Patents

Literature

34results about How to "Guaranteed deflection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

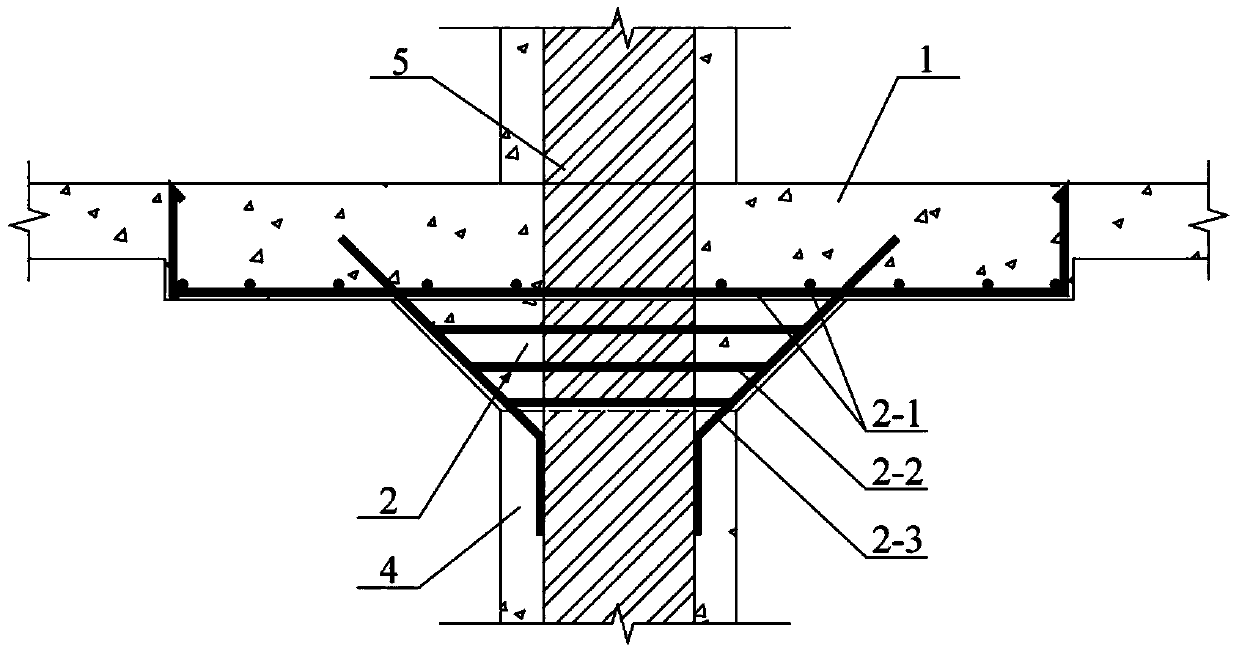

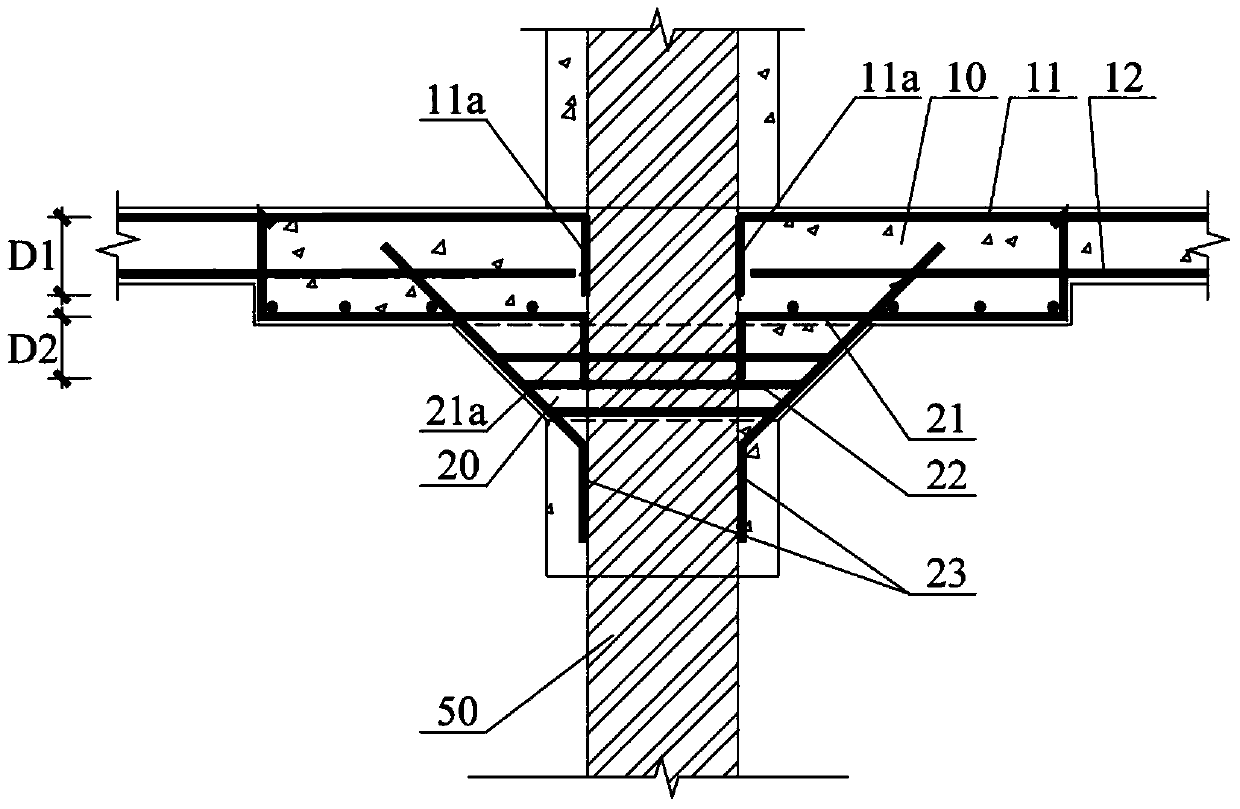

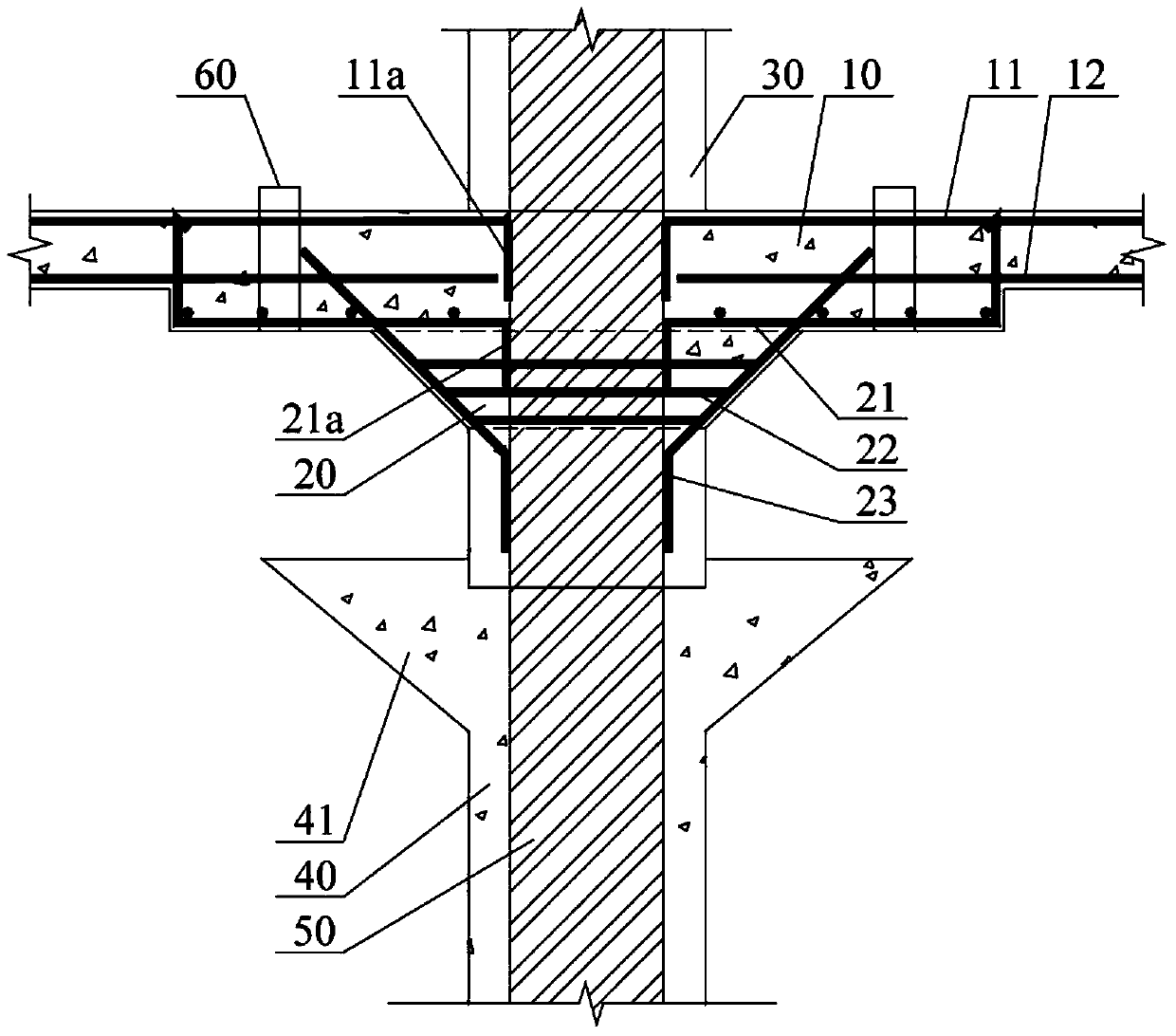

Method for constructing connection joint between flat slab and post cap in reverse construction method

ActiveCN103790379AClosely connectedImprove mechanical performanceBuilding material handlingPunchingSteel columns

The invention provides a method for constructing a connection joint between a flat slab and a post cap in a reverse construction method, and relates to the technical field of concrete supporting components. The method aims to solve the problems that in the prior art, a flat slab and a post cap are poured and constructed successively, accordingly, shrinkage cracks are prone to being formed a connection joint, bearing capacity, rigidity and punching-resistant capacity of the flat slab are reduced, reverse construction operations are extremely inconvenient and operation efficiency is reduced. The method includes the following steps that firstly, an upper-layer steel bar and a lower-layer steel bare of the flat slab to be poured and an embedded steel bar, a horizontal hoop rib and radial inclined ribs of the post cap to be poured are distributed surrounding a reserved steel column; a formwork is erected, concrete is poured, the formwork is dismantled after the concrete is hardened, and the flat slab and the post cap, which are connected into a whole, are manufactured. Through the method, the flat slab and the post cap can be poured to form a whole and are connected more tightly, the punching-resistant requirement can be met and stress performance of the connection joint is improved.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

