Thin electrode for electrolytic machining of integral wheel

A technology of integral impeller and sheet, which is used in processing electrodes, electric processing equipment, electrode manufacturing, etc., can solve problems such as poor versatility, narrow cathode application range, and inability to carry out blade profiles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

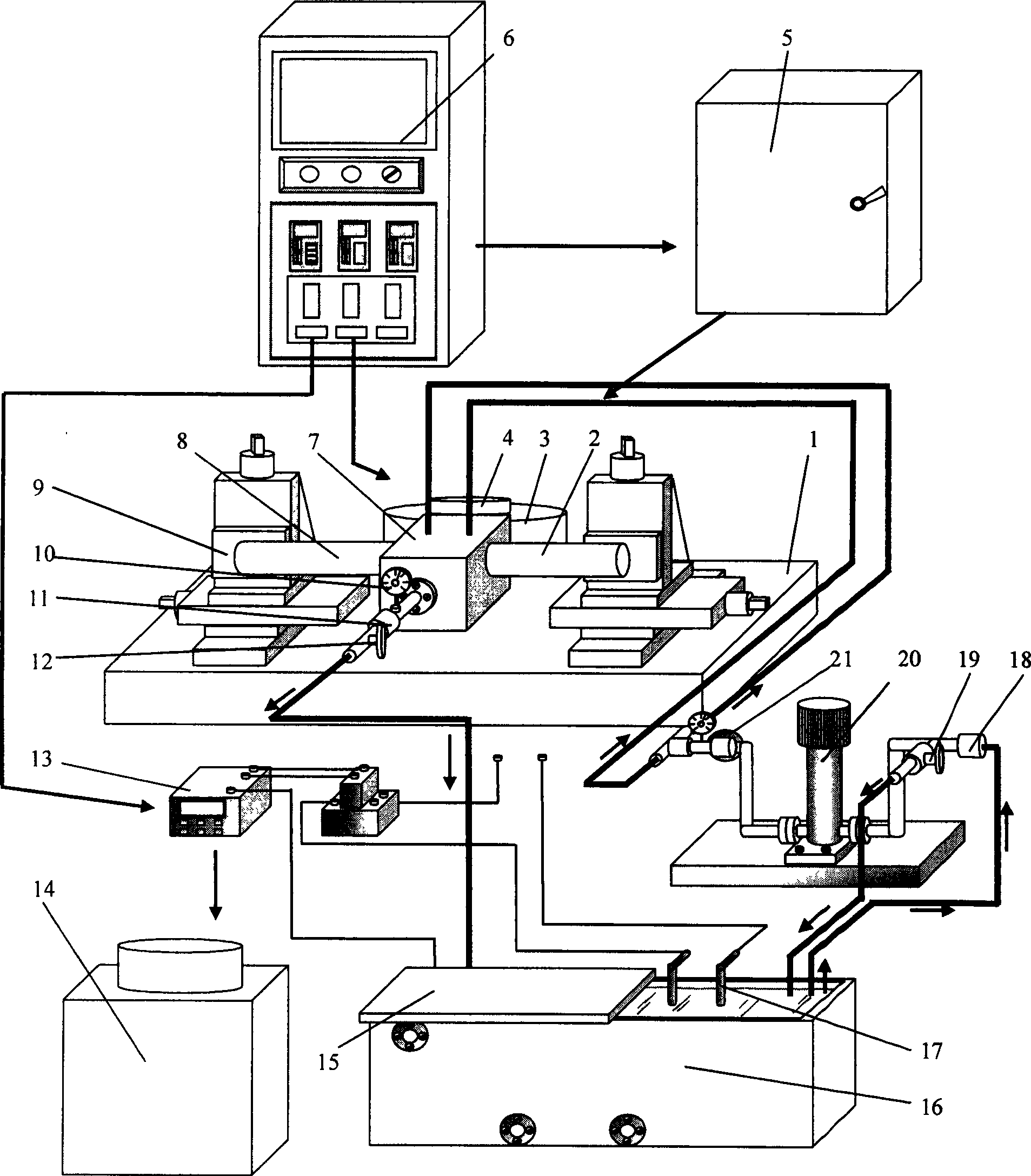

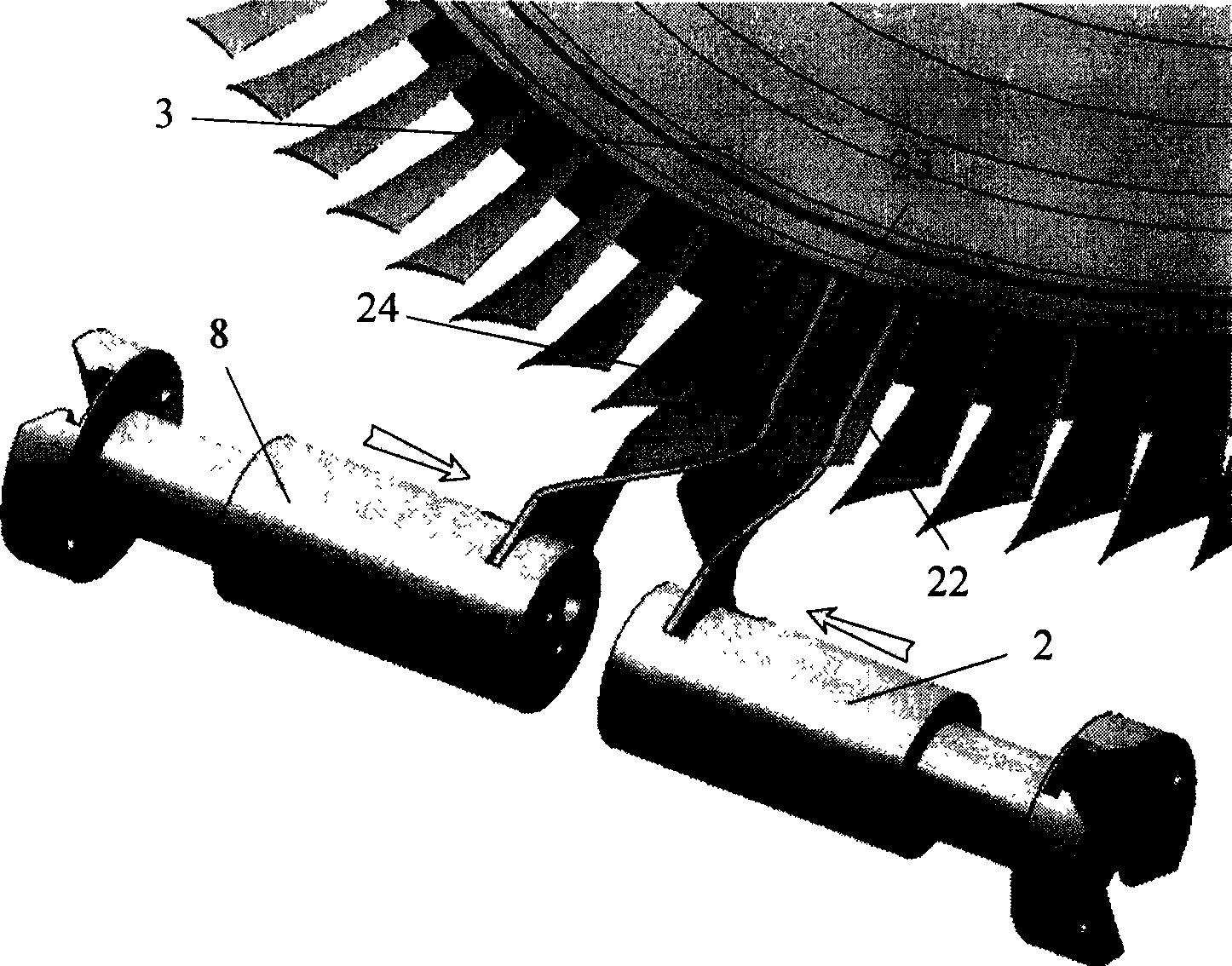

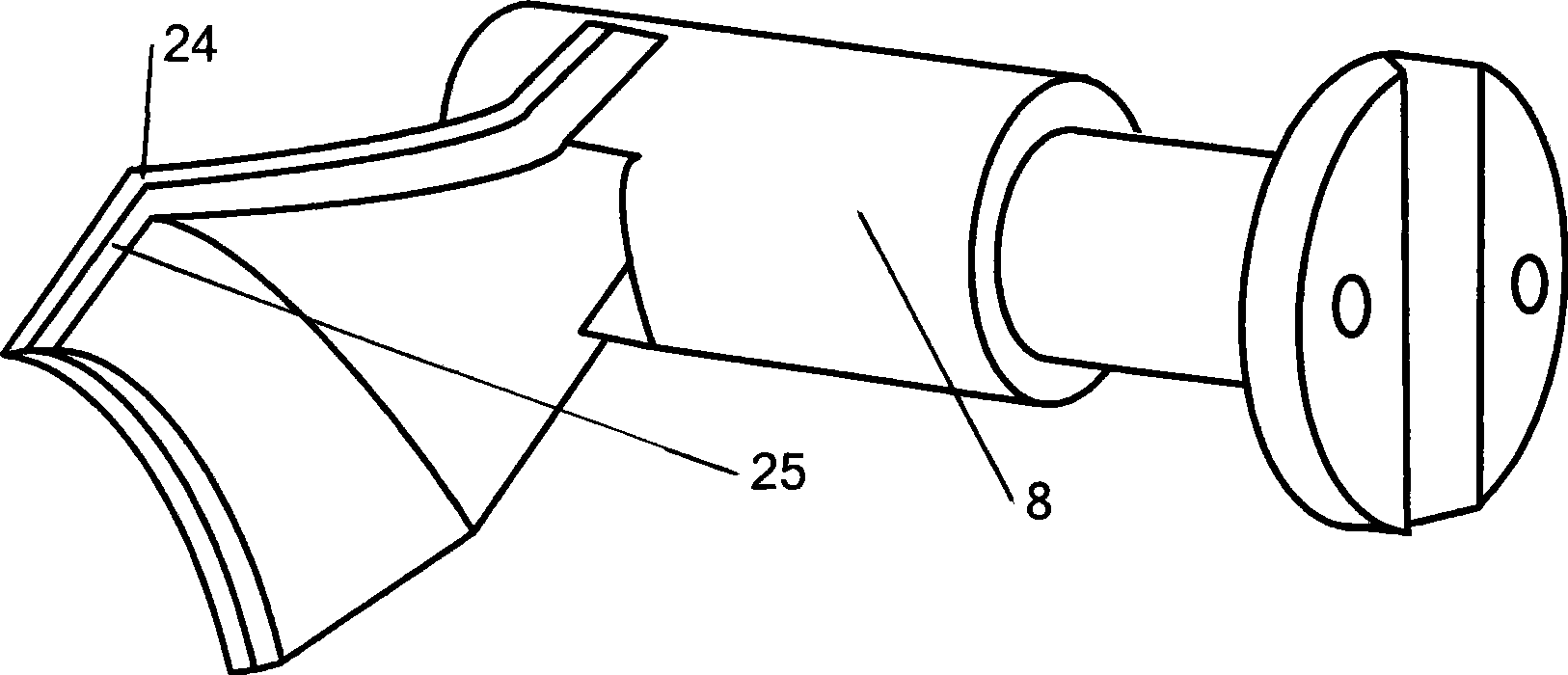

[0012] Such as figure 1 As shown, the impeller electrolytic machining electrolyte circulation system consists of pressure gauge 10, flow meter 11, regulating valve 12, electrolyte tank and electrolyte 16, filter 18, stop valve 19, multi-stage centrifugal pump 20, ball valve 21 and other parts , Supply the electrolyte for processing and discharge the electrolysis product. The machine tool mainly includes machine tool platform 1, leaf back cathode fixture 2, integral impeller 3, indexing turntable 4, DC power supply 5, impeller electrolytic machining fixture 7, three-dimensional comprehensive electric translation table 7, leaf basin cathode fixture 8 and other parts, which are the whole The core component of the machine tool. The temperature controller 13, the cooling tower 14, the thermocouple 15, and the heater 17 form an electrolyte constant temperature control system, which heats and cools the electrolyte in the electrolytic cell. The control host 6 constitutes the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com