Flexible joint clamp, multi-layer mechanical arm with same and full-automatic welding system

A soft connection and manipulator technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as cost, economy, technical equipment constraints, inability to fully automate welding, and unsatisfactory production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

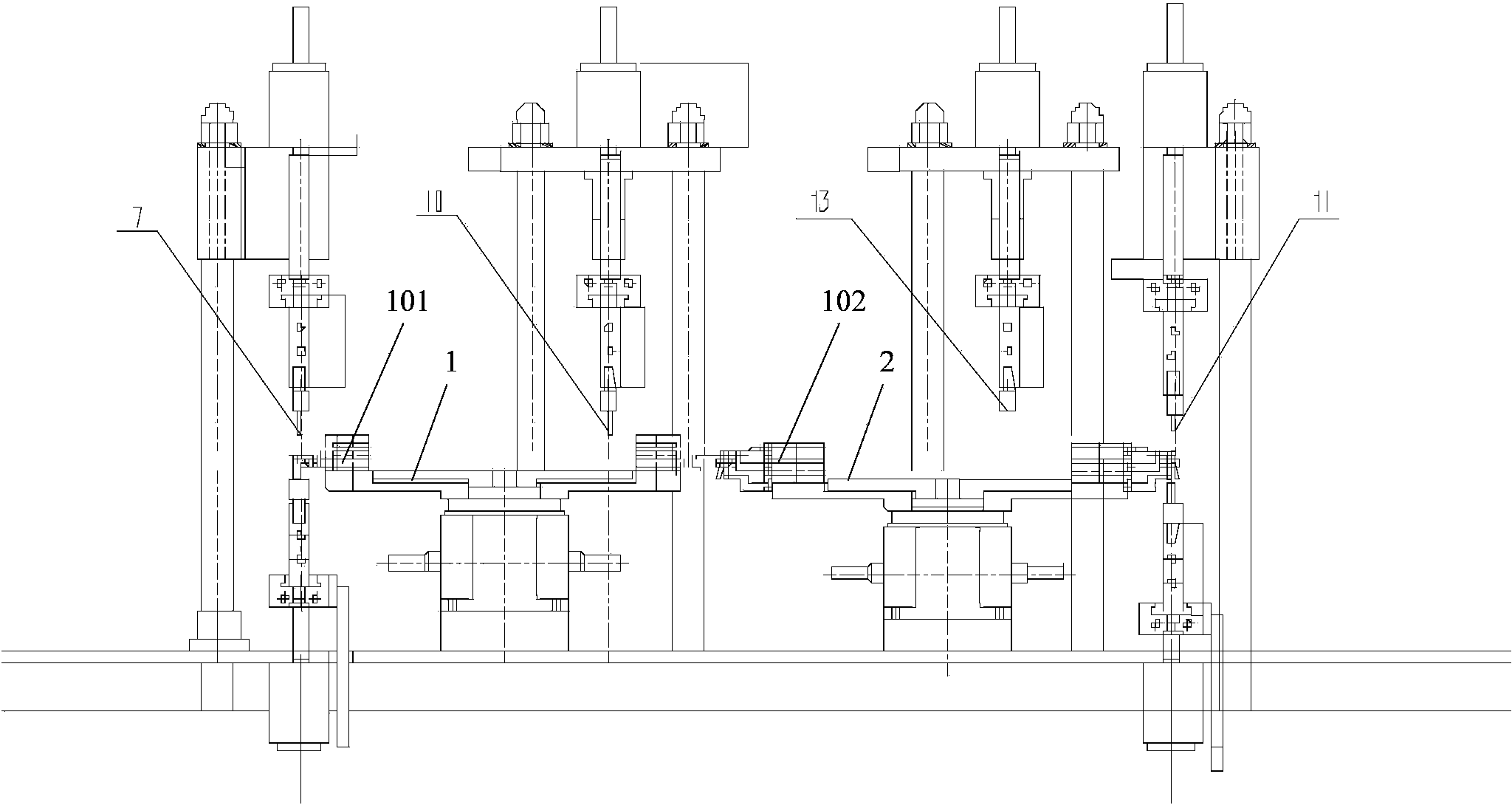

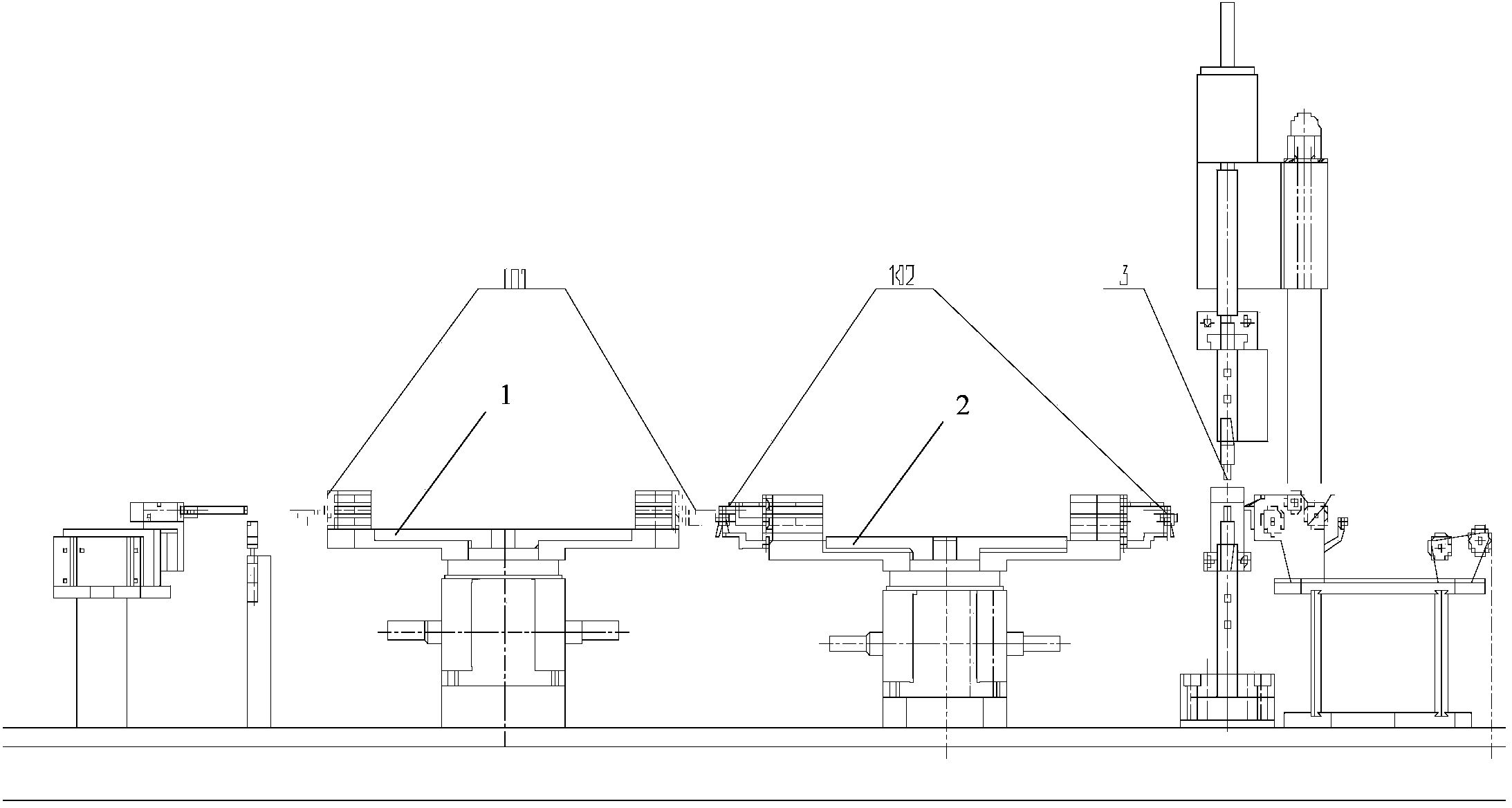

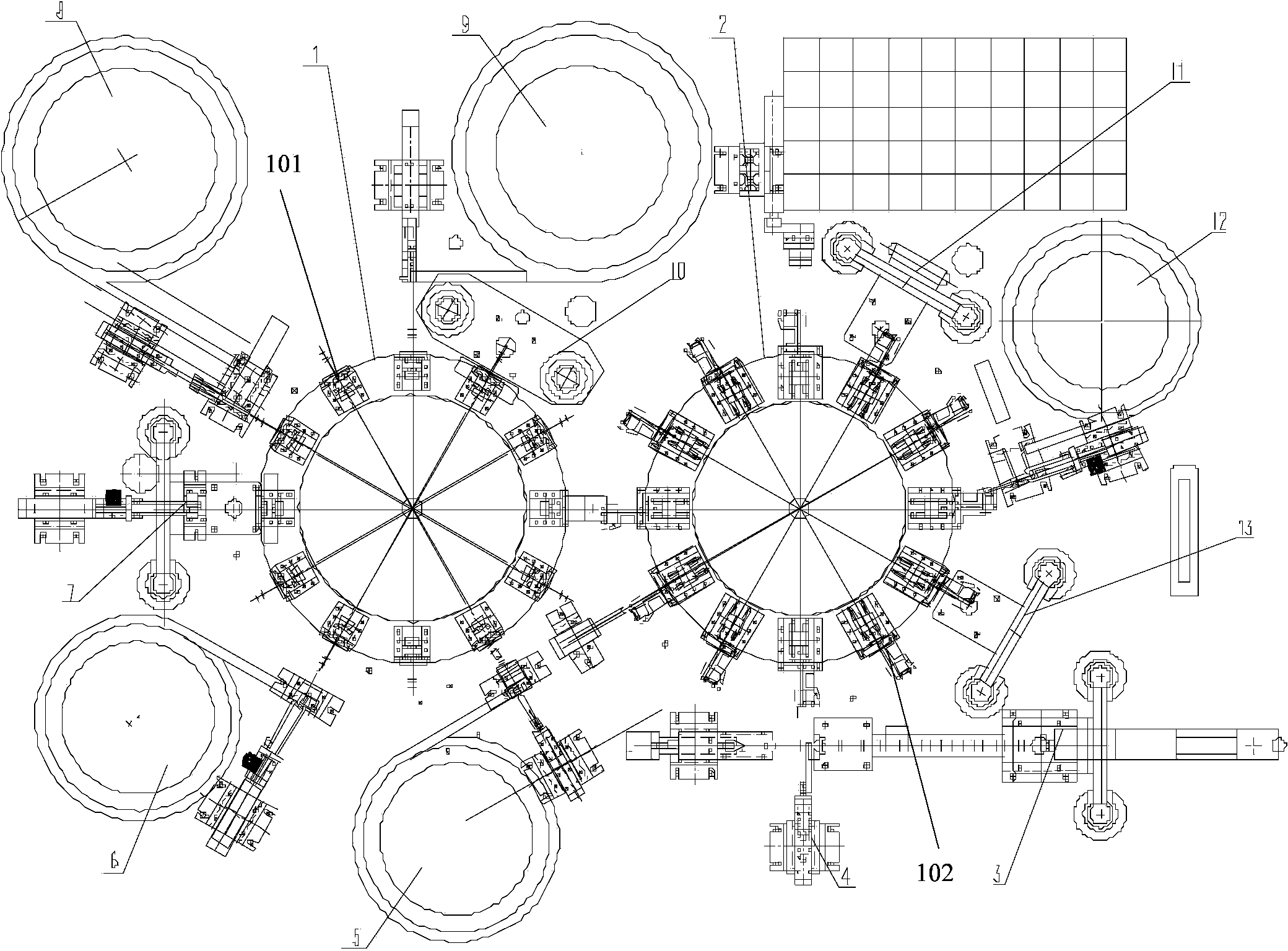

[0039] figure 1 , figure 2 A fully automatic welding system is shown, comprising at least two turntables, at least one welding device is arranged around each turntable, a plurality of first multilayer manipulators 101 are arranged on the first turntable 1, and a plurality of first multilayer manipulators 101 are arranged on the second turntable 2. A plurality of second multi-layer manipulators 102 are set, and at least one layer of manipulators on the first multi-layer manipulator 101 is a soft joint fixture, or at least one layer of manipulators on the second multi-layer manipulator 102 is a soft joint fixture, or Both the first multi-layer manipulator 101 and the second multi-layer manipulator 102 are provided with soft coupling fixtures. A preferred solution is to provide a soft joint fixture on the second multi-layer manipulator 102 .

[0040] Welding a bimetallic stent system as an example, the present invention provides a specific welding optimization process for a bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com