Pultrusion die for material compounding

A pultrusion die and composite material technology, which is applied in the field of material composite pultrusion die, can solve problems such as difficulty in realization, shaking or rotation, and decrease in the precision of the cavity wall thickness of composite materials, and achieve the effect of improving efficiency and precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

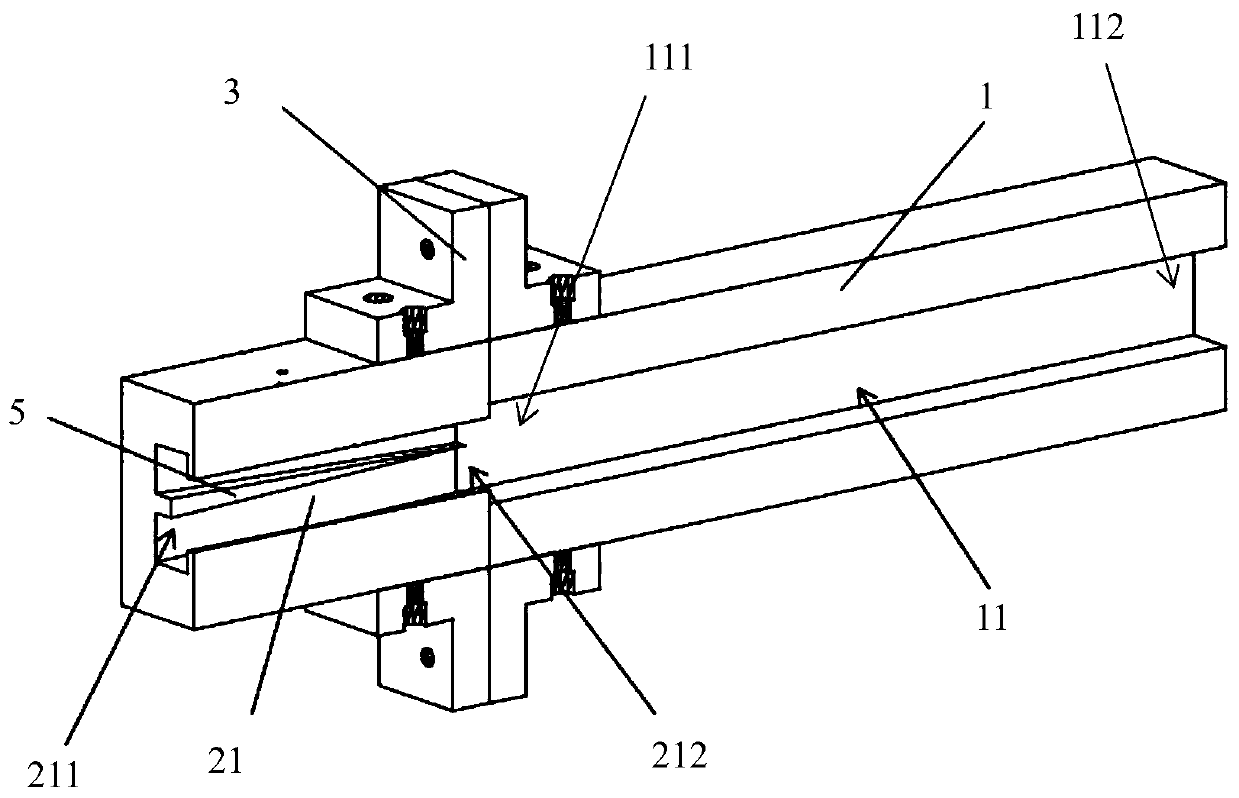

[0074] When the liquid matrix material is polyurethane resin and the fiber is glass fiber, there is a heating device on the molding die, the polyurethane resin infiltrates the glass fiber in the plastic injection box to form a composite material precursor, and the composite material precursor enters the cavity of the heated molding die , The polyurethane resin reacts and cures in the molding die to make the composite material precursor into a composite material, and the composite material is continuously pulled out of the molding die.

[0075] When the liquid matrix material is molten thermoplastic polymer and the fiber is glass fiber, the outlet of the molding die is provided with a cooling and setting device, the thermoplastic polymer is soaked in the glass fiber in the plastic injection box to form a composite material precursor, and the composite material precursor enters the heating In the cavity of the molding die, the thermoplastic polymer is cooled and shaped at the out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com