Supporting structure of automobile suspension rack

A technology for supporting structure and vehicle mounting, which is applied to power plants, vehicle components, jet propulsion devices, etc., can solve the problems of weak connection and poor rigidity of the mounting bracket, and achieve the effect of increasing modal frequency and increasing stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

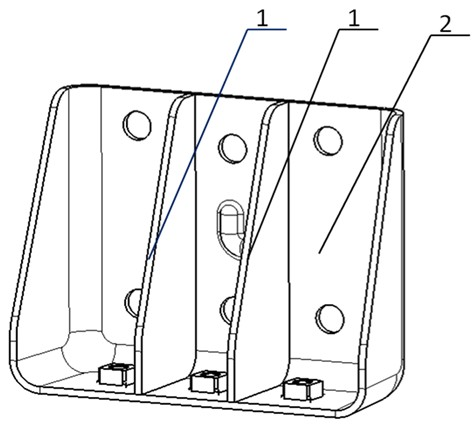

[0021] see figure 1 The first welded assembly of the support structure of the automobile suspension bracket shown is composed of a first reinforcement 2 in the shape of a dustpan and two reinforcement ribs 1 welded on the rear facade and bottom surface of the first reinforcement , two reinforcement ribs 1 and the first reinforcement member 2 are welded by shielded welding, a certain distance should be kept between the two reinforcement ribs, and a certain distance should also be ensured from the side of the first reinforcement member 2; in the first reinforcement member 2 Six bolt holes 8, 9, 10, 11, 12, 13 are provided on the rear facade of the car, and three bolt holes 14, 15, 16 are provided on the bottom surface.

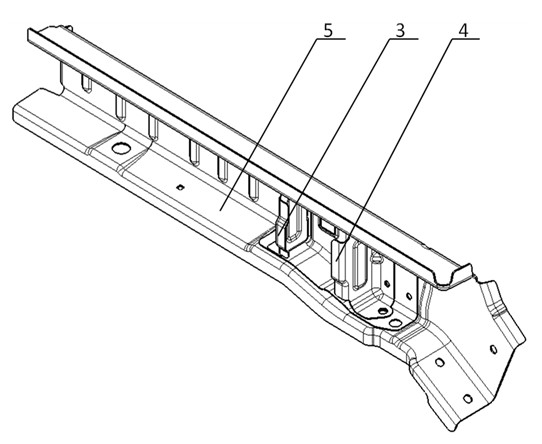

[0022] see figure 2 , the second welding assembly is composed of the second reinforcement 3 and the third reinforcement 4 and the longitudinal beam 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com