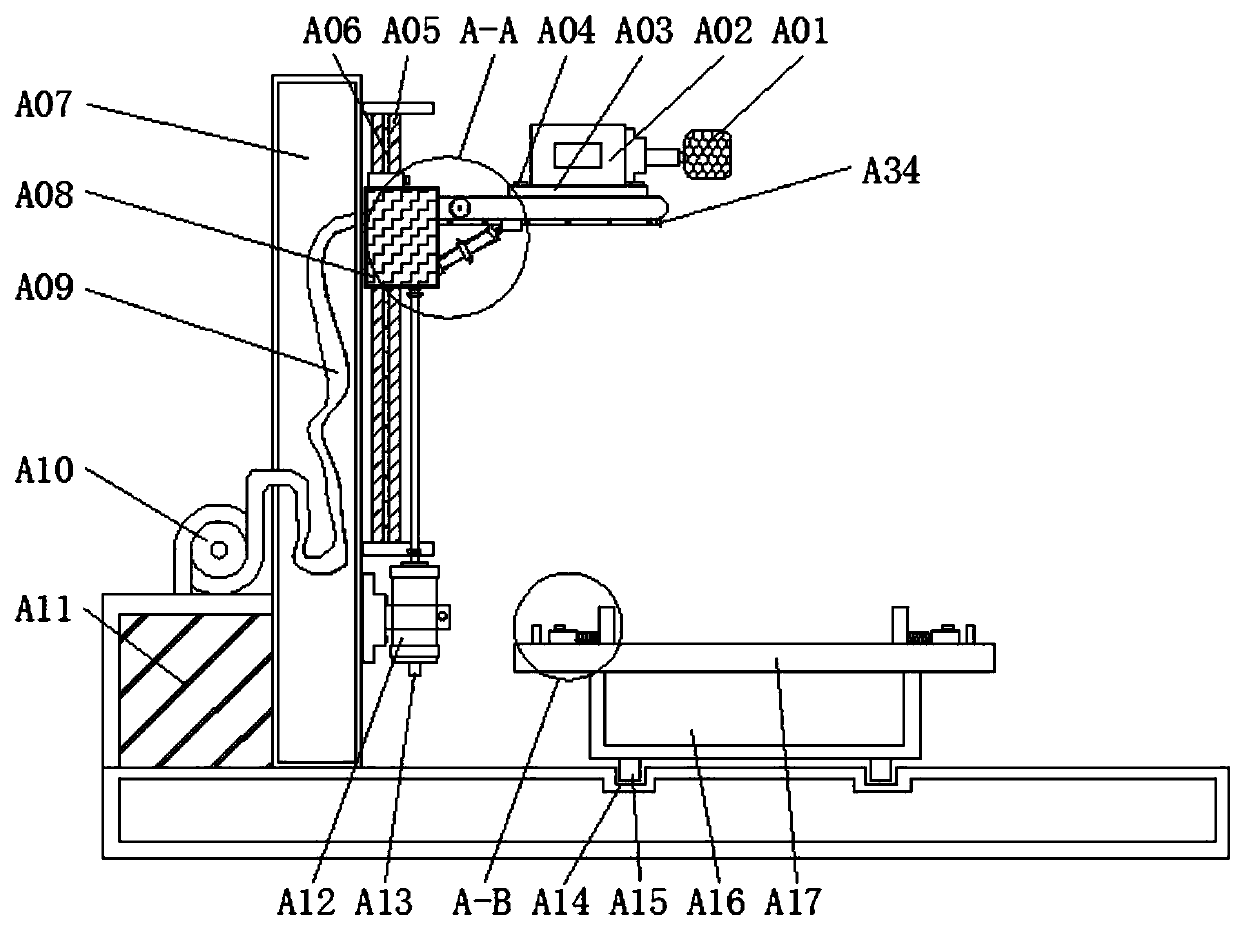

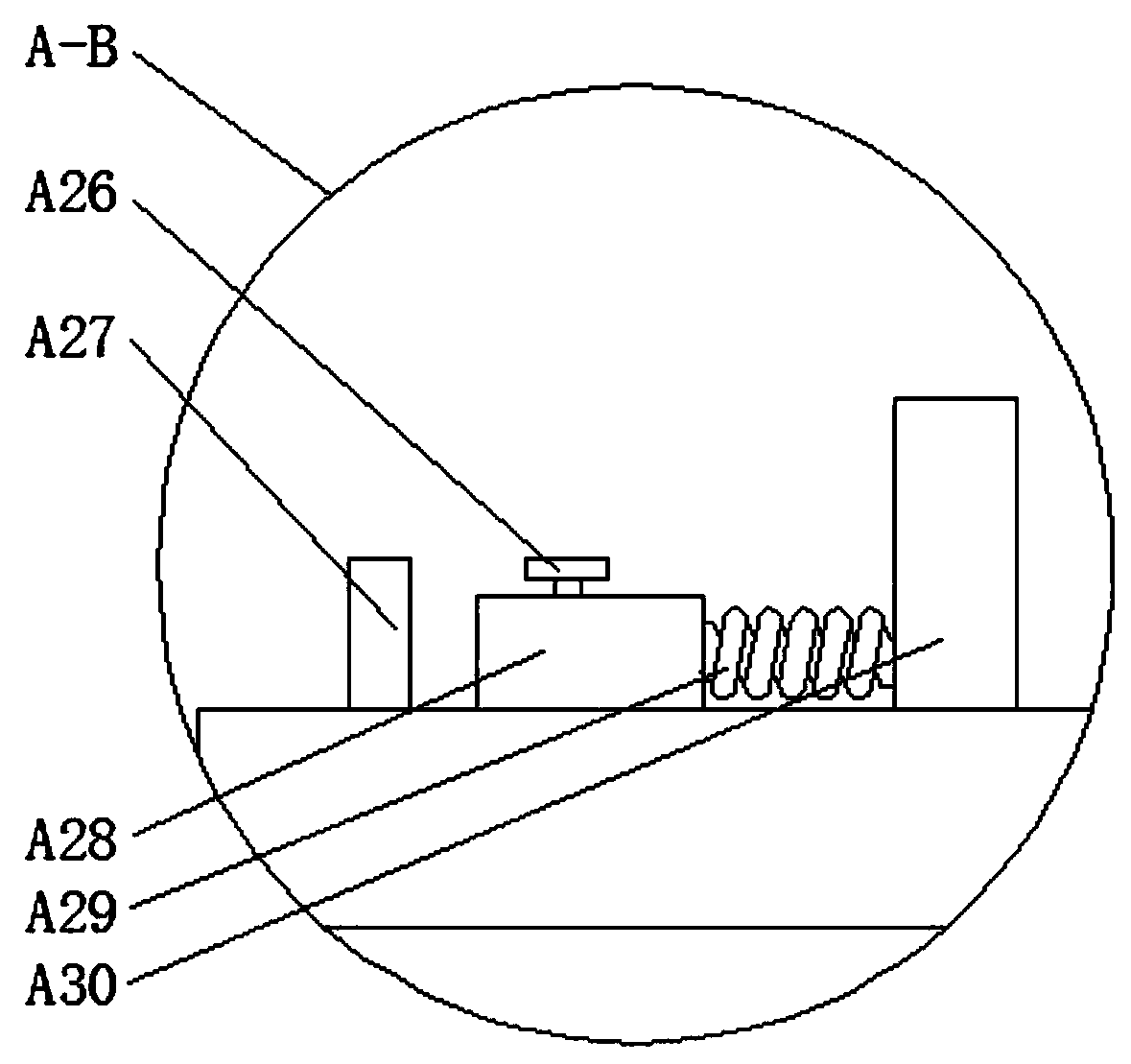

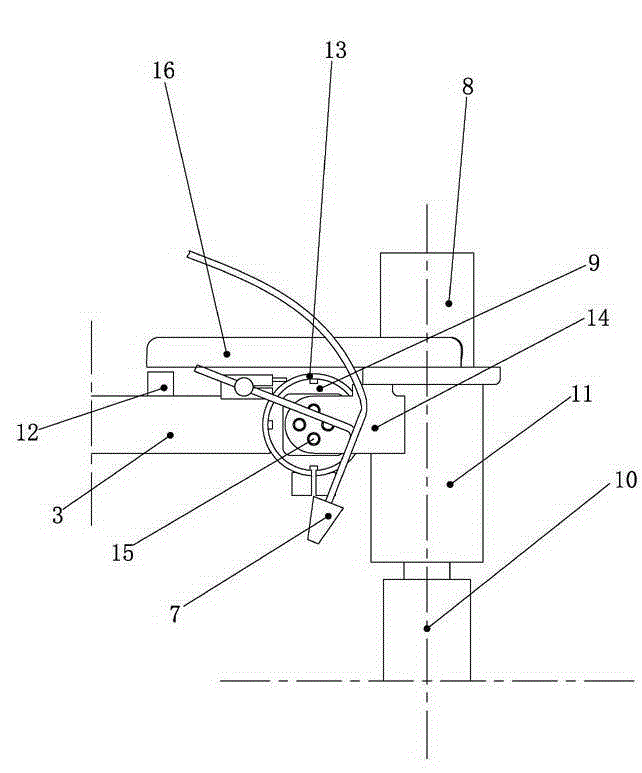

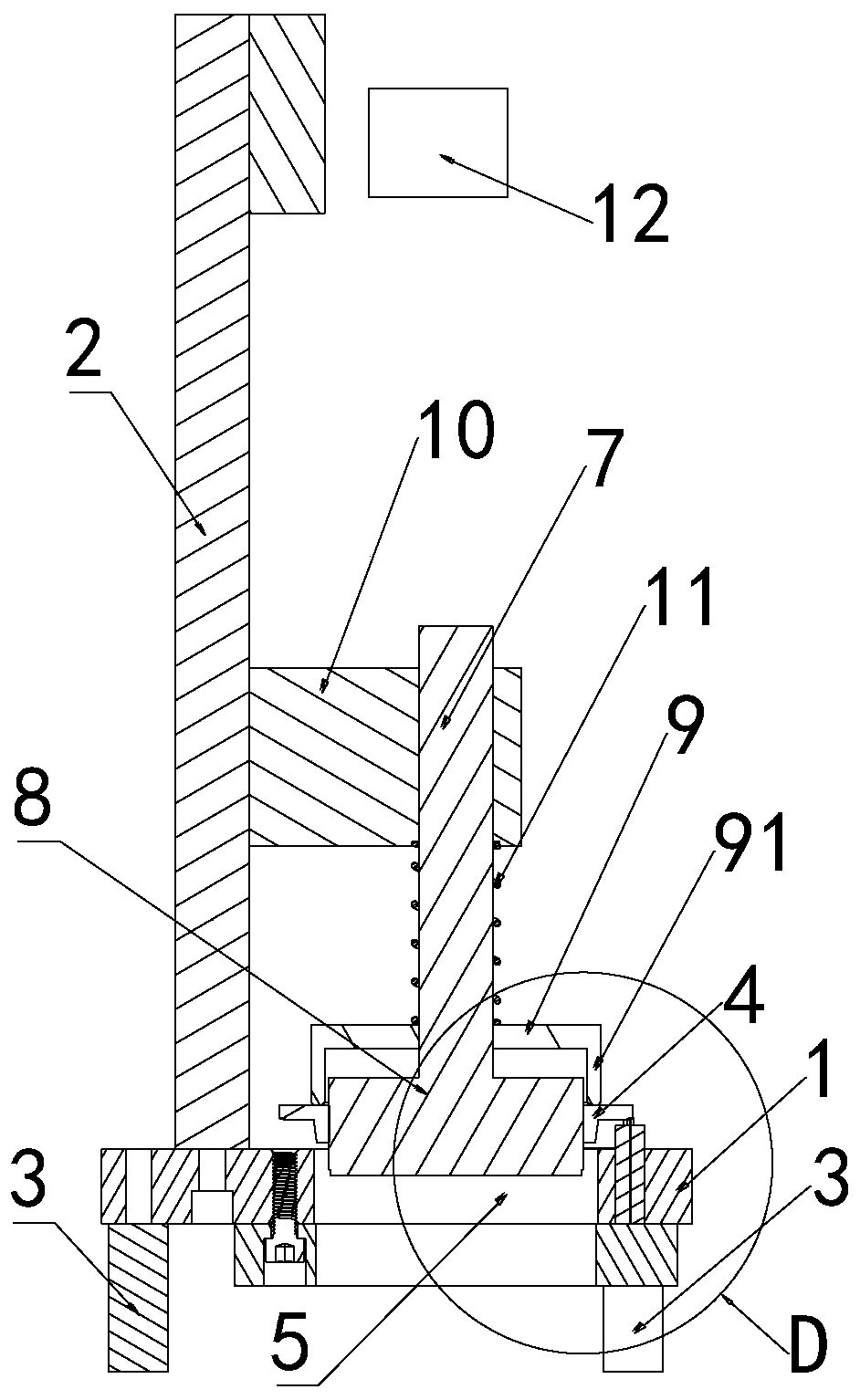

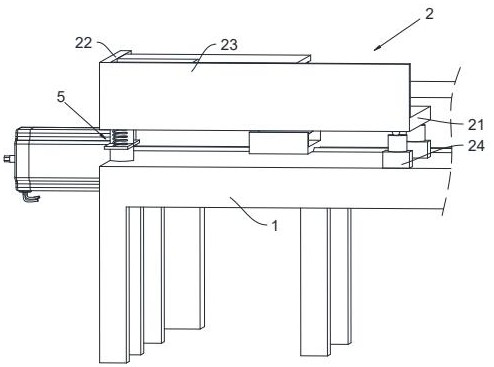

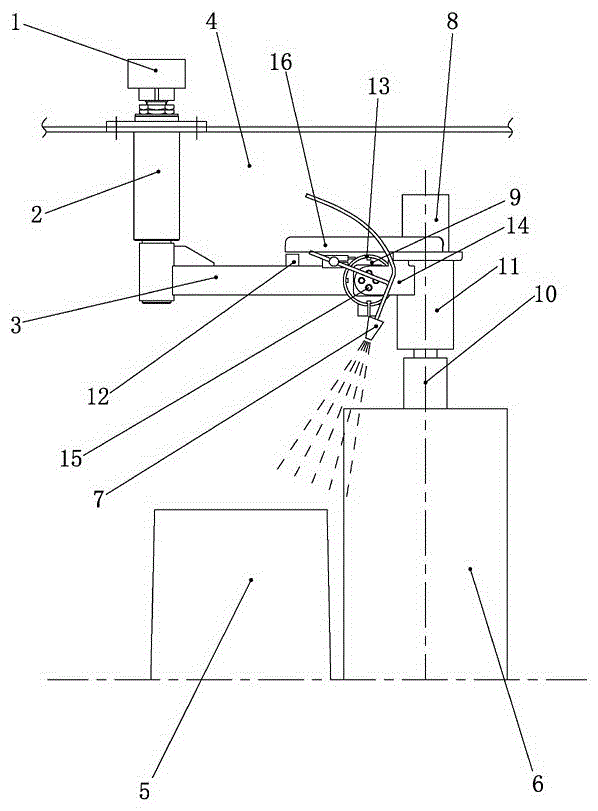

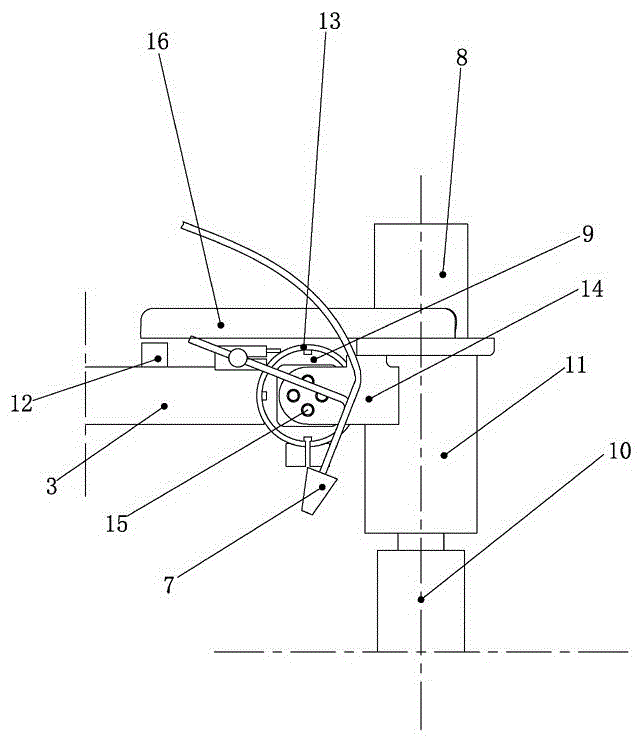

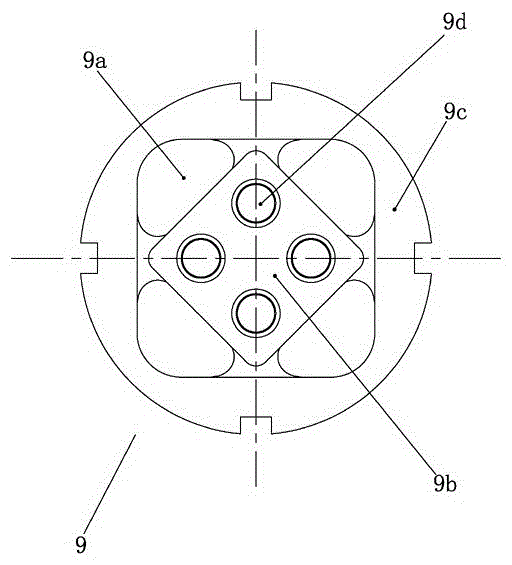

New-energy automotive parts polishing device with cleaning function

InactiveCN110026904AEasy to adjustEasy to adjust and grindGrinding carriagesGrinding drivesNew energyElectric machinery

The invention discloses a new-energy automotive parts polishing device with a cleaning function. The polishing device comprises a polishing drill bit, a column and a worktable, wherein a motor is installed on the left side of the polishing drill bit; fixing bolts are arranged inside a engine base; a fixing buckle is arranged at the lower portion of a transverse plate; the left side of a third sliding block is provided with a hydraulic tappet; a water pump is arranged on the left side of the column; a water pipe is arranged inside the column; a limiting plate is arranged at the upper portion ofthe worktable; a second fixing screw is installed at the upper portion of a limiting block; and a clamp is arranged on the right side of a spring. Compared with an existing polishing device, the new-energy automobile parts grinding device with the cleaning function can clean and collect waste debris generated by polishing at the first time, so that the pollution to the surrounding environment isreduced; most of new energy automobile parts can be polished, so that the applicability is wide; and the clamping is stable and convenient, and the polishing from different angles can be achieved, sothat the working time is saved, and the labor efficiency is improved.

