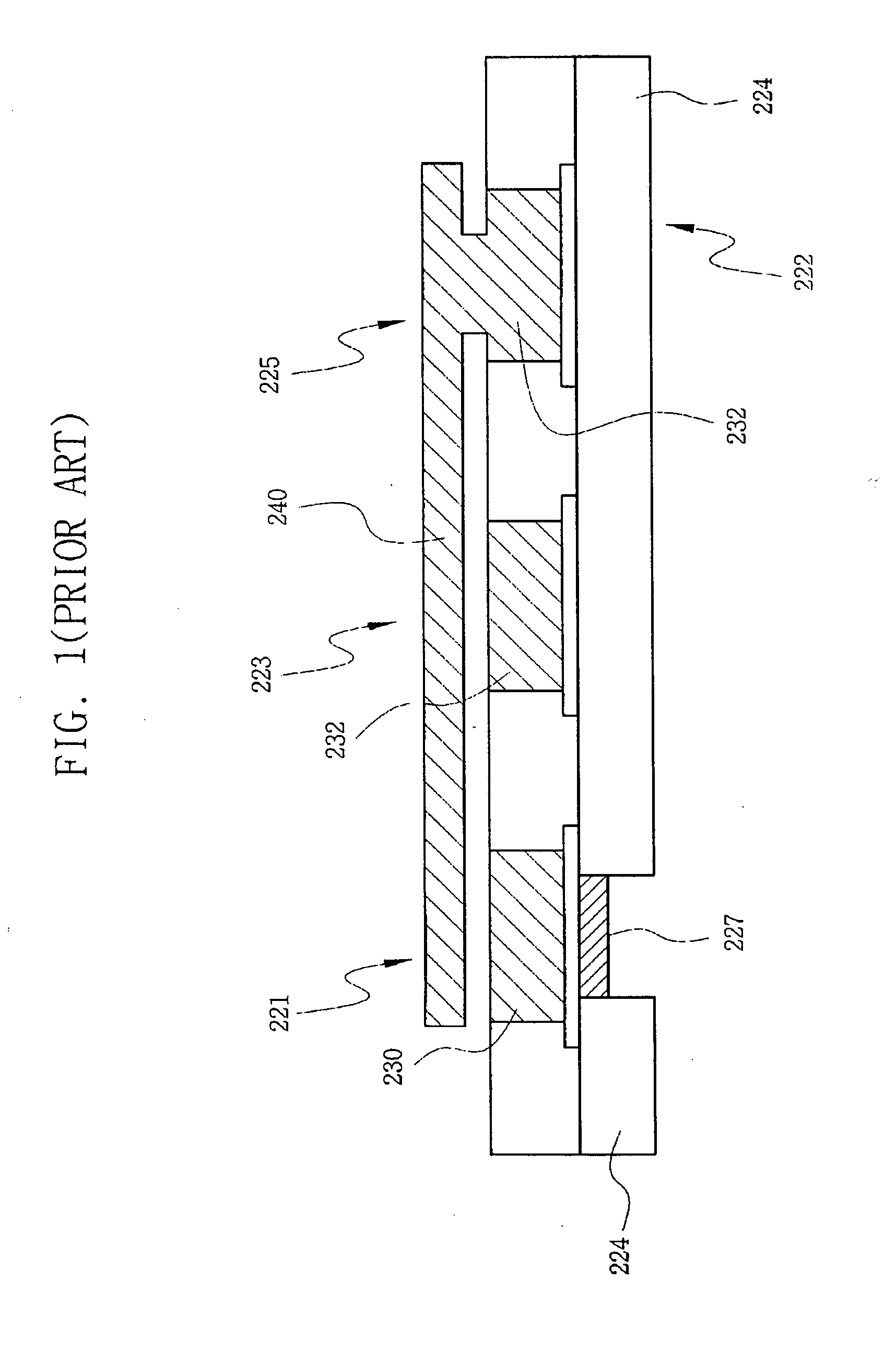

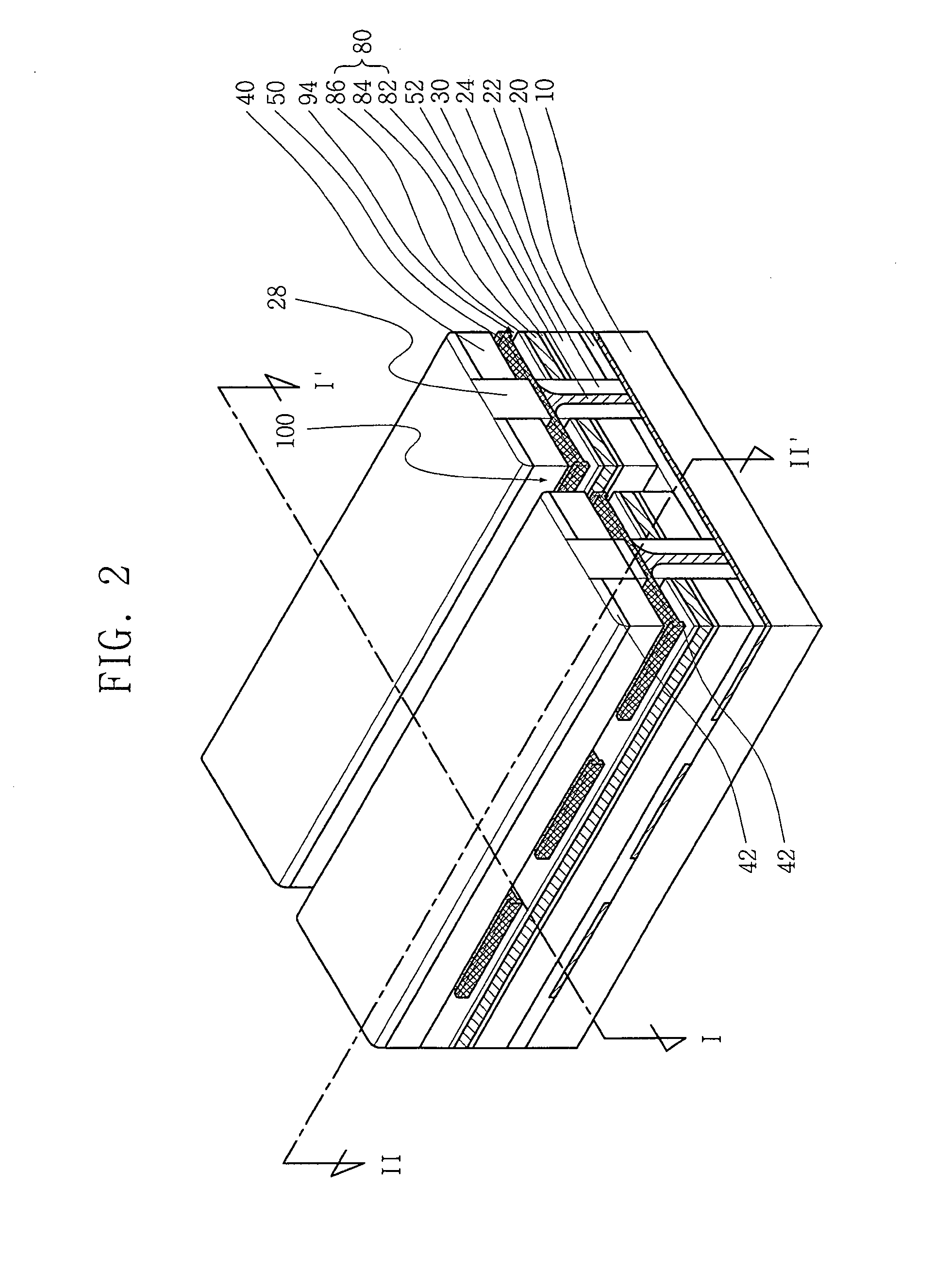

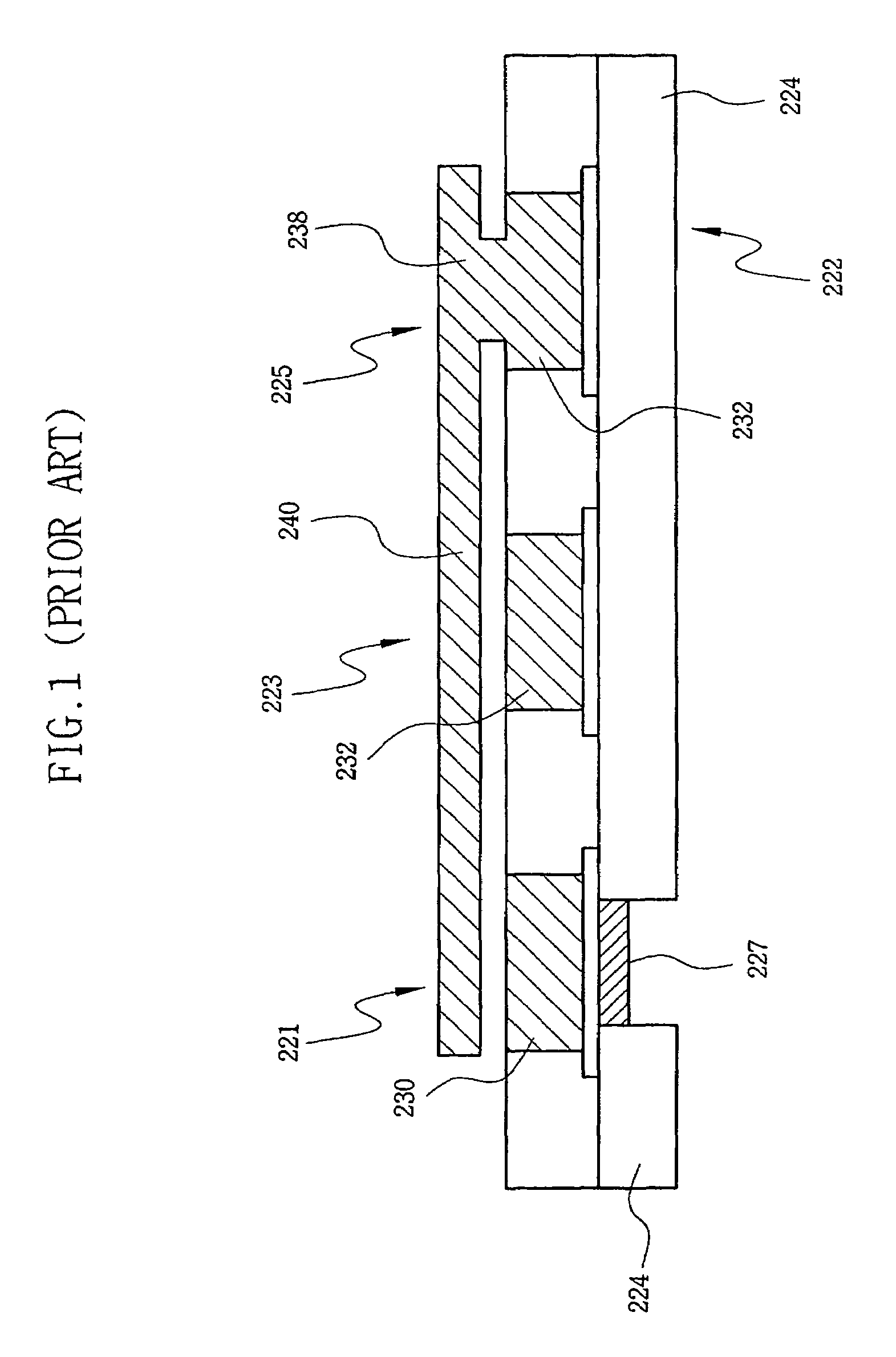

Multi-bit electro-mechanical memory device and method of manufacturing the same

InactiveUS20080144364A1Reduce lengthDegree of integration be enhanceTransistorSemiconductor/solid-state device manufacturingElectricityEngineering

There are provided a multi-bit electromechanical memory device capable of enhancing or maximizing a degree of integration of the memory device and a method of manufacturing the multi-bit electromechanical memory device which includes a substrate, a bit line on the substrate, and extending in a first direction; a word line on the bit line, insulated from the bit line, and extending in a second direction transverse to the first direction, and a cantilever electrode including a shape memory alloy. The cantilever electrode has a first portion electrically connected to the bit line and a second portion extending in the first direction, and spaced apart from the word line by an air gap, wherein the cantilever electrode, in a first state, is in electrical contact with the word line, and, in a second state, is spaced apart from the word line.

Owner:SAMSUNG ELECTRONICS CO LTD

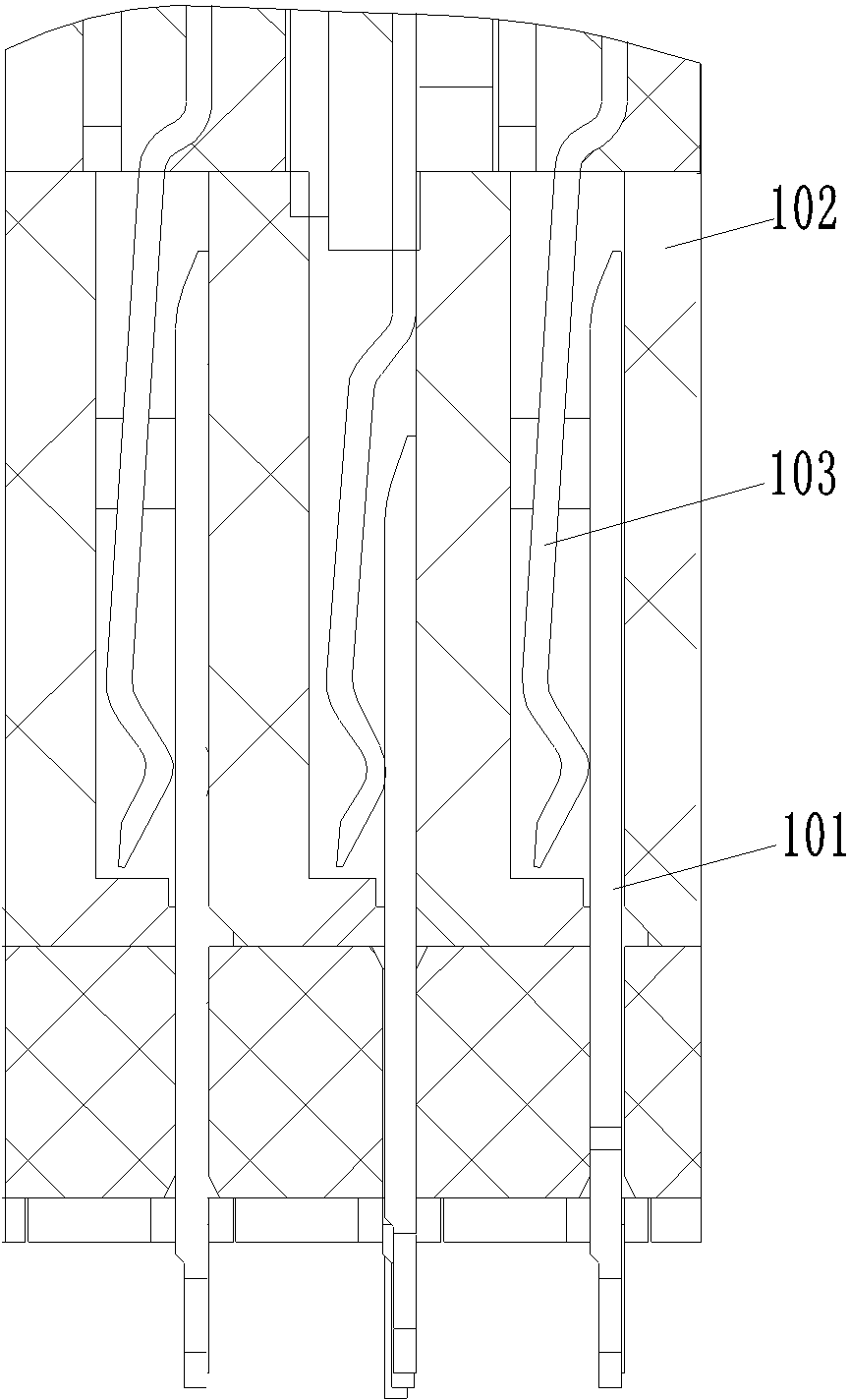

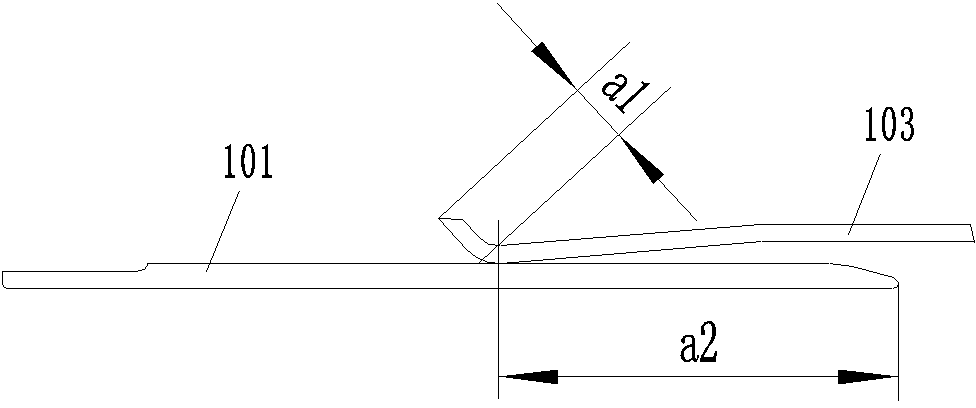

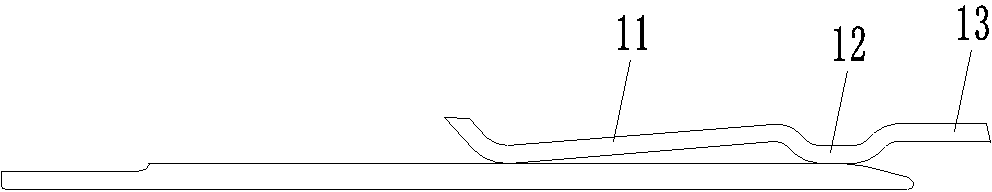

Bent contact member, jack module and electrical connector

ActiveCN104167620ALow insertion lossShorten the cantilever lengthCoupling contact membersFlangingEngineering

The invention relates to the field of electrical connectors, and especially relates to a bent contact member, a jack module and an electrical connector. The front end of the bent contact member is used as a plugging end. The bent contact member comprises a plugging part and a horizontal mounting part disposed behind the plugging part. The front end of the plugging part is provided with a flanging formed through upward bending. The lower side of the bend of the flanging forms a front contact part used for contacting a matching contact member. A concave part which is concave downward relative to the plugging part is arranged between the plugging part and the mounting part. The concave part forms a rear contact part of the contact member. The plugging part gradually slopes downward from back to front from the joint of the plugging part and the concave part. Before use, the front and rear contact parts can be respectively in contact with the root and the end of the matching contact member, so that the formation of a cantilever structure on the matching contact member is avoided or the length of the cantilever of the matching contact member is shortened at least, thereby reducing the insertion loss of a differential connector. In conclusion, the bent contact member can reduce the insertion loss between a plug and a socket of a differential connector.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

