Anchorage performance detection testing apparatus and method for carbon fiber adhesion reinforcement

An anchoring performance and test device technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems that carbon fiber reinforced beams cannot accurately exert the reinforcement effect, failure of the anchorage area of carbon fiber reinforced beams, and structural damage of carbon fiber reinforced beams. Achieve the effects of reducing the length of the cantilever, facilitating processing and manufacturing, and reducing the internal force of the bending moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

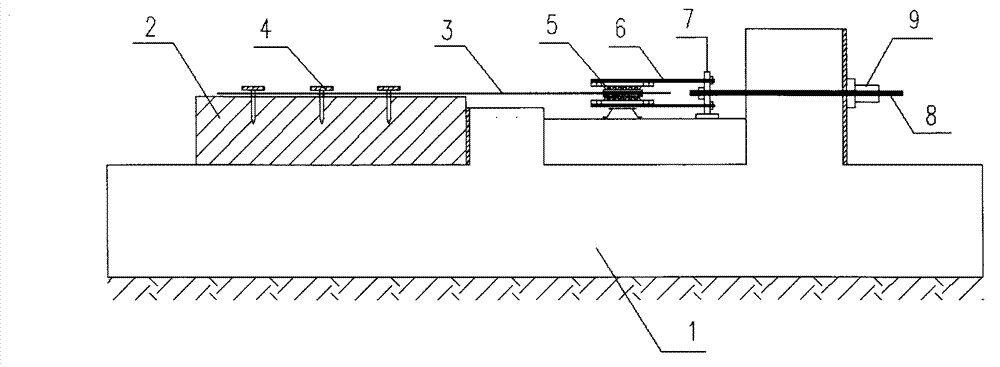

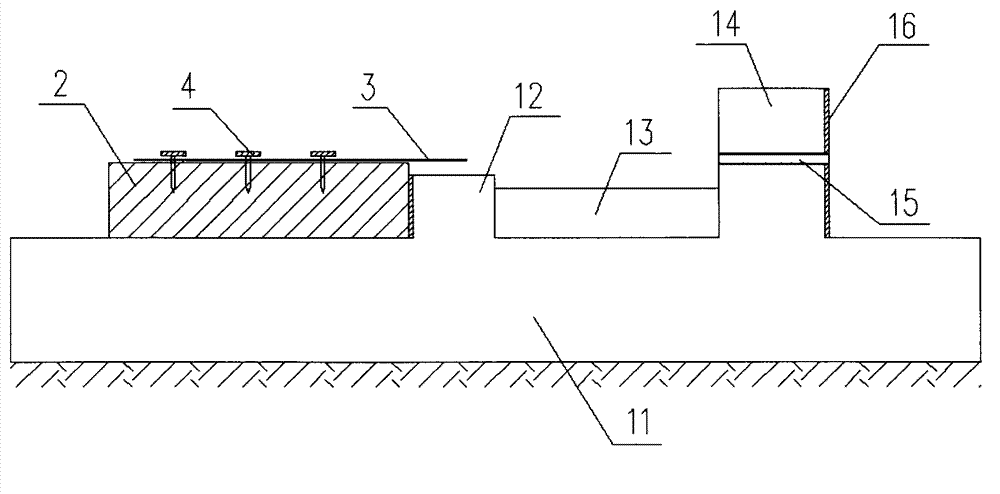

[0044] The anchoring performance testing device for carbon fiber paste reinforcement of the present invention consists of a reinforced concrete test bench 1, a reinforced concrete cuboid test piece 2, a carbon fiber sheet test piece 3, an auxiliary anchor 4, a test fixture 5, a connecting screw rod 6, and a tension connection Steel plate 7, tension screw rod 8, through-hole jack and sensor 9 are formed. Reinforced concrete cuboid specimen 2 is placed on the top surface of reinforced concrete test bench 1, and is tightly connected to the block of reinforced concrete test bench 1. Carbon fiber sheet test specimen 3 is pasted on the upper surface of reinforced concrete cuboid specimen 2, and the auxiliary anchor 4 Compress the carbon fiber sheet test piece 3, the tail of the carbon fiber sheet test piece 3 is clamped by the test fixture 5, and four connecting screws 6 are welded on the surface of the outer cover steel plate of the test fixture 5, and the test fixture 5 is connecte...

Embodiment 2

[0049] The above-mentioned anchoring performance testing device for carbon fiber paste reinforcement is used for testing, including the following steps:

[0050] Step 1) Make a plurality of reinforced concrete cuboid specimens 2, stick the carbon fiber sheet test piece 3 on the upper surface of the reinforced concrete cuboid specimen 2 with impregnated structural glue, use the auxiliary anchor 4 to compress the carbon fiber sheet test piece 3, and wait After the impregnated structure is hardened, transport the test specimen to the structure test center;

[0051] Step 2) Place the above-mentioned test specimen on the top surface of the reinforced concrete test bench 1, and tighten it with the stopper of the reinforced concrete test bench 1, and clamp the tail of the carbon fiber sheet test specimen 3 with the test fixture 5, pass The connecting screw 6 connects the test fixture 5 with the tension connecting steel plate 7, and installs the tension screw 8, the through-type jack ...

Embodiment 3

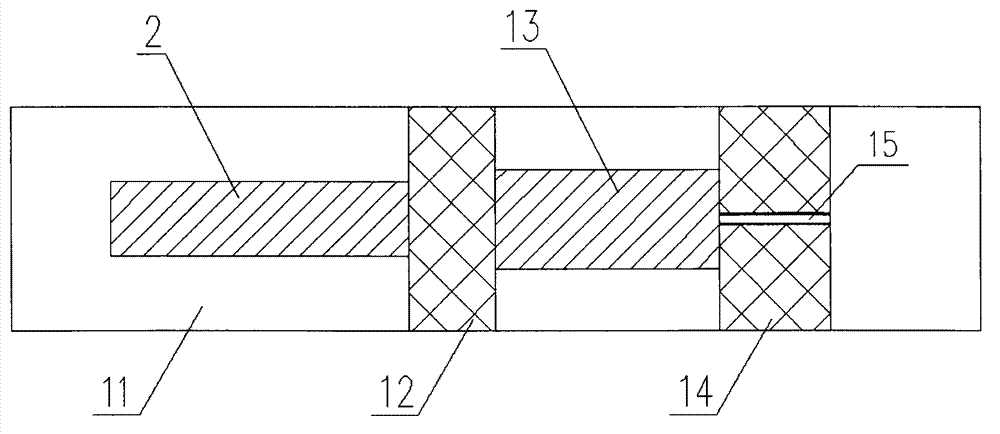

[0054]An anchoring performance test device for carbon fiber reinforcement is made to verify the rationality of the carbon fiber reinforcement anchoring scheme and to detect the construction quality of carbon fiber reinforcement. The plane size of the base of the reinforced concrete test bench is 900×3900mm, and the thickness is 500mm. On the base, a stopper, a connecting stand and a tensioning stand are arranged in sequence. 200mm, the section size of the tensioning table is 450×600mm, a φ40mm reserved hole is set in the middle of the tensioning table, and the thickness of the embedded iron plate on the right side of the tensioning table is 12mm. The size of the reinforced concrete cuboid specimen is 300×300×1200mm, with 4φ12 longitudinal steel bars and φ6200 stirrups inside. The carbon fiber sheet pasting method and auxiliary anchor setting method are divided into three groups, and the width of each carbon fiber sheet is 100mm. Group a: paste two layers of 0.168mm thick carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com