Owner:诸暨市奔宝弹簧有限公司

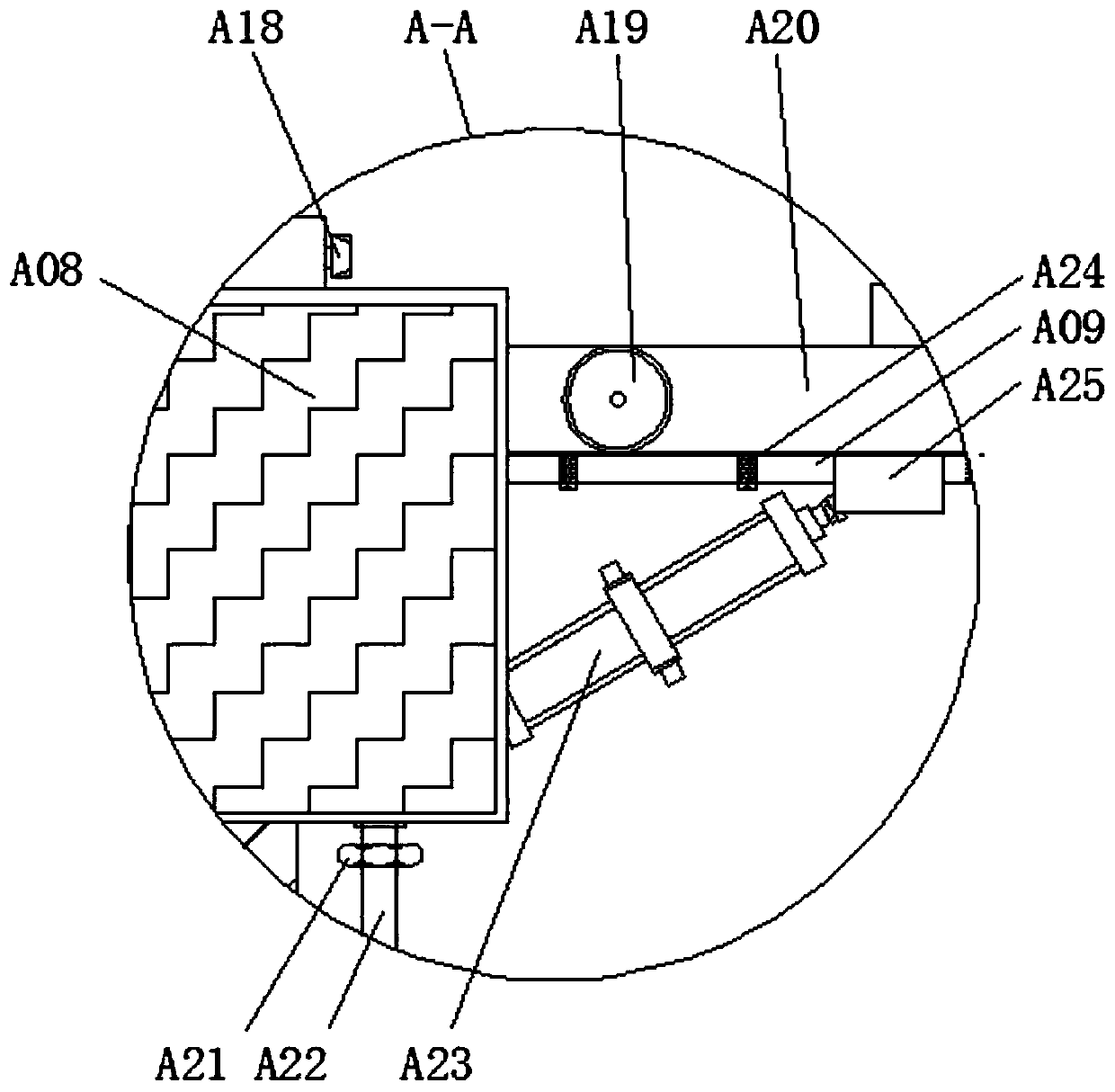

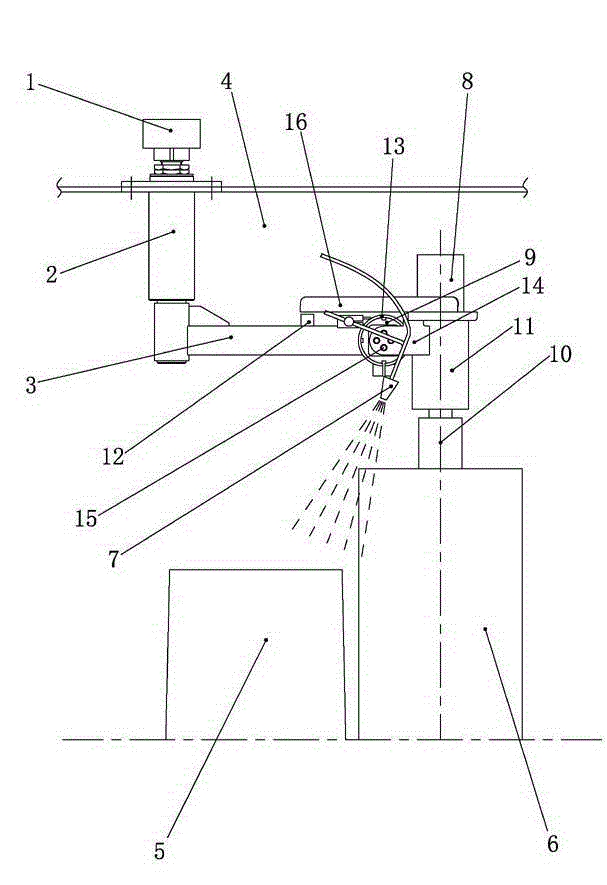

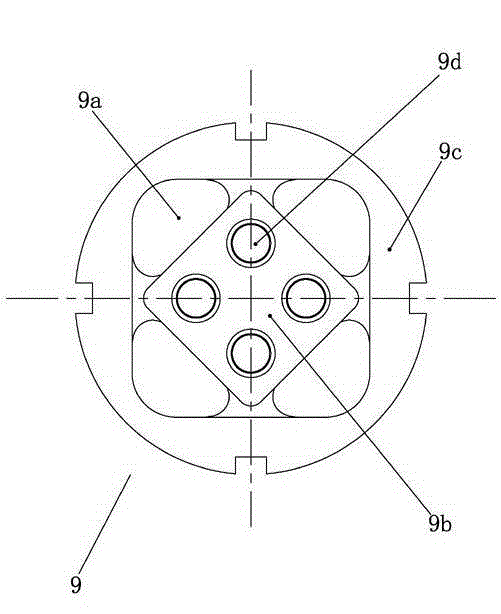

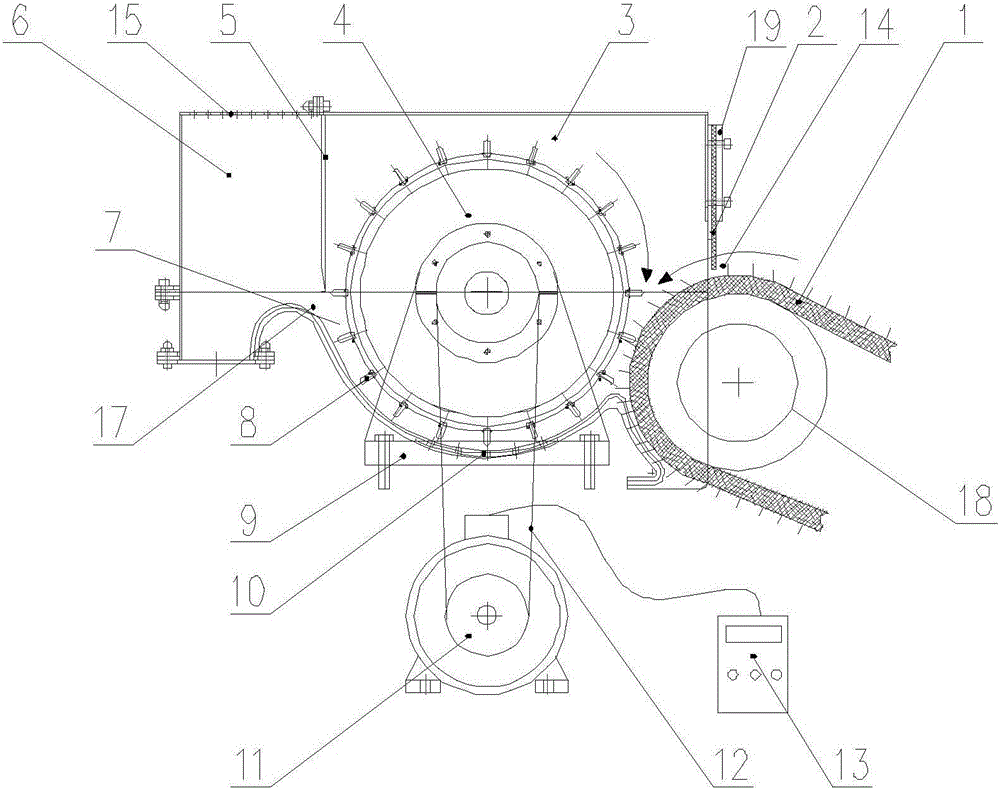

Rubbish can cleaning system

The invention discloses a rubbish can cleaning system and belongs to the technical field of environmental sanitation equipment. The rubbish can cleaning system comprises a driving source, a power spindle, a rotating arm, a rinsing assembly and a spraying mechanism. The rinsing assembly comprises a driving motor, a fixed base, a rotating shaft and a cleaning brush. The axis of the rotating shaft is perpendicular to the extension direction of the rotating arm. A fixed clamping sleeve is fixedly mounted at the end of the rotating arm, and a deflection assembly is fixedly sleeved with the fixed clamping sleeve. The fixed base is fixedly connected with a pair of connecting lug plates. The deflection assembly comprises a central spindle and an outer sleeve body, and the outer sleeve body is sleeved with the fixed clamping sleeve. The cross section of a hollow cavity of the outer sleeve body is square, and the four side faces of the central spindle right face the four corner sides of the hollow cavity of the outer sleeve body. Rubber bodies are plugged between the side faces of the central spindle and the corner sides of the hollow cavity of the outer sleeve body. The two ends of the central spindle are detachably connected with the connecting lug plates. The rubbish can cleaning system can ensure that the cleaning brush has deflection capacity, and accordingly the phenomenon that the outer wall of a rubbish can is abraded due to overlarge contact acting force between the cleaning brush and the outer wall of the rubbish can is avoided.

Owner:YANGZHOU JINWEI ENVIRONMENTAL PROTECTION TECH CO LTD

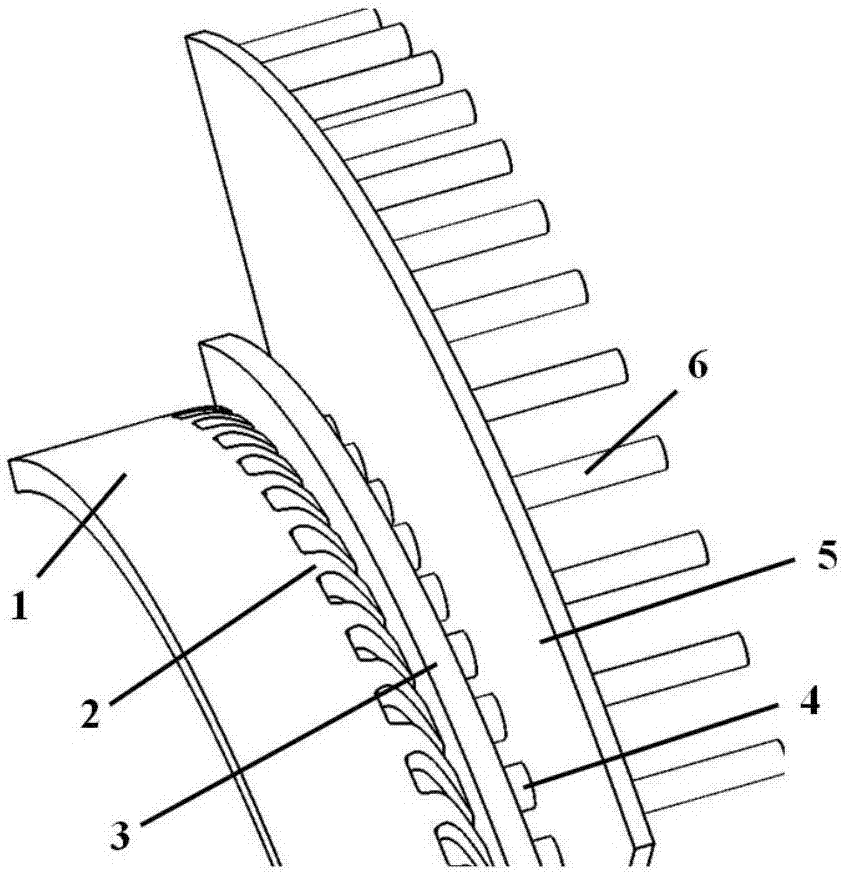

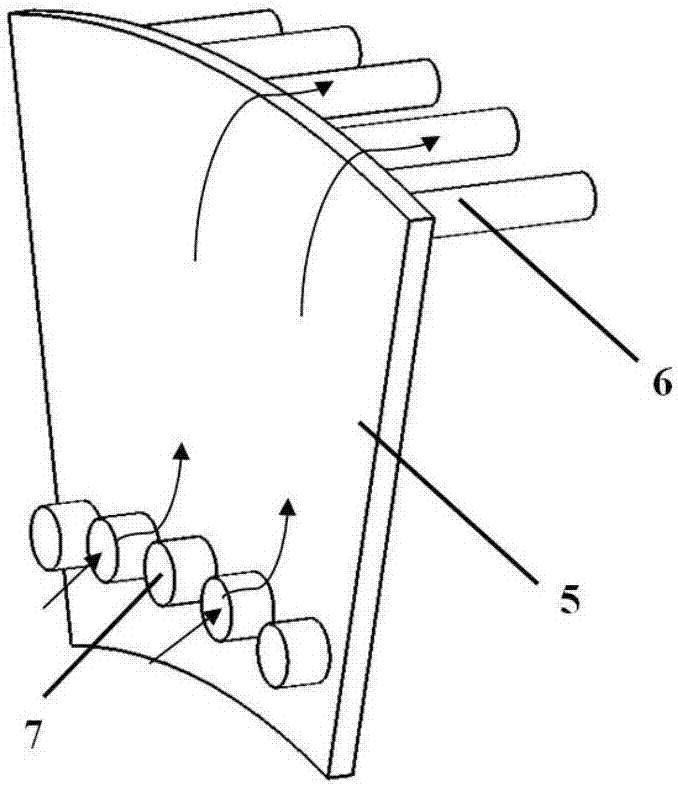

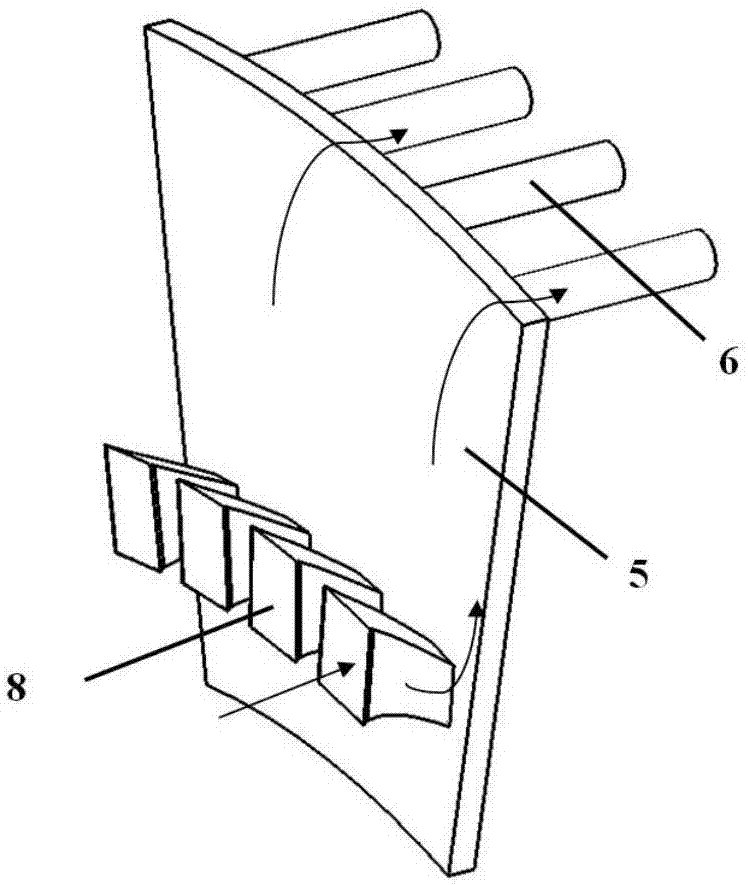

Blade profile receiving hole structure for prewhirl cooling system

InactiveCN107313860AReduce flow lossImprove flow coefficientTurbine/propulsion engine coolingEngineeringSuction surface

The invention discloses a blade profile receiving hole structure for a prewhirl cooling system. Each blade profile receiving hole is an inclined hole deflecting in the rotating direction of a rotary disc, a blade profile receiving hole runner is of a gradual contraction structure so that the effect that airflow is gradually accelerated in the axial flowing process. A blade profile receiving hole deflected profile comprises a self-designed blade profile force suction surface and a self-designed blade profile pressure surface and is used for ensuring the effect that the flowing loss of the airflow is the smallest when the airflow deflects along the blade profile receiving hole deflected profile. Each blade profile receiving hole has a blade profile receiving hole air inlet angle and a blade profile receiving hole air outlet angle which are determined by the nozzle outlet airflow rotating ratio and the receiving hole outlet target rotating ratio. The radial height, extending in the axial direction, of the blade profile receiving holes is gradually decreased. The acceleration characteristic of the blade profile receiving holes is ensured through blade profile receiving hole radial contraction curved surfaces on the two sides of the inlet section radial height and the outlet section radial height of the blade profile receiving holes. The flowing loss of the blade profile receiving holes and the flowing loss of air supply holes are decreased, so that the nozzle outlet rotating ratio is increased, the system temperature lowering seed is increased, and power consumption is reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