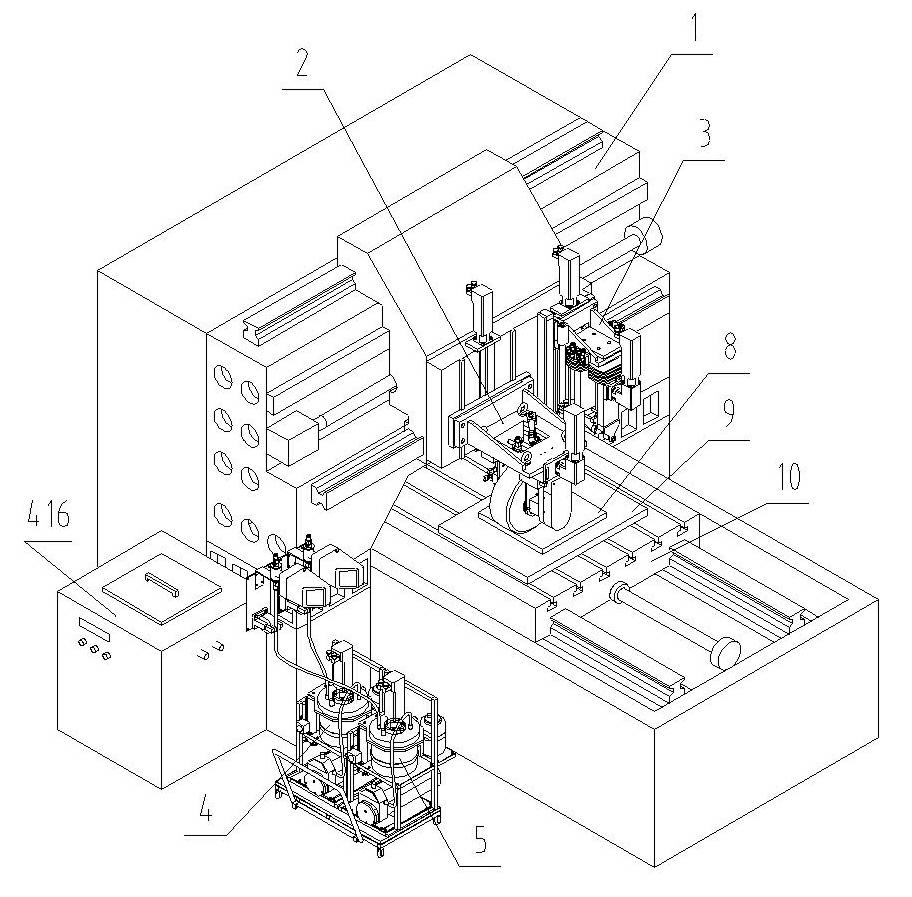

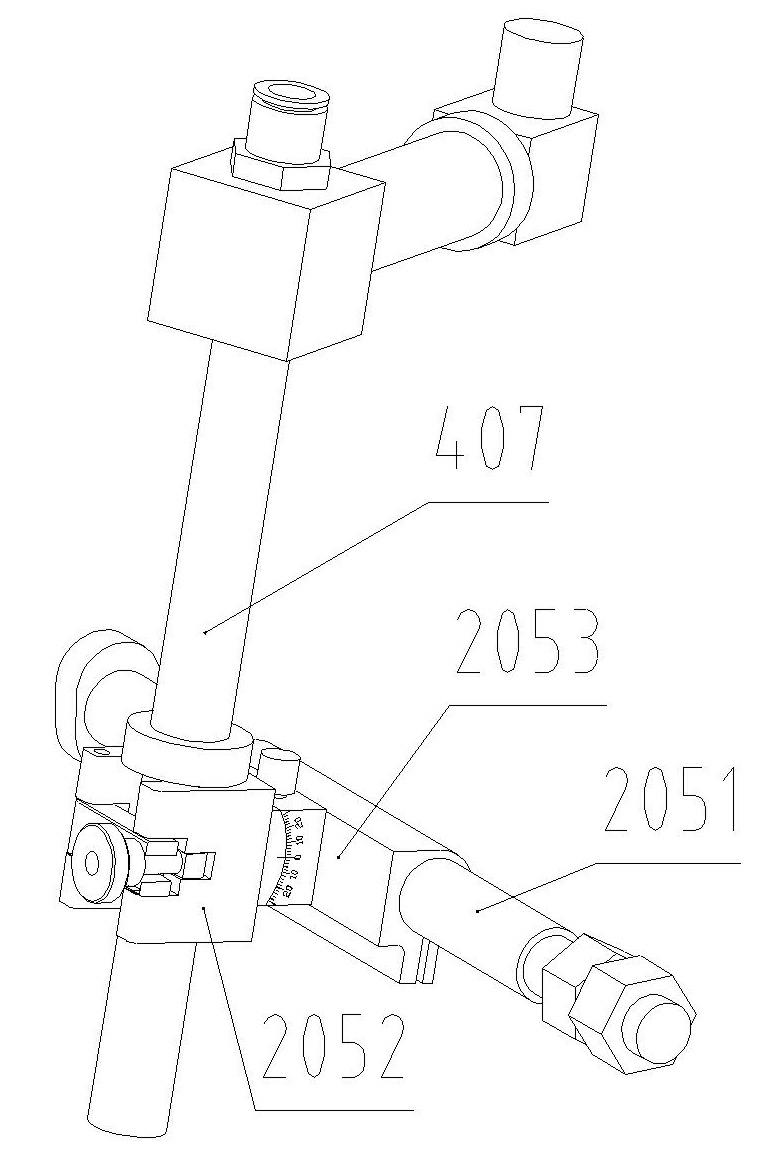

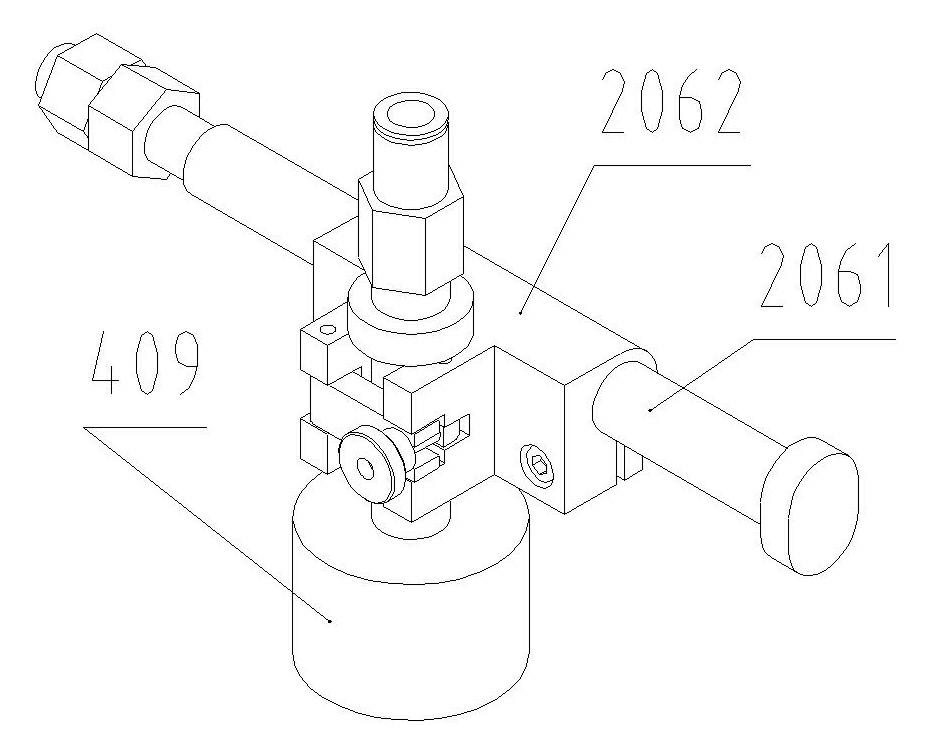

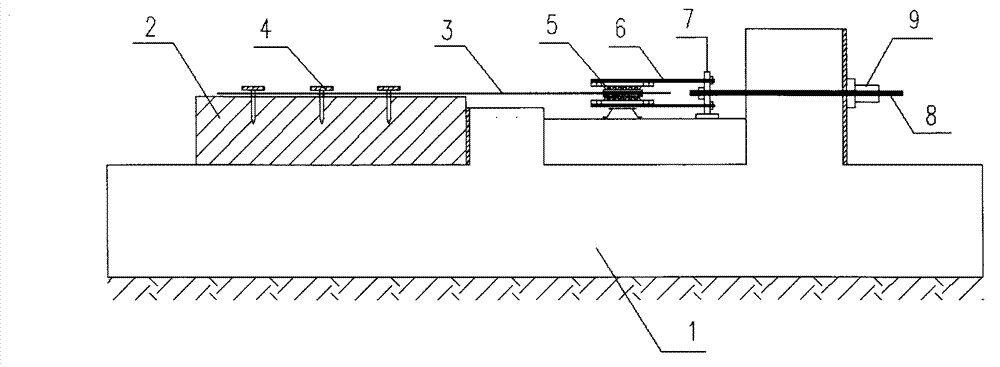

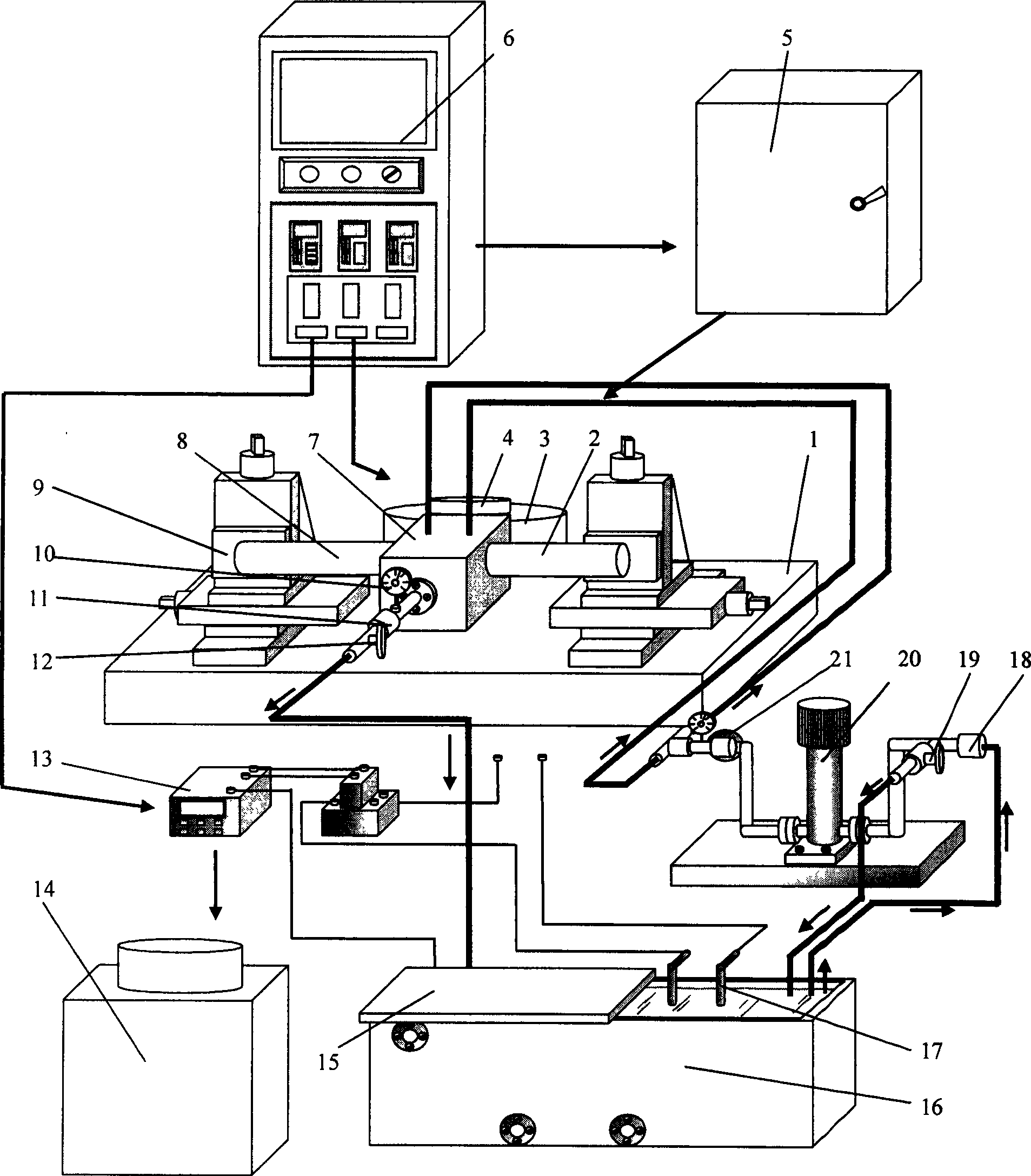

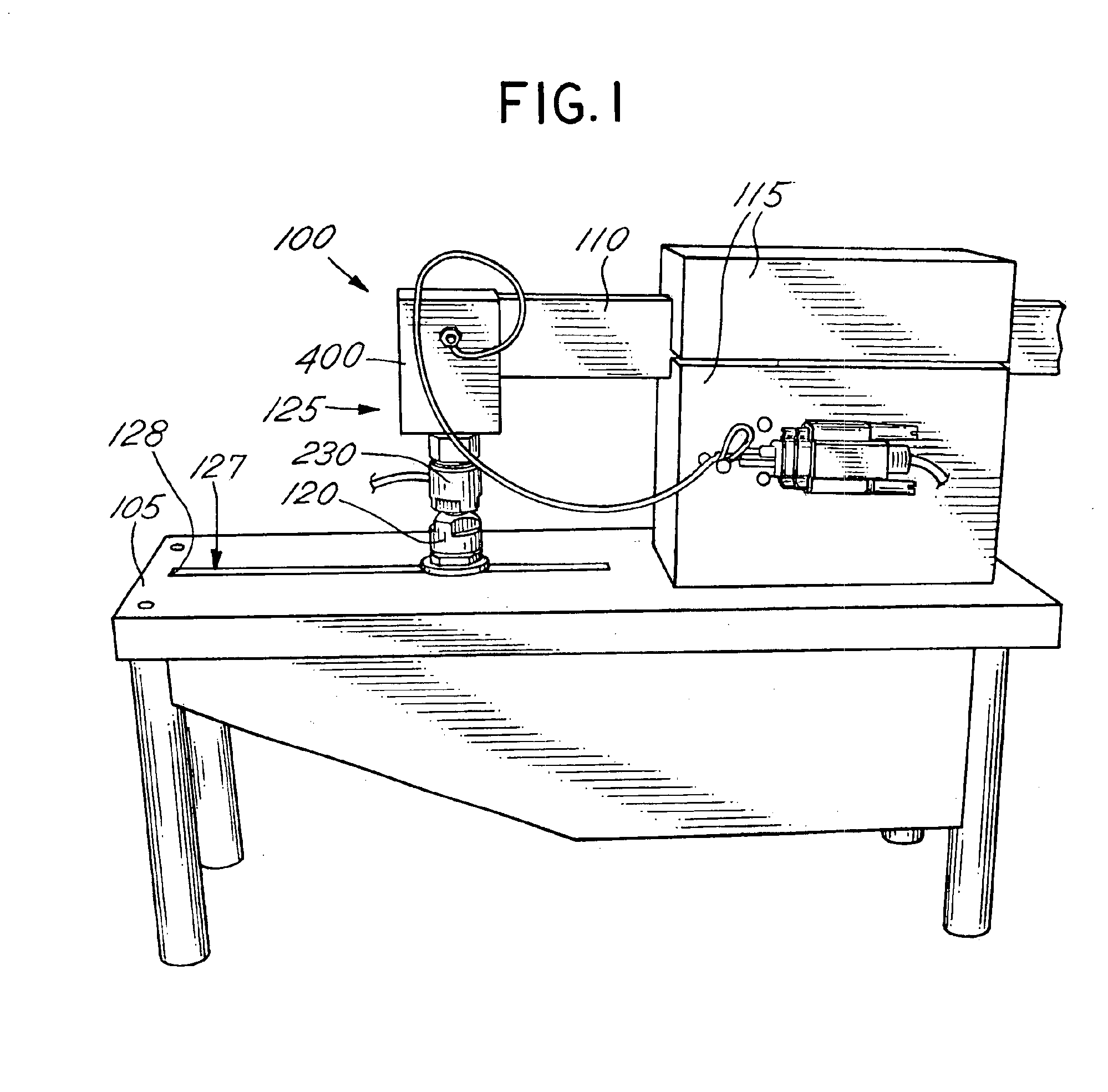

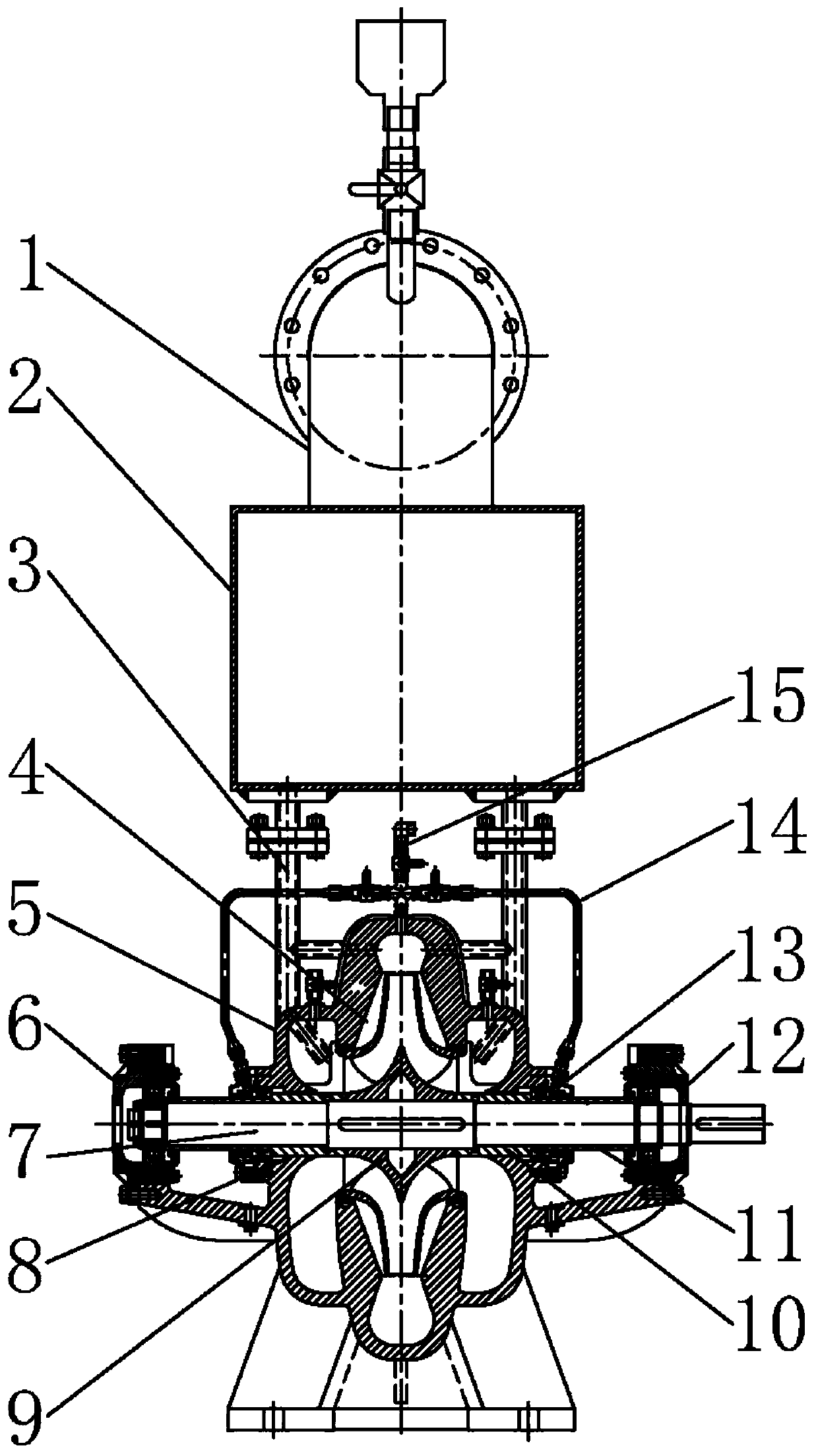

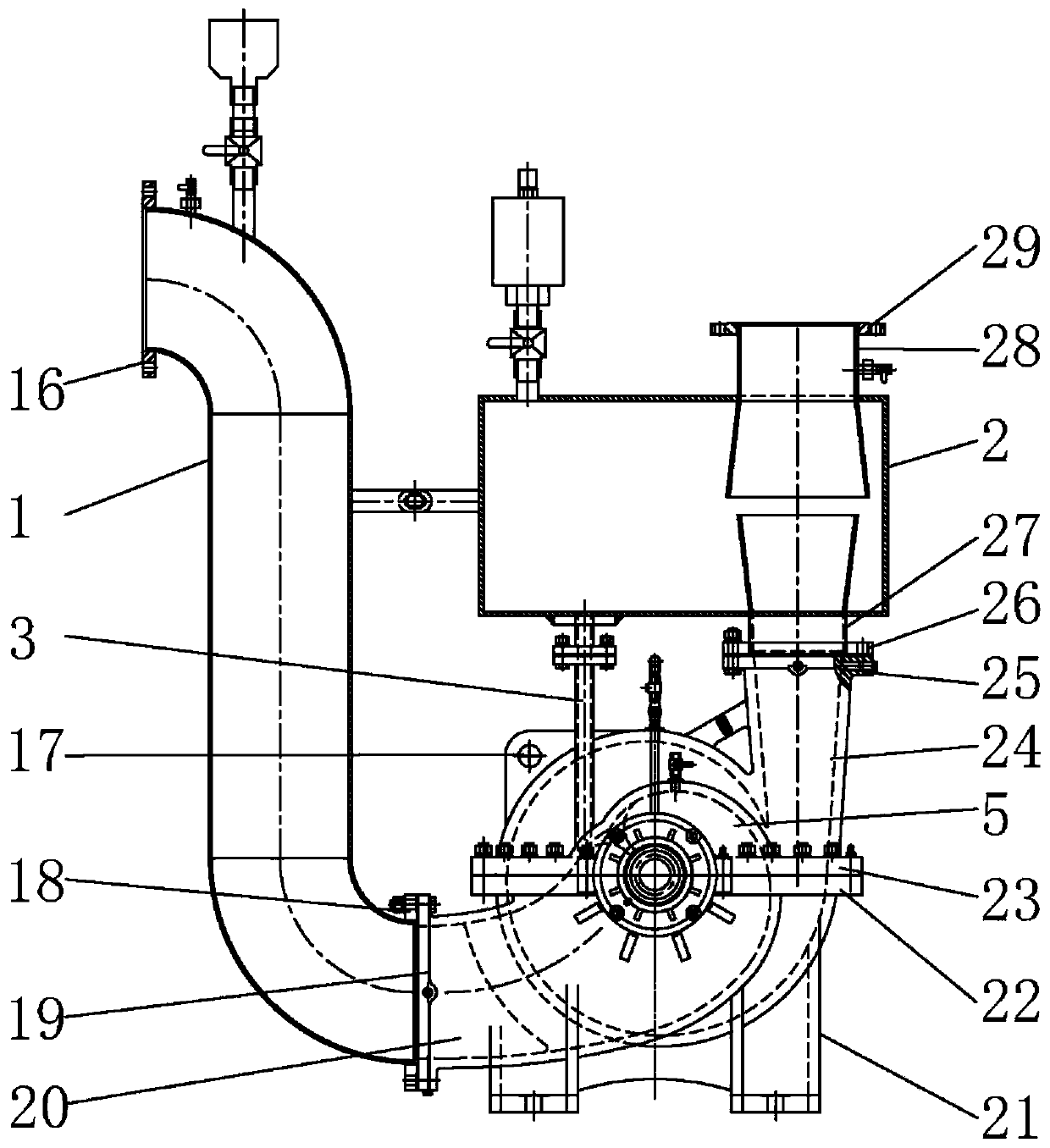

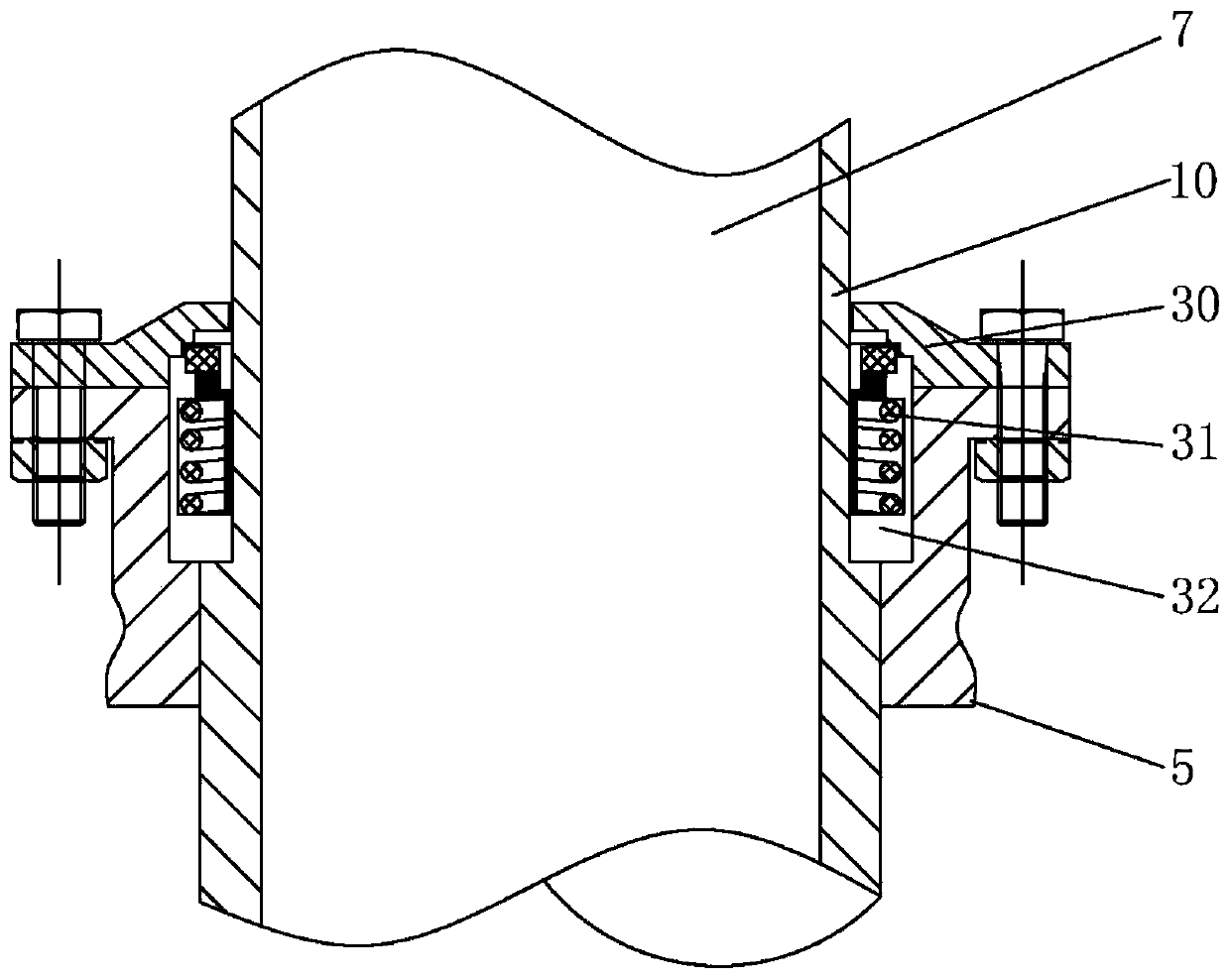

Double-flexible-grinding-head magnetorheological polishing device

ActiveCN102632435AEfficient removalEffectively match processing efficiencyGrinding drivesGrinding feed controlMagnetic currentEngineering

The invention discloses a double-flexible-grinding-head magnetorheological polishing device. In the device, a vertical gantry of a bed body and an X-axis are both fixed on a horizontal base; a worktable is fixed on a sliding block of the X-axis; a Y-axis is fixed on a horizontal beam of the vertical gantry; and a first Z-axis and a second Z-axis are arrangedon the Y-axis in parallel. A large flexible grinding head is installed on the first Z-axis; and a small flexible grinding head is arranged on the second Z-axis. A high-flow circulation system connected with the large flexible grinding head and a low-flow circulation system connected with the small flexible grinding head are arranged on a trolley. A control cabinet is arranged at the rear part of the vertical gantry; and a circulation system cabinet and a cleaning system are arranged at the side surface of the vertical gantry. The double-flexible-grinding-head magnetorheological polishing device provided by the invention has the advantages of high accuracy, high rigidness, high stability and high dynamic property. The double-flexible-grinding-head magnetorheological polishing device not only can be used for processing of large-caliber phase elements, but also can be used for high-accuracy processing of large-caliber planar optical elements within the range of full caliber. The optimal matching of the processing efficiency and the processing accuracy can be realized.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

