Method and mold for continuously and gradually extruding high-rib profile

A high-rib and type technology, which is applied in the field of continuous gradient extrusion of high-rib type materials, can solve the problems of low mold service life, difficulty in mass production, and easy damage to the cantilever of the lower mold, so as to improve the service life and improve the quality of life. Force conditions, effect of cantilever length reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

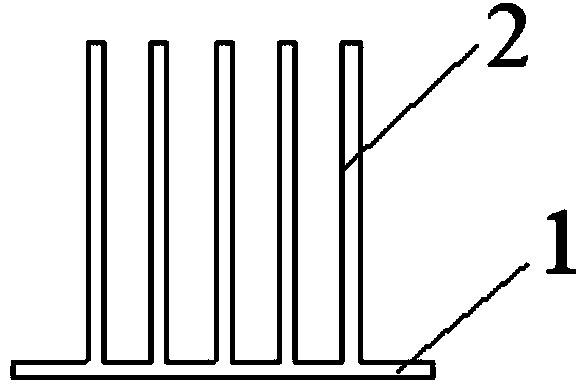

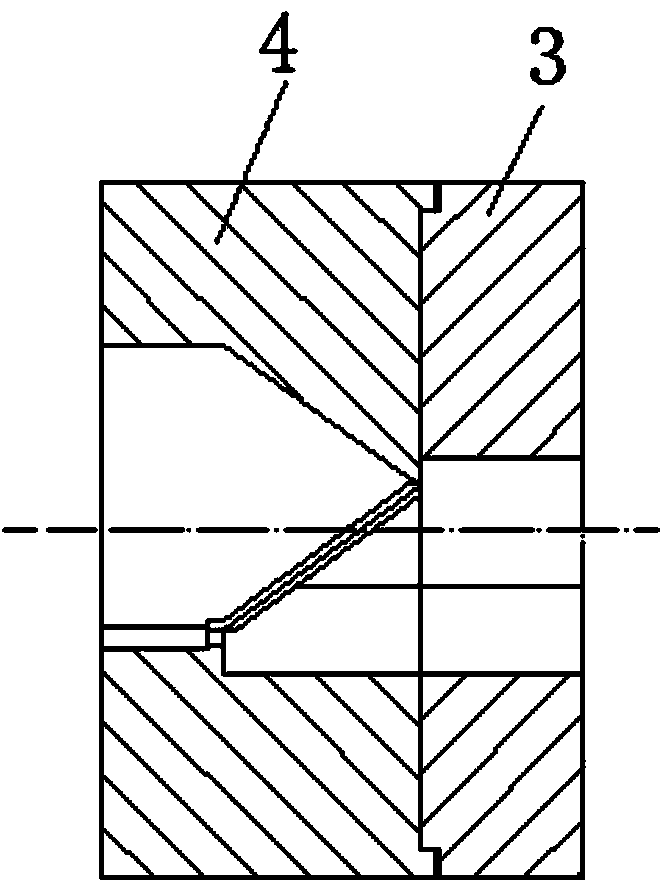

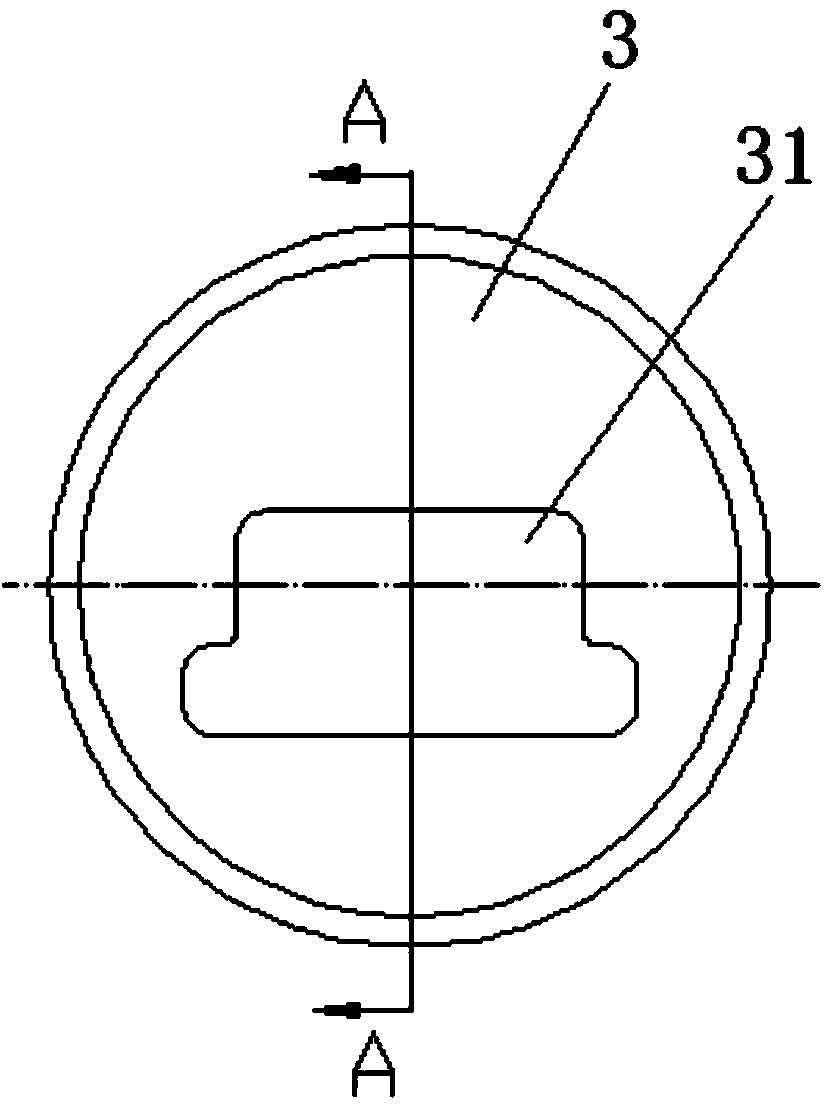

[0026] The structure of the high-reinforcement type material is as follows: figure 1 As shown, it consists of a base plate 1 and a high rib tooth 2. The mold of the continuous gradual extrusion high-rib type material of the present invention is as follows figure 2 As shown, it includes an upper mold 3 and a lower mold 4, and the rear end surface of the upper mold 3 and the front end surface of the lower mold 4 respectively have protrusions and depressions with conforming shapes. Such as image 3 , Figure 4 As shown, the center of the upper mold 3 has a guide hole 31 . Such as Figure 5 , Figure 6 , Figure 7 As shown, the middle position of the front end surface of the lower mold 4 is provided with a material-relieving hole 45 having the same shape and size as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com