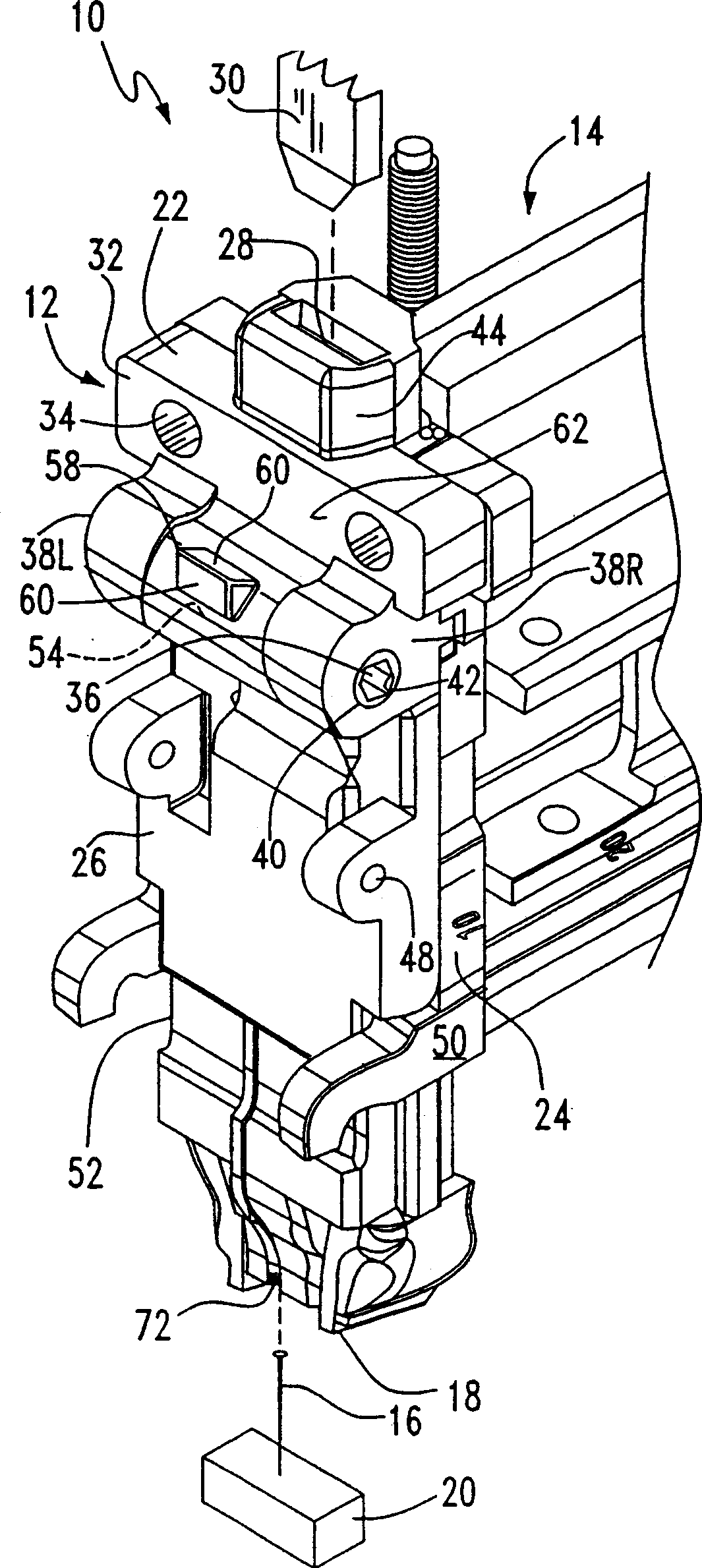

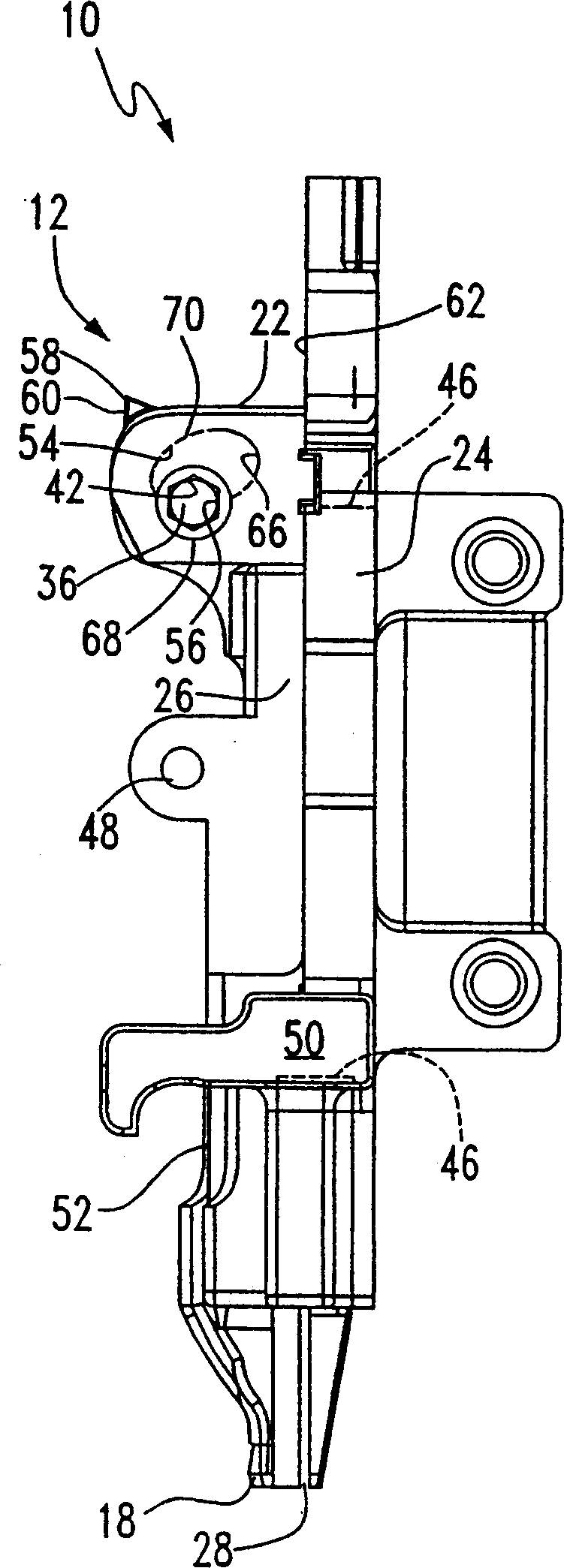

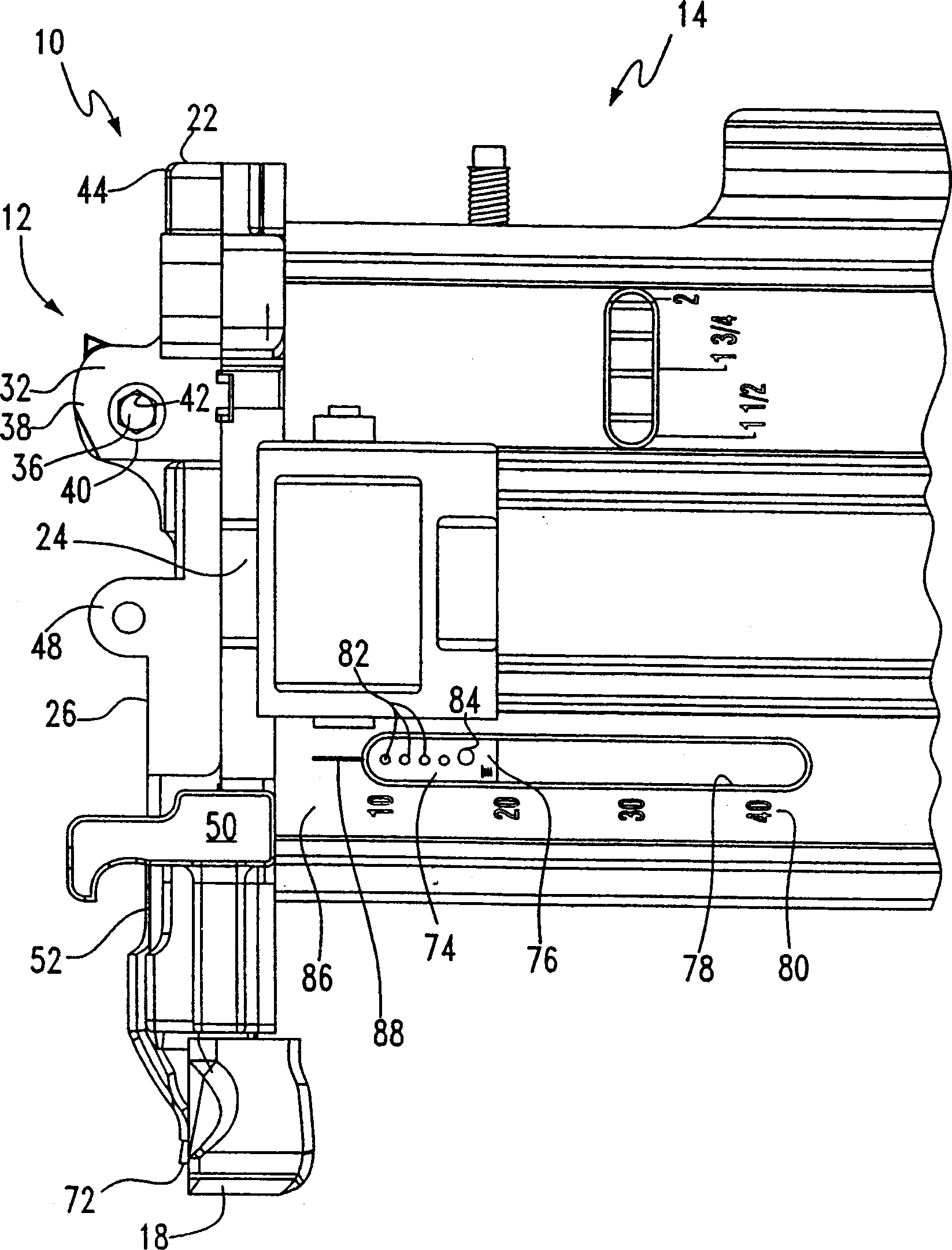

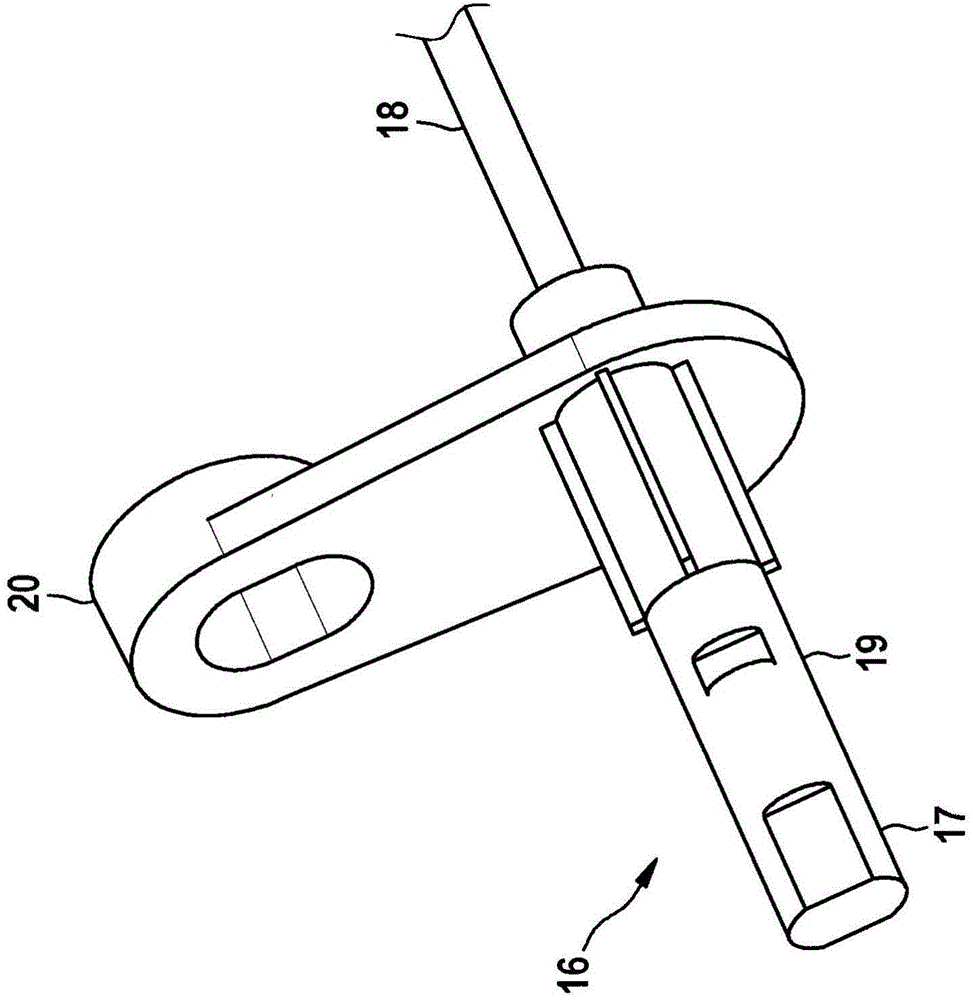

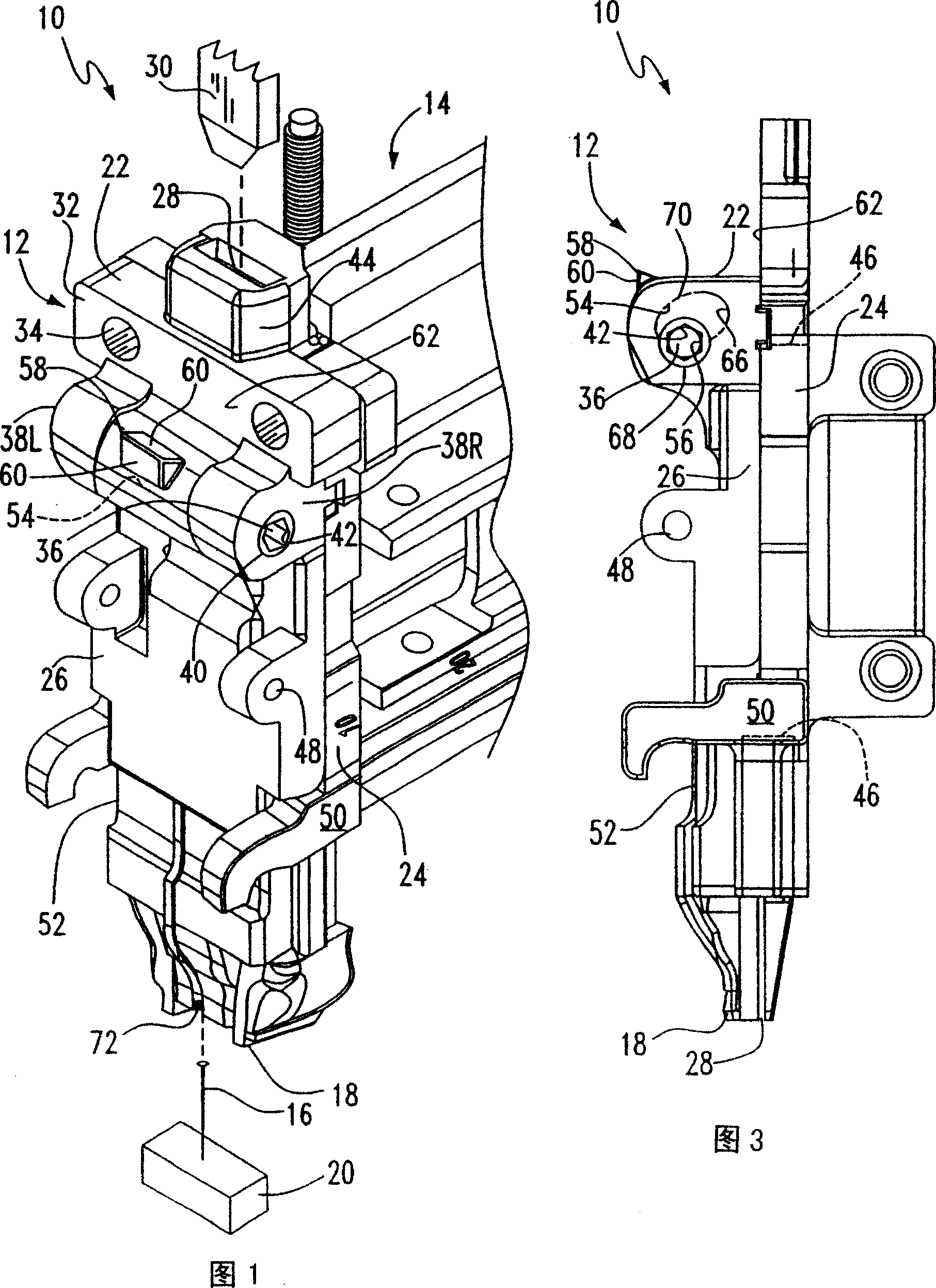

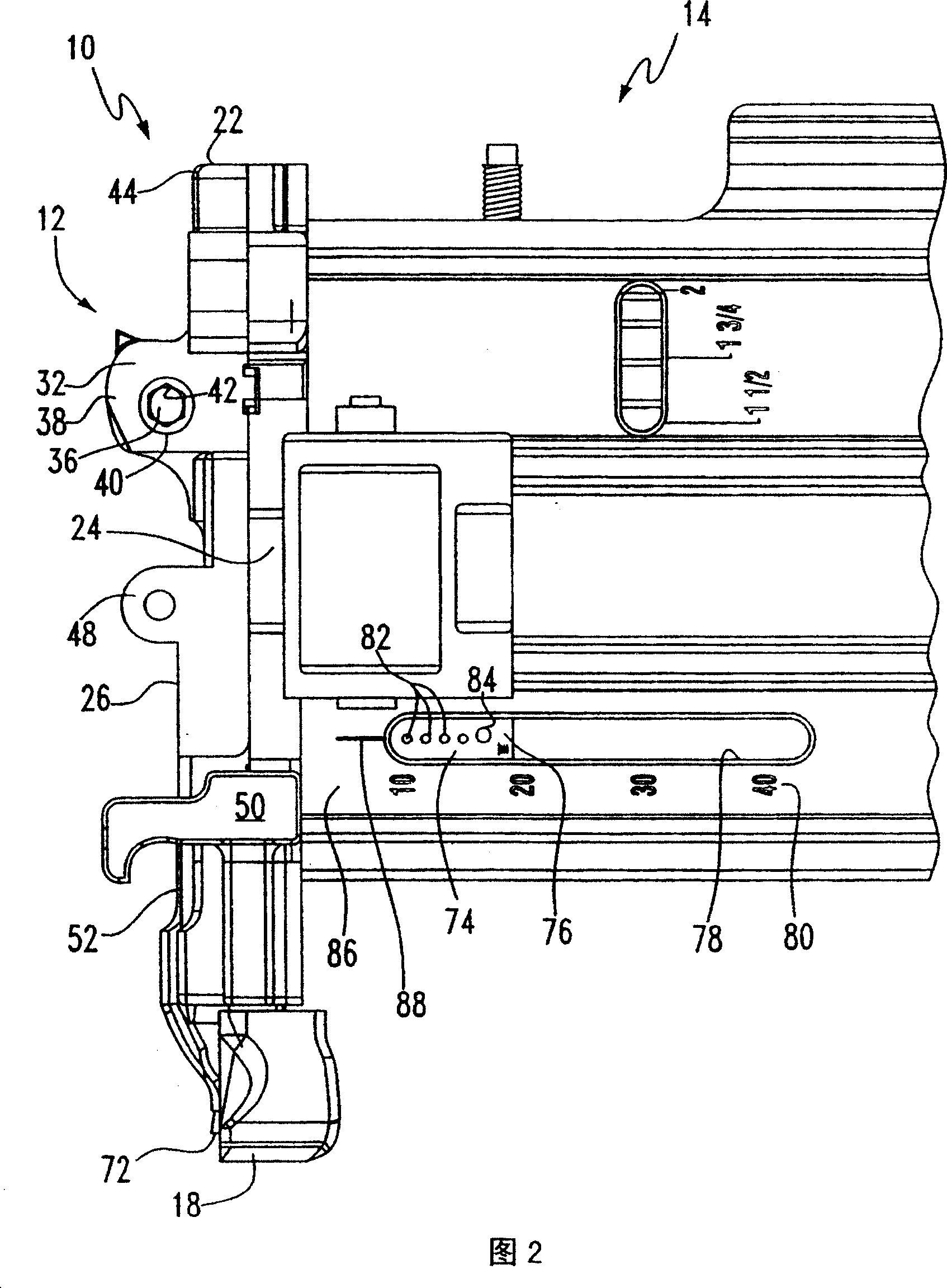

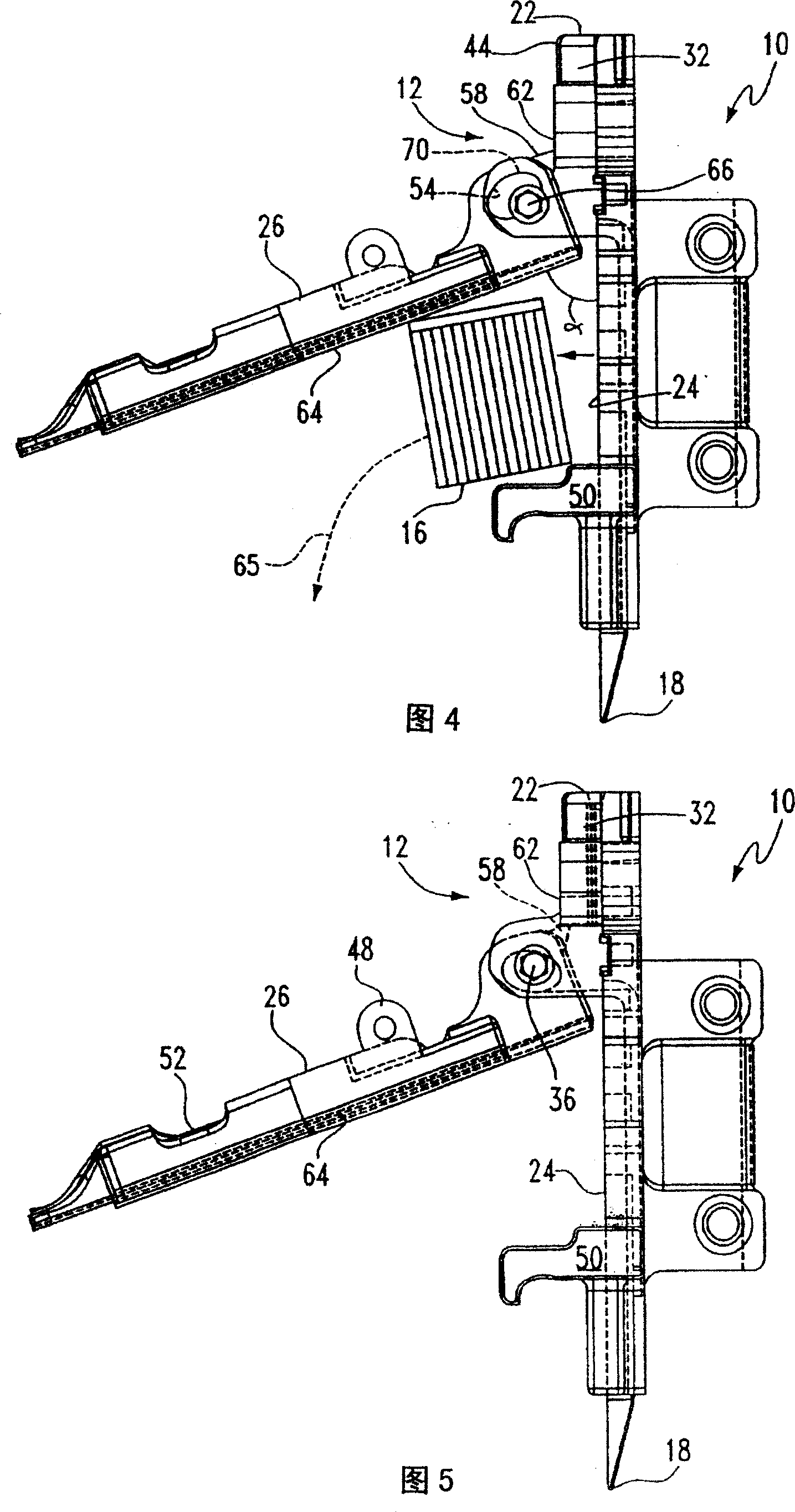

Fitting-up fastenr driving tool

InactiveCN1383959AGuaranteed deflectionOpen fullyStapling toolsDispensing apparatusPower toolFastener

A powered tool (10) constructed to drive a fastener (16) into a workpiece (20) includes a nosepiece assembly (12) including a back plate (24) and a front plate (26) combining to define a path (28) for a driver blade (30), the front plate (26) being pivotally movable relative to the back plate (24) between a closed position, in which the front plate (26) and the back plate (24) are in contact with each other, and an open position. The front plate (26) is movable to an interim deflecting position between the closed position and the open position. A handle portion (90) has an outer surface at least partially defining a grip, and an inner surface at least partially defining a chamber (92). The handle portion (90) includes a substrate having at least one aperture, and an overmold (102) configured for forming a gripping surface on the outer surface and for extending through the apertures into the chamber for forming a resilient mounting point. <IMAGE>