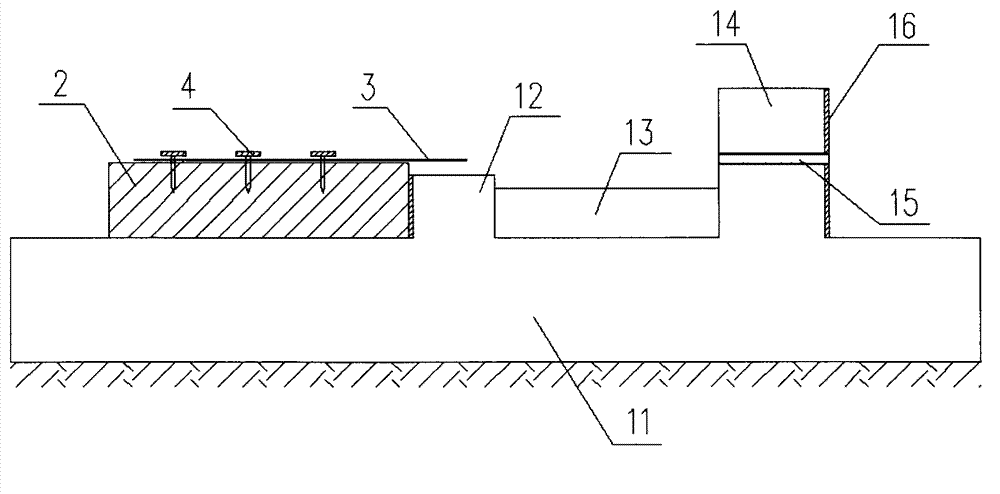

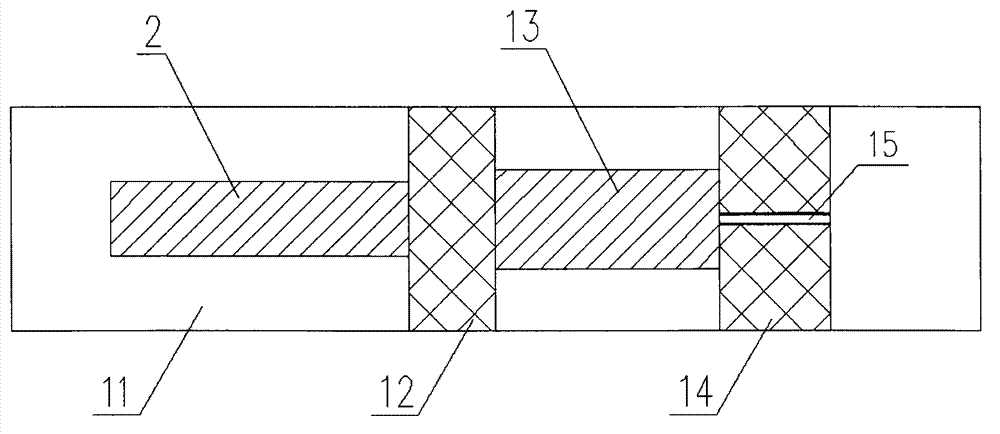

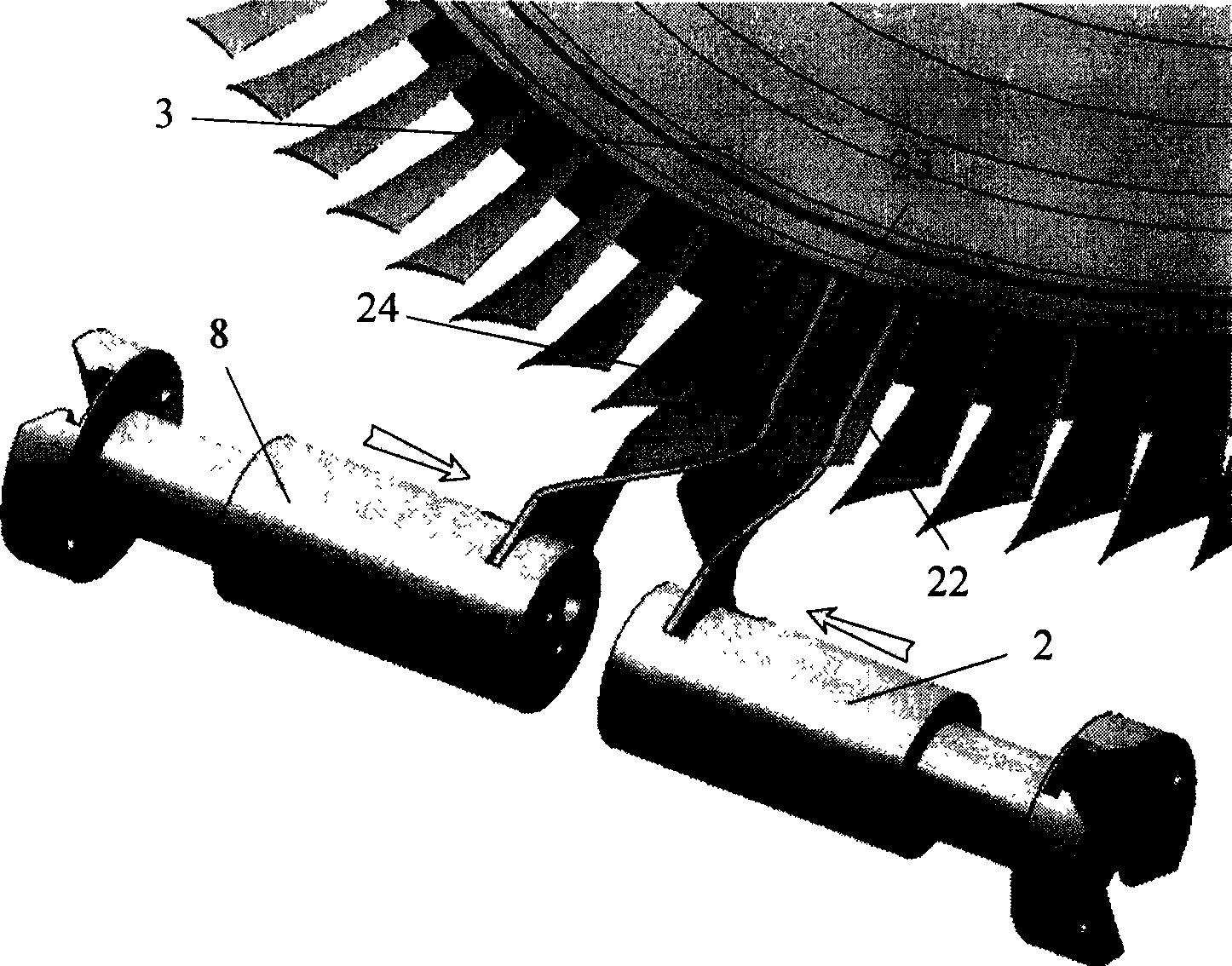

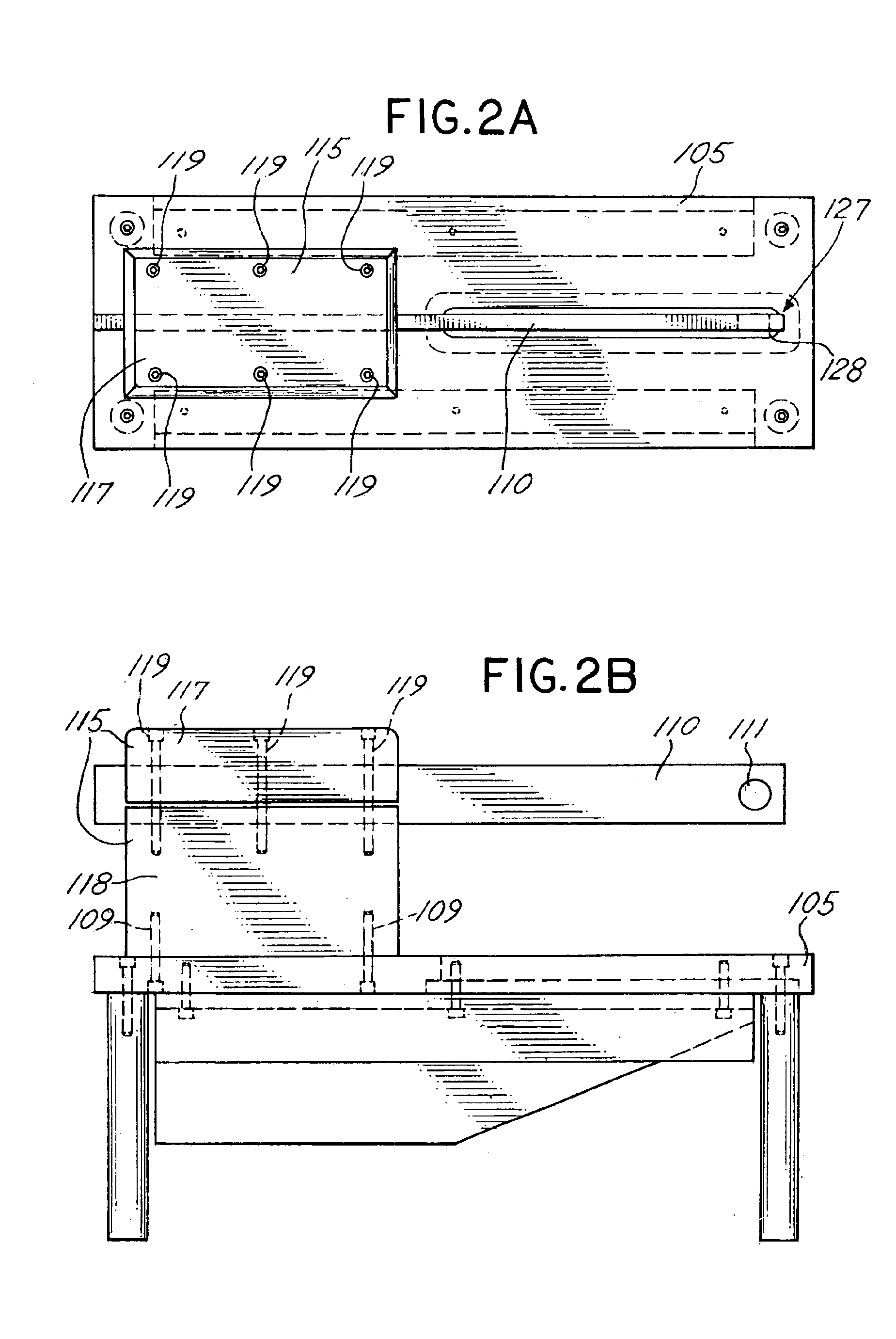

Anchorage performance detection testing apparatus and method for carbon fiber adhesion reinforcement

InactiveCN103048264AJudging the mechanical performance of anchorageCheck construction qualityUsing mechanical meansMaterial analysisFiberCarbon fibers

The invention discloses an anchorage performance detection testing apparatus for carbon fiber adhesion reinforcement. The testing apparatus comprises a testing bench, a concrete test piece, a test fixture and a loading system. The reinforced concrete test bench is composed of a base, a blocking bed, a connecting bed and a stretching bed, carbon fiber sheets are adhered to the test piece, and a steel pressing plate and an anchor bolt are taken as auxiliary anchoring pieces; the test fixture is composed of an external covering steel plate, two inner clamping steel plates and a high-strength split bolt, strip-shaped steel teeth are formed on the surface of the external covering steel plate, pole steel teeth are formed on the surfaces of the inner clamping steel plates, the carbon fiber sheets are placed between the two inner clamping steel plates, the carbon fiber sheets and the two inner clamping steel plates are firmly adhered together by dipping glue, and the high-strength split bolt clamps the external covering steel plate, the inner clamping steel plates and the carbon fiber sheets; and the loading system is composed of a connecting screw rod, a tensile connecting steel plate, a tensile screw rod, a lifting jack and a sensor. The testing apparatus provided by the invention can quickly carry out an anchorage zone stress performance test on a concrete beam reinforced with adhesion of the carbon fiber sheets, and has the advantages of being convenient to make and simple to operate, and the like.

Owner:江苏华通工程技术有限公司

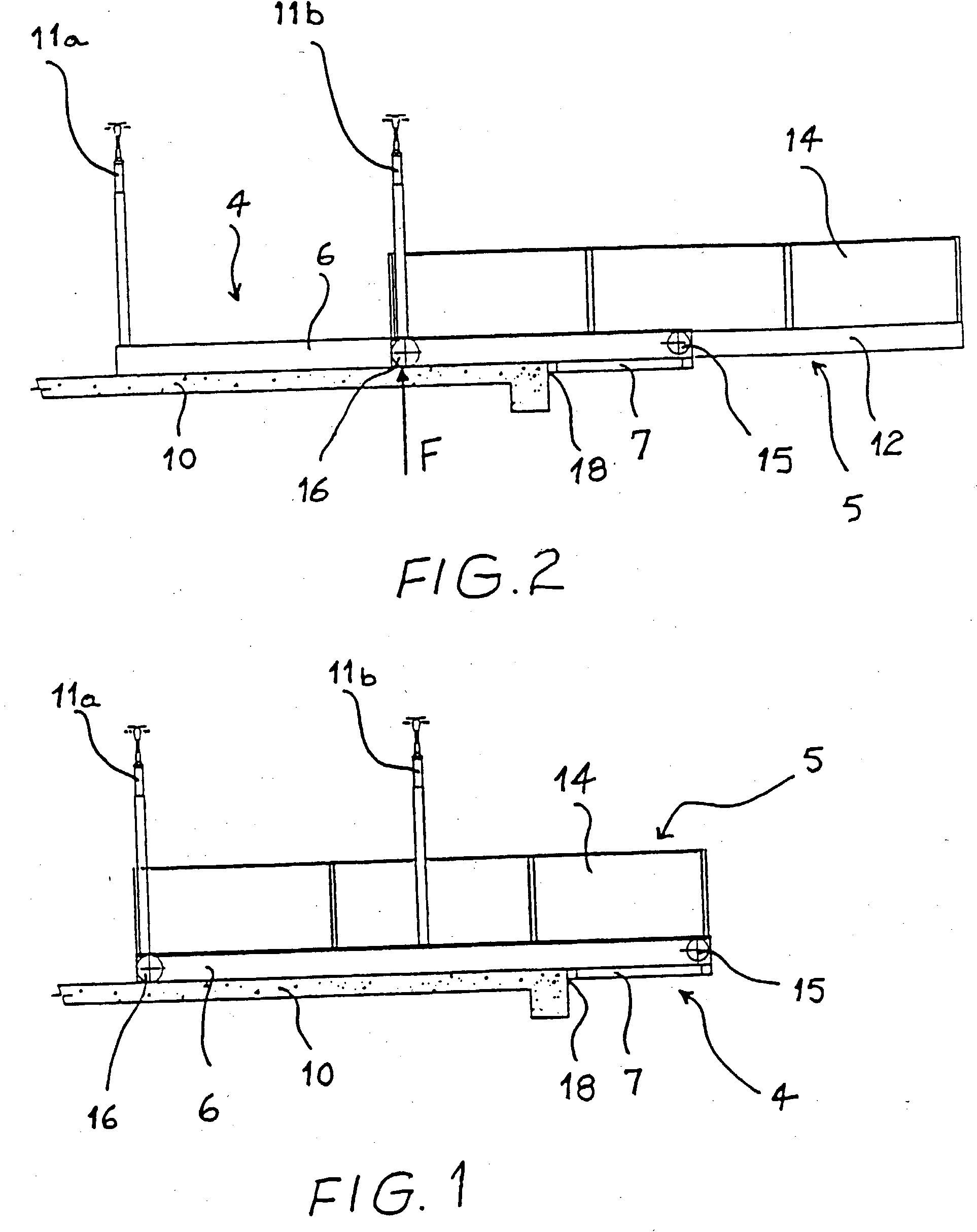

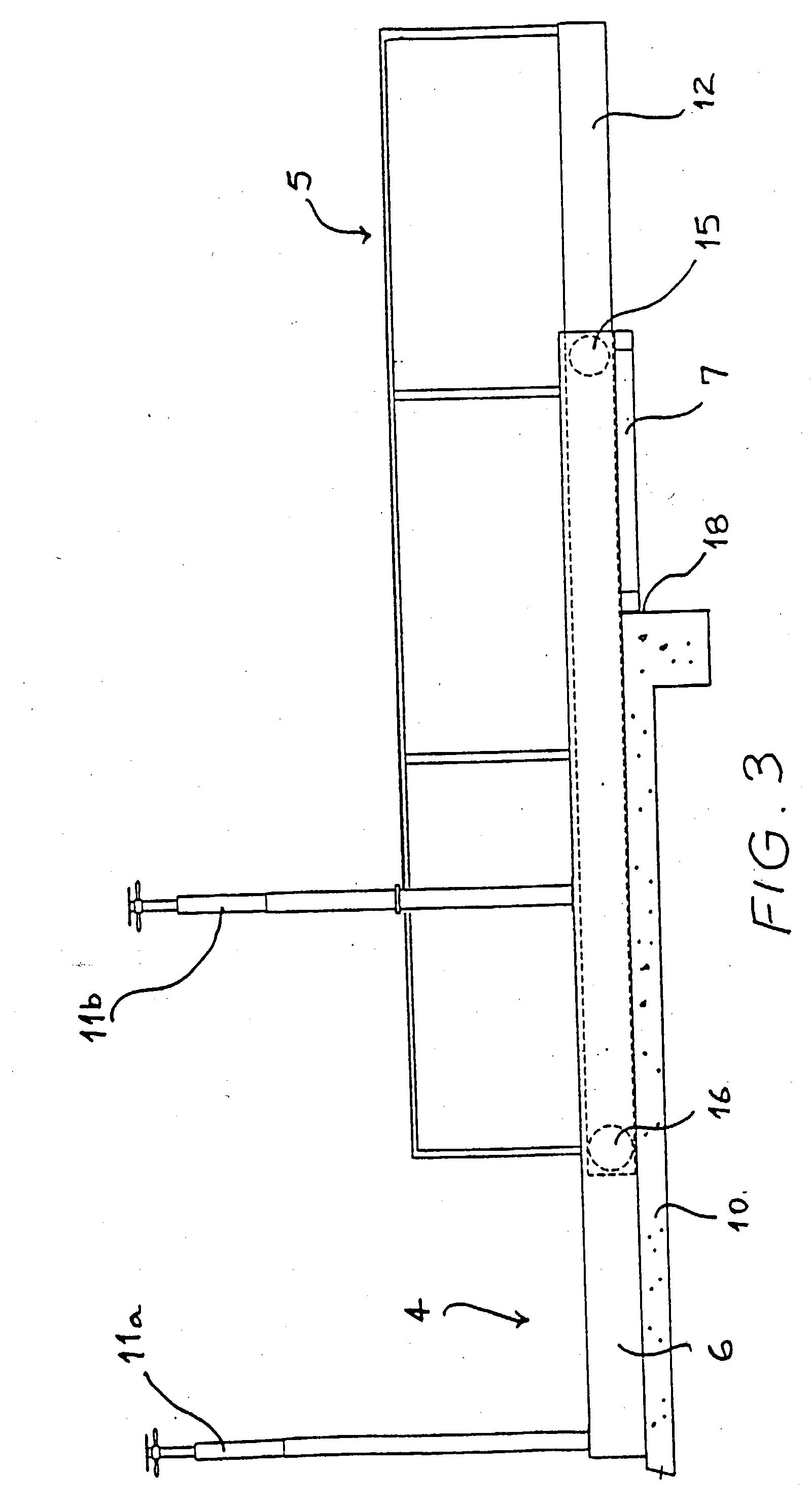

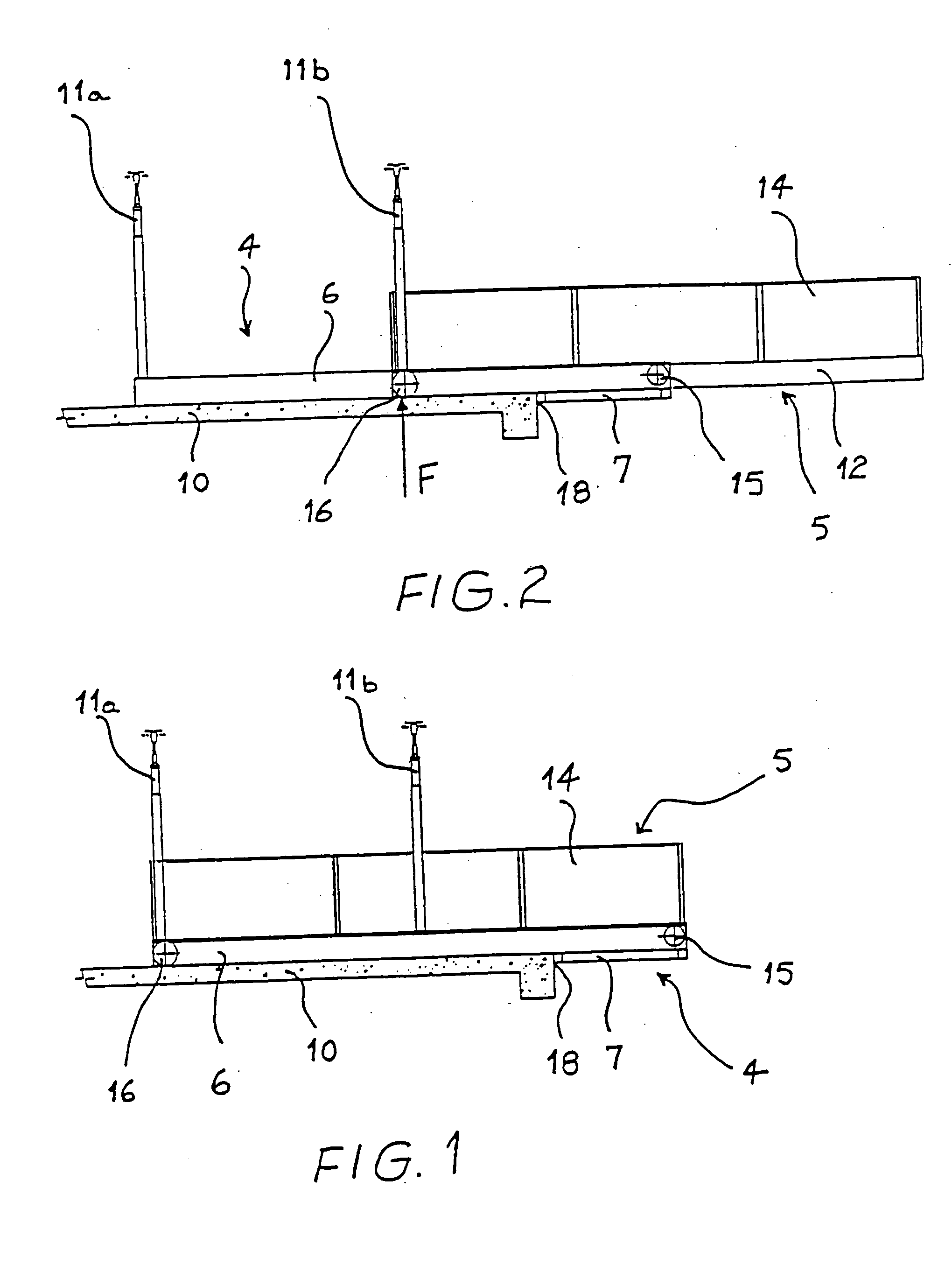

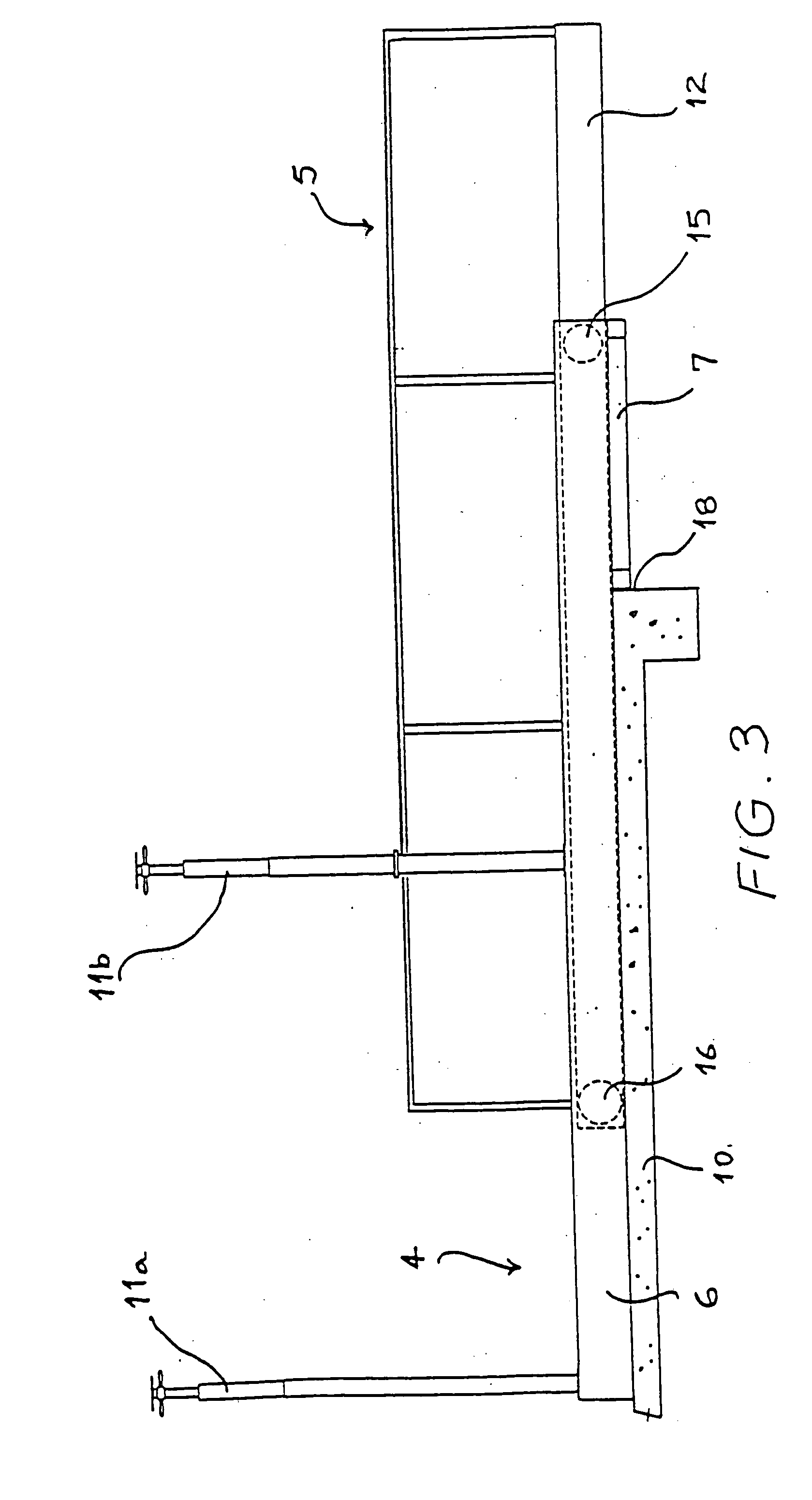

Partly retractable construction platform

InactiveUS20030079940A1Reduce the total massReduce the overall heightBuilding material handlingScaffold accessoriesBuilding under constructionCantilever

A construction platform comprising a stationary support structure adapted to be fixedly secured to the floor of a building under construction and project from the edge of the building to a predetermined maximum extent, and a movable deck mounted on the stationary structure which may be extended as a cantilever therefrom or retracted into at least substantial registration therewith.

