Single-stage double-suction horizontal self-sucking pump

A single-stage double-suction, self-priming pump technology, used in non-variable-capacity pumps, non-displacement pumps, pumps, etc., can solve the problems of small flow and low efficiency of self-priming pumps, increase water discharge, and improve working environment. , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

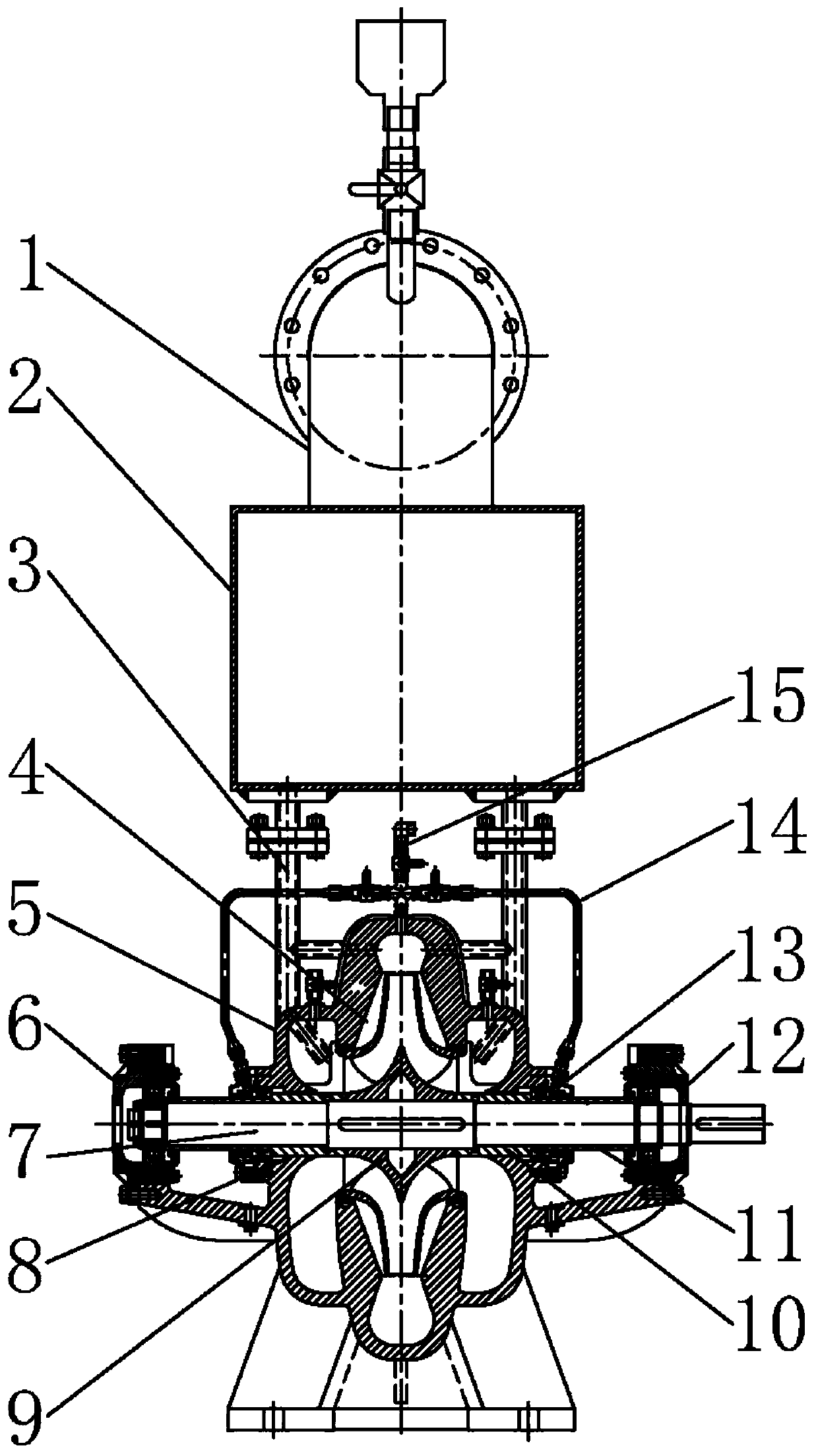

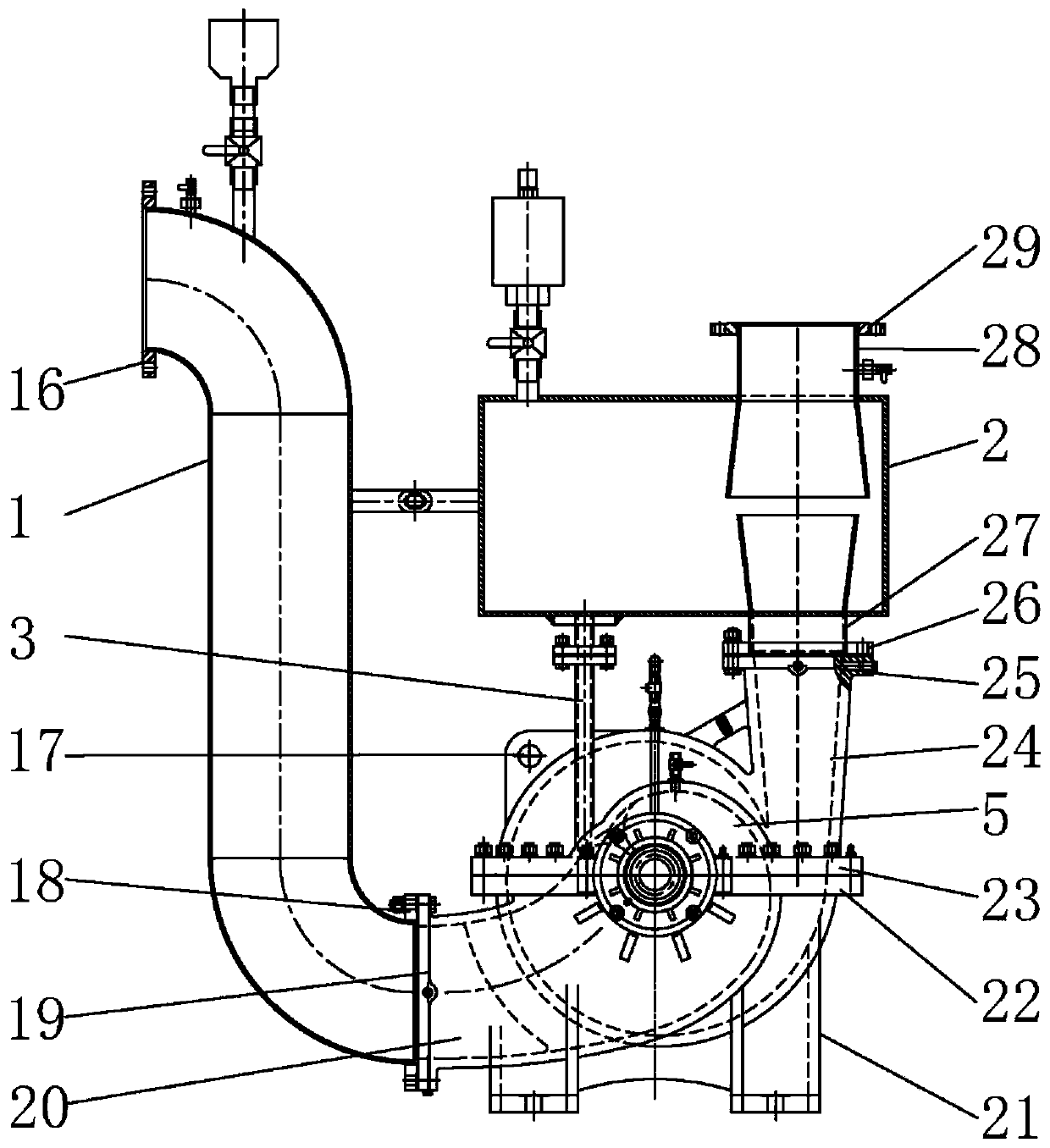

