Stabilizer bar system for Formula SAE race car and operation method of stabilizer bar system

A technology of student formula and stabilizer bar, which is applied in the field of racing car operation, can solve the problems of large reduction of roll stiffness, expansion of adjustment range, and inability to completely suppress it, so as to reduce the length of the cantilever, realize light weight, and expand design adjustment range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

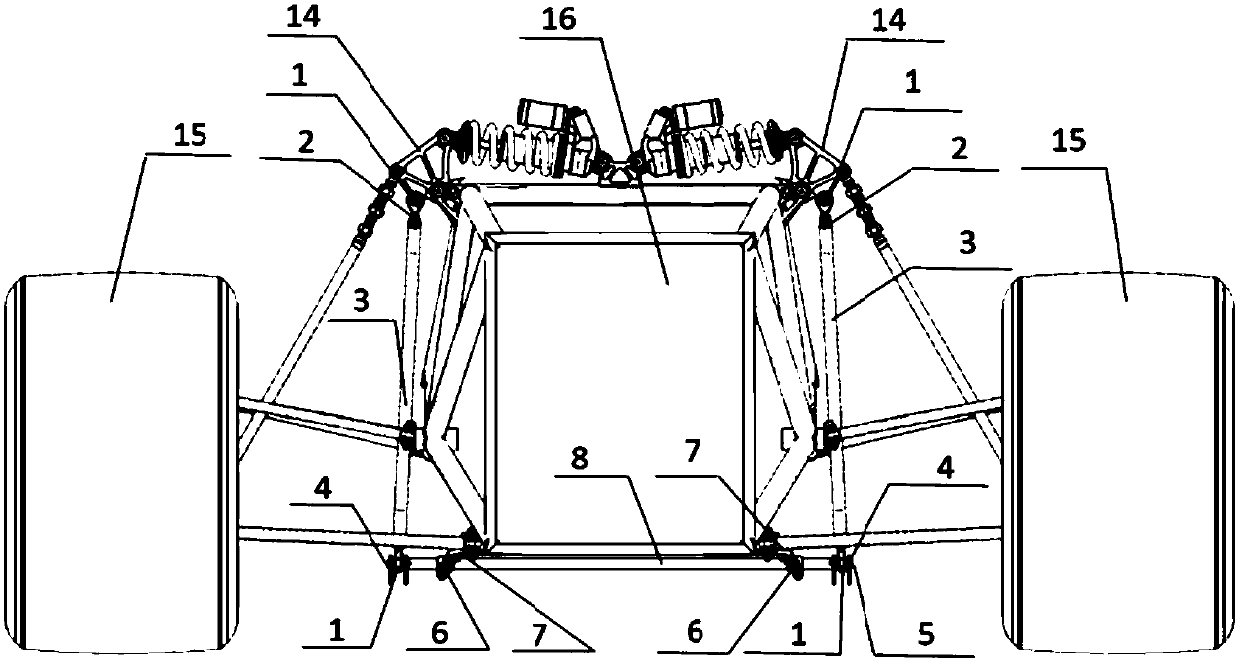