Owner:MEVON PTY

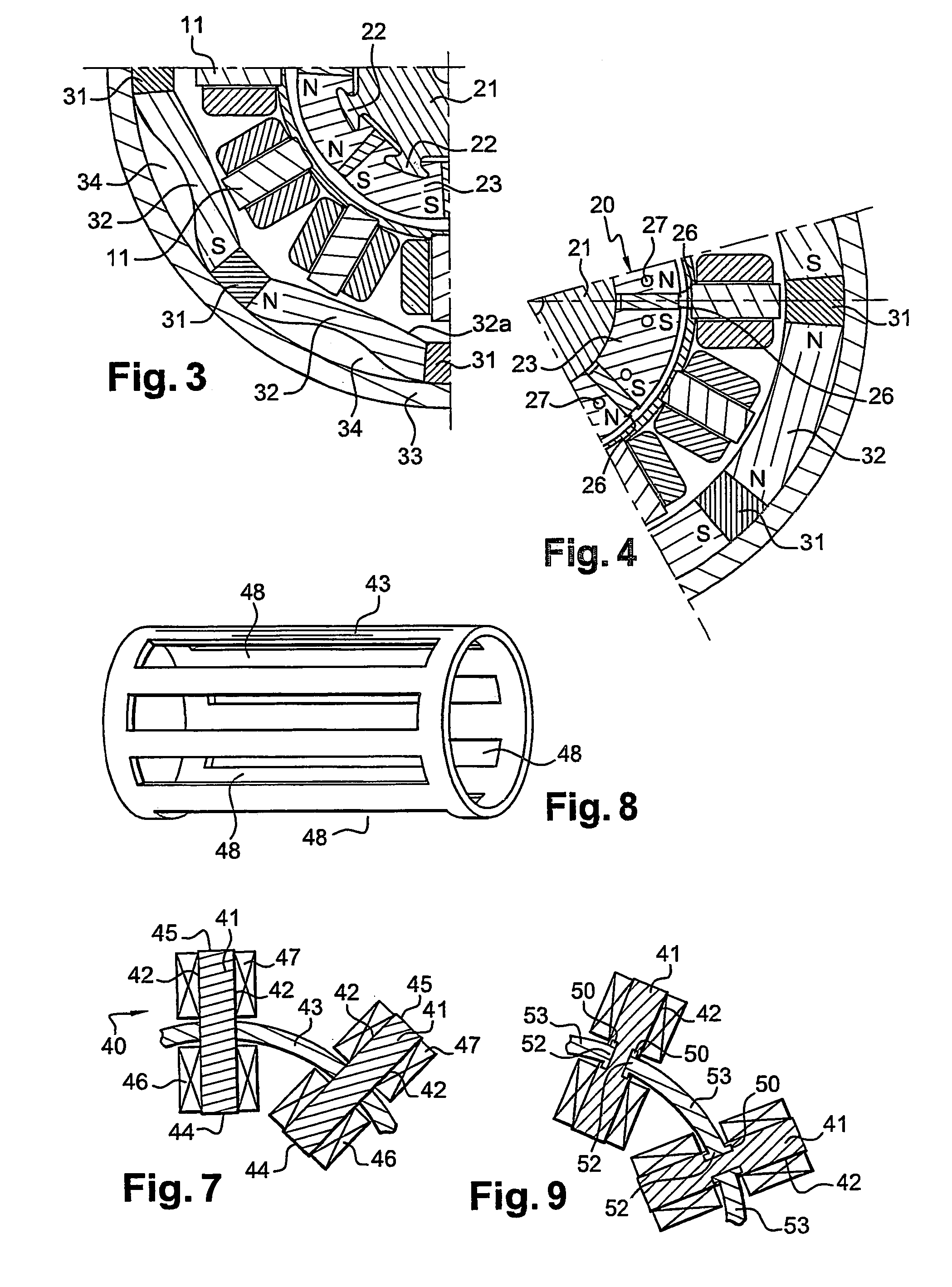

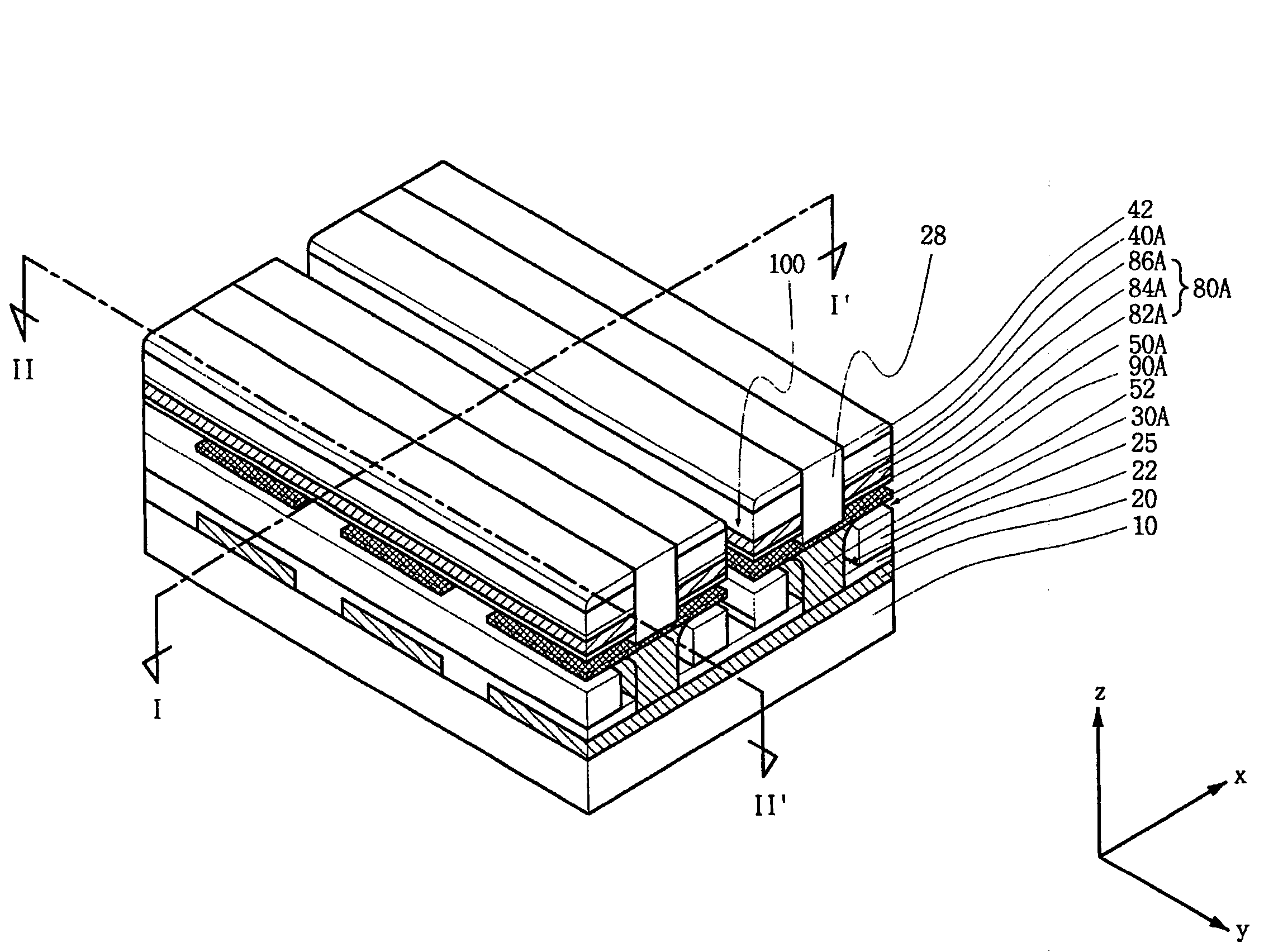

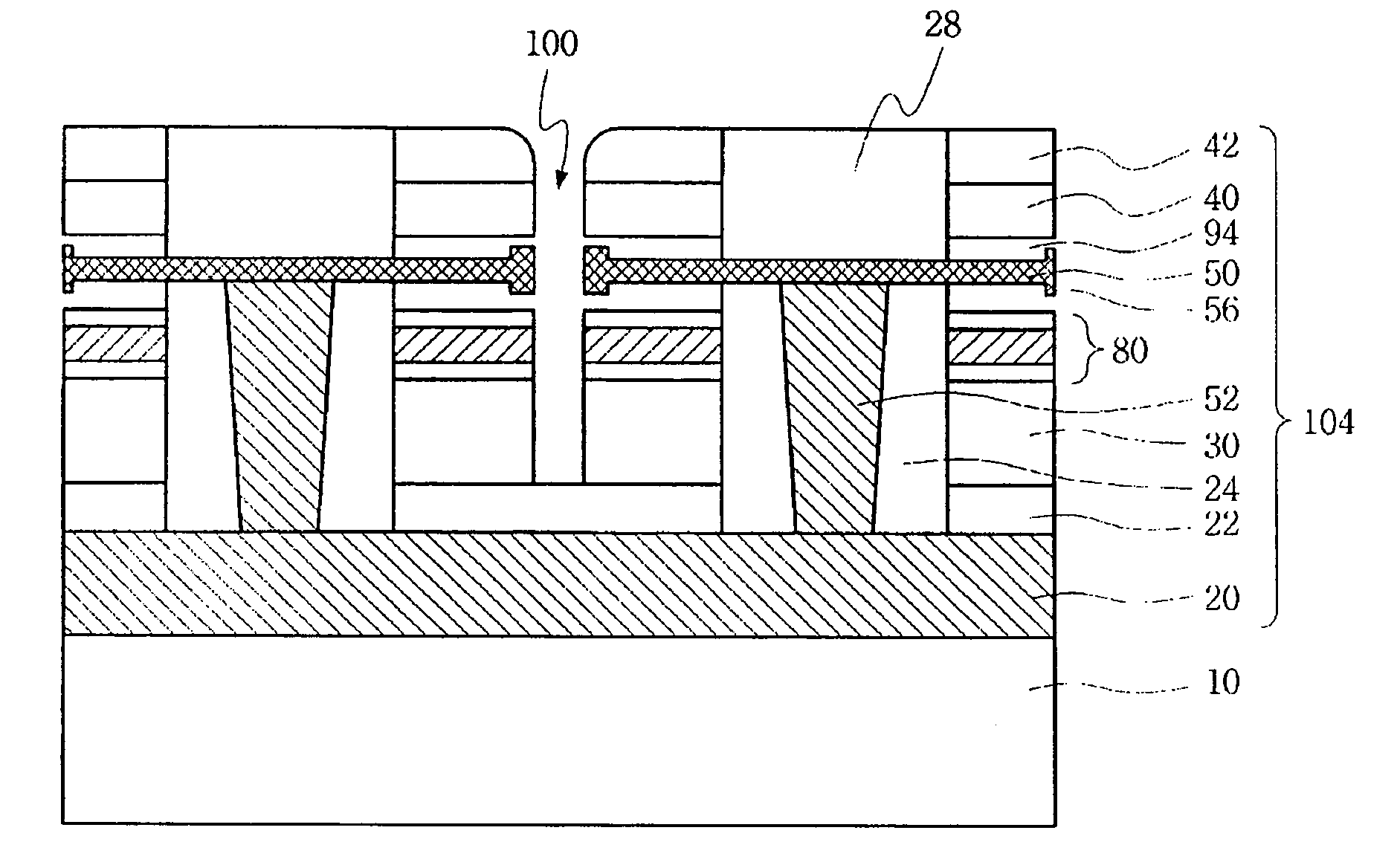

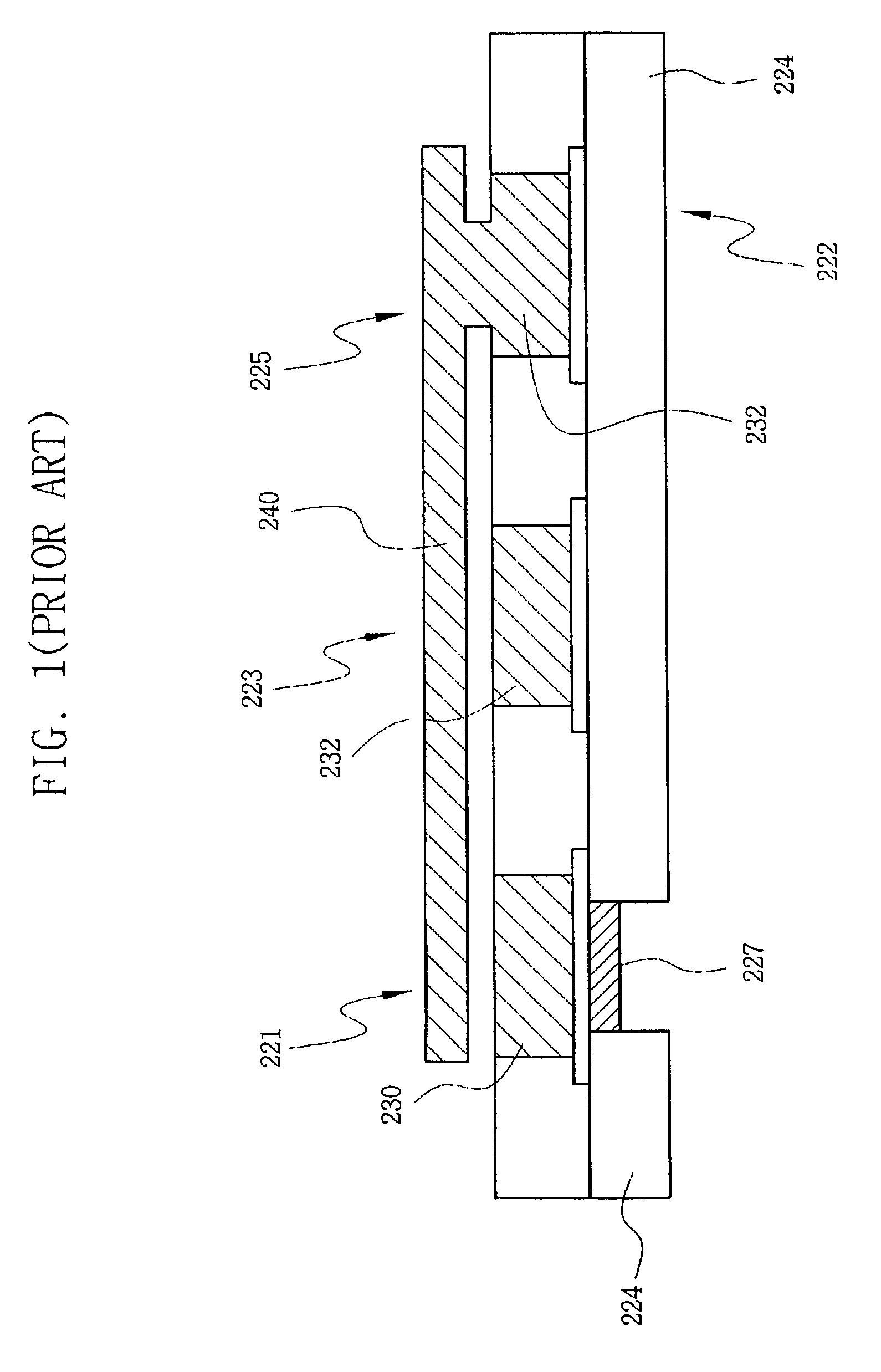

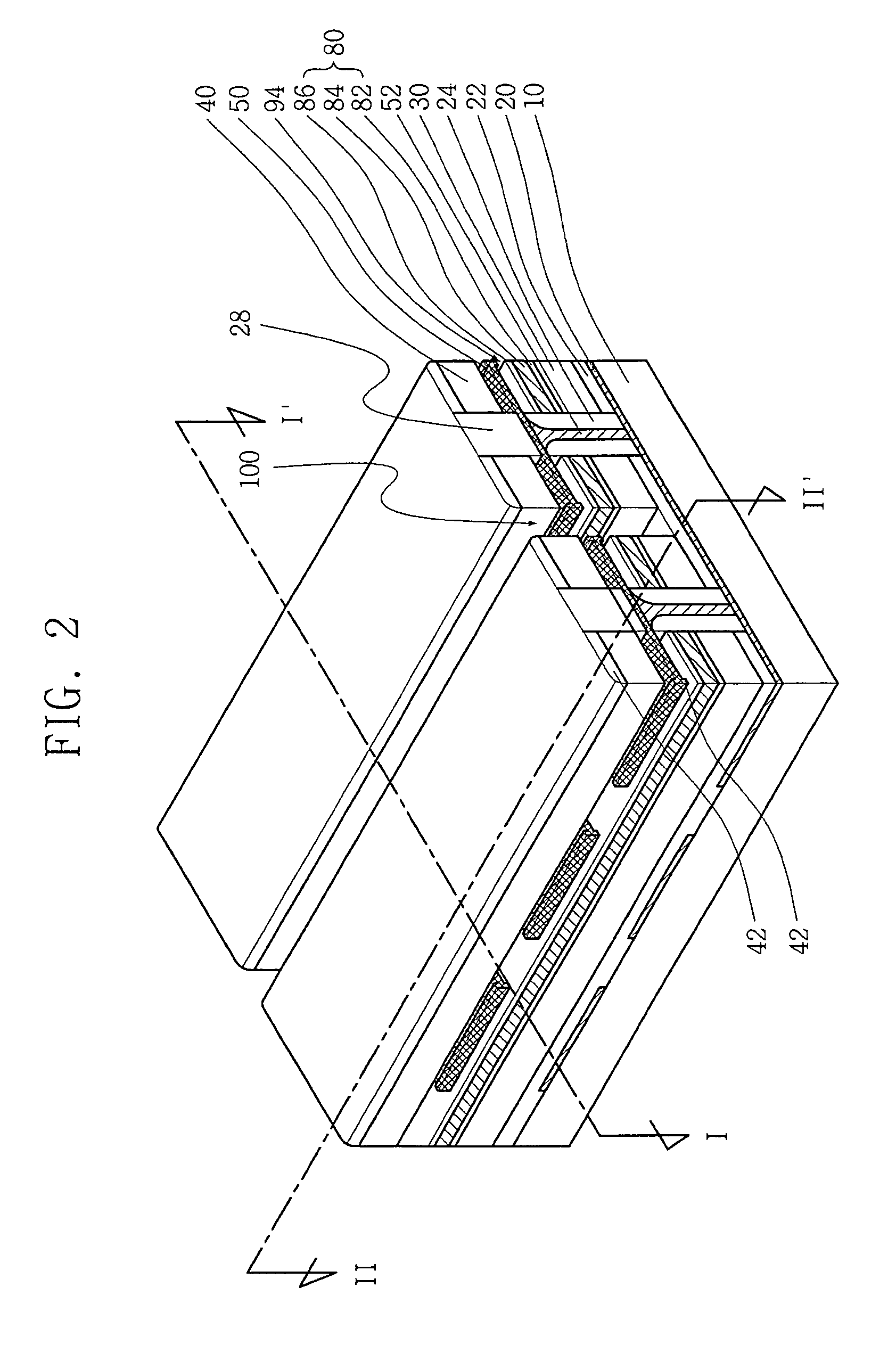

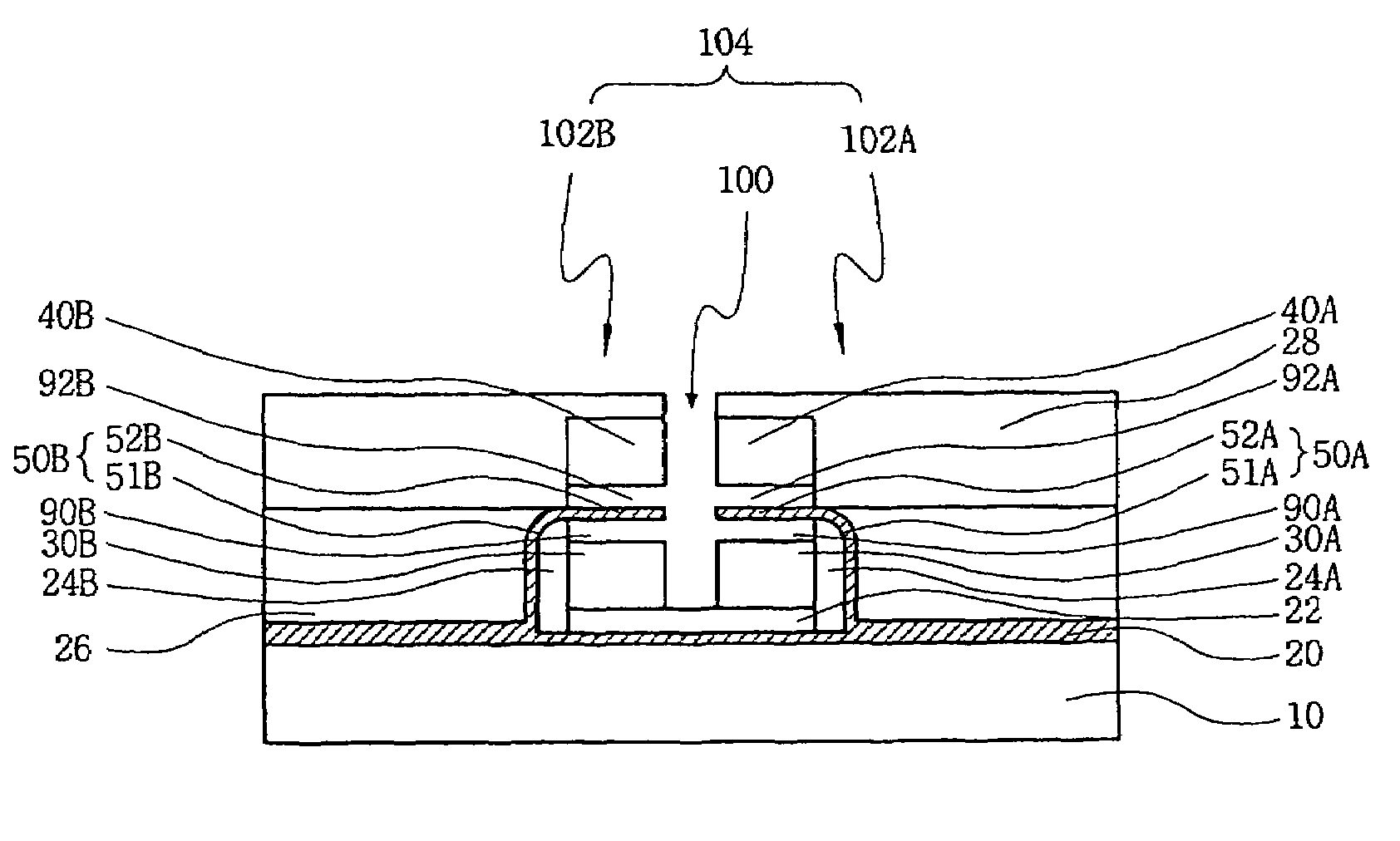

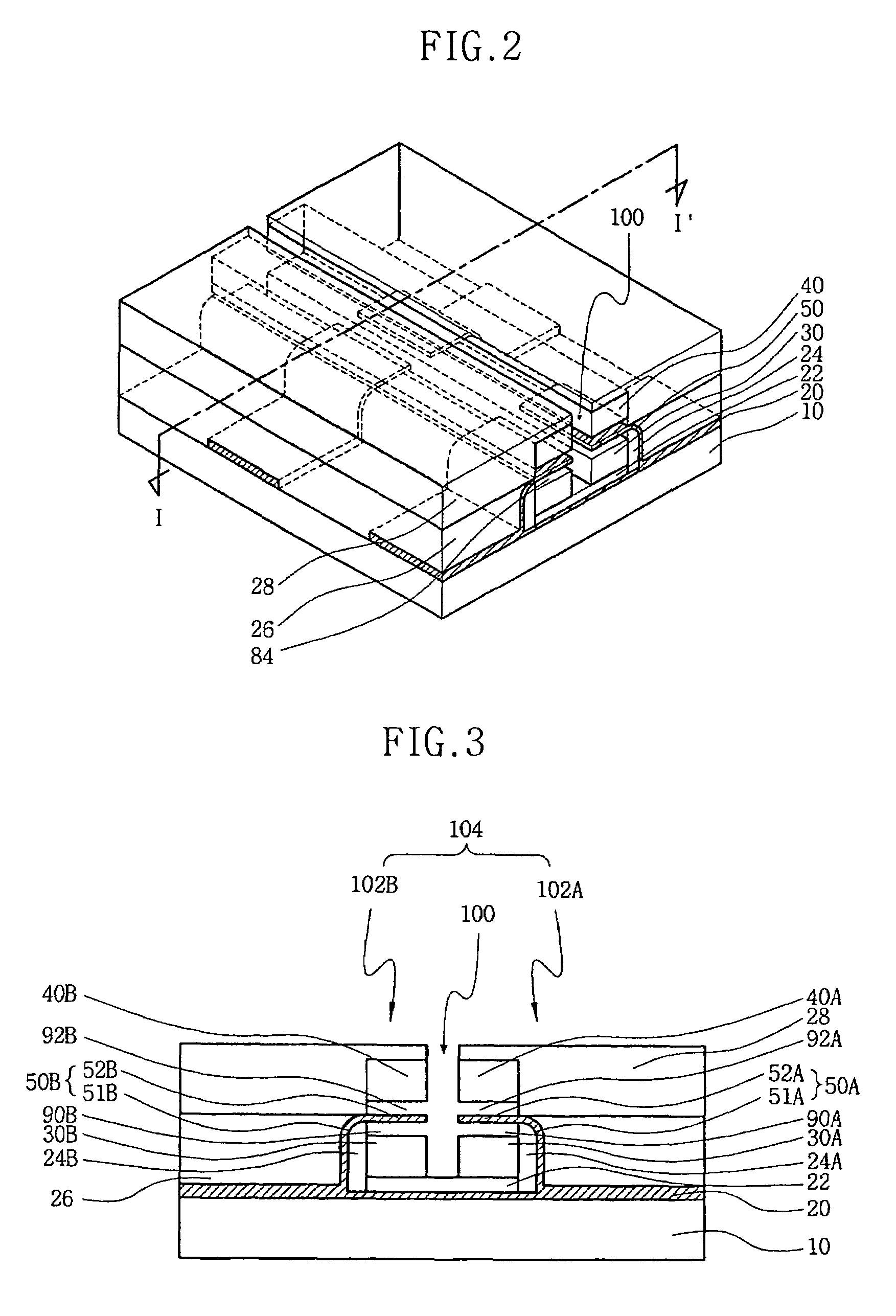

Multibit electro-mechanical memory device and method of manufacturing the same

InactiveUS20090097315A1Highly integratedShorten the cantilever lengthSolid-state devicesRead-only memoriesBit lineEngineering

A multibit electro-mechanical memory device comprises a substrate, a bit line on the substrate, a first interlayer insulating film on the bit line, first and second lower word lines on the first interlayer insulating film, the first and second lower word lines separated horizontally from each other by a trench, a spacer abutting a sidewall of each of the first and second lower word lines, a pad electrode inside a contact hole, first and second cantilever electrodes suspended over first and second lower voids that correspond to upper parts of the first and second lower word lines provided in both sides on the pad electrode, the first and second cantilever electrodes being separated from each other by the trench, and being curved in a third direction that is perpendicular to the first and second direction; a second interlayer insulating film on the pad electrode, first and second trap sites supported by the second interlayer insulating film to have first and second upper voids on the first and second cantilever electrodes, and first and second upper word lines on the first and second trap sites.

Owner:SAMSUNG ELECTRONICS CO LTD

Thin electrode for electrolytic machining of integral wheel

InactiveCN101502901AImproving the precision of electrolytic machiningNo significant increase in thicknessMachining electrodesElectrical-based machining electrodesImpellerEngineering

The invention relates to an electrolytically-processed slice electrode of an integral impeller and pertains to the field of electrolytic processing. The invention is characterized in that the slice electrode is a twisted profile and the twist extent is similar to a blade profile; one side of the slice electrode is a processing surface and the other side is a non-processing surface; the non-processing surface is coated with an insulation layer; wherein the thickness of the insulation layer varies along the axial direction of a cathode slice, the insulation layer close to the mounting end of the cathode slice is thicker and the coating layer close to the processing end is thinner; the slice electrode is vertically arranged on an electrode fixture. With twisted profile, the invention can process deformed and narrow impeller slots; the insulation layer with optimized thickness coated on the non-processing surface of the cathode prevents the secondary erosion on the non-processing surface and increases the intensity of the cathode slice, thus achieving the stable feeding of the cathode slice in the processing and ensuring smoothness and stability of a flow field in the processing area.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Multibit electro-mechanical memory device and method of manufacturing the same

ActiveUS20080219048A1Reduce power consumptionImprove the level ofElectrostatic/electro-adhesion relaysNanoinformaticsBit lineEngineering

A multibit electro-mechanical memory device capable of increasing an integrated level of memory devices, and a method of manufacturing the same, are provided. The memory device includes a substrate, a bit line on the substrate; a lower word line and a trap site isolated from the bit line, a pad electrode isolated from a sidewall of the trap site and the lower word line and connected to the bit line, a cantilever electrode suspended over a lower void in an upper part of the trap site, and connected to the pad electrode and curved in a third direction vertical to the first and second direction by an electrical field induced by a charge applied to the lower word line, a contact part for concentrating a charge induced from the cantilever electrode thereon in response to the charge applied from the lower word line and the trap site, the contact part protruding from an end part of the cantilever electrode, and an upper word line formed with an upper void on the cantilever electrode.

Owner:SAMSUNG ELECTRONICS CO LTD

Roof-type unfolding locking device of aircraft

ActiveCN102923319AShorten the cantilever lengthSolve the problem of too low base frequencyCollapsable antennas meansCosmonautic vehiclesFundamental frequencyCantilever

The invention provides a roof-type unfolding locking device of an aircraft. The roof-type unfolding locking device comprises an aircraft platform, a driving locking device, a compressing and releasing device, a driving hinge and at least two pairs of inner planar antenna plates and outer planar antenna plates, wherein at the closing-up state, the inner planar antenna plates and the outer planar antenna plates are arranged at two sides of the aircraft platform in a roof layout and are fixed by the compressing and releasing device; and at the unfolded state, the inner planar antenna plates and the outer planar antenna plates are driven to be unfolded through the driving locking device and the driving hinge. Compared with the prior art, the roof-type unfolding locking device of the aircraft sufficiently utilizes the aircraft platform as an installation fixing plane of a planar antenna, the length of the cantilever arm of the antenna is reduced, and the problem that the fundamental frequency of the antenna is too low due to the fact that the cantilever arm is too long while the planar antenna is closed up is effectively solved; and meanwhile the roof-type unfolding locking device has the functions of fastening, unfolding and locking of one, two and more than two antennaes.