Owner:ILLINOIS TOOL WORKS INC

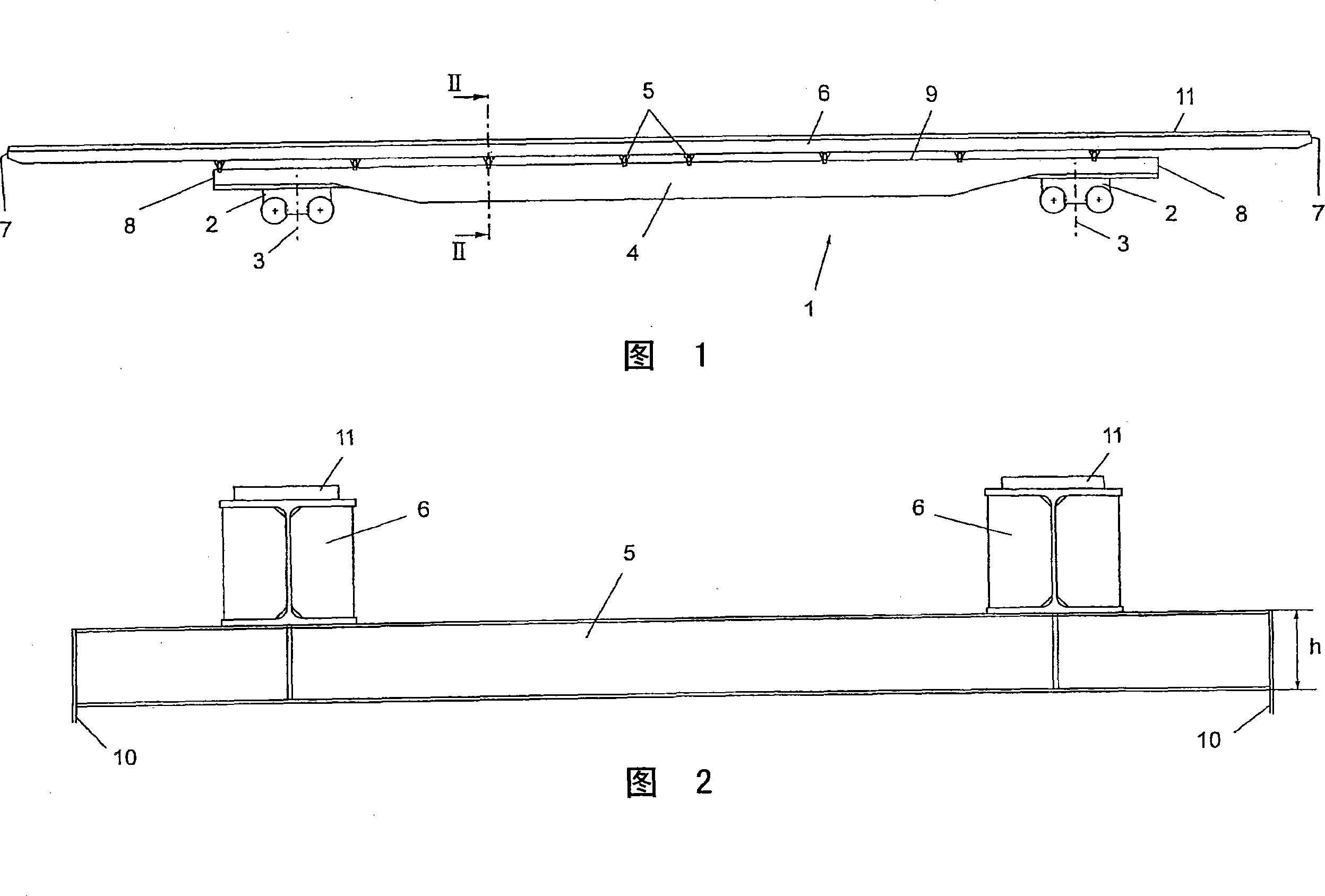

Device for transporting track sections or mounted track connections

InactiveCN101208480AIncreased assembly levelStable structureRailway track constructionWagons/vansEngineeringMechanical engineering

The invention relates to a device for transporting track sections or pre-mounted track connections on railborne platform wagons (1). A plurality of platform wagons (1) can be displaced in a coupled manner. A platform wagon (1) arranged between two other platform wagons comprises at least one carrier or support (5), said carrier or support being higher (4) than the smallest vertical distance between parts which are fixed or mounted on the carriers or supports (5) and project past the platform wagon (1) in the direction of the adjacent platform wagon, such as longitudinal rails (6), or the track section to be transported, and the platform (4) or loading surface of the adjacent platform wagon.

Owner:VAE火车系统有限责任公司 +1

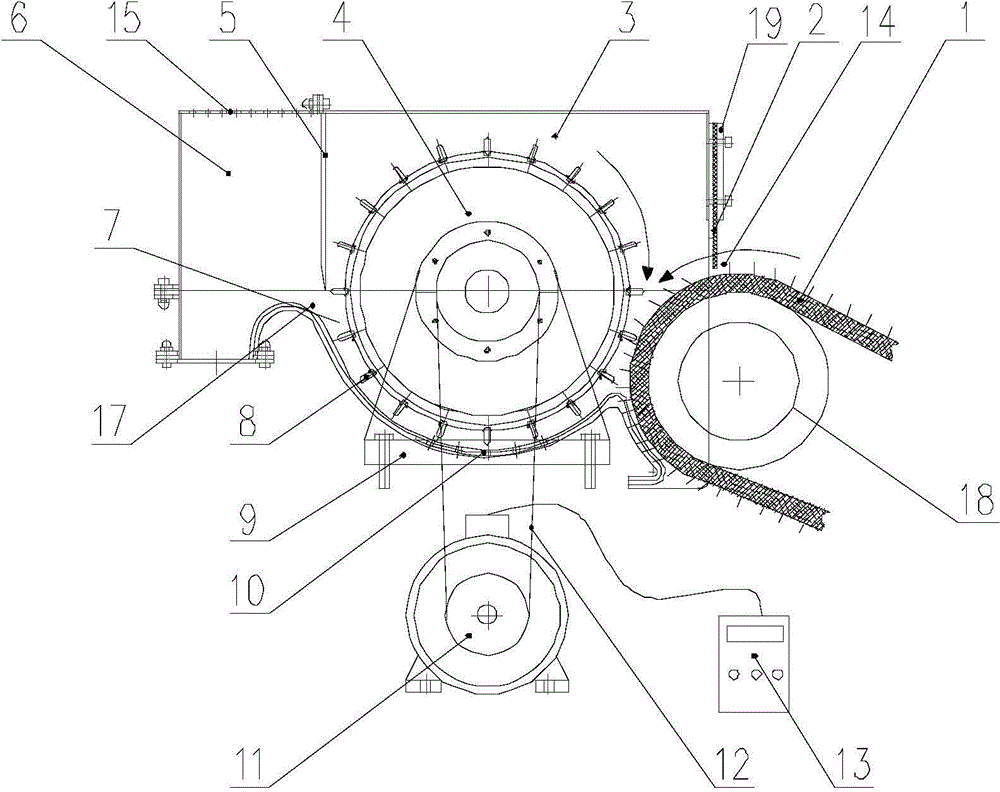

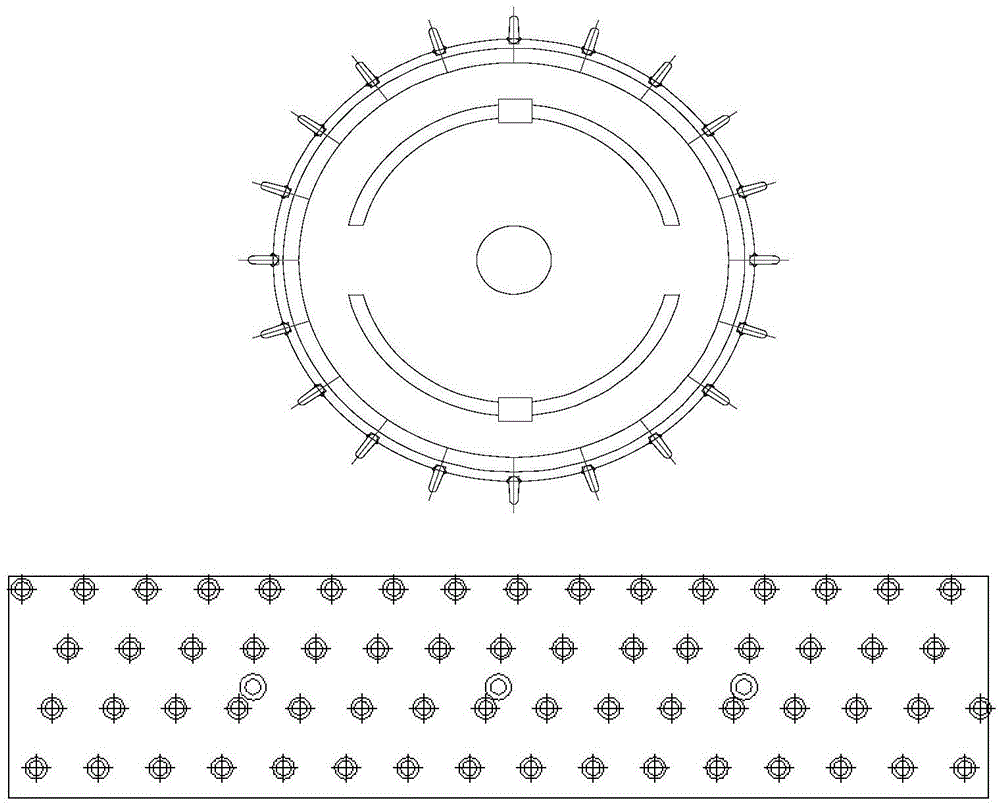

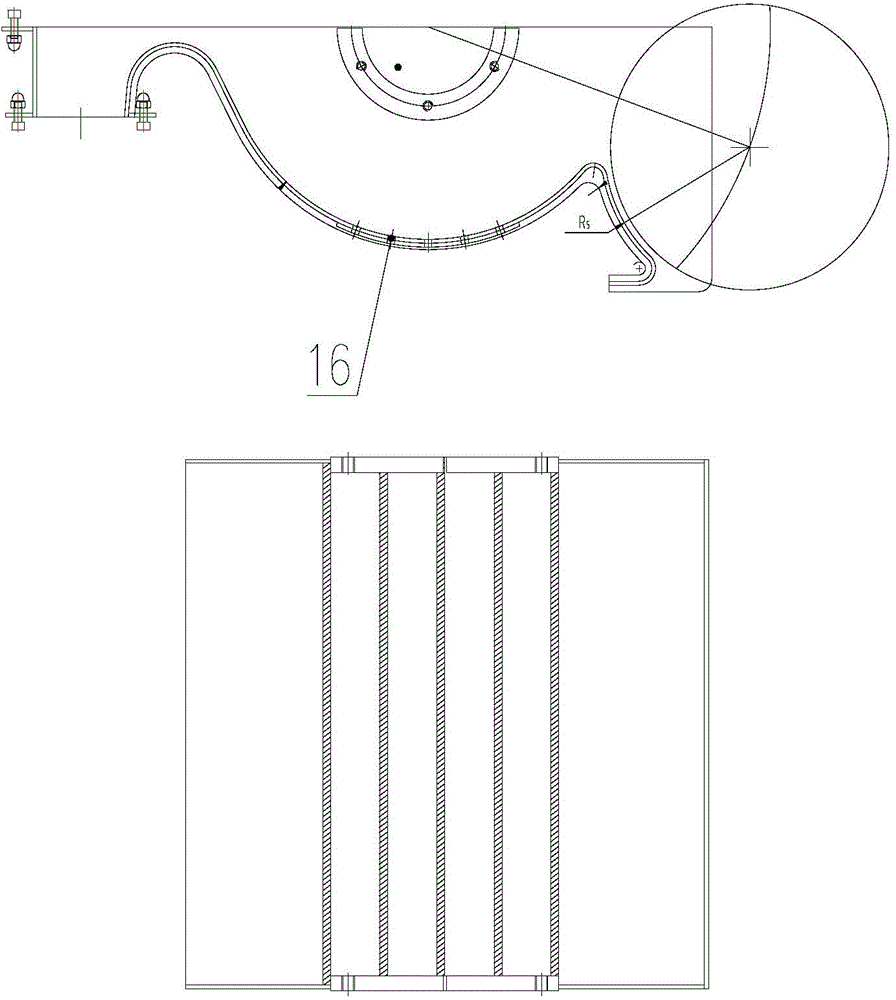

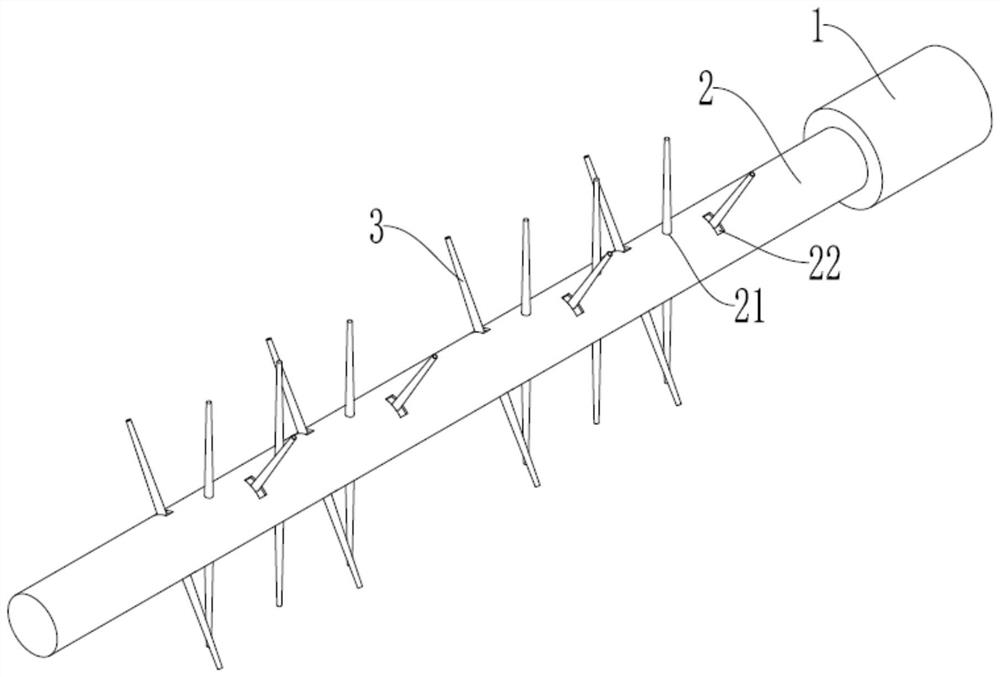

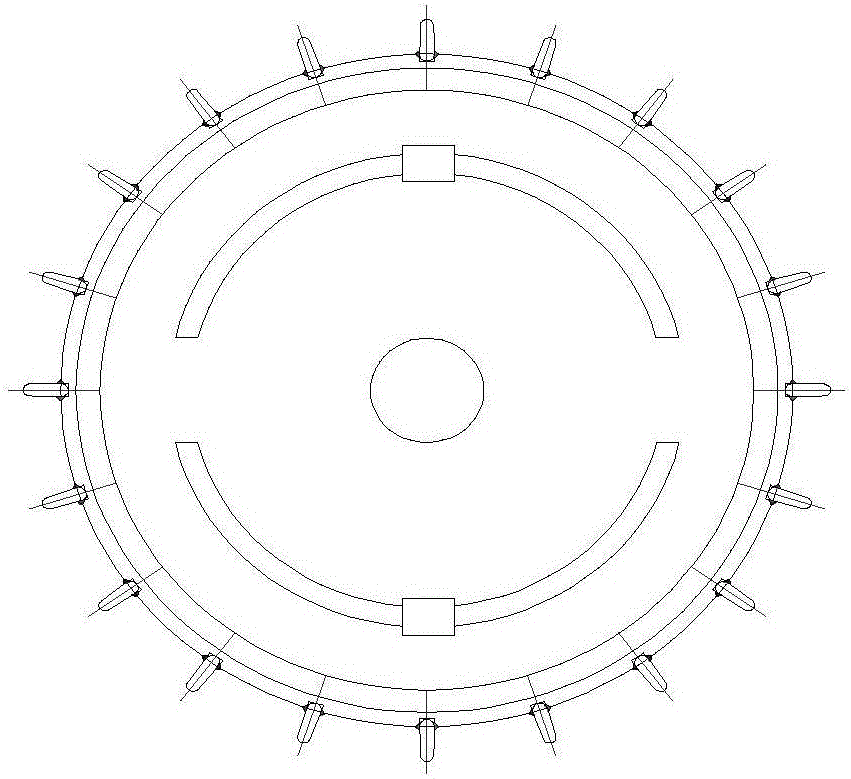

Lint cotton opening device

InactiveCN104695062AAvoid damageEasy to shapeFibre cleaning/opening by toothed membersFibre cleaning/opening machinesFiberEngineering

The invention relates to a lint cotton opening device. The lint cotton opening device comprises an opening roller, an upper opening shell, a lower opening shell, a lint cotton throwing curve, a variable-frequency motor, a frequency converter, a spiked nail conveying belt and a transverse adjustable bearing seat. The upper opening shell and the lower opening shell are connected together via a sealing gasket to form an opening shell. The lint cotton throwing curve is mounted on the outlet side of the opening shell. The opening roll shaped in a cylinder is positioned at the inner center of the opening shell and portioned into an outer layer and an inner layer. The spiked nail conveying belt is capable of cooperating with a lint cotton scraping and evening plate to hook and pull lint cotton so as to preopen the lint cotton while conveying the to-be-checked lint cotton. The lint cotton opening device has the advantages that cotton bales can be fully opened via striking of spiked round-headed nails and rubbing of a bottom-shell fence structure, damage to cotton fibers is small, and foreign fiber trait is kept well.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

