Bent contact member, jack module and electrical connector

A contact, bending technology, applied in the direction of contact parts, connections, parts of connecting devices, etc., can solve problems such as increasing the insertion loss between the plug and the socket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

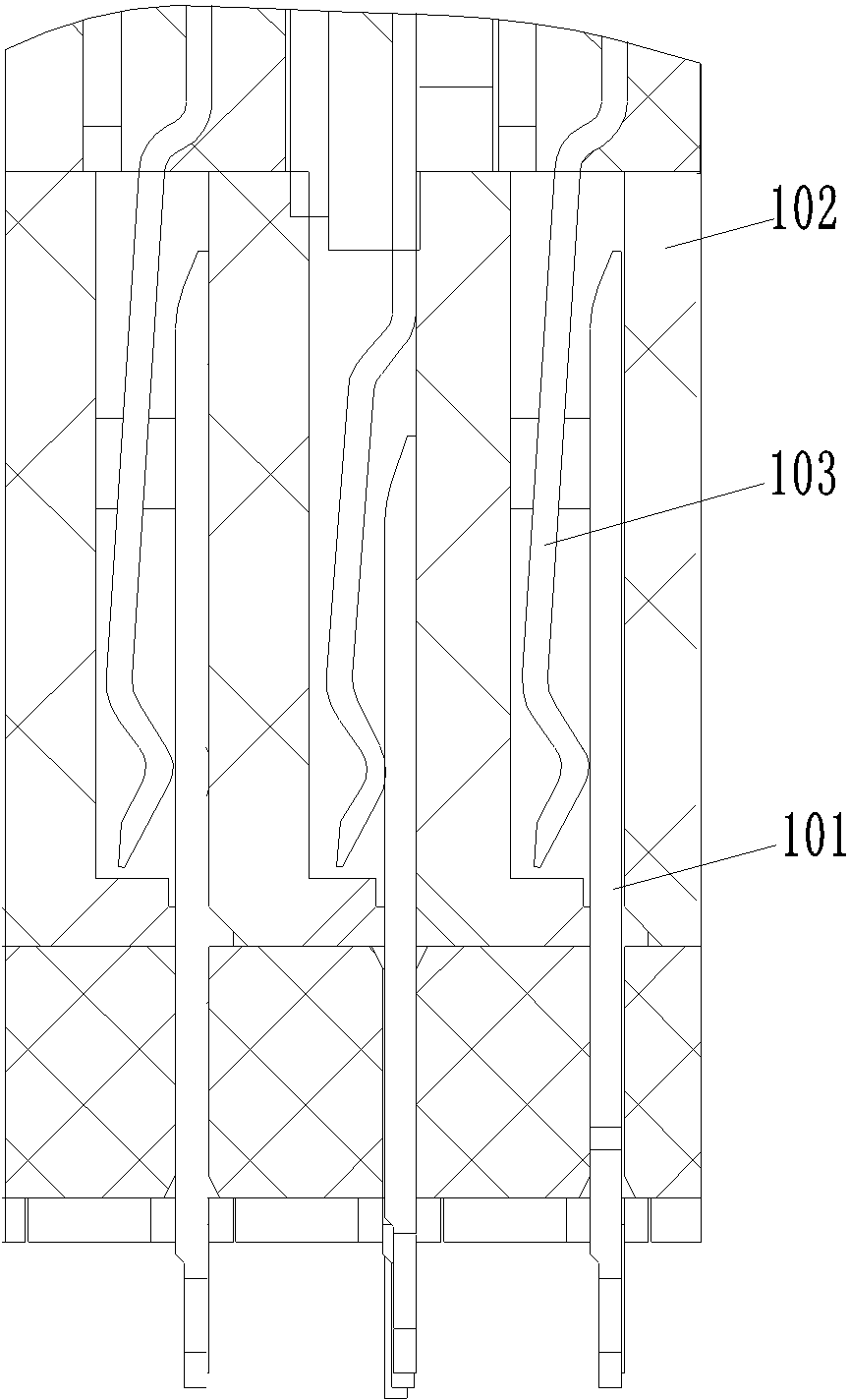

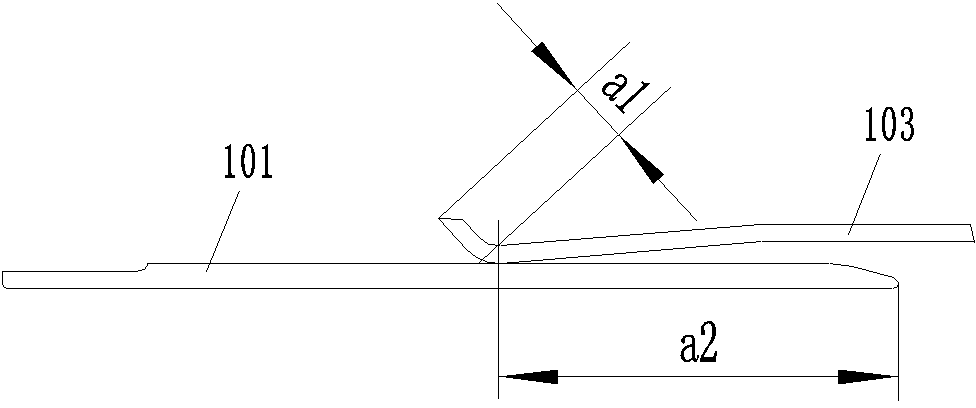

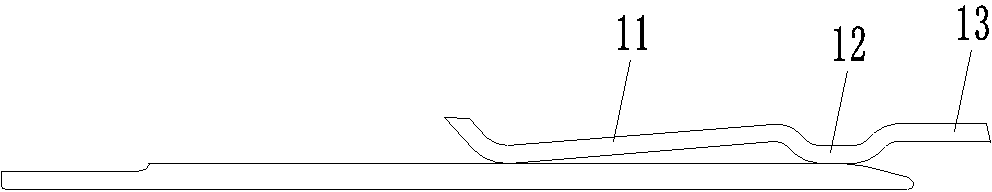

[0024] Example 1 of the bent contact, such as image 3 As shown, the contact piece takes the front end as the plug-in end, which includes a plug-in part 11, a concave part 12 and a horizontal mounting part 13 located behind the plug-in part, and the plug-in part 11, concave part 12 and mounting part 13 are from front to back Set in turn. Wherein, the front end of the insertion part 11 has a flange formed by turning upwards, and the lower side of the flange is formed as a front contact part for contacting with the matching contact piece. In this embodiment, the concave part 12 is U-shaped. And relative to the rear end of the socket part 11, it is recessed downwards, and its lower side forms the rear contact part of the contact piece. The mounting part 13 is horizontally located at the rear end of the recessed part 12. The position is gradually inclined downward from the back to the front. In this embodiment, the front and rear contact parts are located on the same horizontal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com