Owner:SHANGHAI AEROSPACE SYST ENG INST

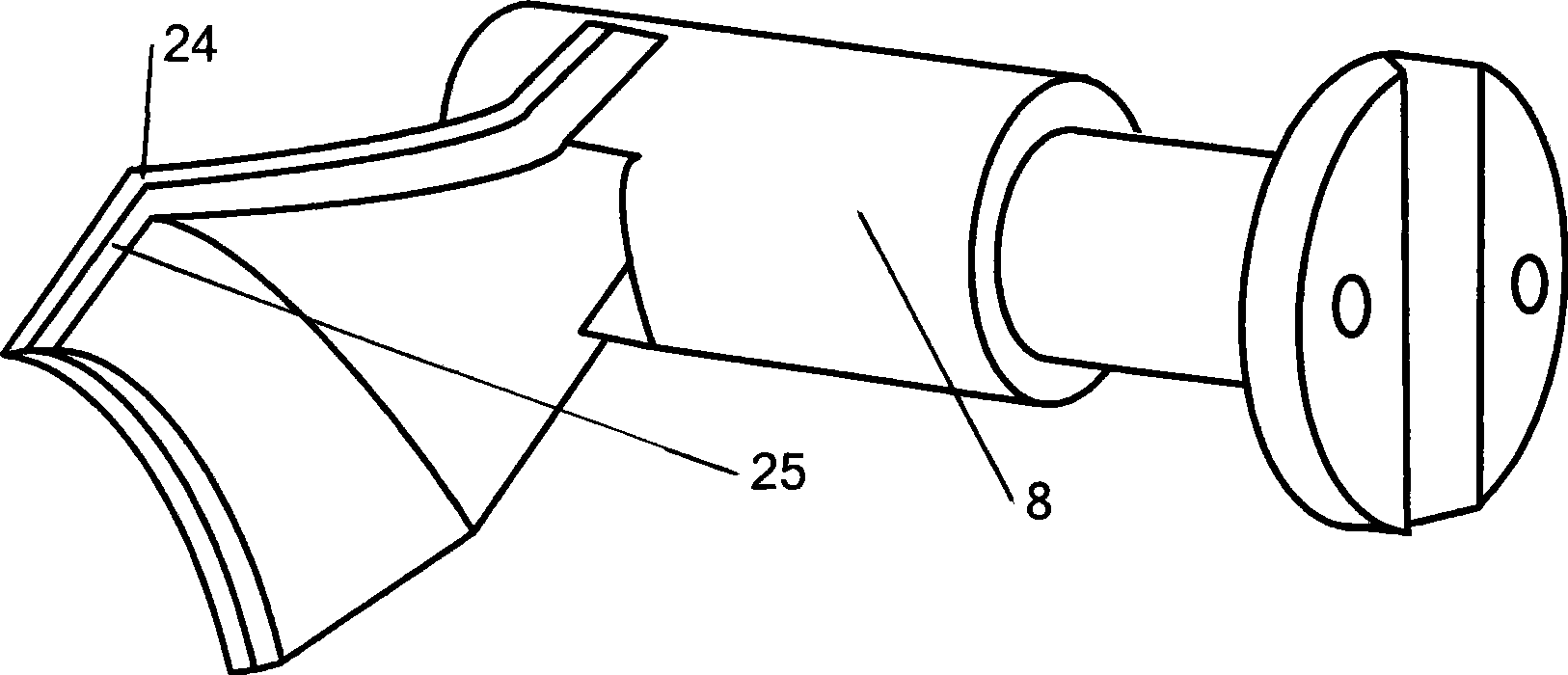

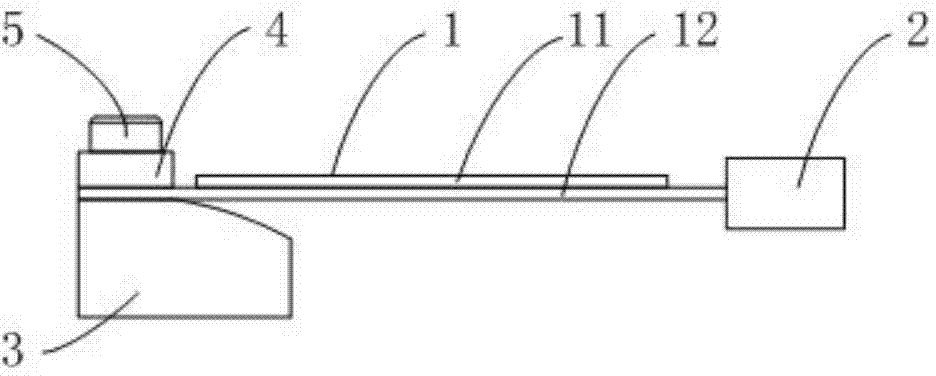

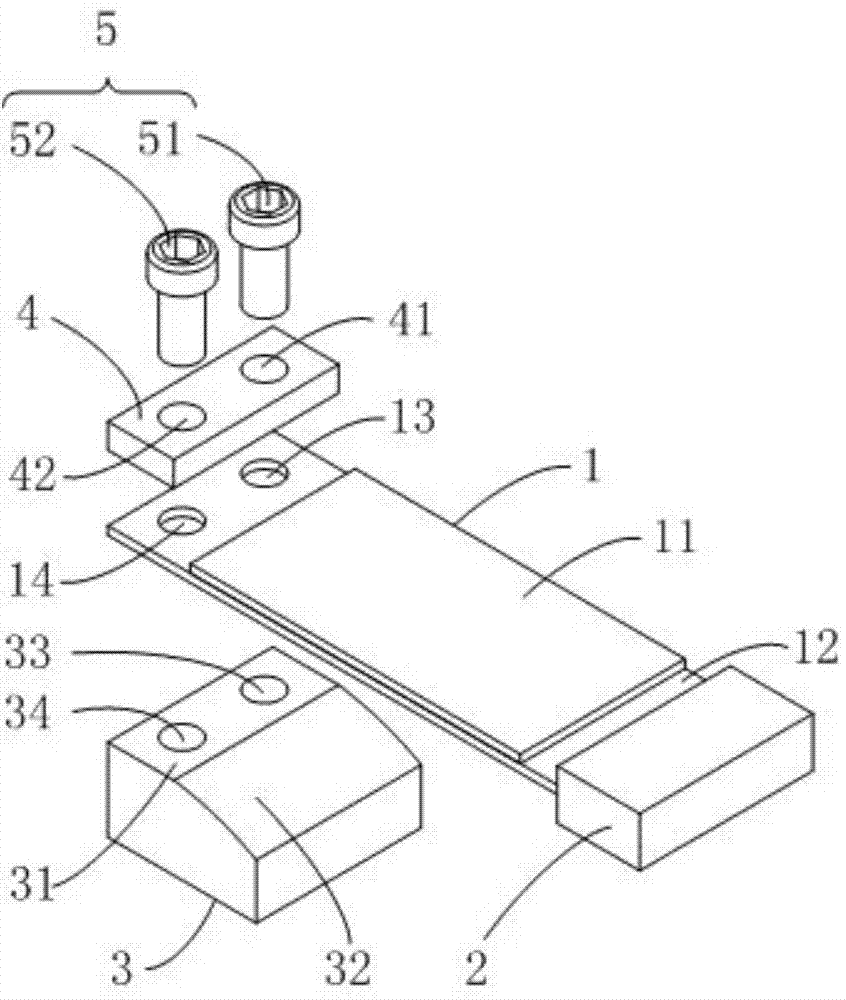

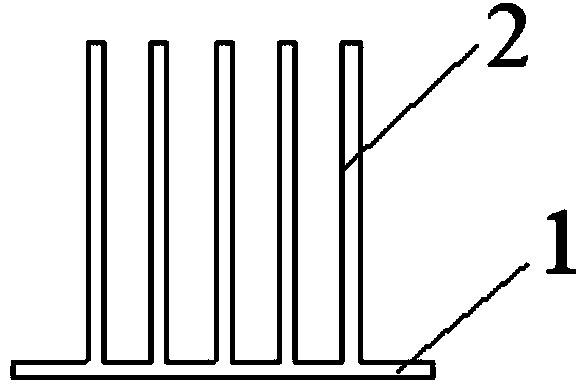

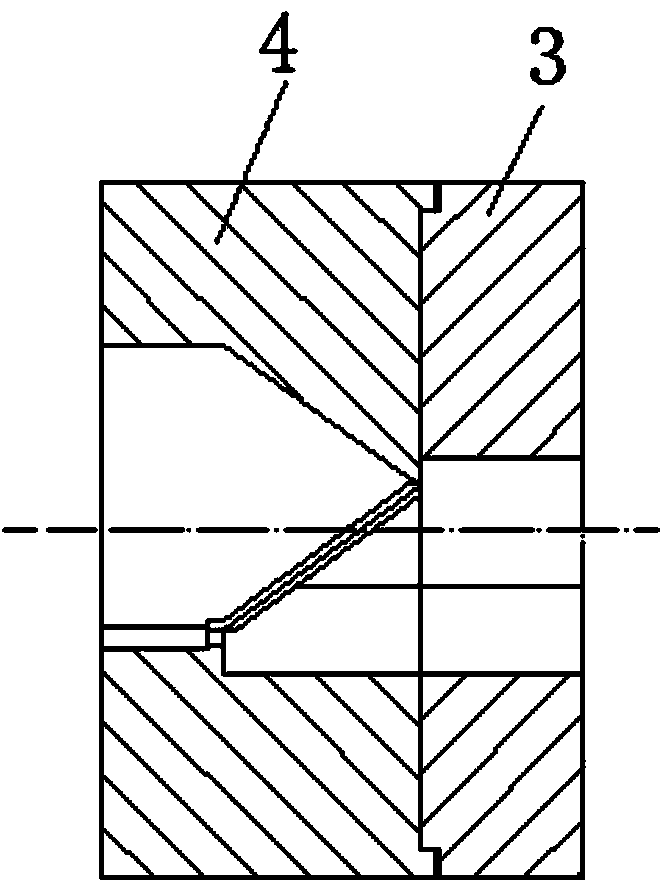

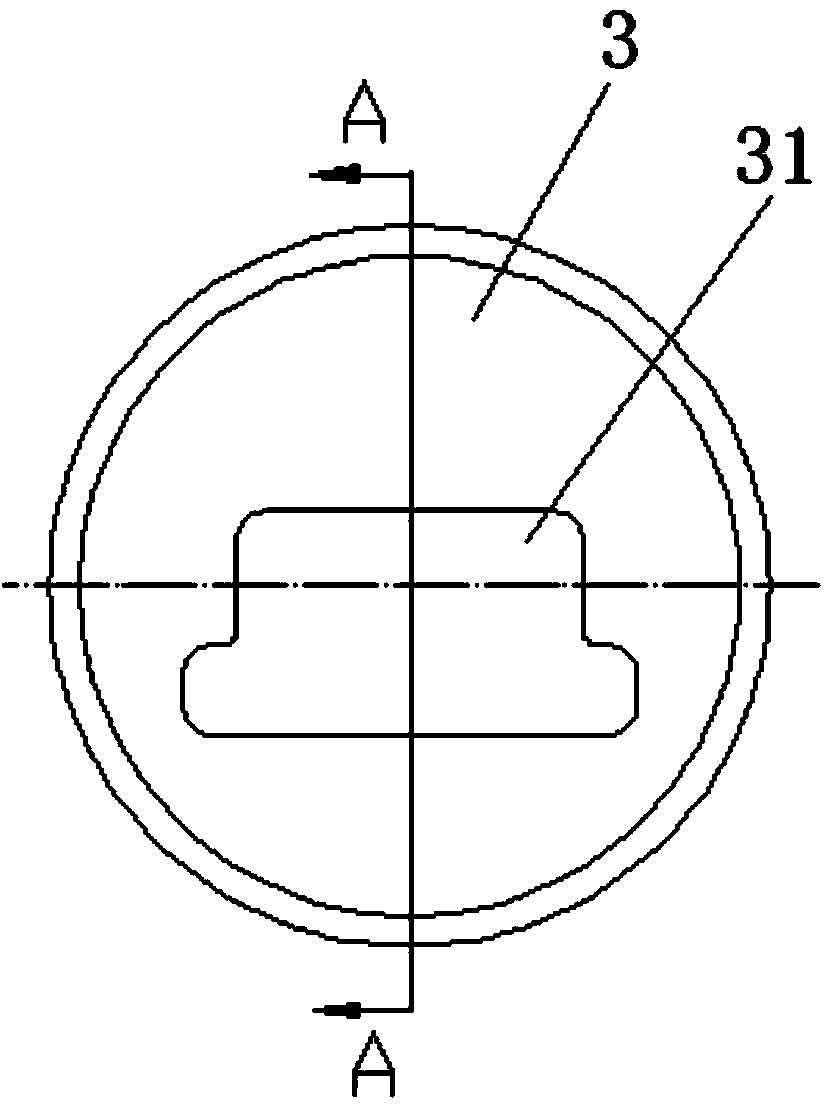

Self-adaptive piezoelectric generation cantilever beam

InactiveCN104218848AShorten the cantilever lengthIncrease stiffnessPiezoelectric/electrostriction/magnetostriction machinesElectricitySelf adaptive

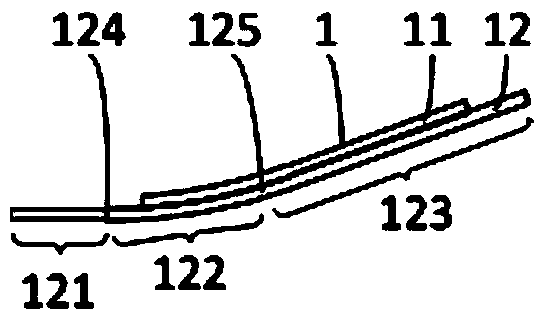

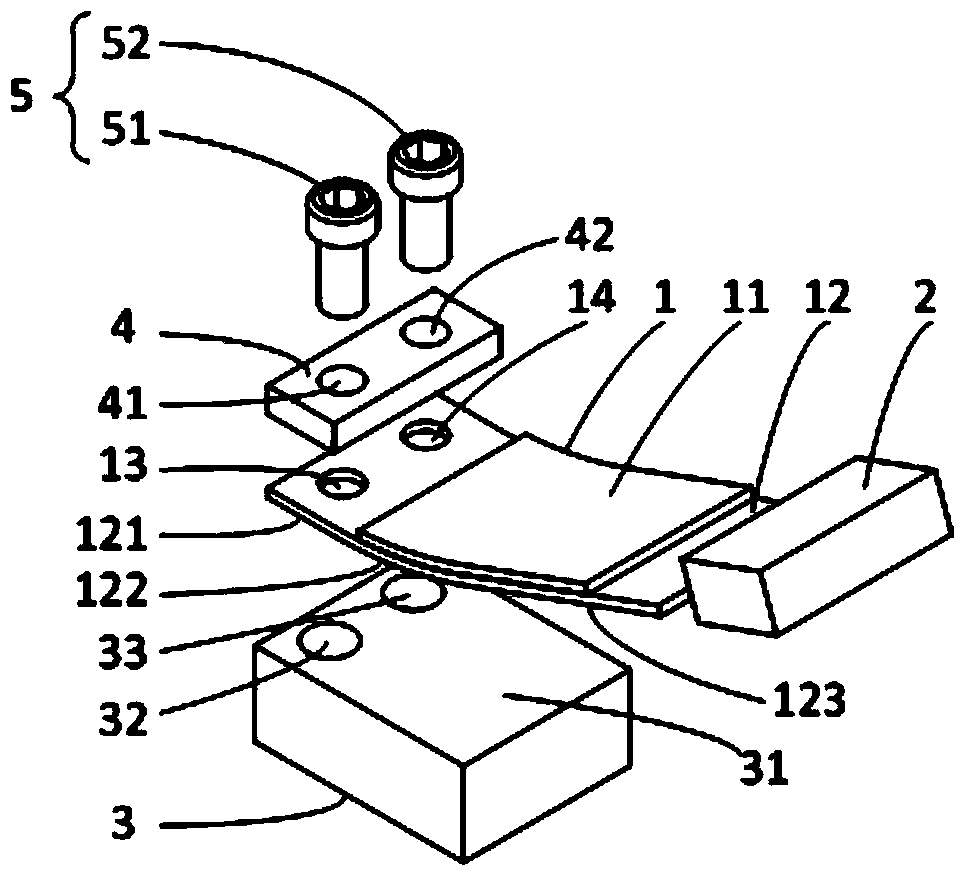

The invention relates to a self-adaptive piezoelectric generation cantilever beam. The self-adaptive piezoelectric generation cantilever beam comprises a piezoelectric vibrator (1), a free end mass block (2), a curved-surface fixed support end (3), an installation gasket (4) and a bolt (5), wherein the free end mass block (2) is arranged at one end of the piezoelectric vibrator (1), and the other end of the piezoelectric vibrator (1) is fixed on the curved-surface fixed support end (3), and fixed through the installation gasket (4) and by the bolt (5); the curved-surface fixed support end (3) is provided with a vibrator installation surface (31) and a variable support curved surface (32) adjacent to the vibrator installation surface (31); the vibrator installation surface (31) and the variable support curved surface (32) adjacent to the vibrator installation surface (31) are vertical to the side surface adjacent to the both. A system is installed on a rotation device and used as a generation device, and capable of realizing the self-adaptive changes of an inherent frequency according to a rotation speed, thus the inherent frequency bandwidth of a generation device is increased, and a generation amount is increased.

Owner:JILIN UNIV

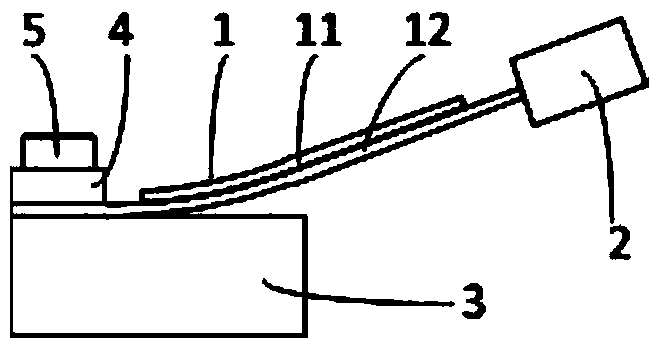

Curved surface piezoelectric power generation cantilever beam

InactiveCN104270034AShorten the cantilever lengthIncrease stiffnessPiezoelectric/electrostriction/magnetostriction machinesCantilevered beamEngineering

The invention relates to a curved surface piezoelectric power generation cantilever beam. The cantilever beam comprises a curved surface piezoelectric vibrator, a free-end mass block, a fixed supporting end, a mounting pad and bolts, wherein the curved surface piezoelectric vibrator is formed by three parts, namely, a vibrator mounting plane, a changeable supporting curved surface and a cantilever stretching-out plane, which are sequentially connected and are in smooth transition, the cantilever stretching-out plane is connected with the free-end mass block, and the vibrator mounting plane is connected with the fixed supporting end by the bolts through the mounting pad and arranged on a rotating device to serve as a power generation device. The self-adaptation change of inherent frequency can be achieved according to the change of the rotating speed, so that the inherent frequency range of the power generation device is expanded, and accordingly the power generation amount is increased.

Owner:JILIN UNIV

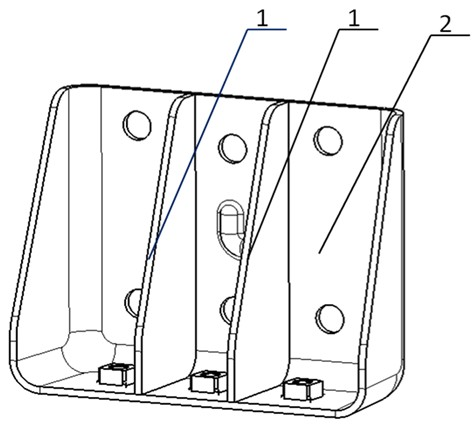

Supporting structure of automobile suspension rack

InactiveCN102029885ARaise the modal frequencyIncrease stiffnessJet propulsion mountingInternal combustion mountingEngineeringCantilever

The invention discloses a supporting structure of an automobile suspension rack, which comprises a first welding assembly and a second welding assembly. The supporting structure is characterized in that the first welding assembly comprises a first dustpan-shaped reinforcing member and two reinforcing ribs welded on the rear vertical surface and the bottom surface of the first reinforcing member, six bolt holes are arranged on the rear vertical surface of the first reinforcing member, three bolt holes are arranged on the bottom surface of the first reinforcing member; and the second welding assembly is formed by welding a second reinforcing member and a third reinforcing member and a longitudinal beam, and the second welding assembly and the suspension rack are respectively connected with the first welding assembly through bolts. The invention ensures that a surface connecting mode is formed between a front axle and the longitudinal beam so as to improve the mode frequency of the front axle, shortens the jib length of the installing surface of the suspension rack so as to improve the rigidity of the suspension rack, thereby improving the rigidity of the suspension rack. Through verification calculation, the front axle mode avoids the noise peak at 3,000 turns, and the local mode of the suspension racket also avoids 4-order driving frequency at 6,000 turns.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Multibit electro-mechanical memory device and method of manufacturing the same

ActiveUS7791936B2Reduce power consumptionImprove the level ofElectrostatic/electro-adhesion relaysNanoinformaticsBit lineEngineering

A multibit electro-mechanical memory device and a method of manufacturing the same include a substrate, a bit line on the substrate; a lower word line and a trap site isolated from the bit line, a pad electrode isolated from a sidewall of the trap site and the lower word line and connected to the bit line, a cantilever electrode suspended over a lower void in an upper part of the trap site, and connected to the pad electrode and curved by an electrical field induced by a charge applied to the lower word line, a contact part for concentrating a charge induced from the cantilever electrode thereon in response to the charge applied from the lower word line and the trap site, the contact part protruding from an end part of the cantilever electrode, and an upper word line formed with an upper void above the cantilever electrode.

Owner:SAMSUNG ELECTRONICS CO LTD

Multi-bit electro-mechanical memory device and method of manufacturing the same

InactiveUS7719068B2Shorten the cantilever lengthDegree of integration can be enhanced and maximizedTransistorSemiconductor/solid-state device manufacturingBit lineElectricity

There are provided a multi-bit electro-mechanical memory device capable of enhancing or maximizing a degree of integration of the memory device and a method of manufacturing the multi-bit electro-mechanical memory device which includes a substrate, a bit line on the substrate, and extending in a first direction; a word line on the bit line, insulated from the bit line, and extending in a second direction transverse to the first direction, and a cantilever electrode including a shape memory alloy. The cantilever electrode has a first portion electrically connected to the bit line and a second portion extending in the first direction, and spaced apart from the word line by an air gap, wherein the cantilever electrode, in a first state, is in electrical contact with the word line, and, in a second state, is spaced apart from the word line.

Owner:SAMSUNG ELECTRONICS CO LTD

Polymer shrinkage tensometer

InactiveUS6871550B2Easily adaptedReduced specimen failureImpression capsMaterial strength using tensile/compressive forcesEngineeringCantilever

An apparatus and method for measuring the characteristics of curing polymers. The apparatus and method utilize cantilever beam technology to determine characteristics of polymers during the curing process, including but not limited to, stress-related forces that develop during the polymer curing process. The apparatus and method also provide for controlling and monitoring environmental conditions during the curing process.