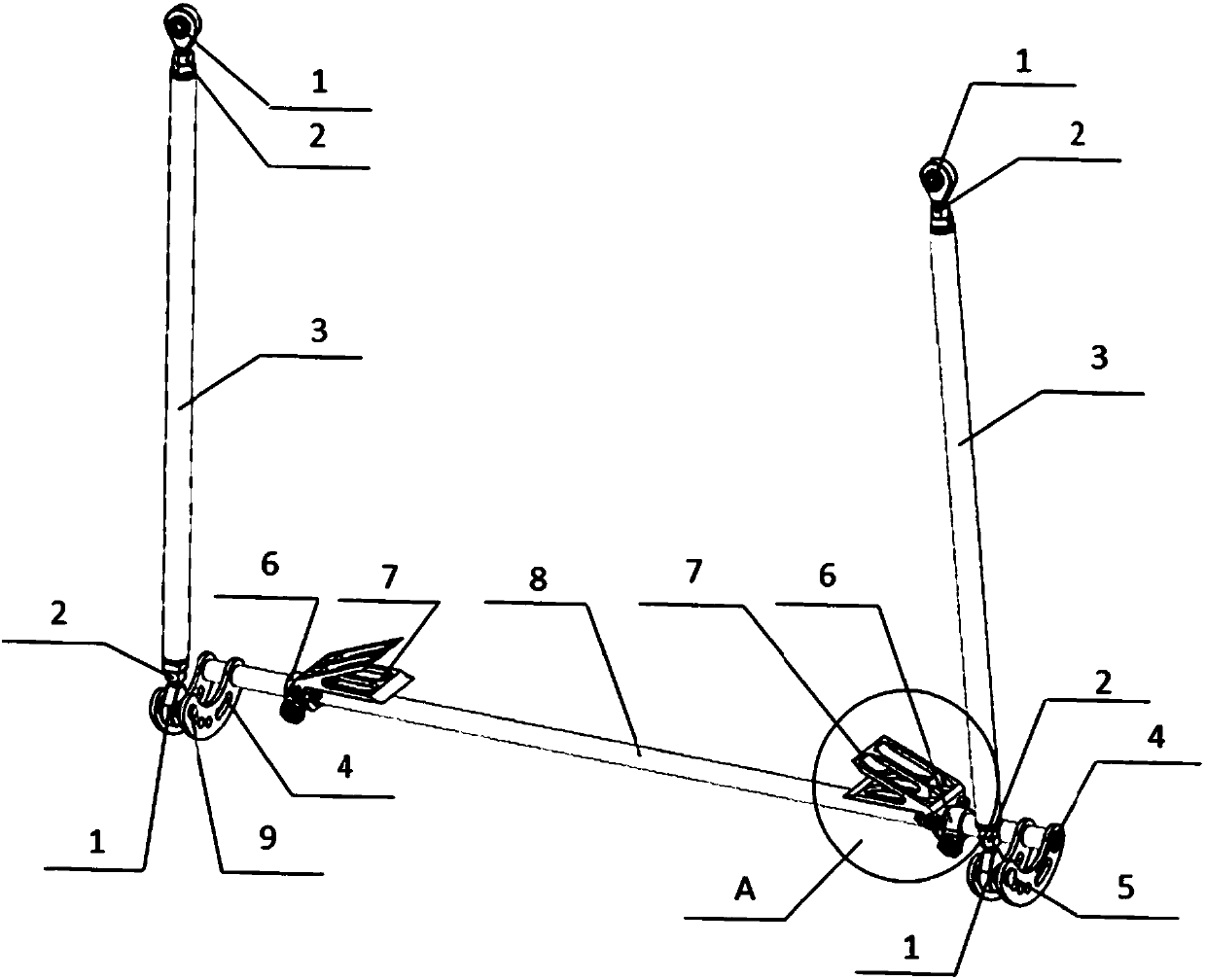

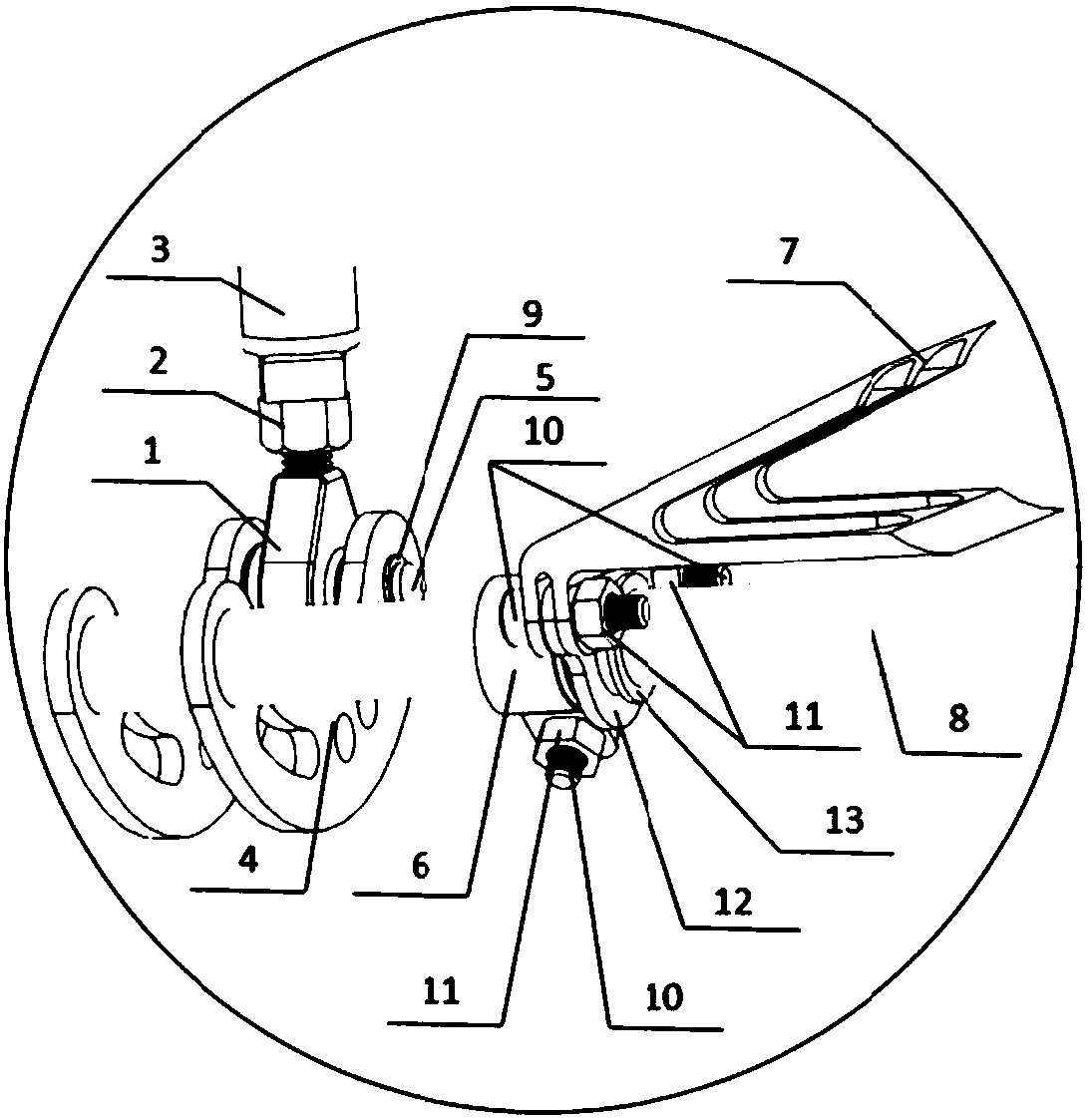

[0034] The following is attached Figure 1-3 The technical solution of the present invention is described in detail.

[0035] Such as Figure 1-3 As shown, a stabilizer bar system for a Formula Student racing car, including: rod end bearing 1, M6 nut 2, pull rod 3, adjustment arm 4, latch 5, ferrule 6, upper fixed lug 7, torsion bar 8, shaft Circlip 9;

[0036] Among them, there are four rod end bearings 1 in total, and the rod end bearings 1 are connected with the tie rods 3 through M6 nuts 2 to realize locking; the upper two rod end bearings 1 are connected with the suspension rocker arm 14 through bolts, and the lower ones The two rod-end bearings 1 are connected to the adjustment arm 4 through the pin 5 and the shaft circlip 9, and transmit the movement of the suspension guide rod caused by the reverse run-out of the wheels 15 on both sides to the adjustment arms on the left and right sides respectively. 4. Realize the reverse rotation of the adjustment arms 4 on both s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com