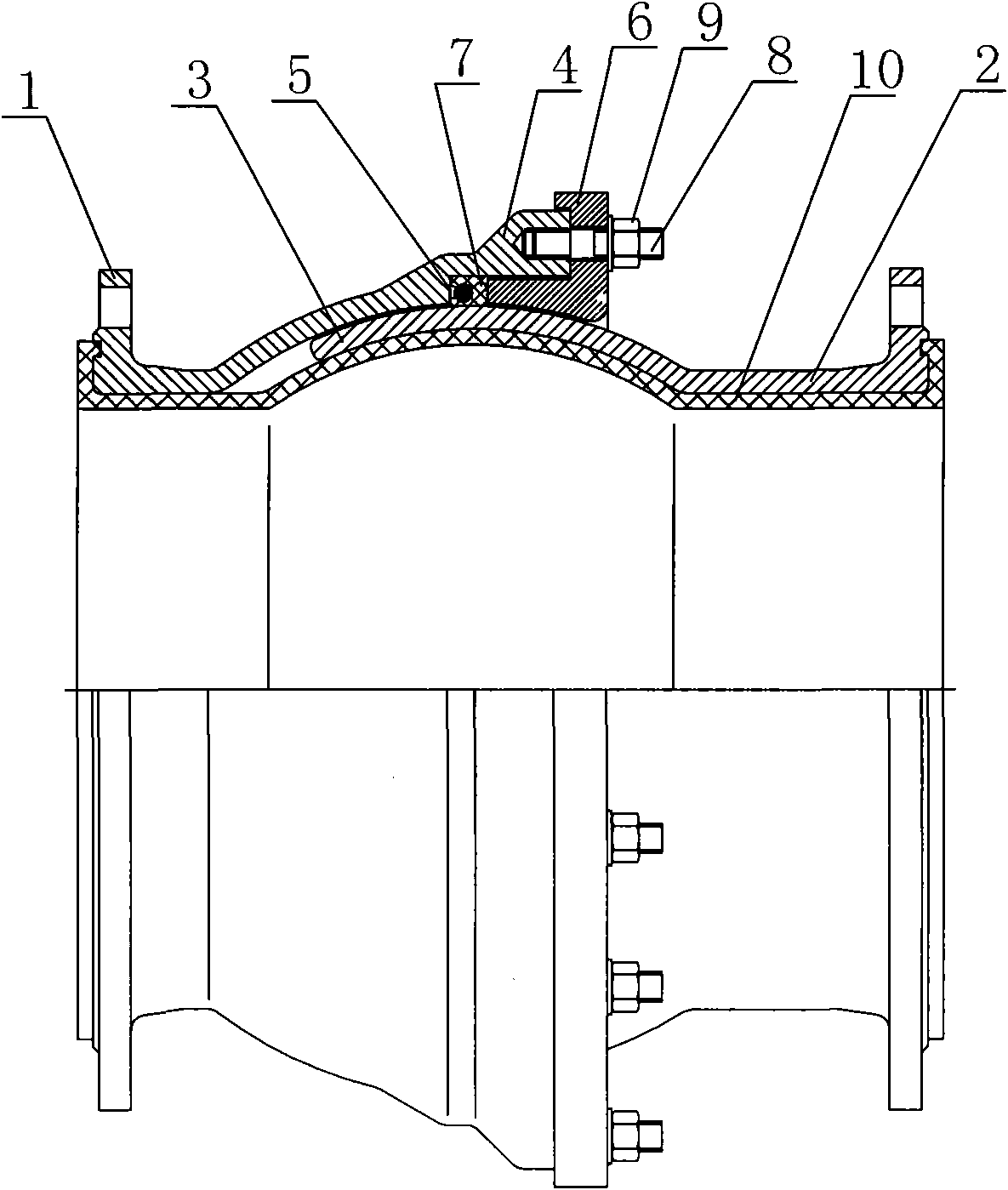

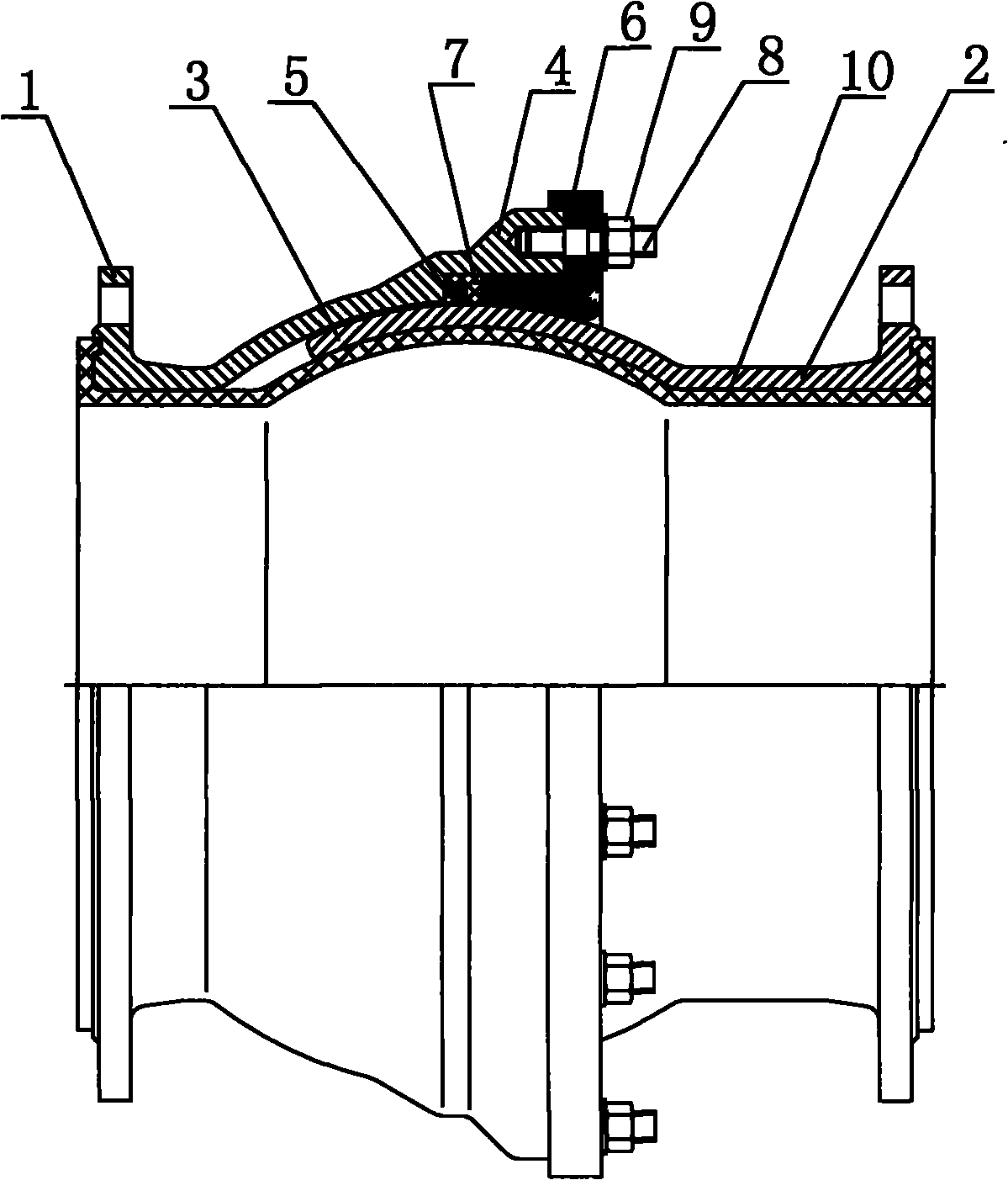

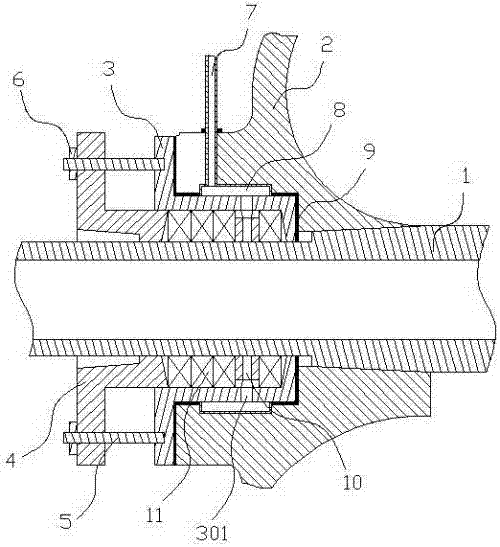

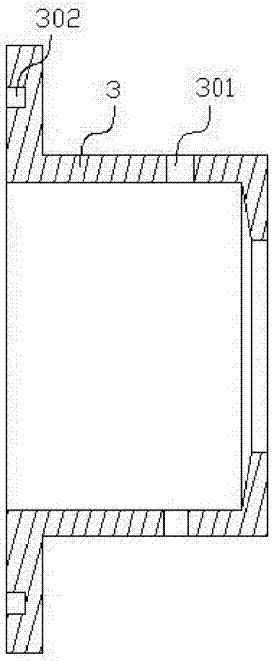

Dual-seal spherical compensating joint

The invention discloses a dual-seal spherical compensating joint which comprises a body and a spherical shell, wherein a section of the inner cavity of the spherical shell is in a spherical shape; the body is correspondingly provided with a section of spherical surface matched with the spherical shell; the spherical surface of the body is arranged in the inner cavity of the spherical shell, and one end of the spherical shell outwards extends to form a joint part; the joint part and the inner wall of the spherical shell form a step; the end surface of the joint part is connected with a press cover through a connecting bolt and a connecting nut, and the shape of the inner cavity of the press cover is matched with the inner cavity of the spherical shell to form a spherical inner cavity; a U-shaped sealing ring is arranged between the end surface of the press cover and the step of the spherical shell; in addition, the spherical inner cavity formed by the body and the spherical shell is also internally provided with a spherical rubber pipe; and two outward ends of the spherical shell and the body are provided with flanges. The invention has the advantages of simple structure, good deflection, good sealing effect and high safety and reliability.

Owner:WUXI JINYANG PIPING FITTING

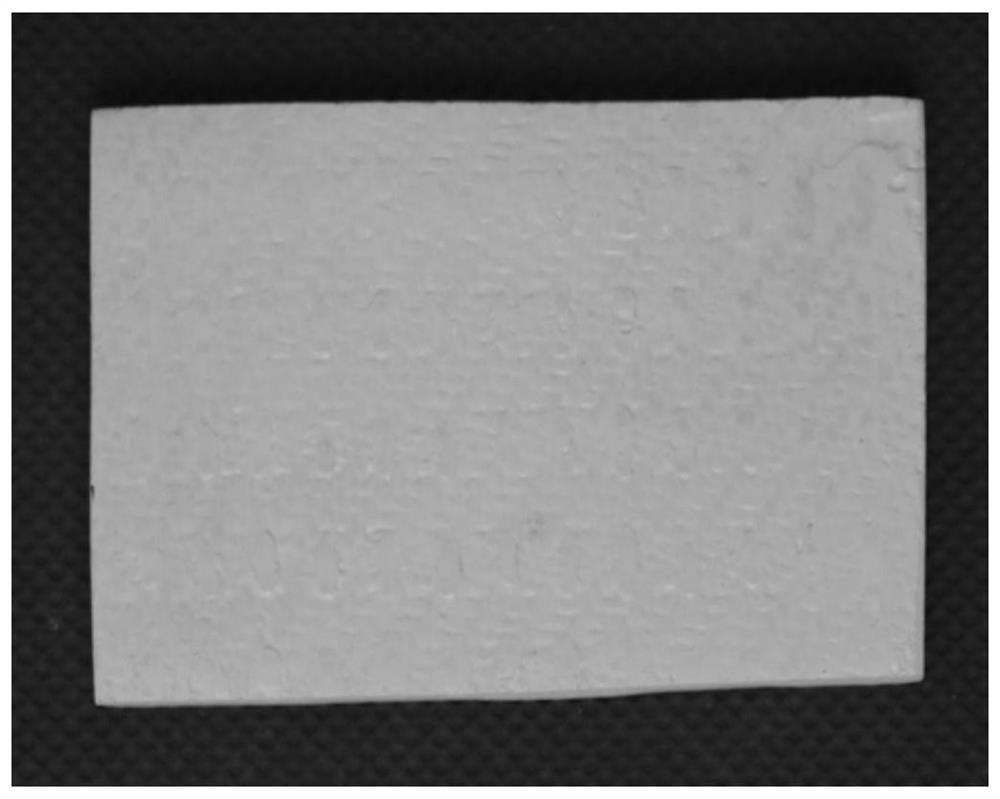

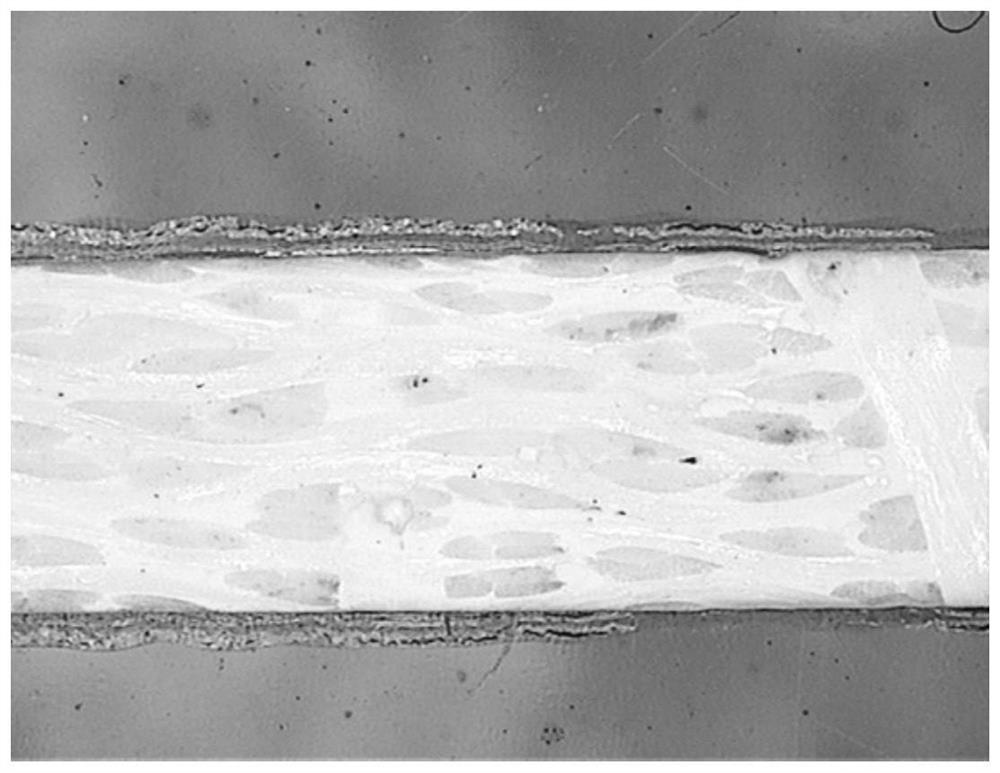

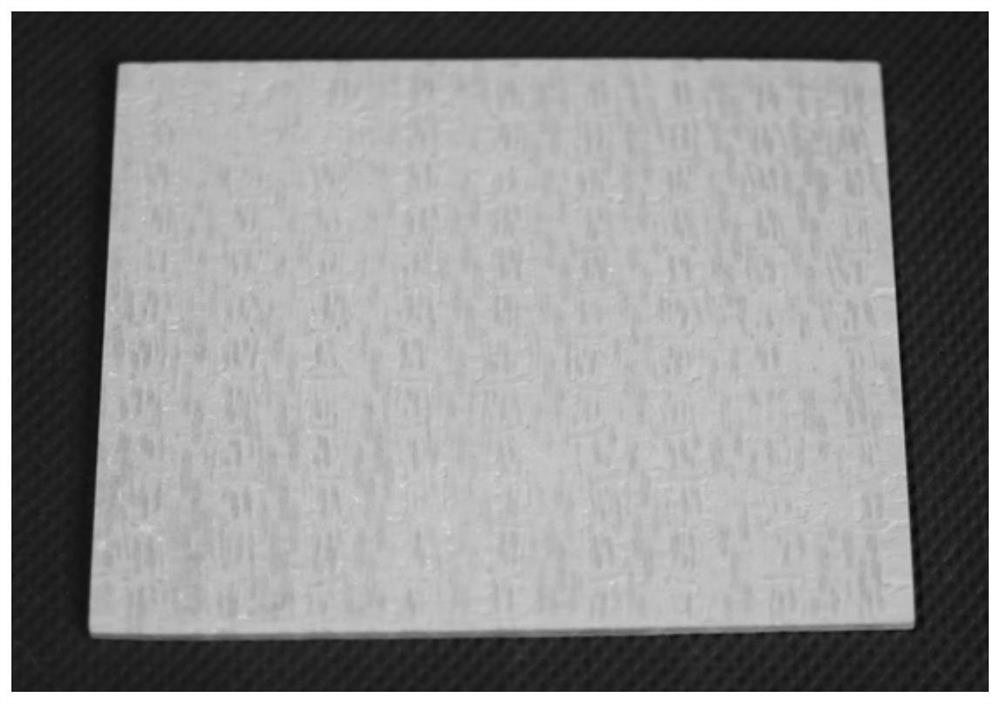

Three-dimensional aluminum oxide fiber woven part reinforced aluminum oxide composite material based on aqueous slurry impregnation process and preparation method of three-dimensional aluminum oxide fiber woven part reinforced aluminum oxide composite material

PendingCN112851386AOvercoming the problem of easy failure without fiber reinforcementGuaranteed deflectionOxide compositeAlumina composite

The invention relates to the technical field of continuous fiber reinforced ceramic matrix composite materials, and particularly discloses a three-dimensional aluminum oxide fiber woven part reinforced aluminum oxide composite material based on an aqueous slurry impregnation process, and the porosity of the composite material is 20-30%. A reinforced phase of the composite material is a continuous aluminum oxide fiber woven part, the woven part is in a fiber cloth sewing, two-dimensional and half or three-dimensional weaving mode, the mass content of alumina in alumina fibers is not lower than 70%, and the volume fraction of the fibers in the composite material is 40-45%. The aluminum oxide matrix of the composite material is prepared through the processes of multiple times of dipping, drying and sintering of water-based aluminum oxide powder slurry with high solid content and low viscosity, the solid content of the water-based aluminum oxide powder slurry is 30-40 vol%, the viscosity of the slurry is 5-30 mPas, the pH is 3-4.5, and the Zeta potential is 60-70 mV. The invention also provides a preparation method of the composite material. The reinforced fibers are arranged between the layers of the composite material, so that the integrity is good. The preparation method disclosed by the invention is simple in process, low in cost, good in environmental protection property and easy to realize large-scale industrialization.

