Bucket tooth installation structure convenient for rapid disassembly and assembly

A technology for installing structures and bucket teeth, which is applied in earth movers/excavators, construction, etc., can solve the problems of small radial expansion force, wear failure, etc., and achieve the effects of large lateral rigidity, long life and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

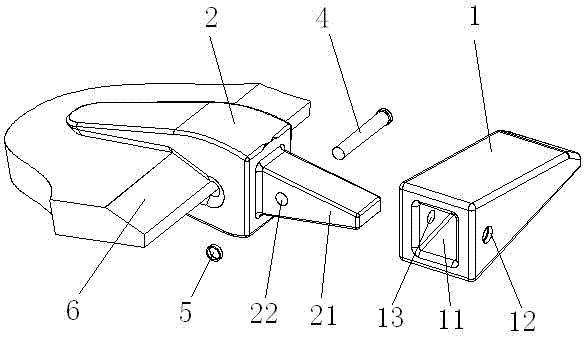

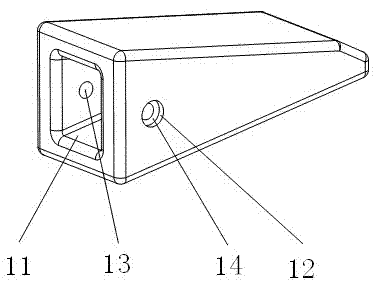

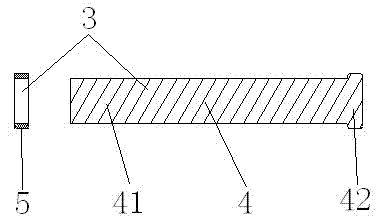

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the present invention includes a bucket tooth 1, a tooth holder 2 and a pin assembly 3; wherein the bucket tooth 1 has a bucket tooth chamber 11, and the front part of the tooth holder 2 has a tooth holder head 21, and the bucket tooth chamber 11 and the tooth holder head 21 The shapes are complementary, the tooth seat head 21 is accommodated in the bucket tooth cavity 11, the bucket tooth 1 and the tooth seat head 21 are fixedly connected by the pin assembly 3; The coaxial hole in the center plane of bucket tooth 1, wherein the inner hole 13 of the tooth cavity on both sides is smaller than the outer hole 12 of the tooth cavity, and the inner hole 13 of the tooth cavity on both sides and the outer hole 12 of the tooth cavity respectively form an annular concave platform; The pin assembly 3 includes a pin 4 and a memory alloy expansion ring 5; one end of the pin 41 of the pin 4 has a pin cap 4...

Embodiment 2

[0035] Such as Figure 6 Shown is an axial center sectional view of the pin assembly in Embodiment 2 of the present invention. and Example 1 image 3 In comparison, an annular groove 43 is provided at the end of the pin 41 of the pin 4 . At high temperature (that is, the temperature is higher than the transition temperature of the memory alloy material), the inner diameter of the memory alloy expansion and contraction ring 5 expands to be larger than the diameter of the end of the pin 4 pin 41, which can be easily installed and disassembled; at normal temperature, the memory alloy expands and contracts The inner diameter of the ring 5 is reduced and tightens around the annular groove 43 . Except for this, Example 2 is the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com