Curved surface piezoelectric power generation cantilever beam

A piezoelectric power generation, cantilever beam technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem that the cantilever beam system cannot be maintained under changing motion conditions Power generation efficiency, frequency constant, low, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

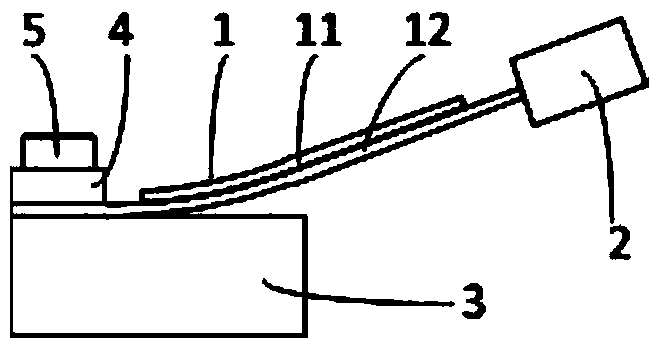

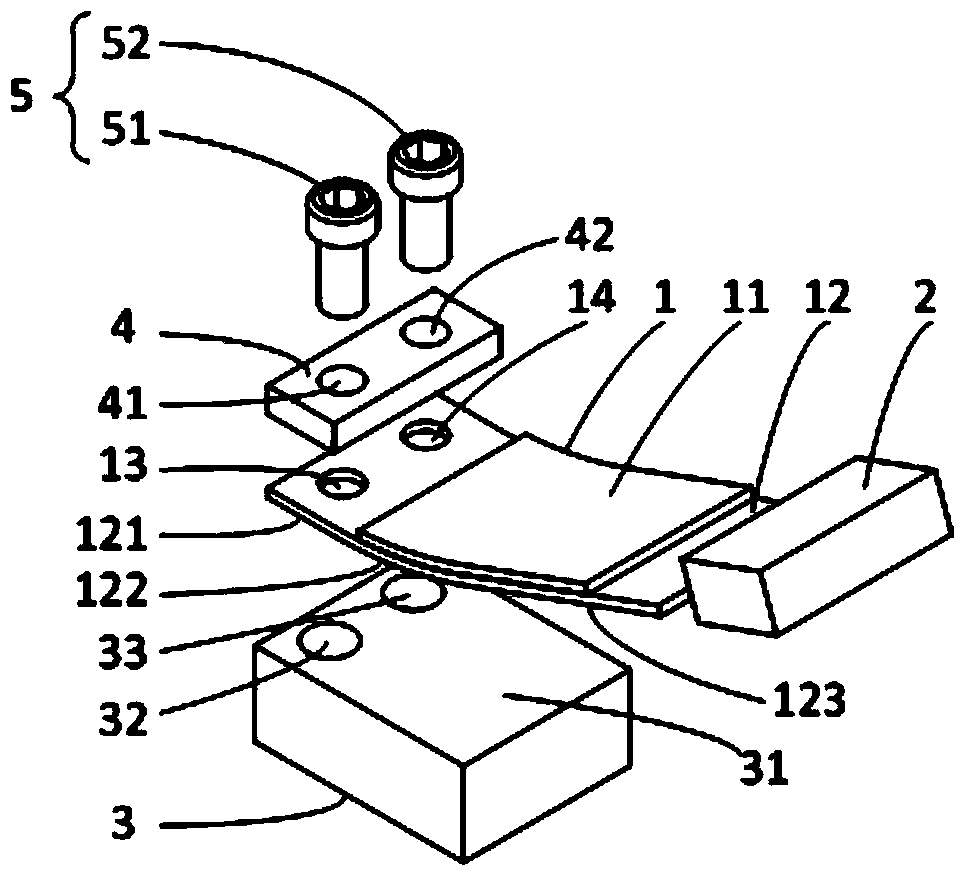

[0014] refer to figure 1 , figure 2 and image 3 , the curved piezoelectric power generation cantilever beam of the present invention is composed of a curved piezoelectric vibrator 1, a free end mass block 2, a fixed support end 3, a mounting gasket 4 and a bolt 5, wherein:

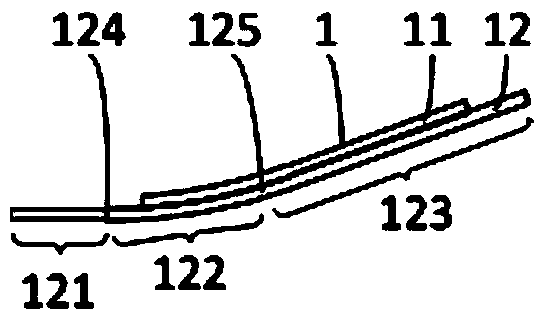

[0015] The curved piezoelectric vibrator 1 is connected in sequence by three parts with a smooth transition, which are the vibrator installation plane 121, the variable support curved surface 122 and the cantilever extension plane 123; one end of the curved piezoelectric vibrator 1 is arranged with a free-end mass block by bonding 2. The other end is fixed on the fixed support end 3, and fixed by the first bolt 51 and the second bolt 52 through the installation gasket 4; the variable support curved surface 122 intersects the vibrator installation plane 121 at the first intersection line 124, the The variable support curved surface 122 intersects the cantilever extension plane 123 at a second intersecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com