Owner:ADA FOUND

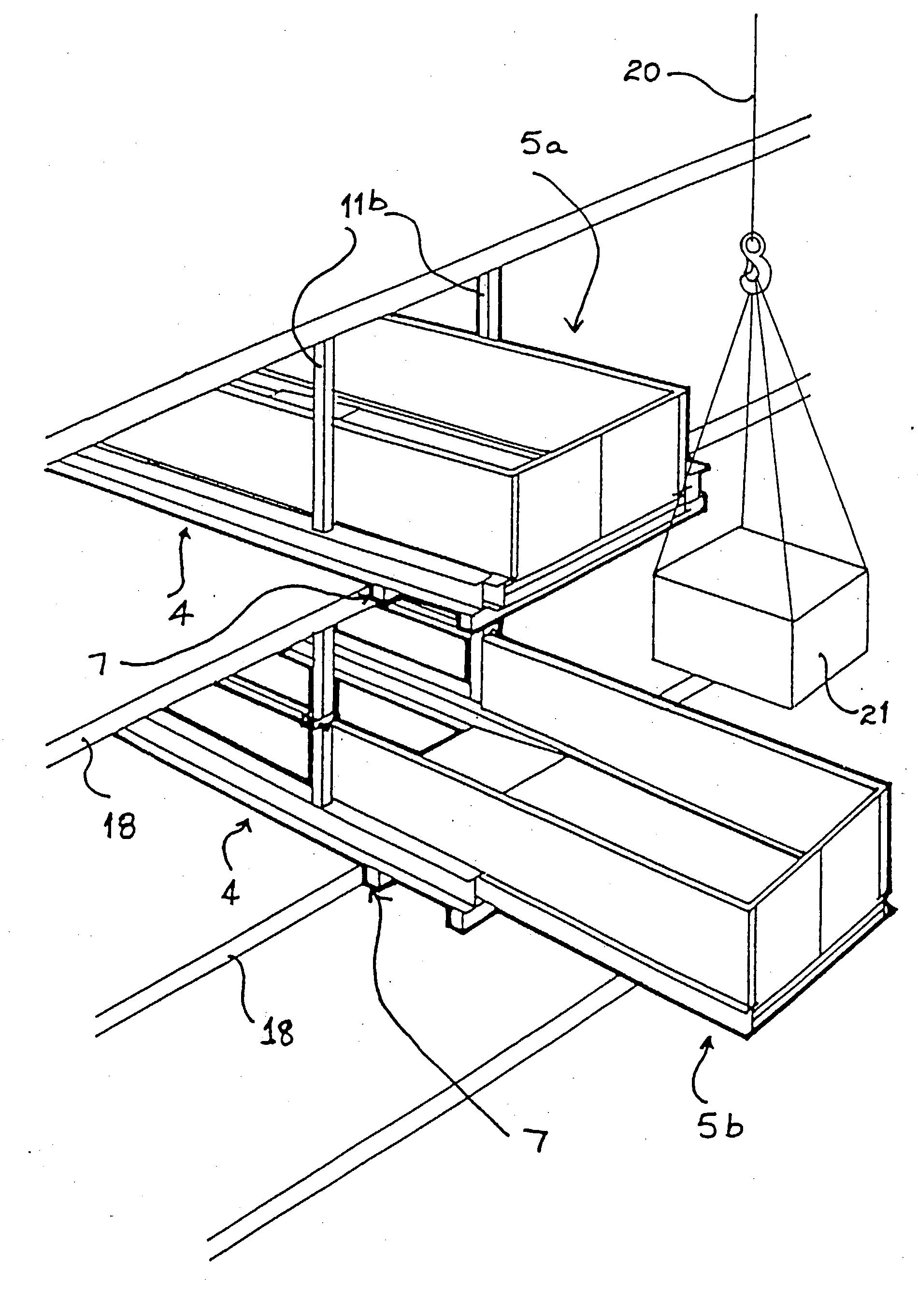

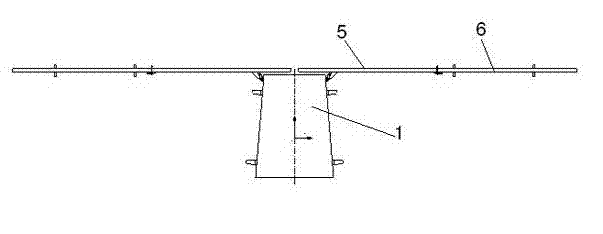

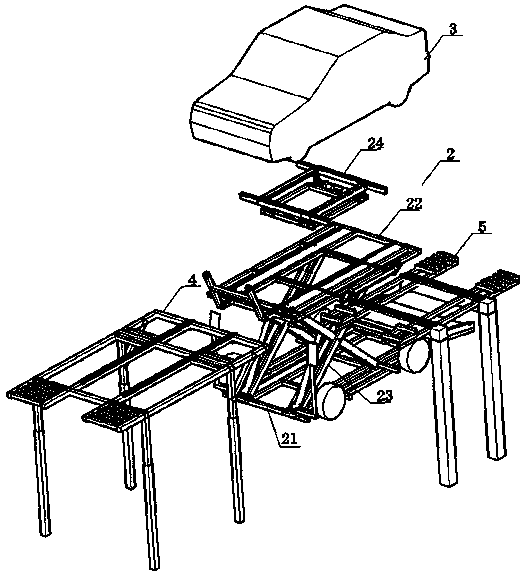

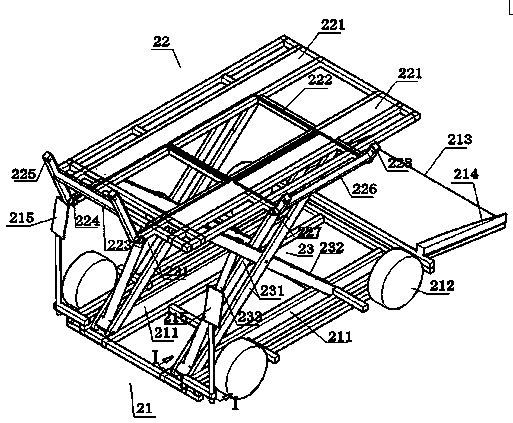

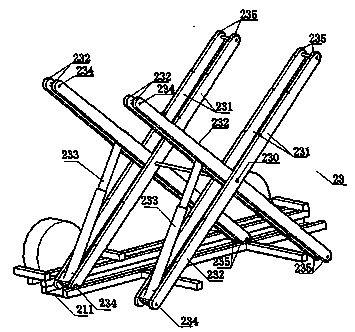

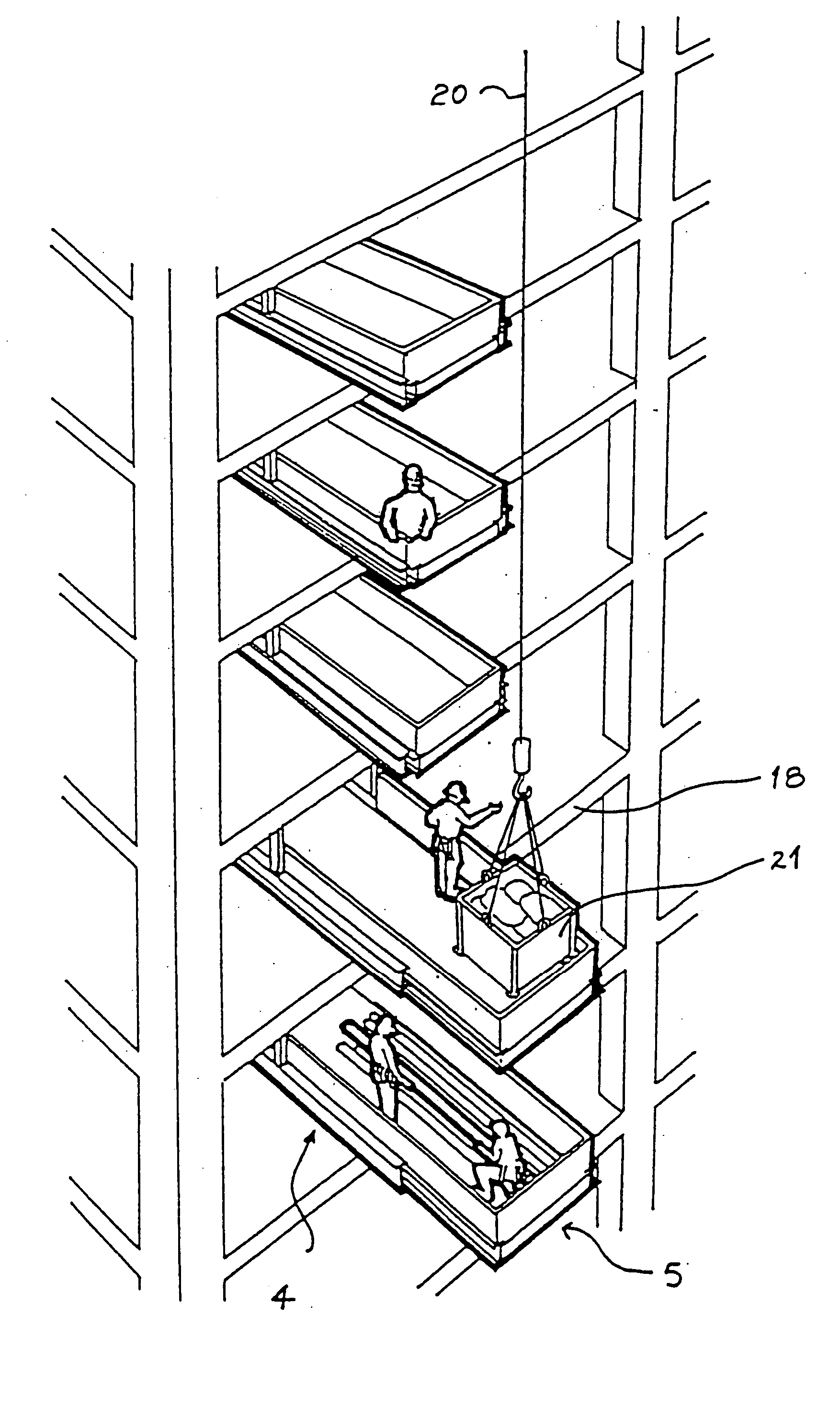

Machine and frame combination parking method and equipment system for implementing same

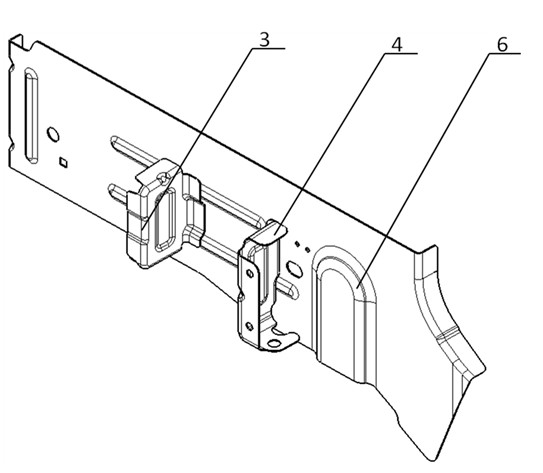

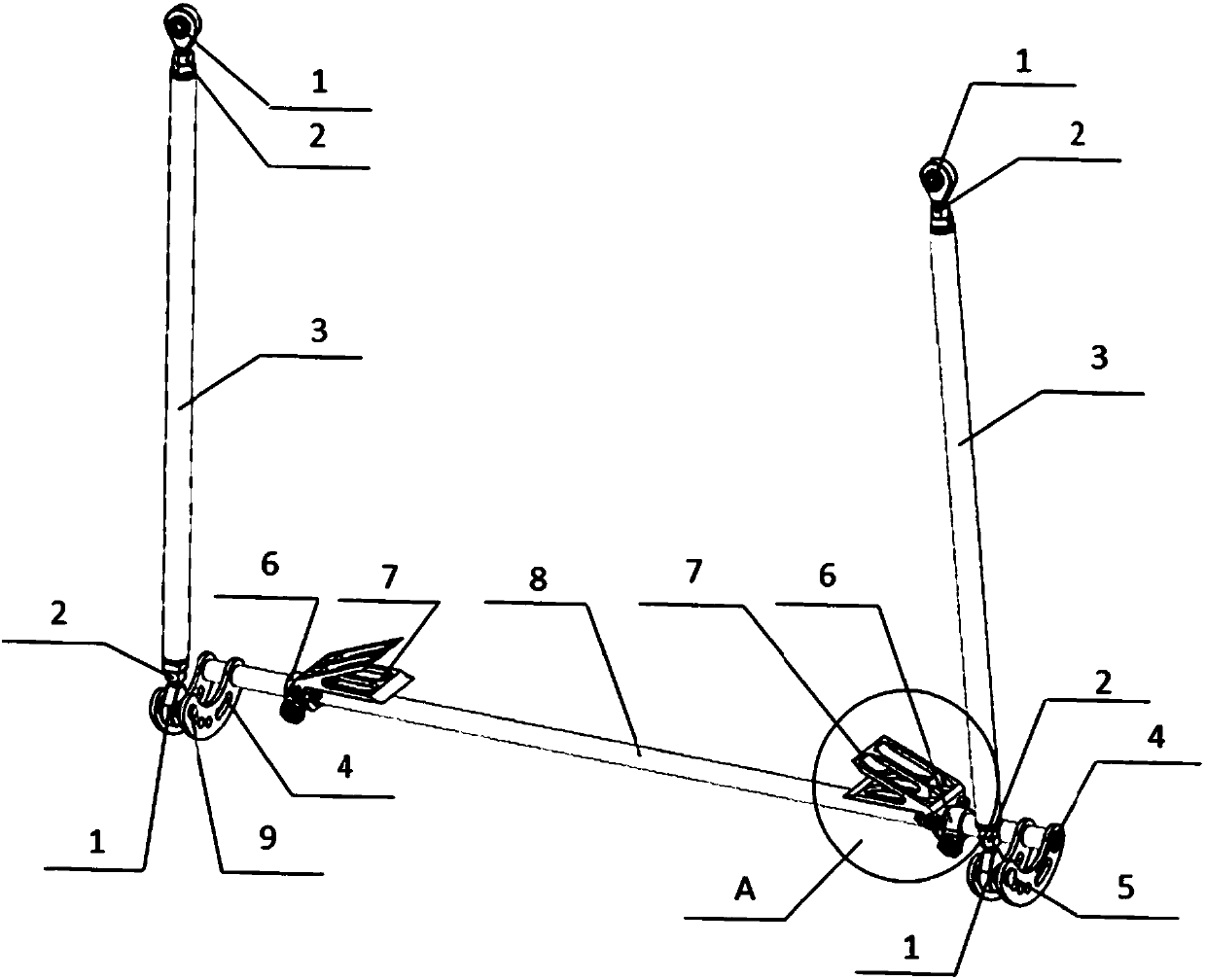

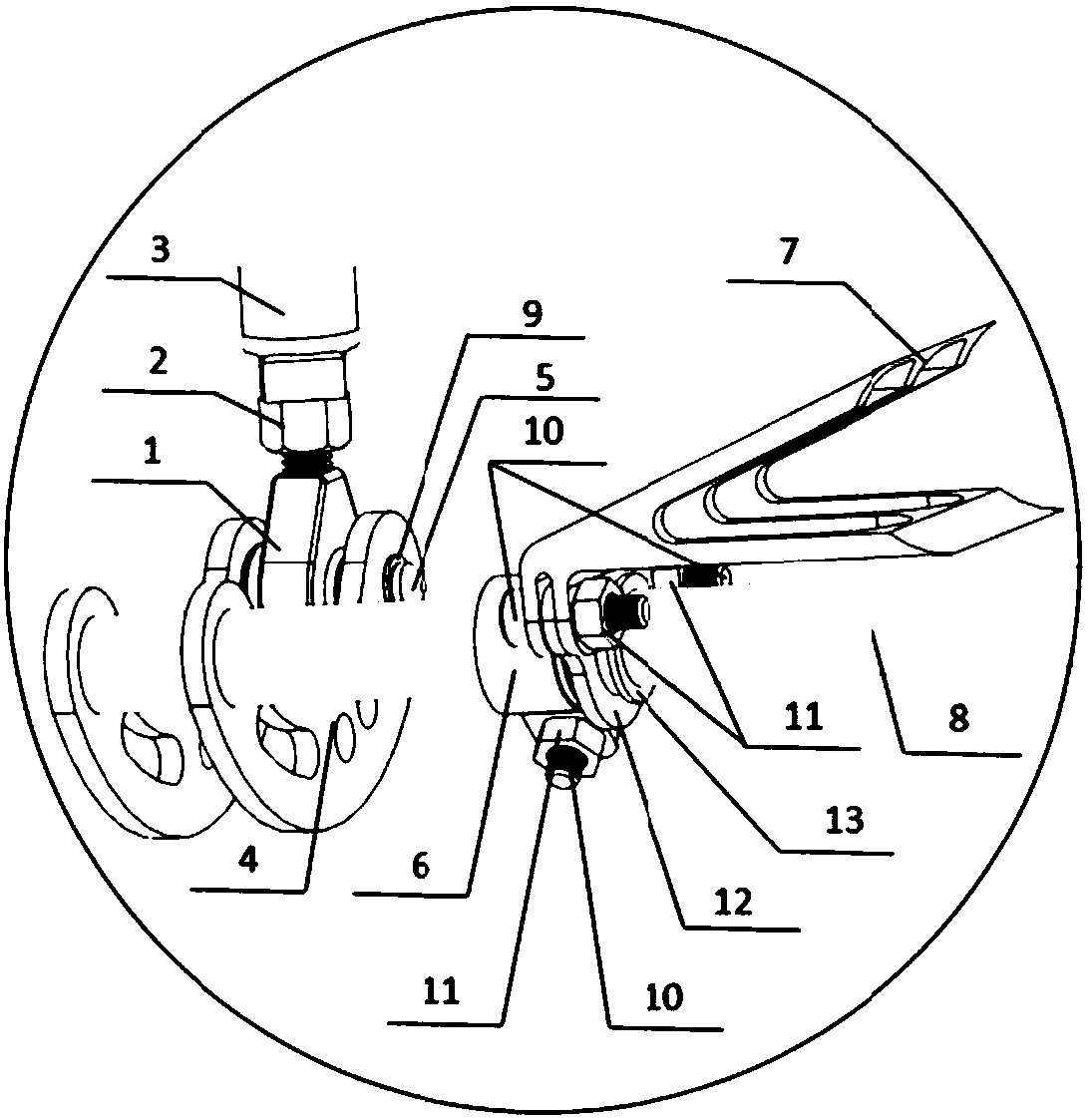

The invention relates to a machine and frame combination parking method and an equipment system as is shown in Figure 1. According to the method, a parking machine is combined with parking frames to park cars into a space above parking spaces, or a sidewalk surface between roadside trees and supports of the sidewalk surface. The method comprises the key steps that a car runs onto the parking machine, planar location of the parking machine is carried out, a main crane boom is lifted, a connecting beam of the parking machine is connected with one parking frame, a traveling crane conveys the car to the parking frame, and the traveling crane returns to the parking machine. The equipment system comprises a combination of the parking machine and the certain number of longitudinal or transverse parking frames, or a combination of the parking machine and a certain number of sidewalk parking frames and sidewalk surface parking spaces. Through light equipment, the cars can be parked in the space above the ground parking spaces and the space, bringing inconvenience to pedestrians, between the roadside trees of a city sidewalk, and therefore the purposes of lowering parking difficulty, reducing road occupation of parking and relieving traffic congestion can be achieved.

Owner:何儒清

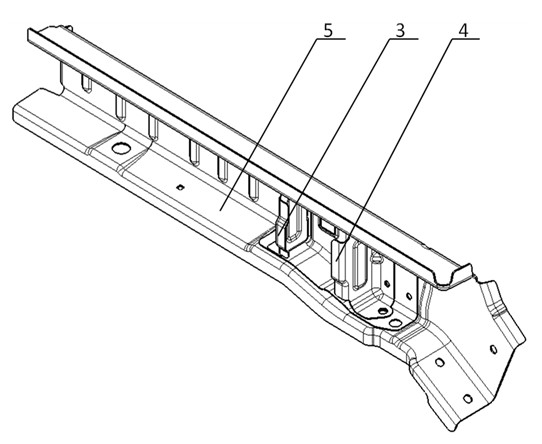

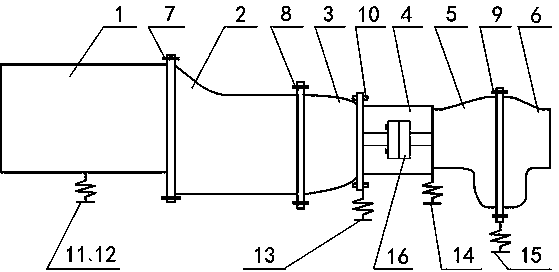

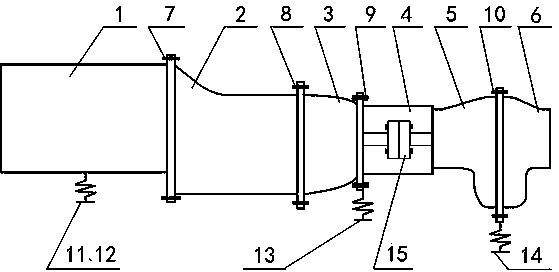

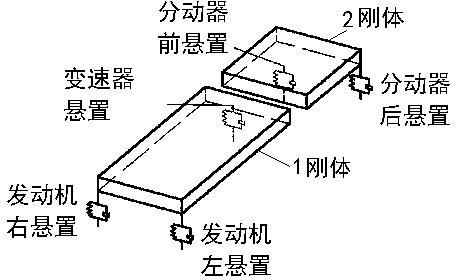

Arrangement method and structure of power assembly for long-wheelbase four-wheel-drive automobile

InactiveCN103448525AShorten the cantilever lengthReduce alternating load stress amplitudeJet propulsion mountingInternal combustion mountingTransfer caseBlocked Connection

Disclosed is an arrangement method and structure of a power assembly for a long-wheelbase four-wheel-drive automobile. The structure is characterized by comprising a power assembly suspension system, a power assembly three-shell block connection, and a transmission shaft connection. The power assembly suspension system comprises an engine left suspension, an engine right suspension, a transmission suspension, a transfer case front suspension and a transfer case rear suspension. The power assembly three-shell block connection is characterized in that an engine housing is rigidly connected with a transmission front shell through bolts; the transmission front shell is rigidly connected with a transmission rear shell through bolts; the transmission rear shell is flexibly connected with a transition plate through a rubber elastic bushing added between the bolts and mounting holes; the transition plate is rigidly connected with a transfer case through bolts; a transfer case front shell is rigidly connected with a transfer case rear shell through bolts. The structure has the advantages that vibration reduction and noise reduction are simultaneous, the change range of the amplitude of stress borne by the power assembly three-shell can be reduced greatly, chances for fatigue breakage of the three-shell are slimmed, and vehicles can be comfortable and reliable to use.

Owner:NANJING UNIV OF TECH +1

Method and mold for continuously and gradually extruding high-rib profile

ActiveCN104014607AShorten the cantilever lengthExtended service lifeExtrusion diesCantileverMaterials science

The invention provides a method and mold for continuously and gradually extruding a high-rib profile. The mold comprises an upper mold and a lower mold. A central position of the upper mold is provided with a deflector hole; a front end surface of the lower mold is provided with a material dodging hole; the upper part of the material dodging hole is provided with a plurality of grooves and teeth which are distributed alternatively side by side; gaps are provided between the teeth and the bottom surface of the material dodging hole; the plurality of grooves and teeth extend to the back end surface of the lower mold; the height of the grooves increases linearly from the teeth end of the teeth until the height is identical to that of the high-rib teeth of the high-rib profile; edges of end parts of the teeth extend obliquely from the top of the material dodging hole and from the top to bottom; end parts of the teeth are in a truncated cone-shaped cleaver head structure; and inlet ends of the grooves are provided with working bands. A gradually changing structure is adopted by the grooves and the teeth; the teeth ends are provided with cleaver head, so that gradual shaping and radial flowing of the metal are realized in an extrusion and deformation process. Meanwhile, the length of the suspension arm is reduced by a half; and the service life of the mold is increased qualitatively.