Owner:NAT UNIV OF DEFENSE TECH

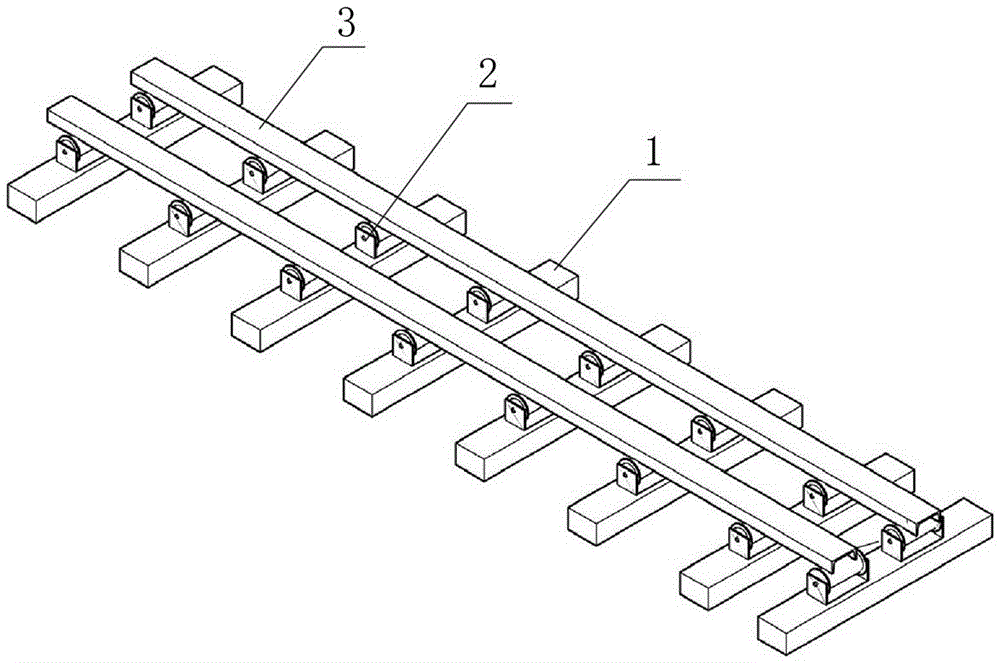

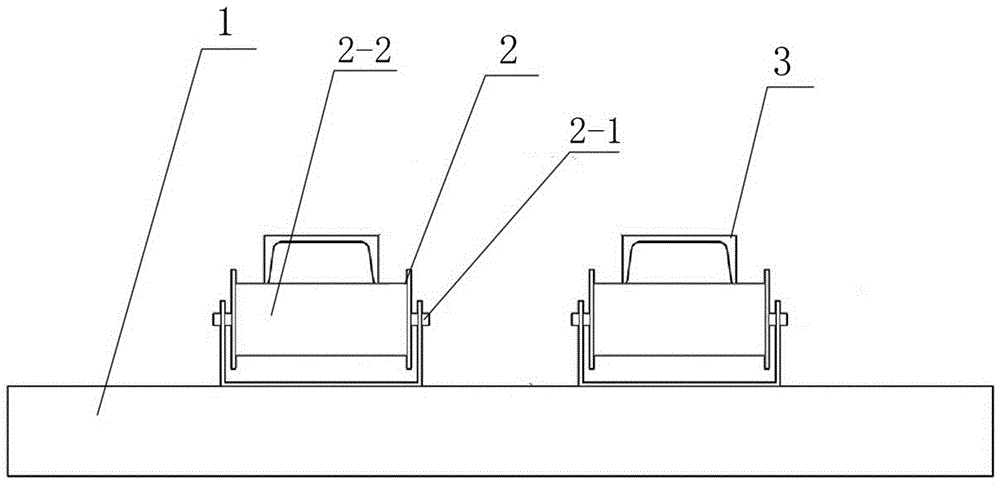

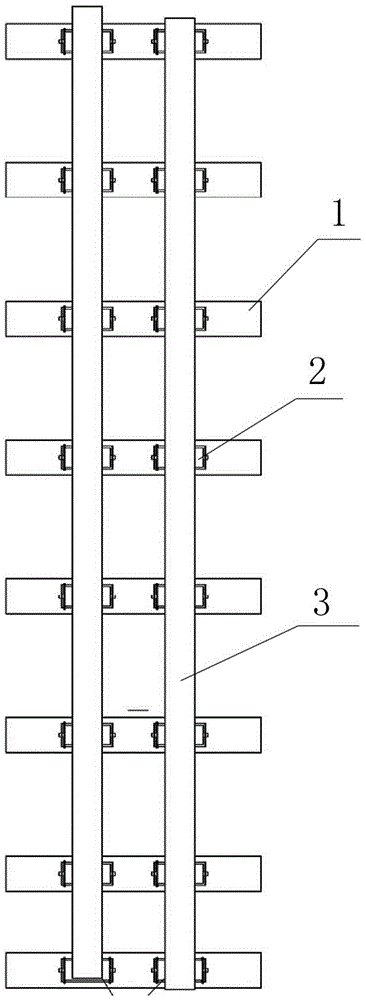

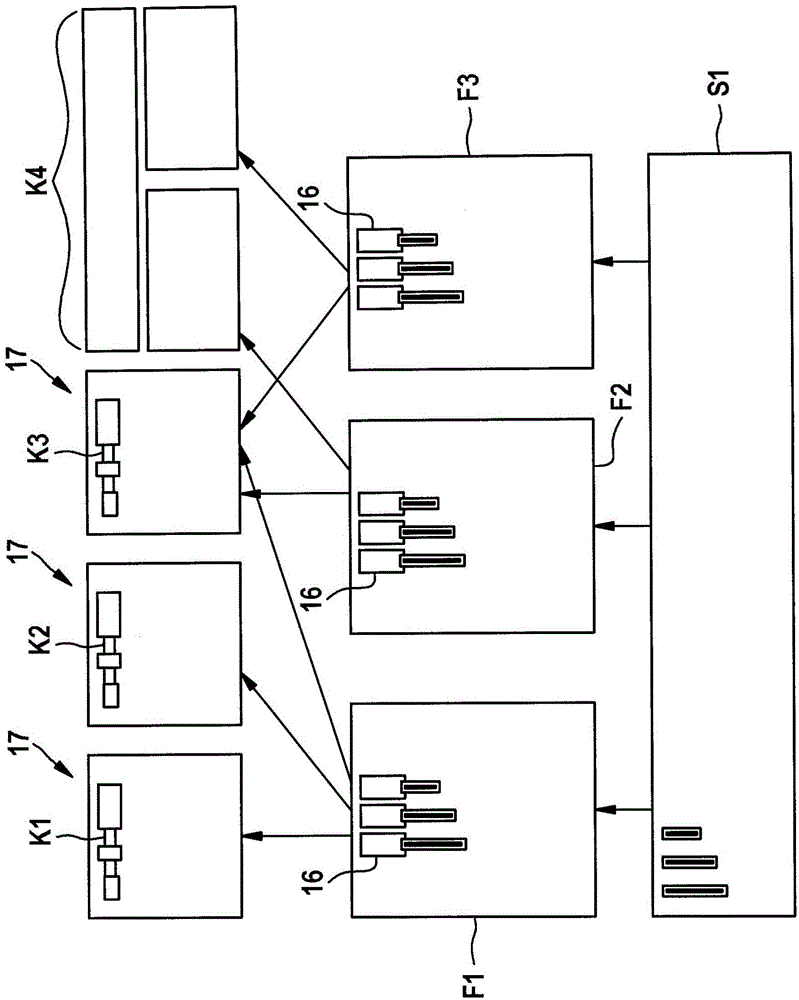

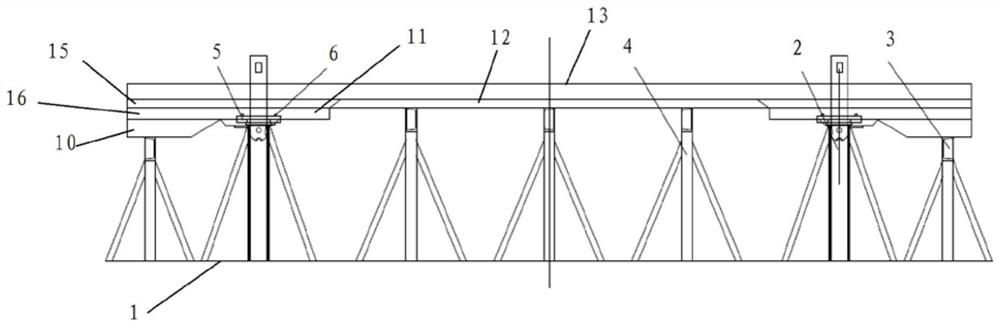

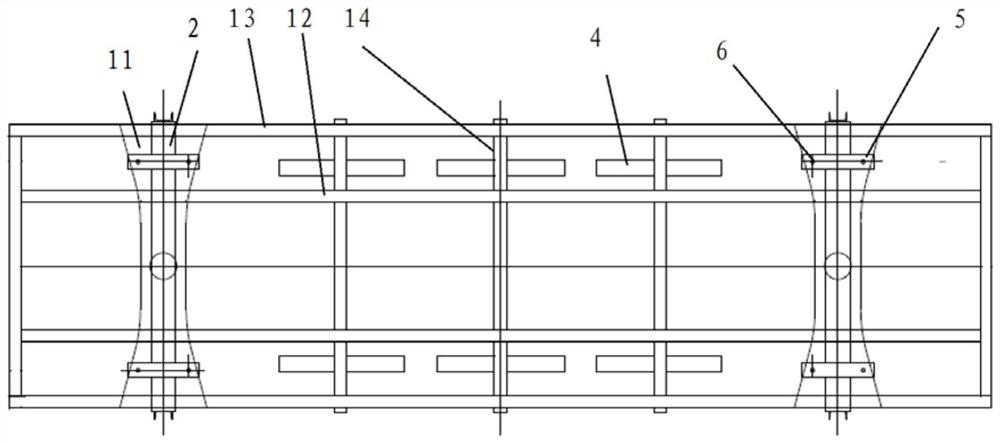

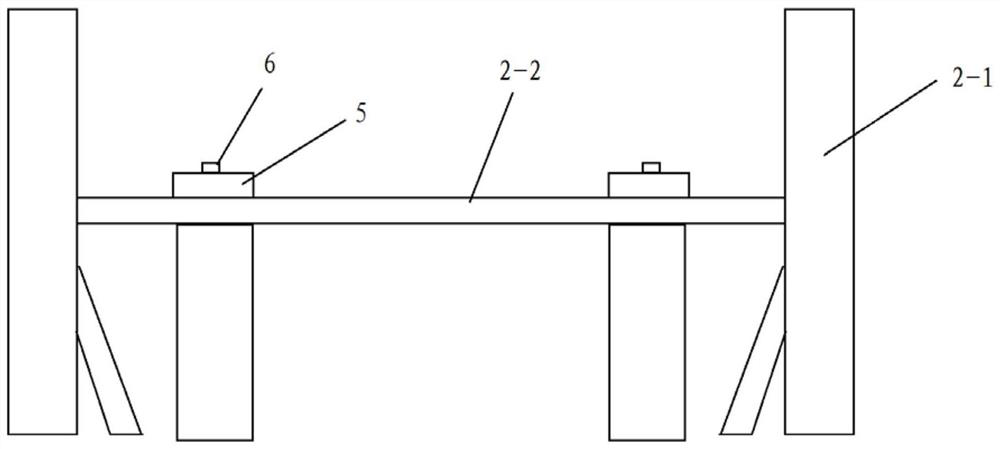

Shuffling device and transferring method for turnout switch rails and stock rail assemblies on bridge

ActiveCN105735065AGuaranteed deflectionSimple methodRailway track constructionEngineeringMechanical engineering

The invention relates to a shuffling device and transferring method for turnout switch rails and stock rail assemblies on a bridge. The shuffling device consists of a rolling structure and a moving platform, wherein the rolling structure is formed by a plurality of square timbers and two roller assembly bodies placed on each square timber, and the moving platform is formed by separately placing a sliding steel girder on two rows of roller assembly bodies. The moving platform can make parallel movement on rollers of the roller assembly bodies through outside thrust. The turnout switch rails and the stock rail assemblies are placed on the moving platform, and can be transferred to a construction position from an unloading position on the bridge. According to the shuffling device and transferring method for the turnout switch rails and the stock rail assemblies on the bridge, disclosed by the invention, the problem that the switch rails and the stock rail assemblies cannot be transferred in place smoothly under the condition of no makeshift roads during bridge construction is solved. The shuffling device for the turnout switch rails and the stock rail assemblies on the bridge is used, so that the construction cost is reduced, and the construction efficiency is improved. The method disclosed by the invention is utilized, so that the construction is safe and reliable, and the condition that the deflection of the switch rails and the deflection of the stock rail assemblies cannot go beyond a design allowed range is guaranteed.

Owner:中国建筑土木建设有限公司

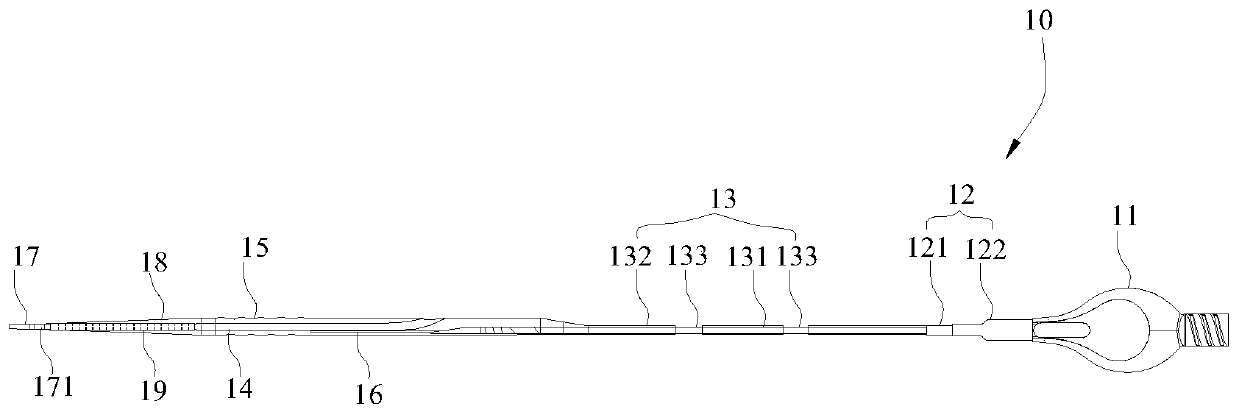

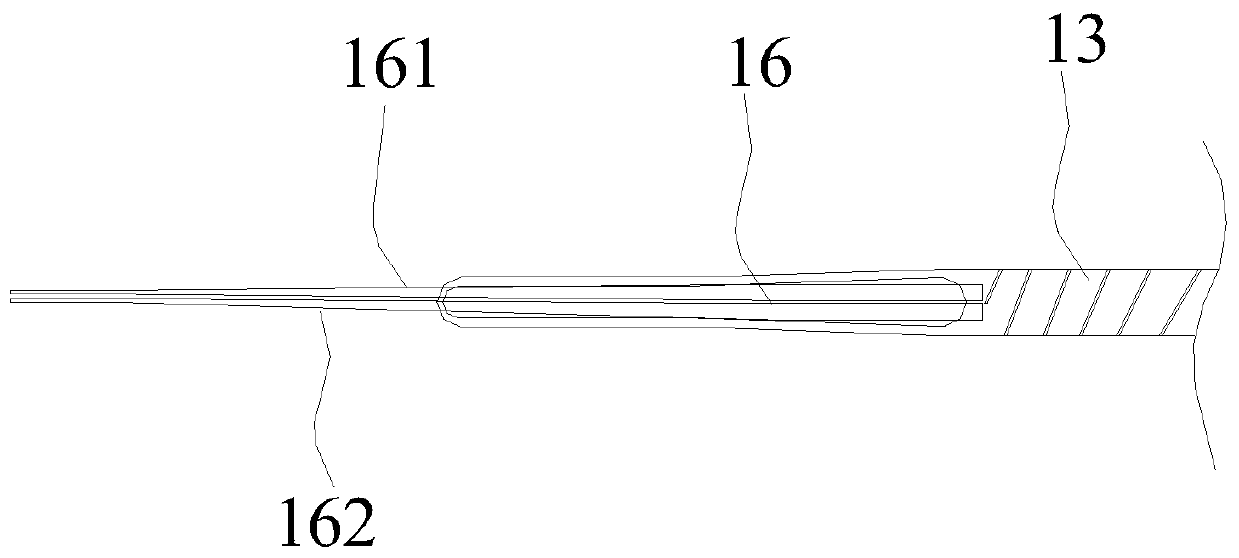

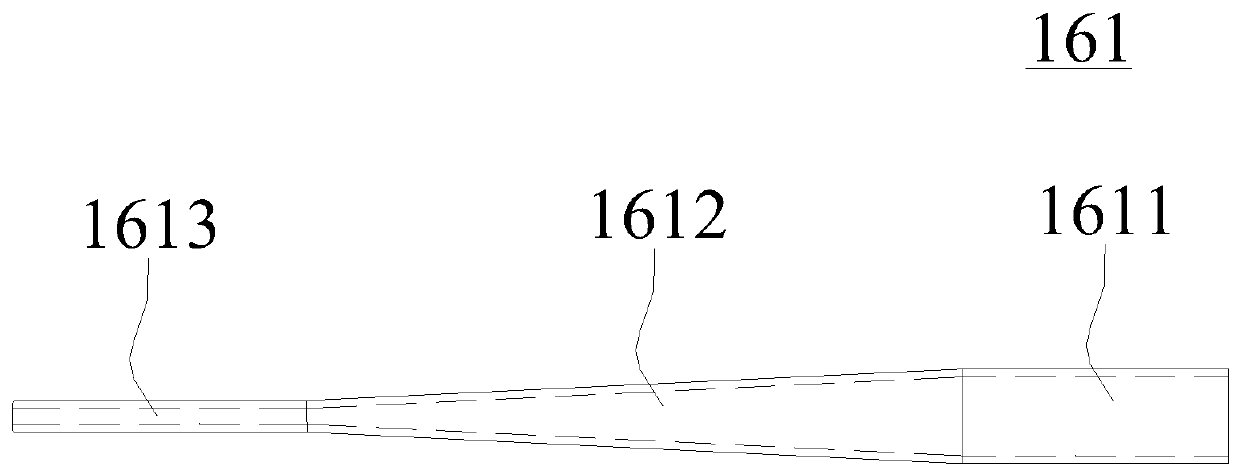

Balloon catheter

ActiveCN110193132ASmooth crossingImprove traversal abilityBalloon catheterGuide wiresSmall LesionBalloon catheter

The invention discloses a balloon catheter, which comprises: a hypotube having an expansion chamber; an inner tube having an expansion chamber, and an outer tube having an outer diameter, wherein theinner tube is located inside the outer tube, the inner tube and the outer tube are coaxially arranged on the longitudinal axis, and a distal end of the hypotube is located between a proximal end of the outer tube and a proximal end of the inner tube; a balloon having only a tapered portion, wherein the proximal end of the balloon is coupled to the distal end of the outer tube, the distal end of the inner tube is positioned within the balloon and coupled to the distal end of the balloon; and a plurality of guide wires located between the inner tube and outer tube, wherein the proximal end of each guide wire is fixed to the distal end of the hypotube. The balloon catheter of the present invention can ensure the flexibility of the guide wire at the distal end while ensuring the pushing performance and anti-bendability of the guide wire at the distal end, and can smoothly pass the balloon catheter through the small lesion to improve the penetration performance of the balloon catheter.

