Foot type stand column and short cantilever five-axis linkage machine tool

A five-axis linkage machine tool and column technology, applied in the field of machine tools, can solve the problems of large swing radius of the double-degree-of-freedom rotary table, difficulty in obtaining cutting speed, and large swing error, etc., to improve cutting speed and surface finish, and shorten the cantilever The effect of compact length and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

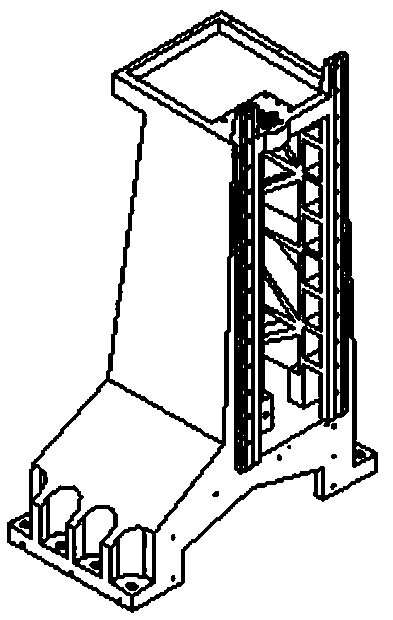

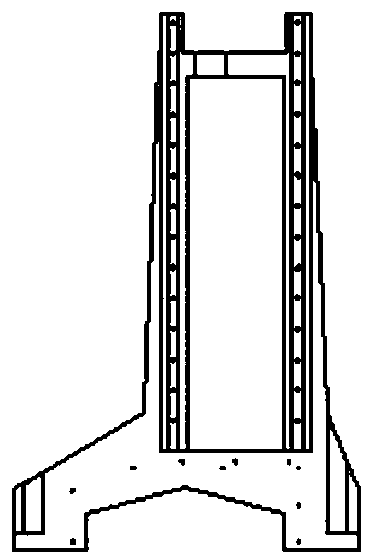

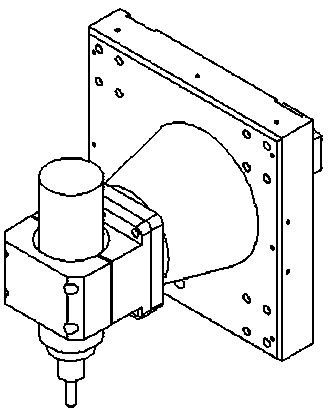

[0028] As shown in Figure 1-3, a five-axis linkage machine tool with a foot-shaped column and a short cantilever includes a machine base 1, an X-axis moving motor 10, a Y-axis moving motor 2, a Z-axis linear moving motor 4, a cross slide, a rotary Workbench 6, swing motor 102, electric spindle 106 and foot-shaped column 3.

[0029] A cross slide is arranged on the machine tool base 1, X and Y-axis carriages are installed on the cross slide, a rotary table 6 is installed on the Y-axis carriage, and a workpiece 5 is installed on the rotary table 6.

[0030] The foot-shaped column 3 is arranged on the base of the machine tool and is located on one side of the cross slide table. The foot-shaped column 3 includes a vertical section and a mounting seat. The lower end of the vertical section is arranged at one end of the mounting seat. A shaft movement channel is provided with a V-shaped through hole in the middle of the width direction of the mounting seat.

[0031] The top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com