Owner:JIANGSU UNIV

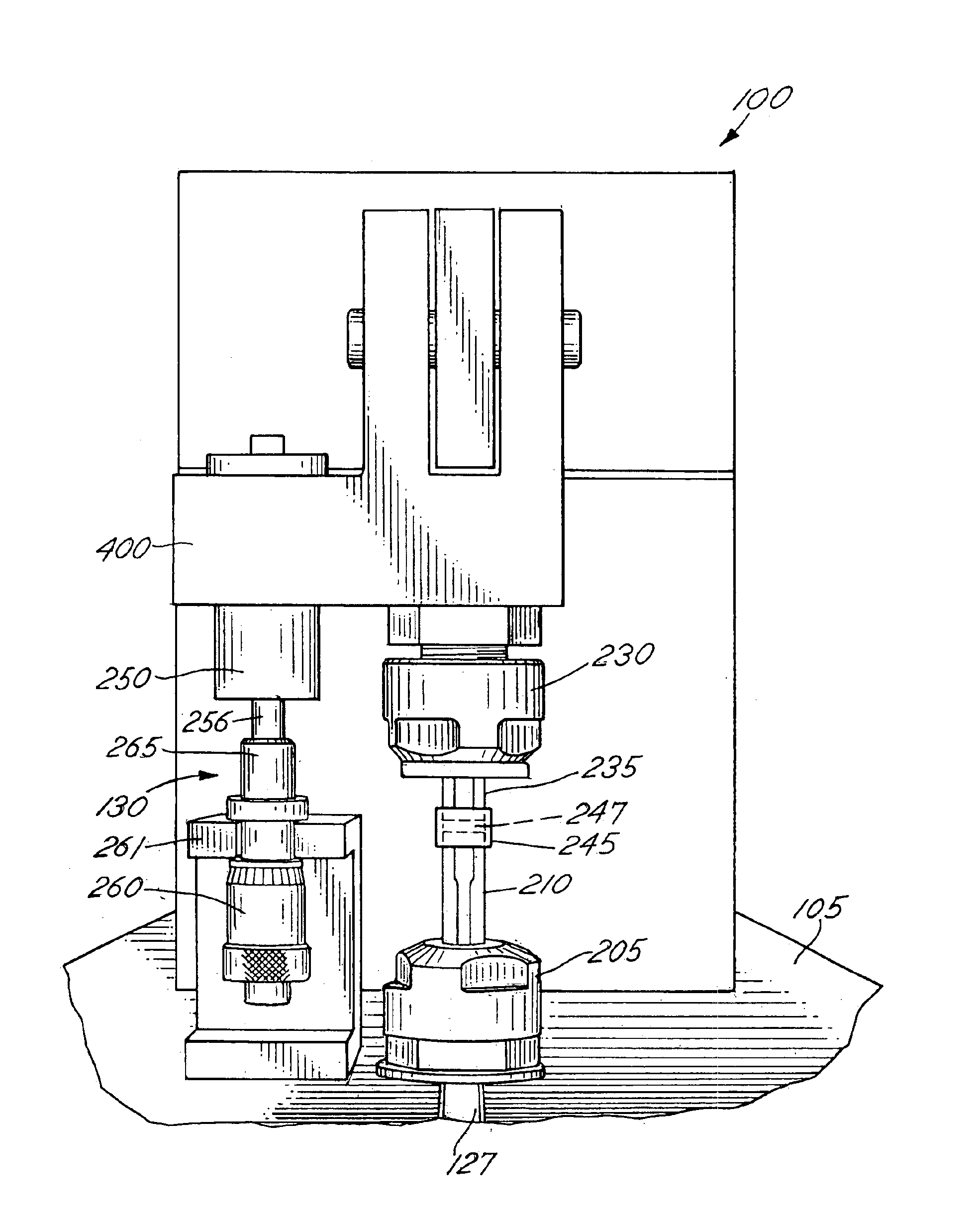

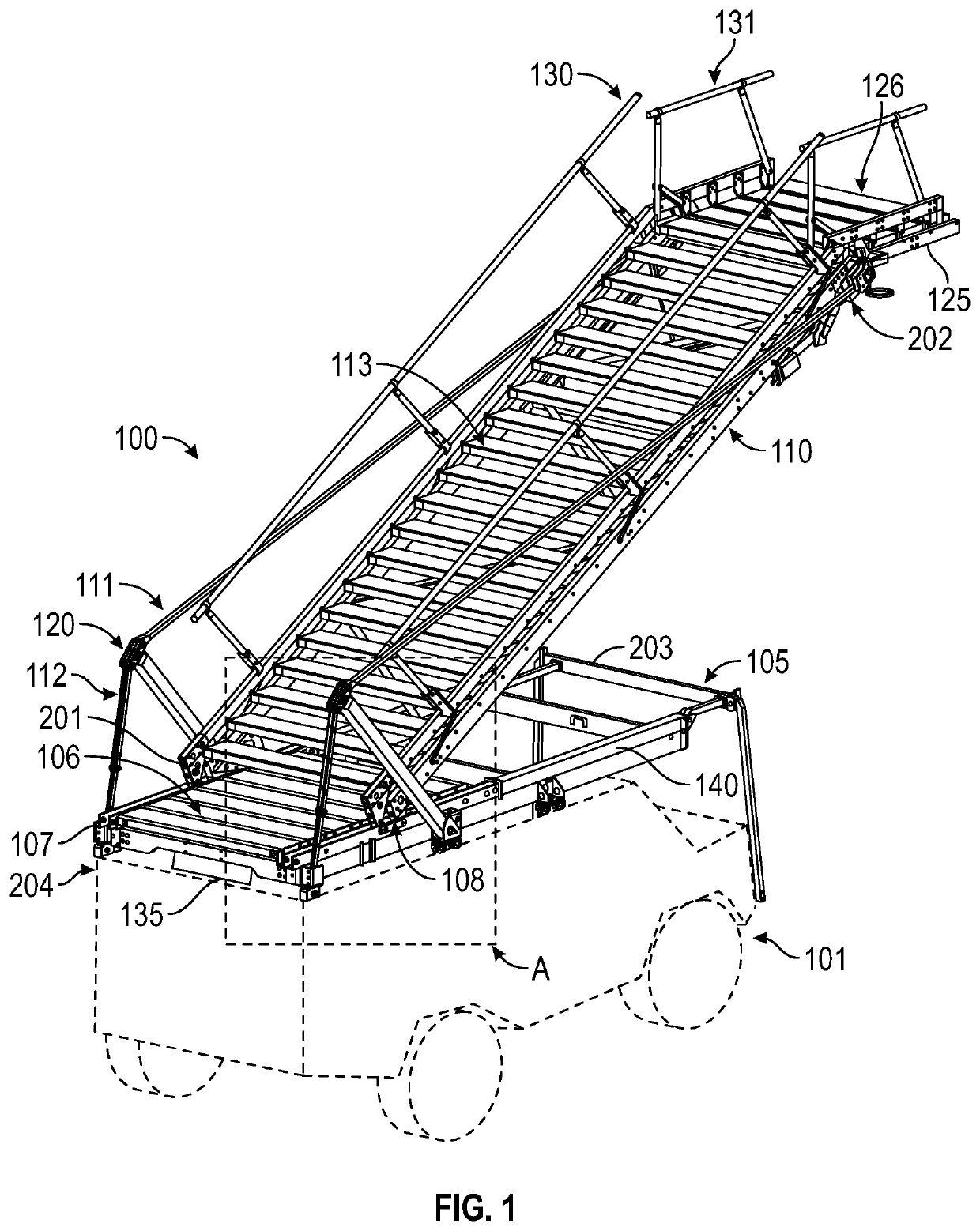

Vehicle-mounted elevated access system

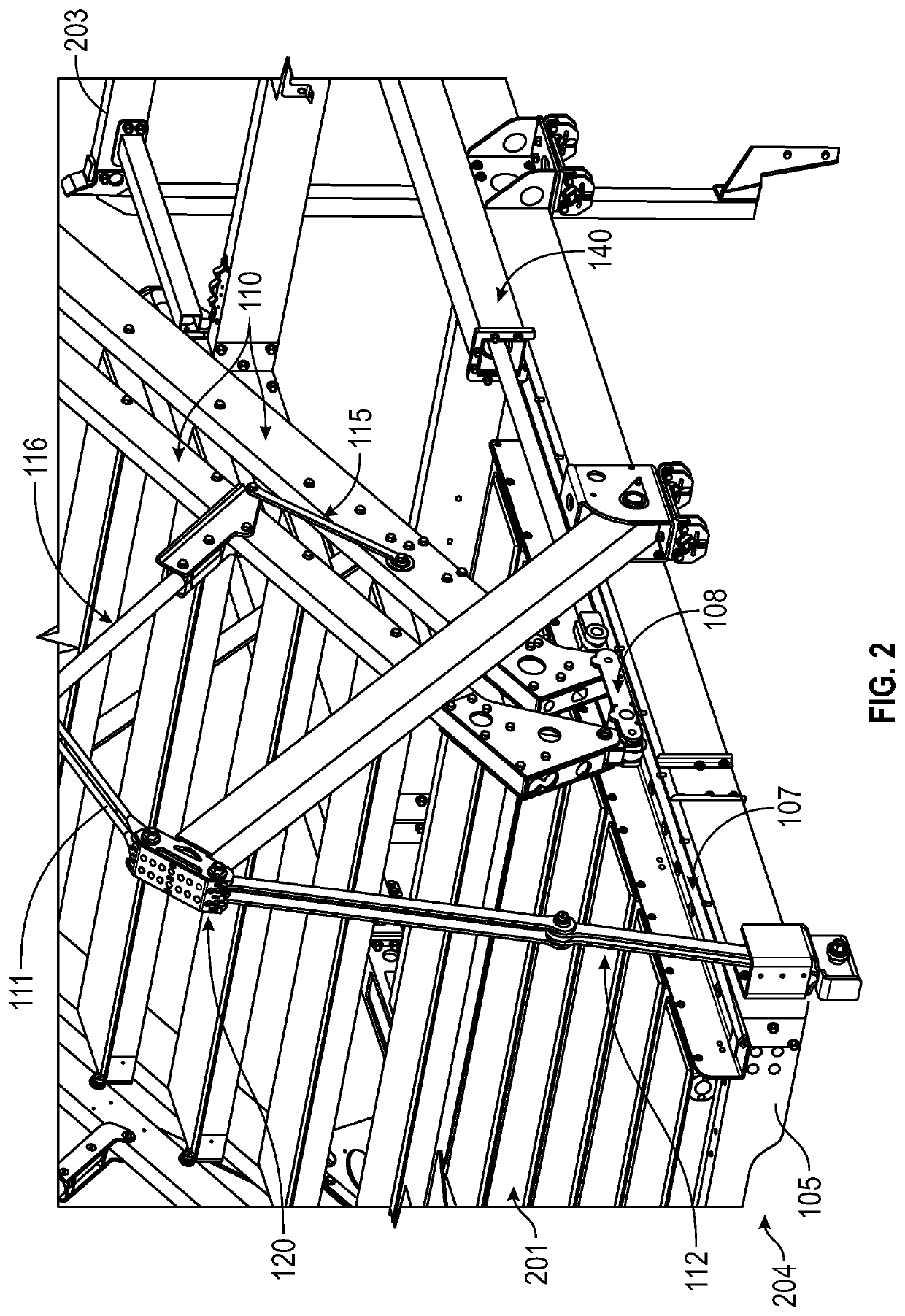

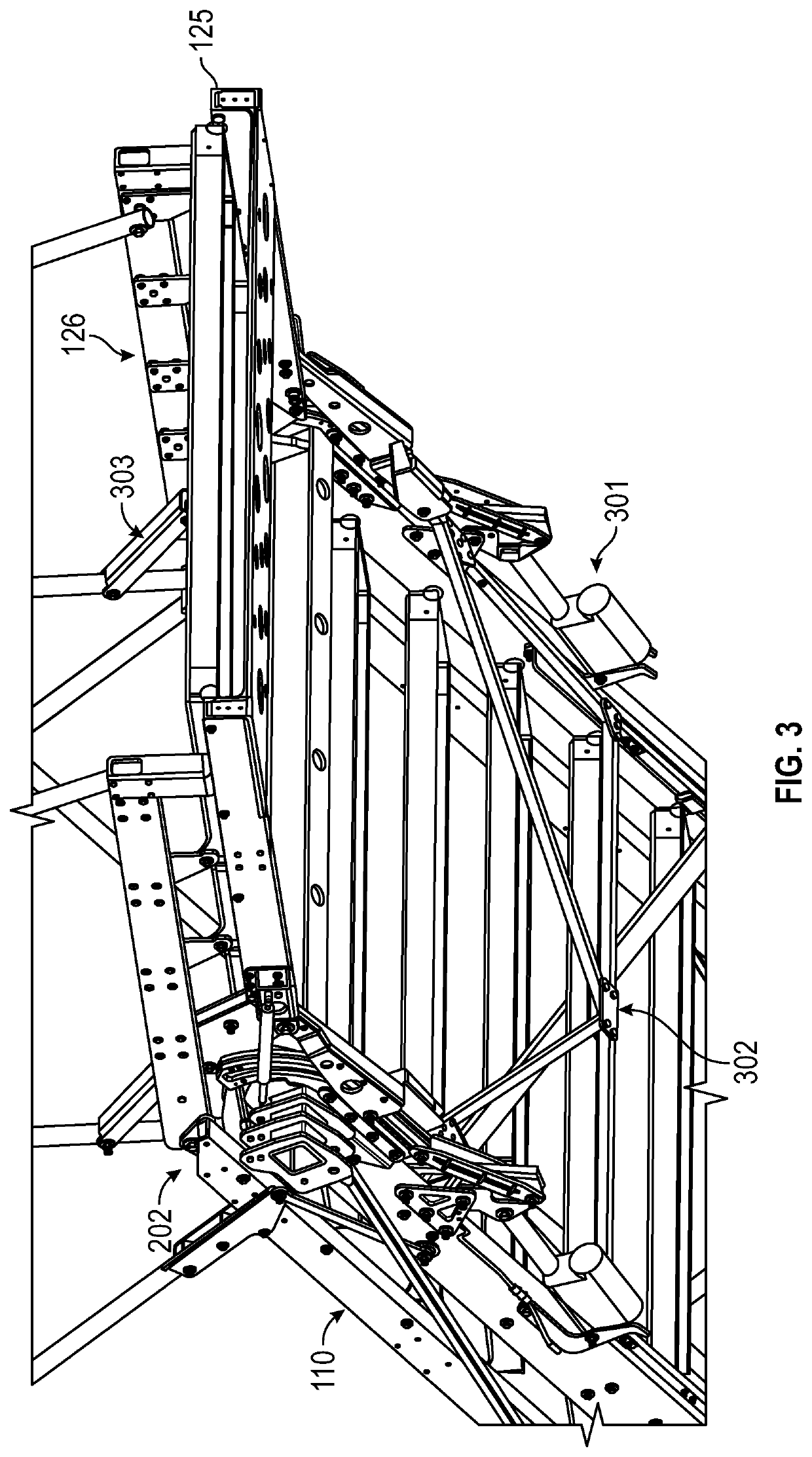

ActiveUS20200157884A1Increase horizontal rangeShorten the cantilever lengthGround installationsLaddersAccess structureInto-structure

A vehicle-mounted access system includes a fixed base structure including a plurality of track channels; a plurality of movable hinge carriages configured to move along the plurality of track channels; an inclinable access structure pivotably connected to the movable hinge points and connected to lifting masts by forward tension elements, lifting masts connected to the fixed base structure by rear tension elements and pivotably connected to the fixed base structure; an actuator connected between the movable hinge carriages and the fixed base structure, the actuator configured to move the movable hinge carriages to raise the distal end of the inclinable access structure via the forward tension elements, the lifting mast, and the rear tension elements.

Owner:CLEMENTE JOSHUA

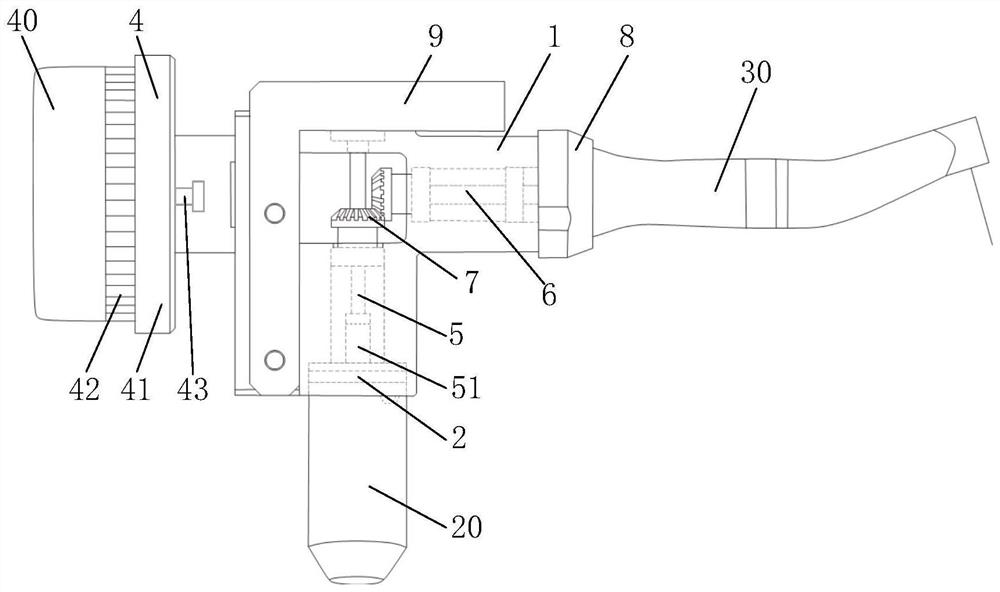

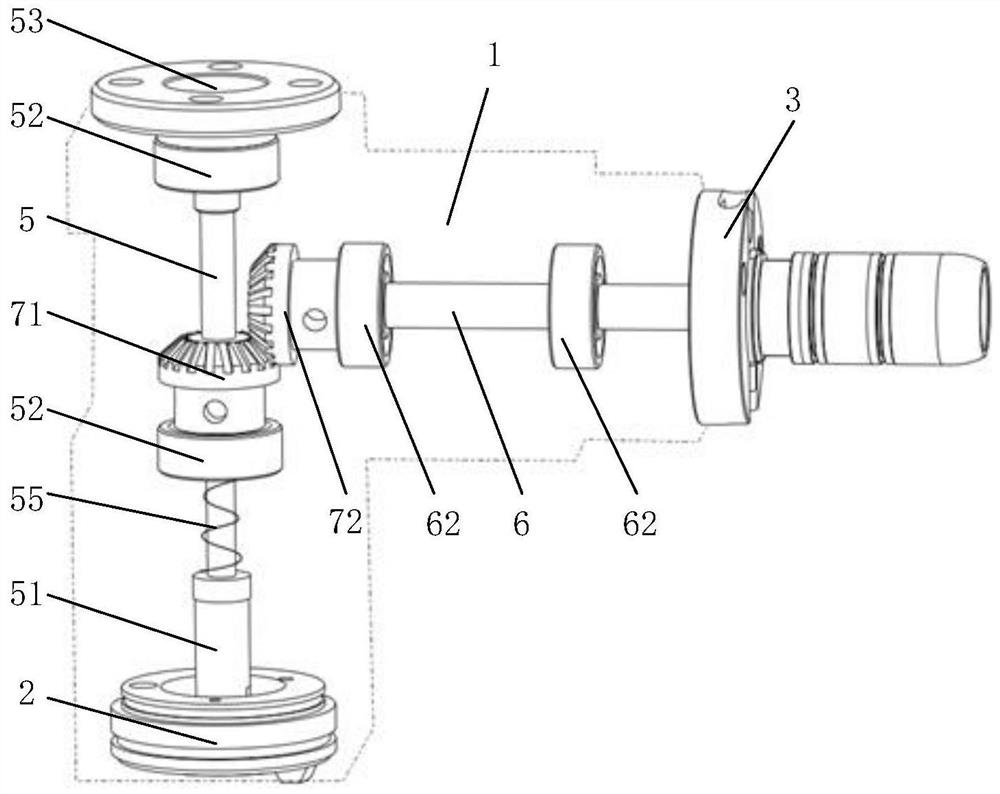

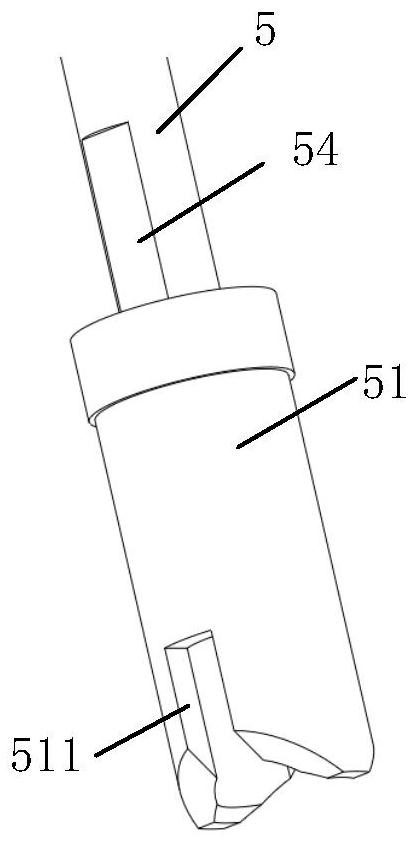

Quick-changing device for planting machine

PendingCN113317894AShorten the cantilever lengthHigh precisionDental implantsDental toolsDrive shaftControl engineering

The invention provides a quick-changing device for planting machine, which comprises a supporting body, a motor mounting connector is arranged at a first end of the supporting body, a machine head mounting connector is arranged at a second end of the supporting body, and a robot connecting piece is arranged at a third end of the supporting body; a driving shaft and a driven shaft in transmission connection with the driving shaft are installed in the supporting body, a motor transmission piece is arranged at the input end of the driving shaft, and the motor transmission piece can be in butt joint with the output end of the motor; a machine head transmission piece is arranged at the output end of the driven shaft and can be in butt joint with the input end of the machine head. According to the quick-changing device for planting machine, the motor and the machine head of the planting machine can be quickly changed, the interchangeability and usability of equipment are improved, meanwhile, the length of a cantilever of the planting machine is shortened, the overall structural rigidity is improved, and therefore the precision of a surgical robot using the planting machine to conduct a dental operation is improved.

Owner:BEIJING YAKEBOT TECH CO LTD

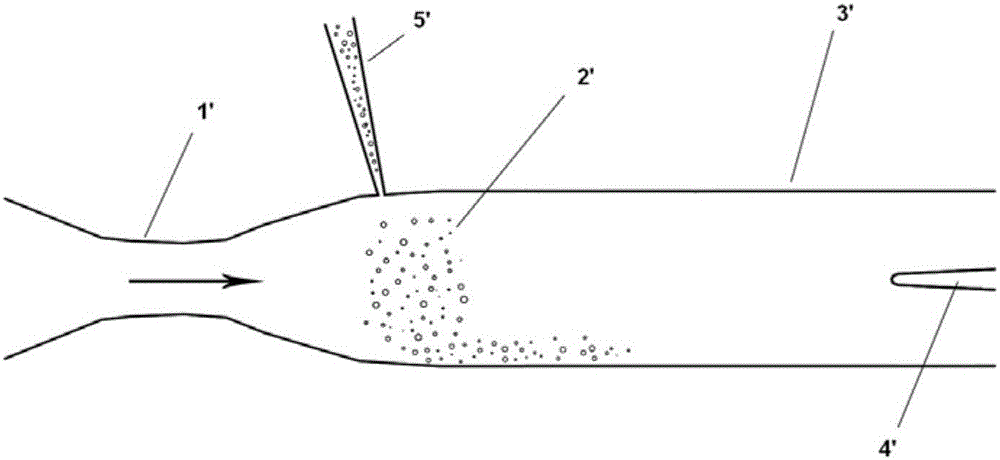

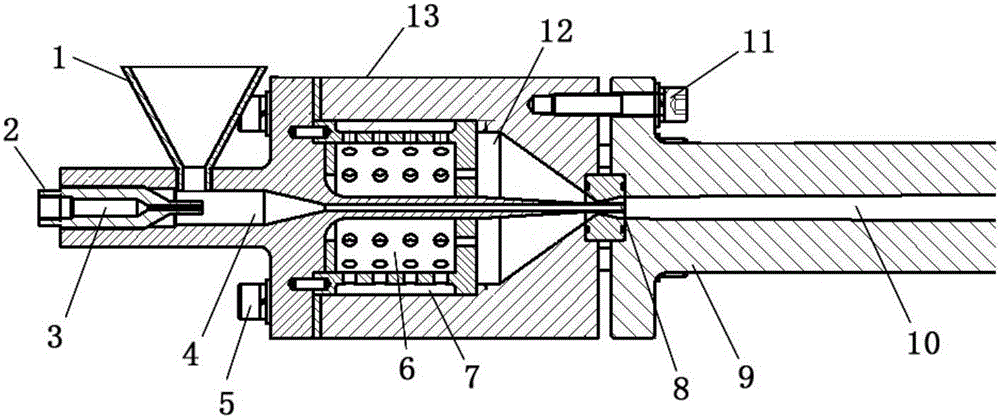

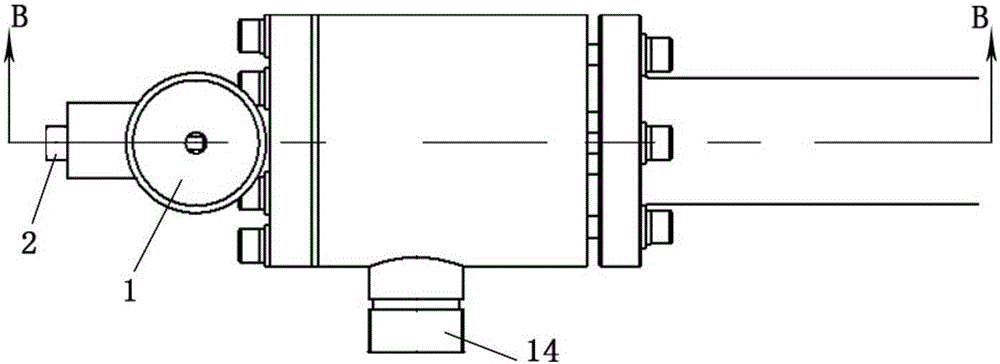

Device of feeding solid powder into high-speed air flow

The invention provides a device of feeding solid powder into a high-speed air flow. The device mainly comprises a supersonic spray pipe, a lateral annular pore plate gas inlet barrel, an auxiliary feeding nozzle, a charging cabin, a feeding pipe and the like. Gas enters through the lateral annular pore plate gas inlet barrel and carries materials fed from the charging cabin and the feeding pipe to collide with a target if being accelerated by the supersonic spray pipe, and the auxiliary feeding nozzle can feed in an auxiliary manner, so that the problem that a powdery material which is fed is likely to block is solved.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

Rotor assembly

ActiveUS9624940B2Increase stiffnessHigh sub-critical speedRolling contact bearingsPump componentsImpellerCantilever

Owner:DYSON TECH LTD

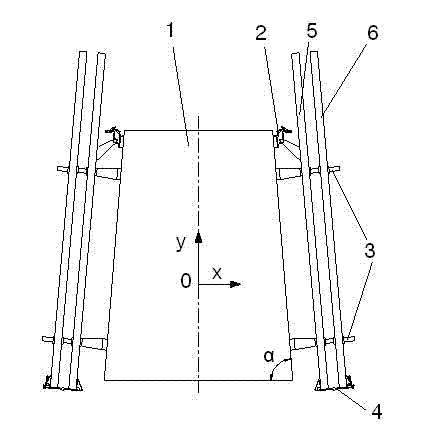

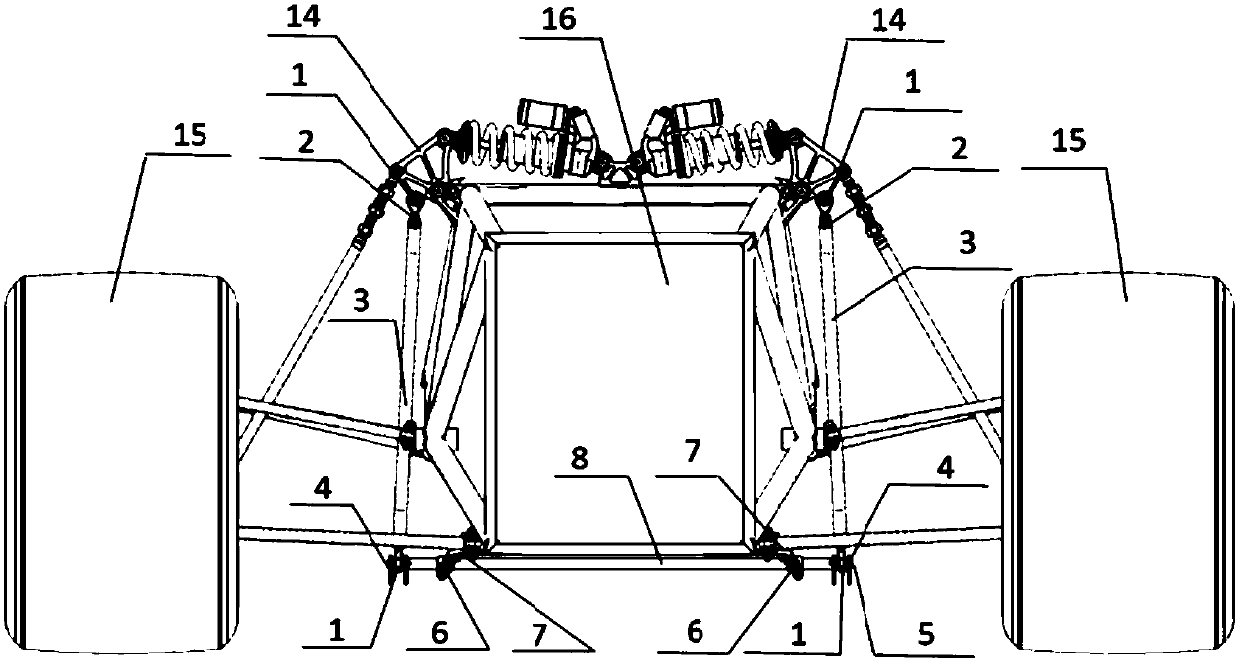

Stabilizer bar system for Formula SAE race car and operation method of stabilizer bar system

ActiveCN107745617AExtended Design Adjustment RangeShorten the lengthInterconnection systemsFormula SAECopper

The invention provides a stabilizer bar system for a Formula SAE race car. The stabilizer bar system comprises bar end bearings (1), M6 nuts (2), tie bars (3), adjusting arms (4), bolts (5), clampingsleeves (6) , upper fixing lugs (7), a torsion bar (8) and shaft circlips (9). The stabilizer bar system adds detachable copper sleeves between the torsion bar and the fixing lugs of a stabilizer barto reduce the friction resistance of the stabilizer bar system, and realizes the necessary replacement according to the wear condition of the copper sleeves so as to ensure the consistency of actual parameters with design parameters of the stabilizer bar system as much as possible; and at the same time, by optimizing the structure of the upper fixing lugs (7) and decreasing the cantilever length of the torsion bar (8), the stabilizer bar system reduces the influence on the roll stiffness provided by the stabilizer bar system due to the bending deformation of the torsion bar (8).