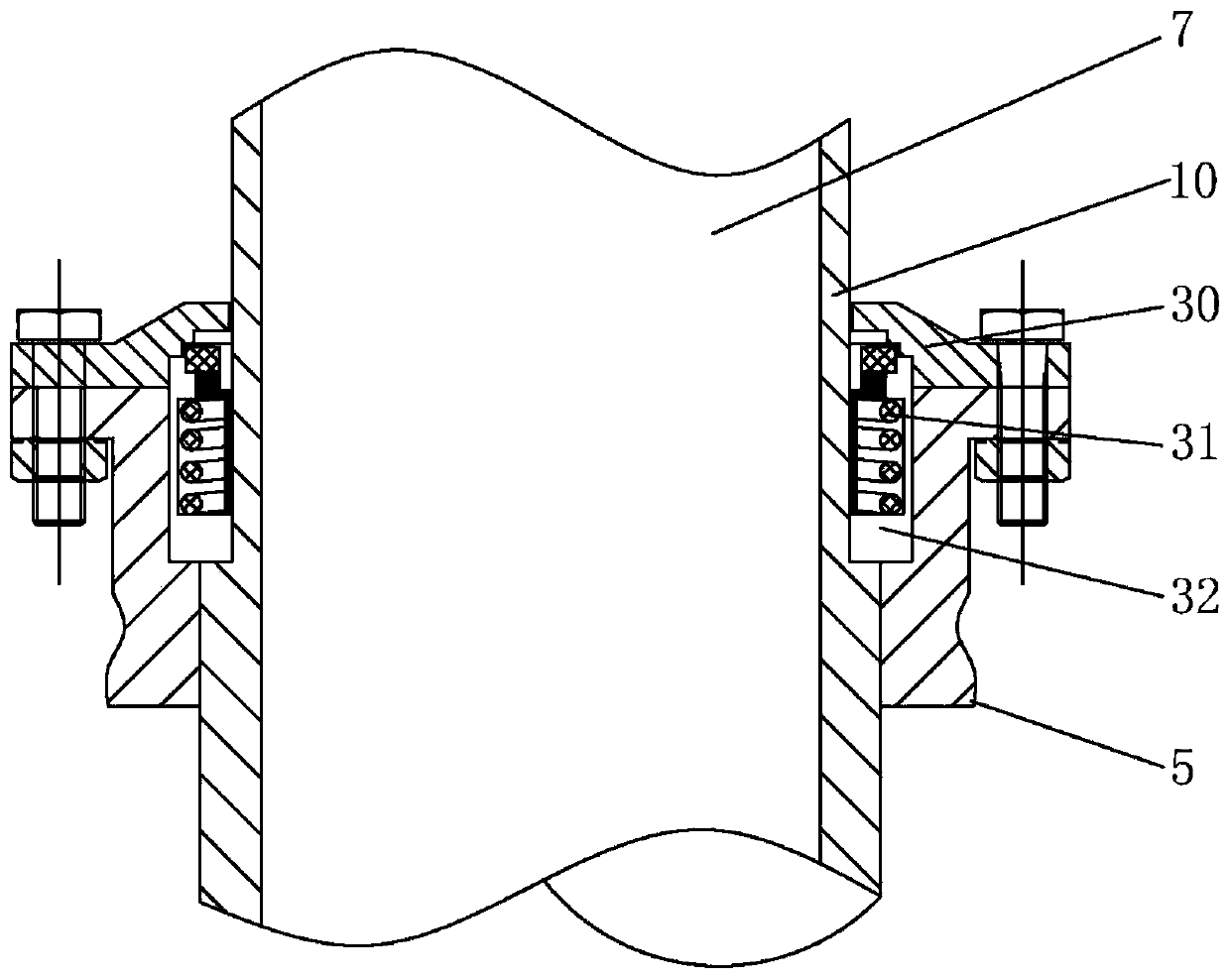

[0025] like figure 1 In the described embodiment, a single-stage double-suction horizontal self-priming pump includes a pump casing 5, the pump casing 5 is provided with a pump casing through hole 8, and a rotating shaft 7 is installed in the pump casing through hole 8, and the rotating shaft 7 and The pump casing 5 is rotatably connected, the pump casing 5 is provided with a pump casing cavity 4, the rotating shaft 7 is fixed with an impeller 9, the impeller 9 is placed in the pump casing cavity 4, and an organic seal assembly 13 is fixed on the outer surface of the pump casing 5, The mechanical seal assembly 13 is placed at both ends of the through hole 8 of the pump casing. The mechanical seal assembly 13 is sleeved on the rotating shaft 7, and the mechanical seal assembly 13 and the rotating shaft 7 are rotatably connected. One of the mechanica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com