Flow control method and system for adding spice liquid in tobacco processing technology

A processing technology and flow control technology, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of large flow fluctuation of mixed silk, large fluctuation of material liquid flow, affecting the internal quality stability of products, etc., to improve the stability. , The effect of reducing the flow fluctuation of the flavoring liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

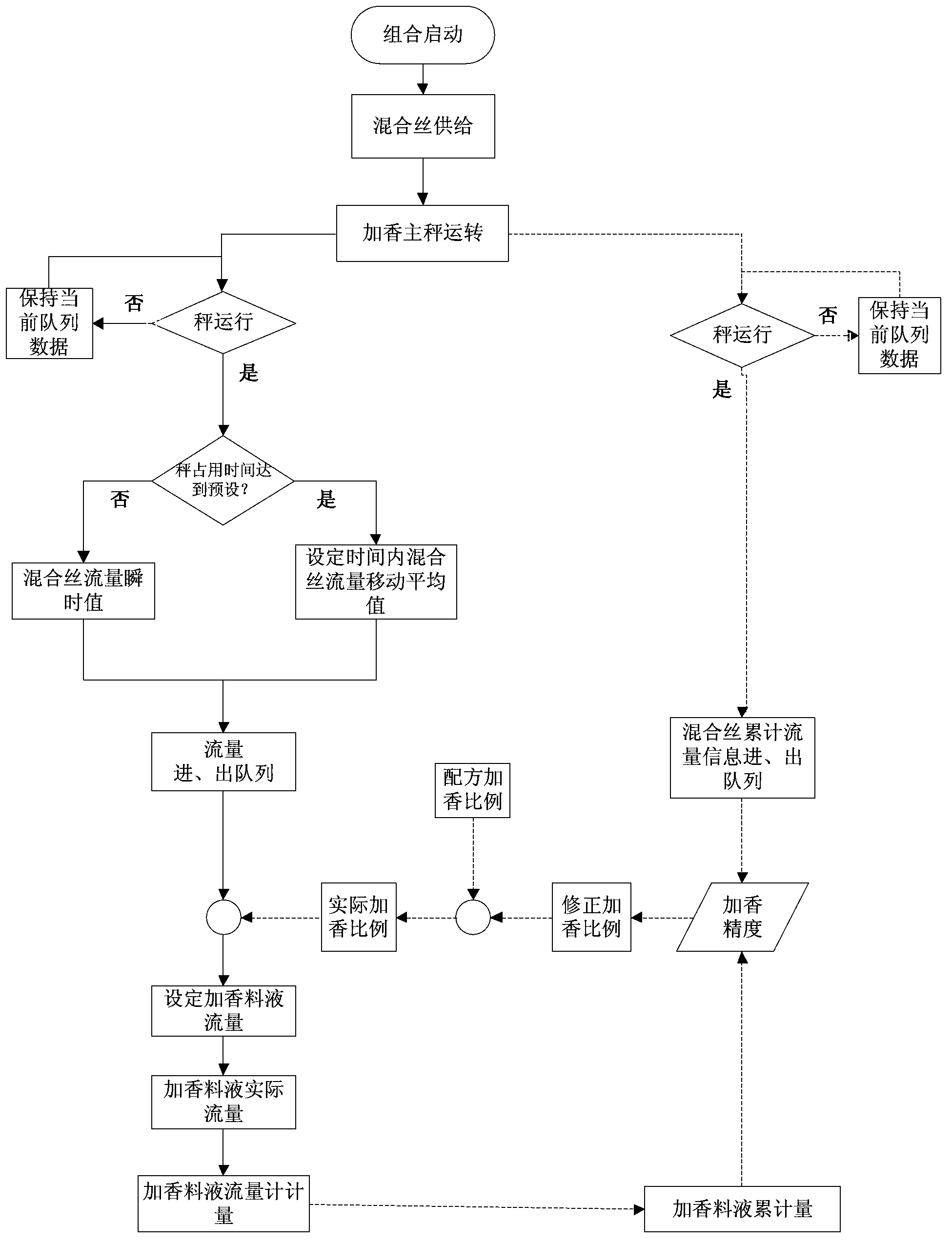

[0018] Such as figure 1 Shown, a kind of flow control method that is used for flavoring liquid in the tobacco processing technology of the present invention comprises:

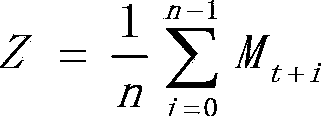

[0019] Step 1, measuring and collecting the instantaneous flow information of the mixed filament within a predetermined period of time with a fixed collection cycle. Specifically, when the system is running, the mixed yarn passes through the metering type flavoring main scale, so as to obtain the instantaneous flow information of the mixed yarn. In this embodiment, the instantaneous flow information of the mixed filaments can be stored in a FIFO queue of size n in chronological order, denoted as M t+0 , M t+1 ..., M t+n-1 . And the data of the instantaneous flow information of the mixed wire is updated according to the collection period. Generally, the collectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com