A rear drive axle housing assembly

A rear drive axle and axle housing technology, applied in axles, wheels, transportation and packaging, etc., to avoid frequency coupling, avoid resonance phenomena, and reduce vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further explain the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

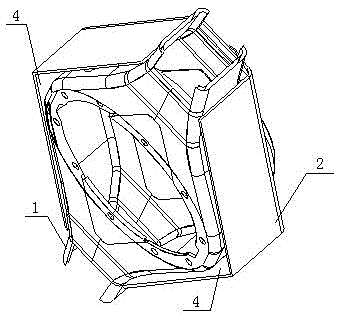

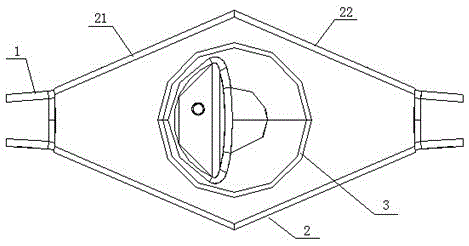

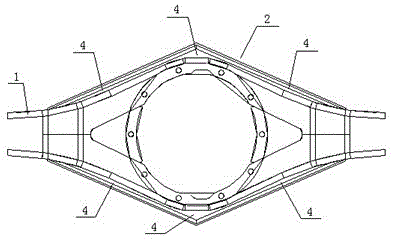

[0014] see Figure 1 to Figure 4 As shown, the rear drive axle axle housing assembly includes an axle housing 1 welded by upper and lower halves, a rear cover 3 and a cover plate 2 arranged at the rear of the middle section of the axle housing. The cover plate 2 is welded by QT500 steel plate with a thickness of 5mm, including the left section 21 and the right section 22 with the same structure and arranged symmetrically. The section 21 and the right section 22 are welded through a wider end, and the side walls of the left section 21 and the right section 22 form the cover edge of the cover plate 2 . The cover plate 2 is buckled at the rear of the middle section of the axle housing and welded to the rear of the middle section of the axle housing. The lower cover edge of 2 is located direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com