Inspection and detection method for cast-in-place large-span concrete hollow slab

A detection method and hollow plate technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of inability to meet the needs of engineering inspection and detection, inability to accurately judge whether the web is through, and the width of the "I" beam web is reduced. Achieve the effect of solving inspection and testing problems, good bearing performance, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

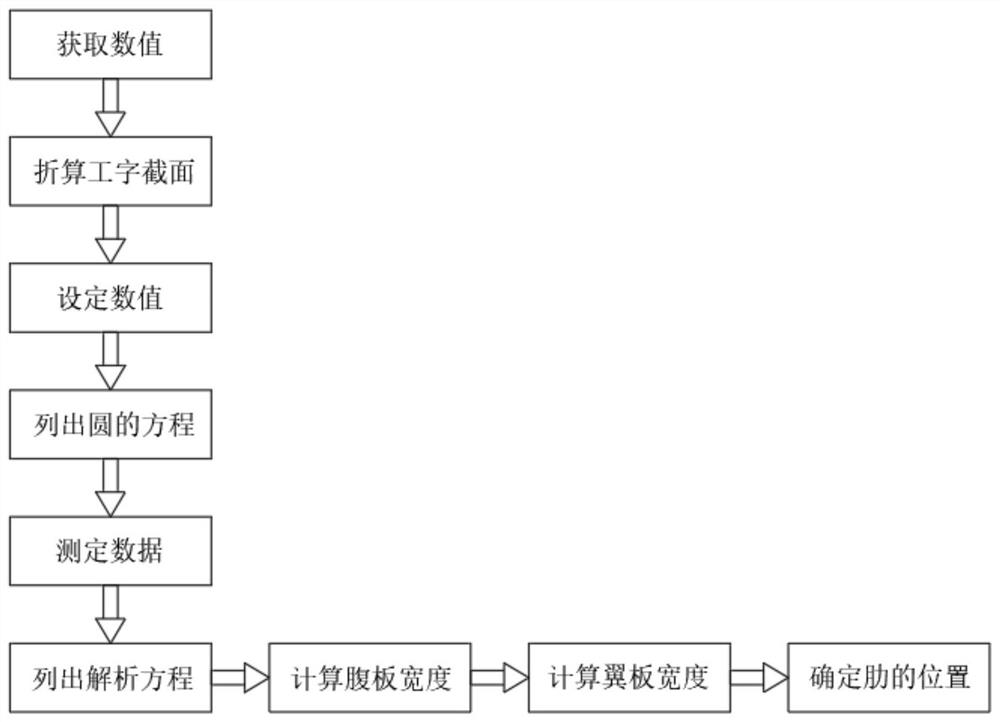

[0020] refer to figure 1 , an inspection and detection method for cast-in-situ large-span concrete hollow slabs, comprising the following steps:

[0021] S1: In the cast-in-place hollow slab member, calculate the plate width B of N holes intercepted in the direction of the parallel holes, calculate the circular hole part into a rectangle with equal area, equal centroid, and equal moment of inertia, and convert it into an "I"-shaped cross section;

[0022] S2: Assuming the diameter of the round hole is d, the width of the converted rectangle is b1, and the height is h1, then: the length L of the plate taken from the center of the rib in the direction perpendicular to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com