Spiral, twill electrolysis electrode head and preparation method of electrode head for electrolysis

A technology of electrolytic electrodes and electrode heads, which is applied in the direction of electrode manufacturing, processing electrodes, electric processing equipment, etc., can solve the problems of high technical requirements, high cost, short service life, etc., and achieve the effect of high electrolytic processing precision and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

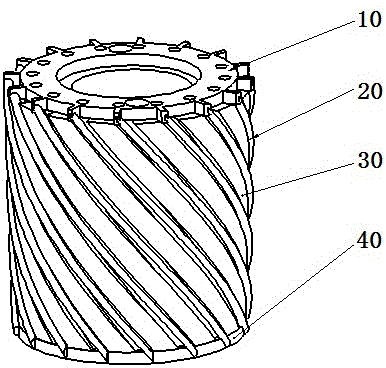

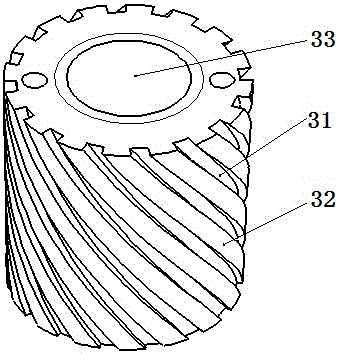

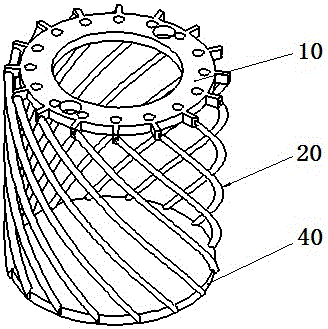

[0026] Such as figure 1 , figure 2 , image 3 As shown, a spiral electrolysis electrode tip of the present invention includes a cylindrical or elliptical column or a circular truncated insulating electrode tip body 30, a spiral groove 31 arranged on the peripheral surface of the electrode tip body 30, and embedded in the electrode tip body. The wire 20 in the groove 31, the upper conductive plate 10 and the lower connecting plate 40 that are arranged on the two ends of the electrode head body 30 and are fixedly conductively connected with the two ends of the wire 20, and the conductive rod that passes through the upper conductive plate 10 and is connected to the electrode head body 30 (not shown in the figure), the conductive rod has a shoulder abutting against the upper conductive plate 10 , and the depth of the groove 31 is 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com