Owner:HUNAN UNIV

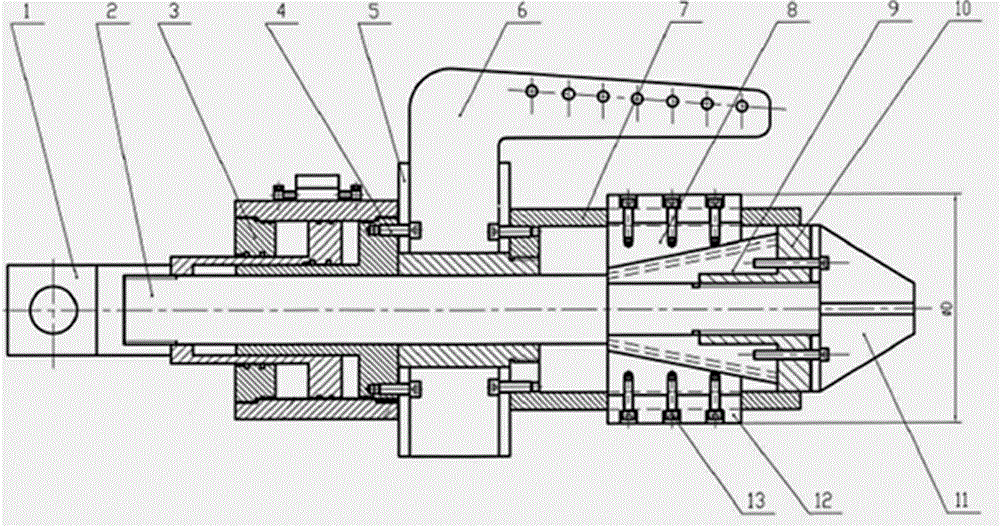

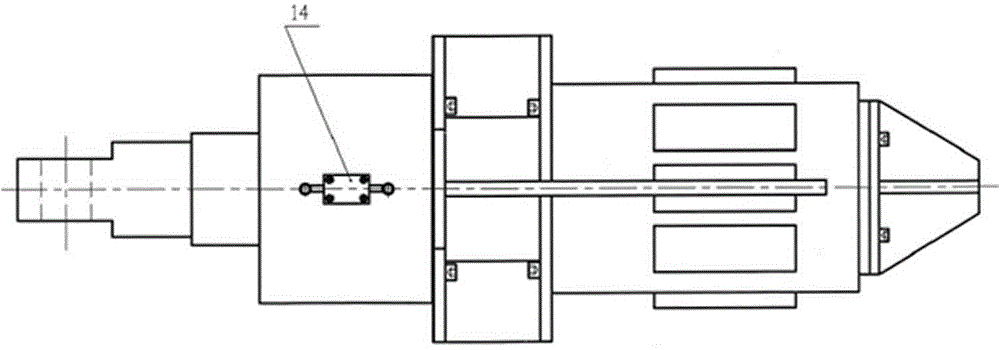

Steel pile pipe internal expansion type pile lifter

ActiveCN104863156AShorten the cantilever lengthEasy pipingBulkheads/pilesCircular coneStructural engineering

Disclosed is a steel pile pipe internal expansion type pile lifter. A lifting lug, a center shaft, a hollow oil cylinder, a connecting base, a guiding cylinder, an axial movement conical wedge and a bearing baffle ring are sequentially installed on the same axis to form a driving cone body. The lifting lug and the hollow oil cylinder are located on the upper portion of the center shaft. The axial movement conical wedge and the bearing baffle ring are located on the lower portion of the center shaft. The hollow oil cylinder is connected with the upper portion of the connecting base through a connecting bolt. The guiding cylinder is connected with the lower portion of the connecting base through a connecting bolt. A balancing suspension arm is welded to the connecting base. The center shaft penetrates through the connecting base. T-shaped grooves are evenly formed in the conical surface of the axial movement conical wedge and matched with T-shaped beams on radial movement wedges. Rectangular windows are evenly distributed in the circumferential direction of the guiding cylinder and matched with the radial movement wedges. The steel pile pipe internal expansion type pile lifter has the advantages that machining difficulty is reduced, improving quality can be improved easily, machining period is shortened, machining cost is reduced, purchasing, piping, installation and maintenance are facilitated, and due to the fact that the hollow oil cylinder is arranged outside, working area is larger, and larger expansion force can be provided.

Owner:中石化石油工程技术服务有限公司 +1

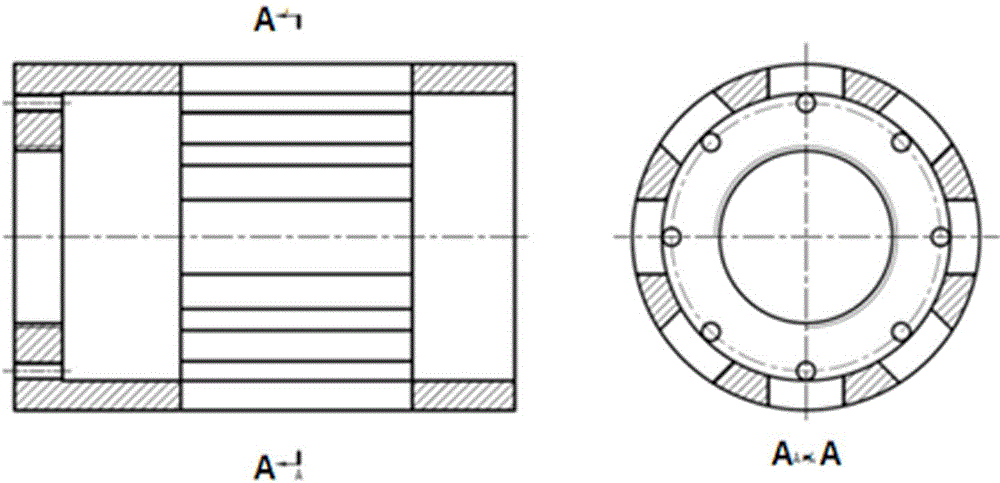

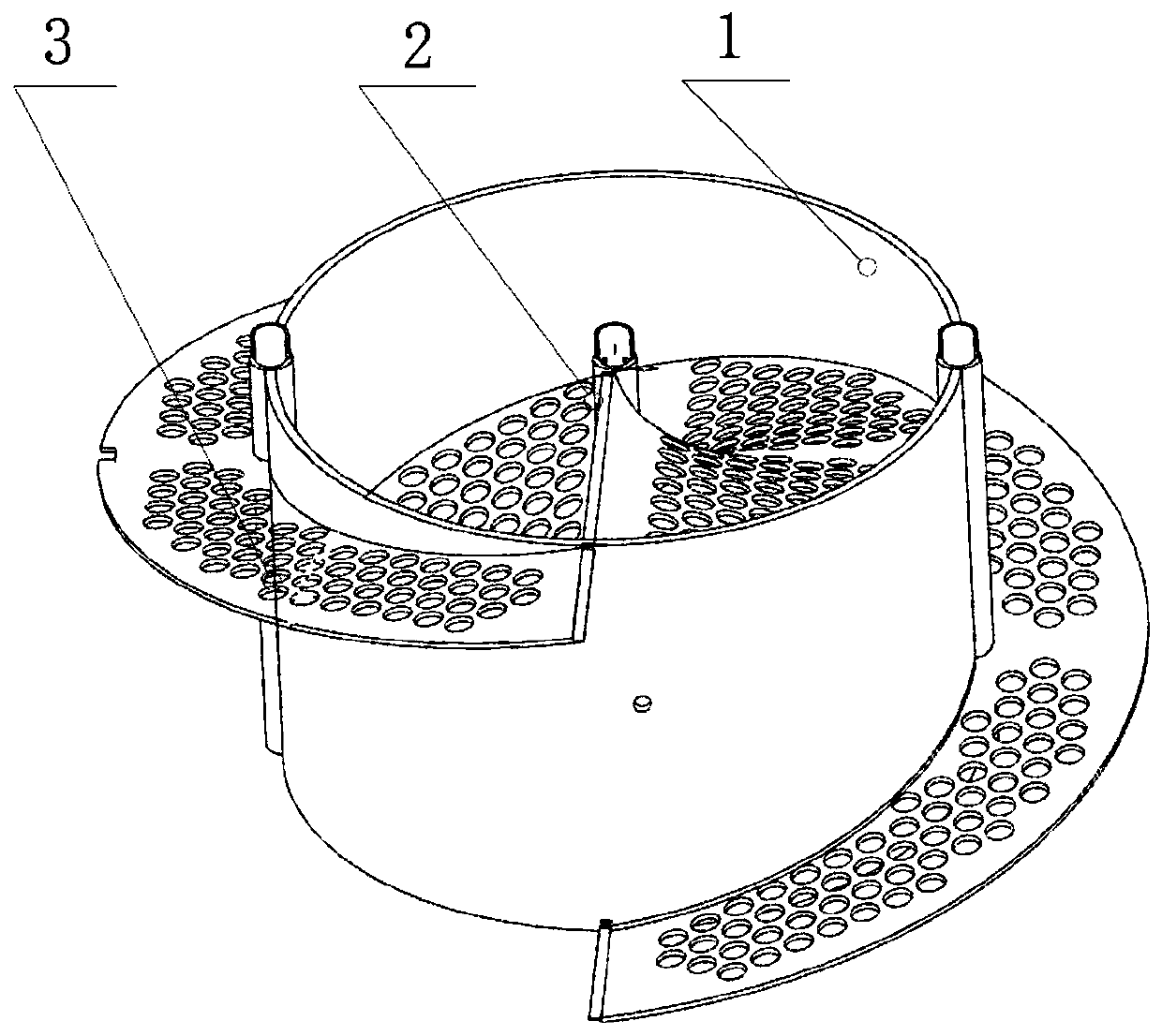

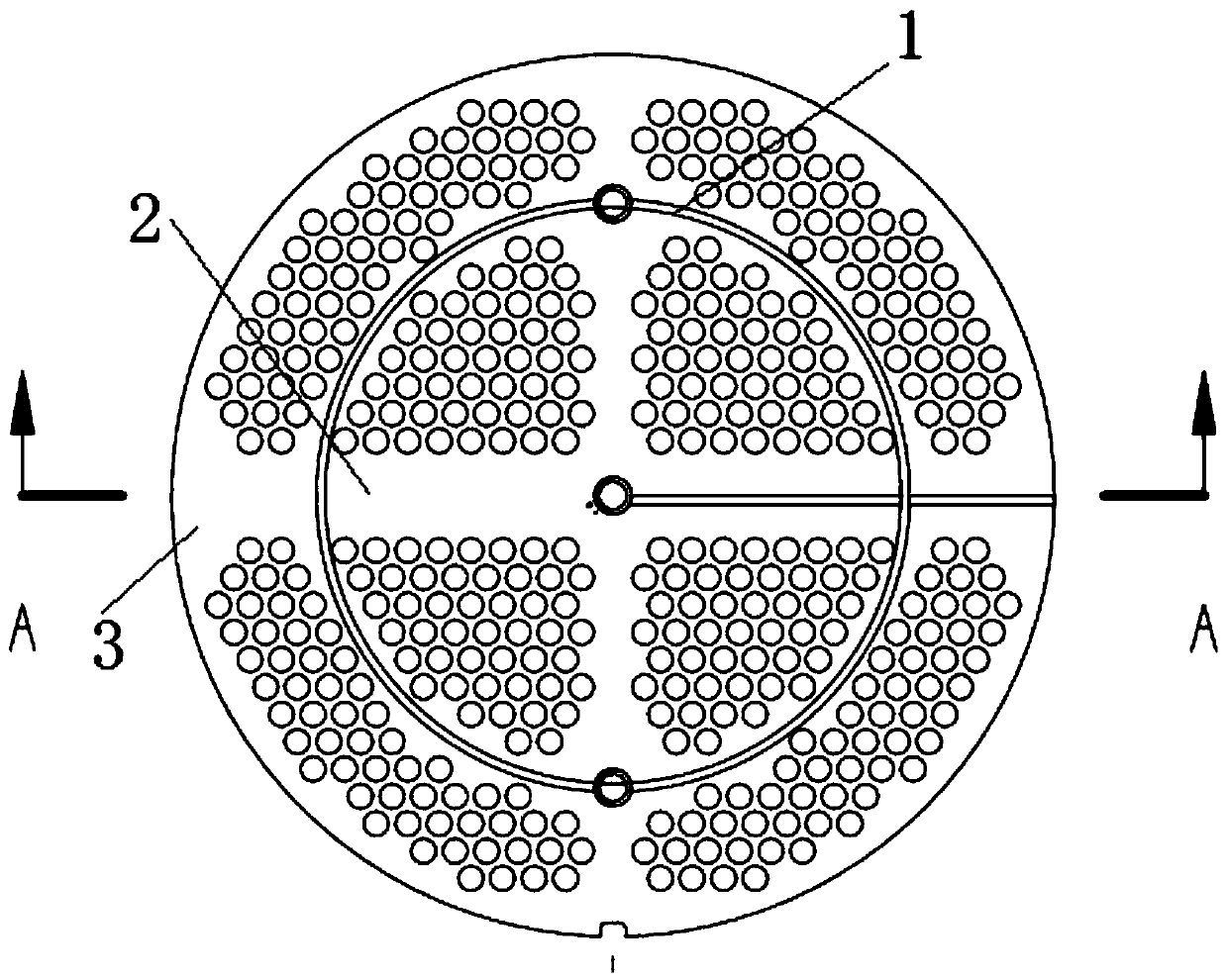

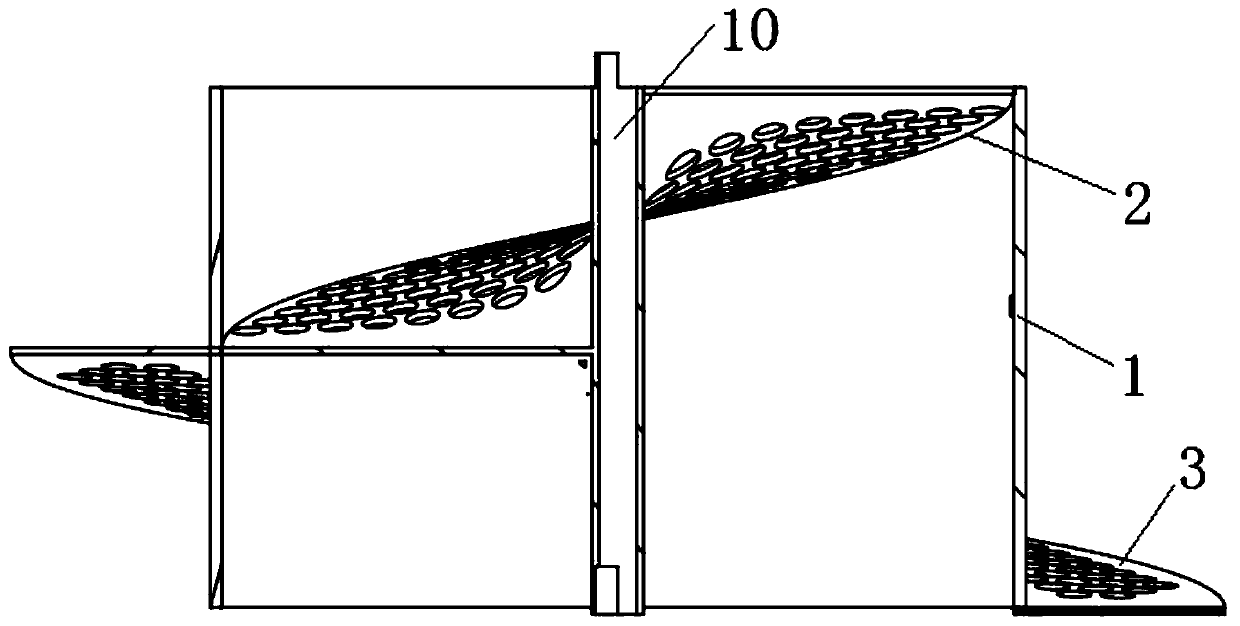

Embedded spiral baffle plate and heat exchanger

ActiveCN110567298APromotes even and stable flowShorten the cantilever lengthHeat exchanger casingsStationary tubular conduit assembliesCircular sectionEngineering

The invention belongs to the technical field of heat exchange equipment, and relates to an embedded spiral baffle plate and a heat exchanger. The baffle plate comprises an inner-layer baffle plate, anouter-layer baffle plate, and a middle support positioned between the inner-layer baffle plate and the outer-layer baffle plate; the inner-layer baffle plate and the outer-layer baffle plate are spirally annular, and are opposite in spiral direction; the circular section radius ratio of the inner-layer baffle plate to the outer-layer baffle plate is not smaller than 1.4: 2; the lead angle of theinner-layer baffle plate is not bigger than the lead angle of the outer-layer baffle plate; the middle support is uniformly provided with multiple bypass holes whose circumcircle diameters are not bigger than 6 mm; through holes for enabling heat exchange pipes to pass through are uniformly distributed on the inner-layer baffle plate and the outer-layer baffle plate; and the hole gap of the inner-layer baffle plate is not smaller than the hole gap of the outer-layer baffle plate. The spiral baffle plate difficultly generates bending deformation and twisting deformation, and can effectively guarantee uniform flowing of cooling mediums in heat exchanger shells; the flow resistance of the cooling mediums is stable and incapable of being increased along with the operation time; and the heat exchange pipes can be excellently supported by the baffle plate.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Single-stage double-suction horizontal self-sucking pump

PendingCN110657099AEasy to disassemble and repairReduce inlet velocityPump componentsPriming pumpImpellerEngineering

The invention discloses a single-stage double-suction horizontal self-sucking pump, and aims at providing a single-stage double-suction horizontal self-sucking pump achieving high flow, high efficiency and zero leakage. The single-stage double-suction horizontal self-sucking pump comprises a pump case. A pump case through hole is formed in the pump case. A rotating shaft is mounted in the pump case through hole. A pump case cavity is arranged in the pump case. An impeller is fixed to the rotating shaft. Mechanical seal assemblies are fixed to the outer side face of the pump case and arranged at the two ends of the pump case through hole. A first bearing body assembly is fixed to one mechanical seal assembly, and a second bearing body assembly is fixed to the other mechanical seal assembly.An inlet pipeline is arranged on one side of the pump case, and a chamber is arranged on the other side of the pump case. The single-stage double-suction horizontal self-sucking pump has the beneficial effects that the double-suction impeller is adopted, axial force is low, the cavitation performance is improved, and the displacement of a pump head is increased; mechanical seal is adopted, performance is stable, and no leakage happens; and a reducer is adopted for butt joint, hydraulic losses are reduced, and the energy utilization rate is increased.

Owner:湖州瑞晨环保科技有限公司

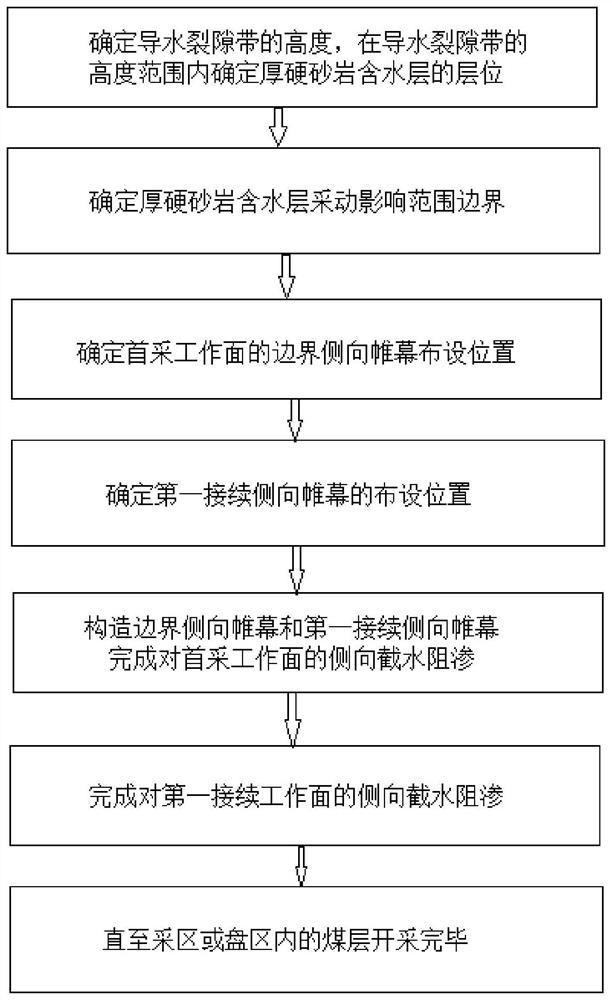

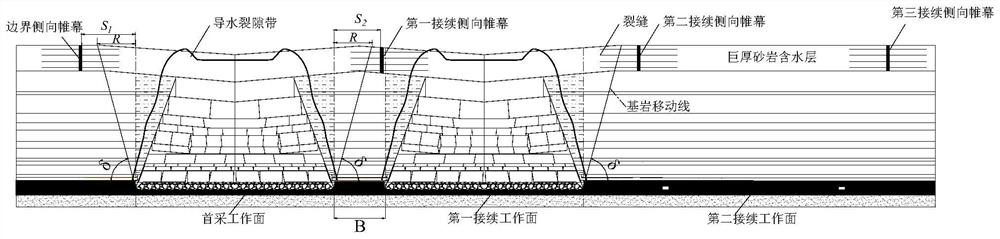

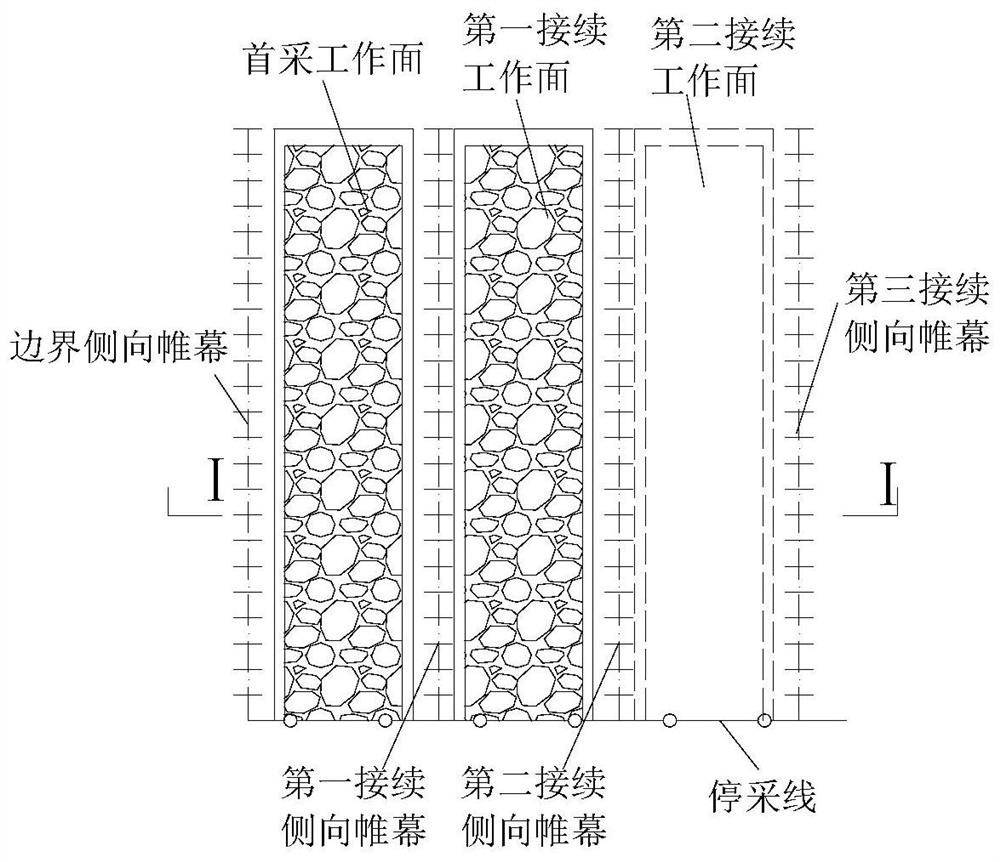

Coal mine thick and hard sandstone roof water disaster and rock burst composite disaster control method

ActiveCN114658485ARealize collaborative prevention and controlReduce water cross sectionMining devicesUnderground chambersSandstone aquiferMining engineering

The invention discloses a coal mine thick and hard sandstone roof water disaster and rock burst composite disaster treatment method which comprises the following steps: determining the height of a water flowing fractured zone, and then determining the position of a thick and hard sandstone aquifer within the height range of the water flowing fractured zone; determining a thick and hard sandstone aquifer mining influence range boundary R; determining the horizontal distance S1 between the lateral curtain of the boundary of the first mining working face and the lateral boundary of the goaf; the arrangement position of a first continuous lateral curtain is determined; a boundary lateral curtain and a first continuous lateral curtain are constructed through hydraulic fracturing grouting; lateral water interception and seepage prevention and normal stoping of the first mining working face are completed; lateral water interception and seepage prevention and normal stoping of the first continuous working face are completed; lateral water interception and seepage prevention are conducted on the second continuous working face; and so on, until the coal seam in the mining area or the panel is completely mined. According to the method, cooperative prevention and control of roof water disasters and rock burst disasters are achieved, the mine water inflow is greatly reduced finally, and the prevention and control effect of getting twofold results with half the effort can be achieved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Foot type stand column and short cantilever five-axis linkage machine tool

ActiveCN104162791ACantilever shortShorten the cantilever lengthFeeding apparatusLarge fixed membersCouplingReduction drive

A foot type stand column and short cantilever five-axis linkage machine tool comprises a base of the machine tool, an X-axis linear movement motor, a Y-axis linear movement motor, a Z-axis linear movement motor, a cross-shaped sliding table, a rotating table, a swing motor, an electric main shaft and a foot type stand column. The foot type stand column is arranged on the base of the machine tool and located on one side of the cross-shaped sliding table, the foot type stand column comprises a vertical section and an installing base, the lower end of the vertical section is arranged at one end of the installing base, the middle of the vertical section in the height direction is of a hollow structure and forms a Z-axis movement channel, and a V-shaped through hole is formed in the middle of the installing base in the width direction; the Z-axis linear movement motor is arranged at the top of the vertical section of the foot type stand column, a speed reducer is installed at the front end of a Z-axis drag plate and connected with the swing motor through a coupler, the electric main shaft is installed at the output end of the speed reducer, the Y-axis movement motor is installed on the base of the machine tool and located in the V-shaped through hole in the installing base of the foot type stand column, and the X-axis movement motor is arranged on the upper surface of the crossed-shaped sliding table. The machine tool is mainly used for machining large parts large in height, high in rigidity and suitable for machining hard materials.

Owner:NANJING GEWAI TRACK TRAFFIC EQUIP CO LTD

Partly retractable construction platform

InactiveUS20040216392A1Reduce the total massReduce the overall heightBuilding roofsExtraordinary structuresBuilding under constructionCantilever

A construction platform comprising a stationary support structure adapted to be fixedly secured to the floor of a building under construction and project from the edge of the building to a predetermined maximum extent, and a movable deck mounted on the stationary structure which may be extended as a cantilever therefrom or retracted into at least substantial registration therewith.

Owner:MEVON PTY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com