A flexible rotor of ultra-high speed liquid hydrogen turbo pump

A flexible rotor and turbopump technology, applied to pumps, pump components, non-variable pumps, etc., can solve the problem that the lift, flow rate and efficiency of hydrogen turbopumps cannot meet the thrust and specific impulse requirements of the new generation of engines, and cannot Large-scale variable working conditions and other issues, to achieve the effect of light weight, shortened shafting length, and strong anti-disturbance ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

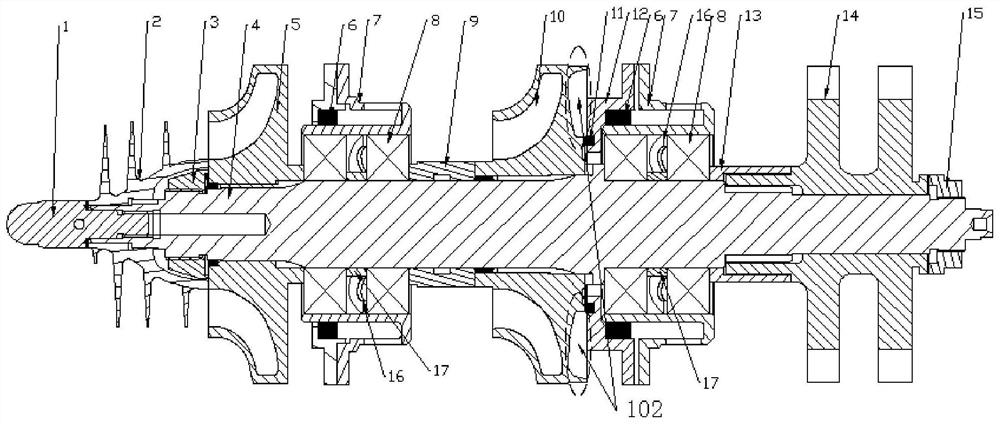

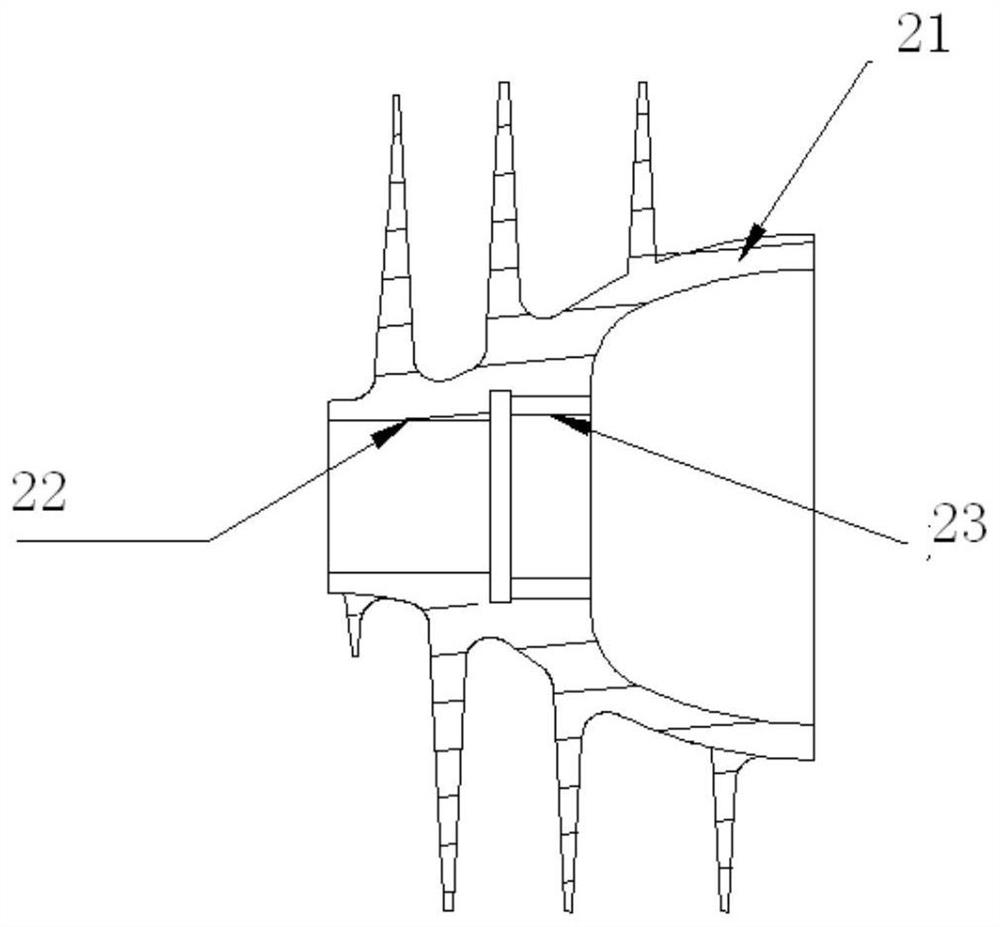

[0030] Such as Figure 1 to Figure 5 As shown, a flexible rotor device of an ultra-high-speed liquid hydrogen turbo pump is structurally composed of a screw 1, an inducer 2, a compression nut 3, a shaft 4, a first-stage centrifugal wheel 5, a metal rubber damper 6, and a squirrel-cage elastic Support 7, bearing pair 8, interstage bushing 9, secondary centrifugal wheel 10, balance piston 11, metal rubber damper baffle 12, first bushing 13, turbine disc 14, large nut 15, preload disc spring 16 , the second shaft sleeve 17, as attached figure 1 shown. Wherein the screw rod 1, the inducer 2, the compression nut 3, the first-stage centrifugal wheel 5, the second-stage centrifugal wheel 10, and the turbine disc 14 are all made of titanium alloy.

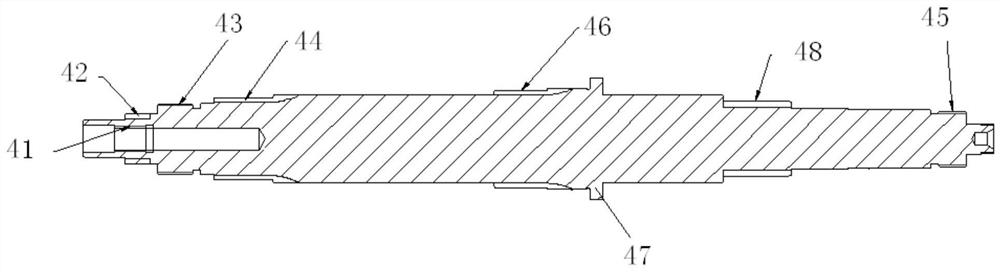

[0031] One end of the shaft 4 is provided with a screw mounting hole, and a screw tightening thread 41 is arranged in the screw mounting hole, and an inducer spline 42, a compression nut tightening thread 43, and a first-stage centrifuga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com