A kind of hydraulic pipeline pressure test method

A pressure test and hydraulic pipeline technology, applied in the field of hydraulic systems, can solve the problems that the pressure cannot reach the test pressure, the pressure test range is not comprehensive, and the pressure peak value is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

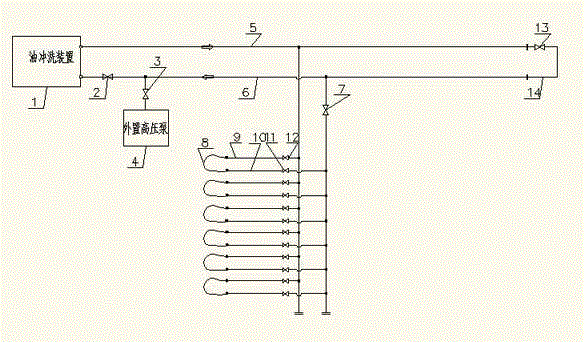

[0014] Such as figure 2 As shown, the pressure test of the present invention is carried out before an oil flushing, and the pressure test medium adopts the medium for flushing, and the test medium is input into the hydraulic pipeline by the oil flushing device 1, and the test pressure is provided by the external high-pressure pump 4, and the external high-pressure pump It is connected with P pipe, A and B pipes; during the pressure test, start the oil flushing device, close the high-pressure ball valve c, open all other high-pressure ball valves, and perform low-pressure circulation first, so that the flushing medium can fill the entire loop; after closing the oil flushing device, Open the high-pressure ball valve b 2 and high-pressure ball valve m 13, open the high-pressure ball valve c 3 and k 11, start the external high-pressure pump 4, and deflate again at the one-way valve set at the high point of the pipeline circuit when the pressure rises to 3MPa and 5MPa respectively;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com