Owner:ORBUSNEICH MEDICAL SHENZHEN CO LTD

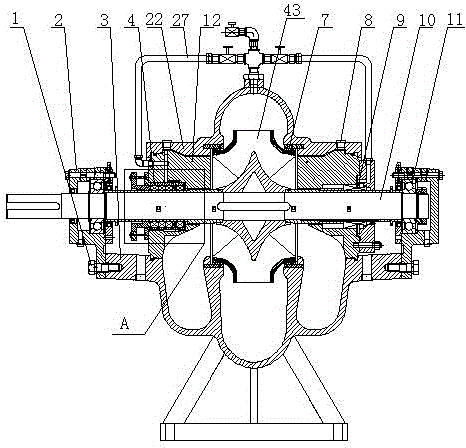

Singe-stage double-suction split case pump with good sealing performance

The invention relates to the field of split case pumps, in particular to a single-stage double-suction split case pump with the good sealing performance. The single-stage double-suction split case pump comprises a front bearing seat, a rear bearing seat and a pump shaft penetrating the front bearing seat and the rear bearing seat. The pump shaft is sleeved with a shaft sleeve. The middle portion of the pump shaft is sleeved with an impeller and a pump body matched with the impeller. The pump body is connected with the front bearing seat and the rear bearing seat through fastening pieces. A sealing component is arranged between the pump body and the impeller. Pump covers are arranged on the two sides of the pump body. The pump covers on the two sides are matched with a padding sealing device and a mechanical sealing device correspondingly. The invention aims at providing the single-stage double-suction split case pump with the good sealing performance, through the specific padding sealing device and the impeller sealing component, the good sealing effect is achieved, meanwhile the bearing span can be lowered, an impeller sealing ring is prevented from falling off, and normal operation of the pump is guaranteed.

Owner:浙江南方泵业有限公司

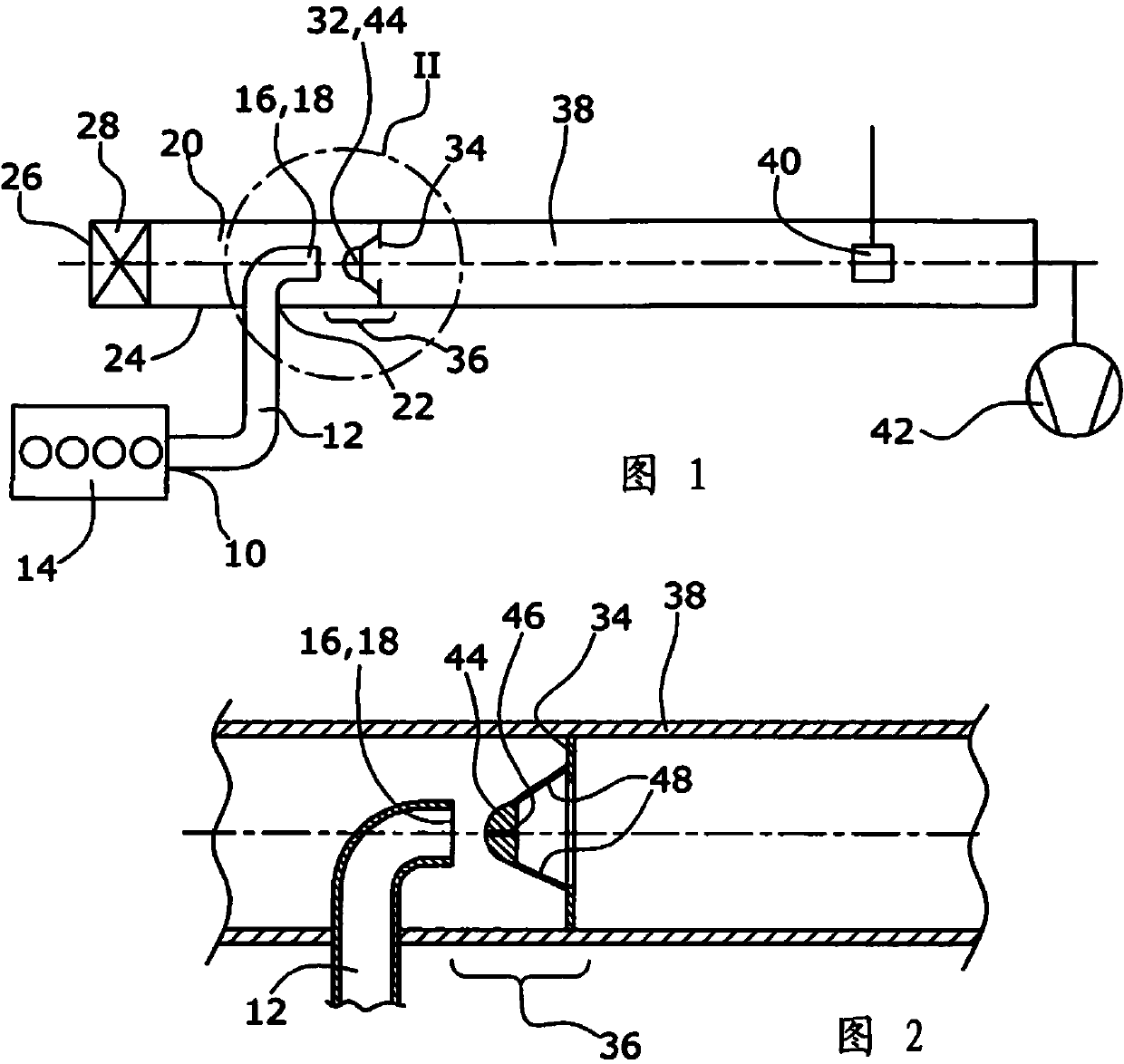

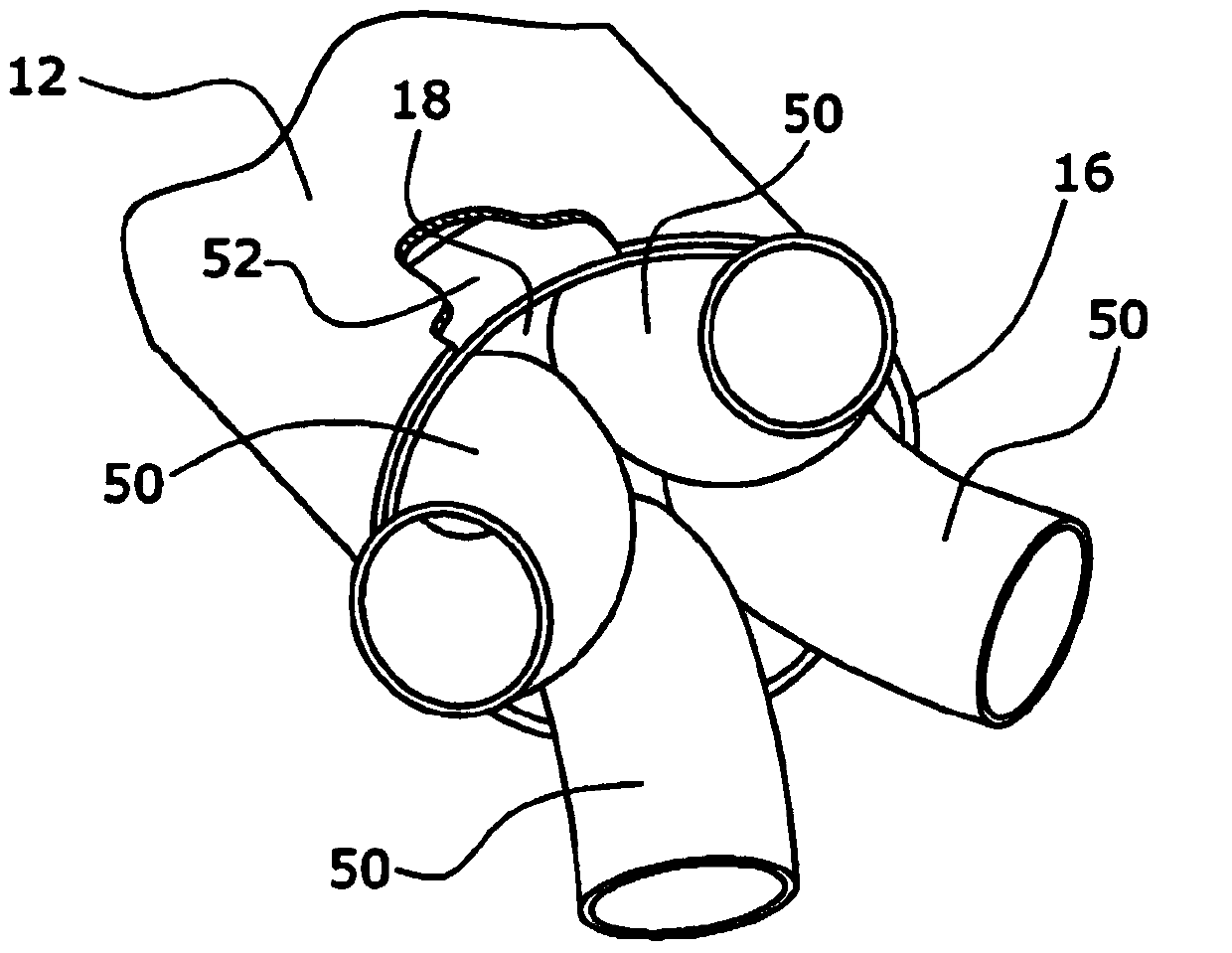

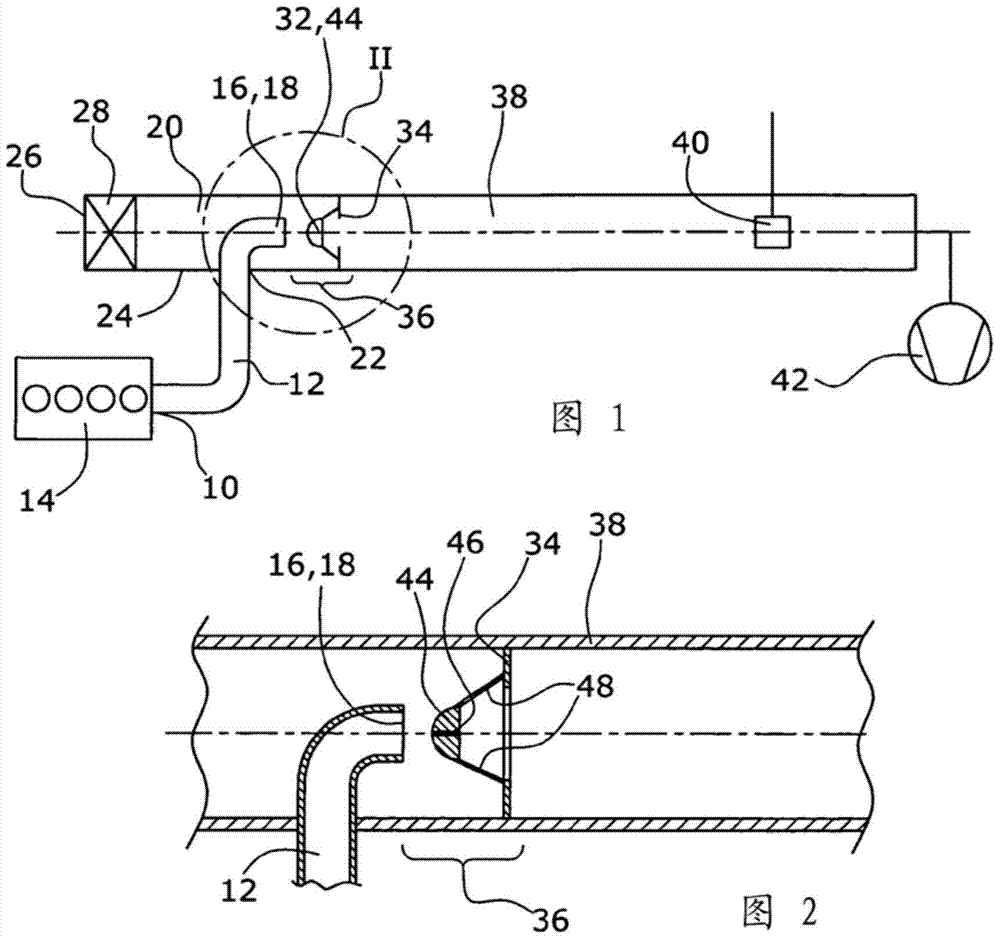

System for removing exhaust gas samples from internal combustion engines

ActiveCN104220860AHigh speedWell mixedEngine testingWithdrawing sample devicesCombustionExternal combustion engine

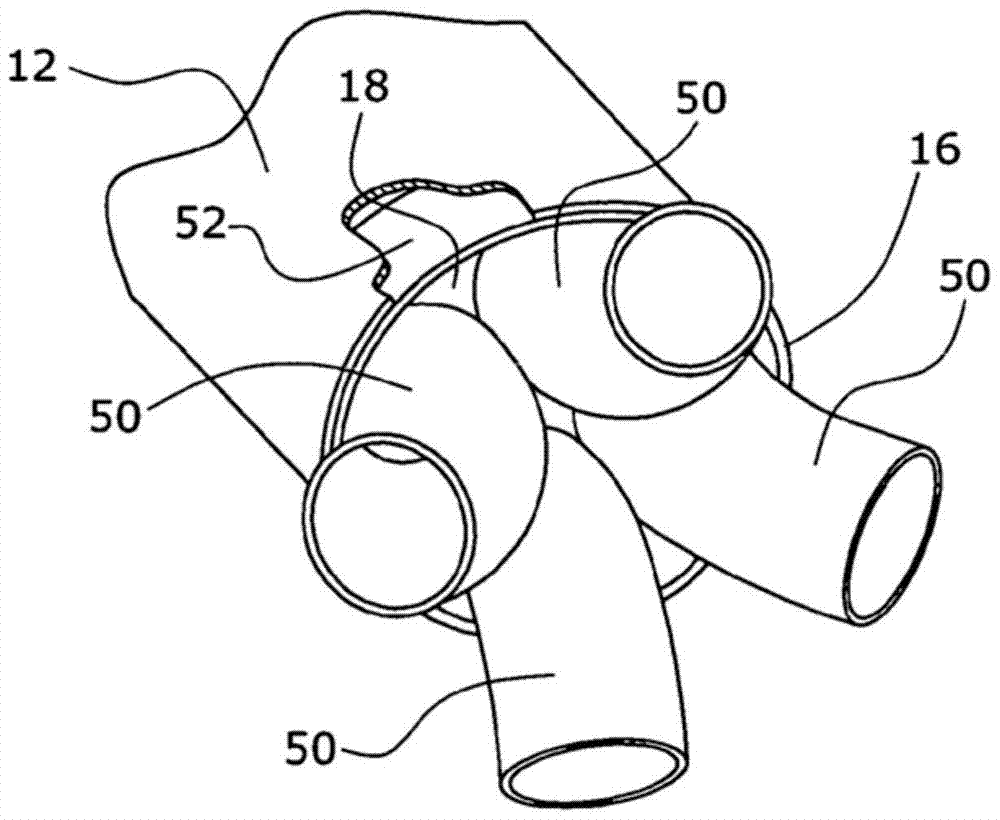

Systems for removing exhaust gas samples from internal combustion engines are know, said systems comprising: an exhaust gas duct (12) having fluid communication with an exhaust gas source (14) via an exhaust gas inlet (10); an air duct (20) into which ambient air can be suctioned via an air filter (28); a fusion zone (36) arranged downstream of an outflow cross section (18) of the exhaust gas duct (12); and a dilution tunnel (38), through which the exhaust gas / air mixture flows, wherein the outflow cross section (18) of the exhaust gas duct (12) is arranged substantially concentric in the air duct (20) and an annular orifice (34) is arranged downstream of the outflow cross section (18) of the exhaust gas duct (12) in the dilution tunnel (38). However, the two gas flows are often inadequately mixed. In order to ensure good mixing and representative sampling, the invention therefore proposes that means (32, 44, 50) are arranged upstream of the orifice (34) and downstream of the outflow cross section (18) of the exhaust gas channel (12), via which means the exhaust gas flow is deflected in such a manner that the exhaust gas flow is removed directly upstream of the means (32, 44, 50) and asymmetrically from the centre axis of the dilution tunnel (38).

Owner:AVL EMISSION TEST SYST GMBH

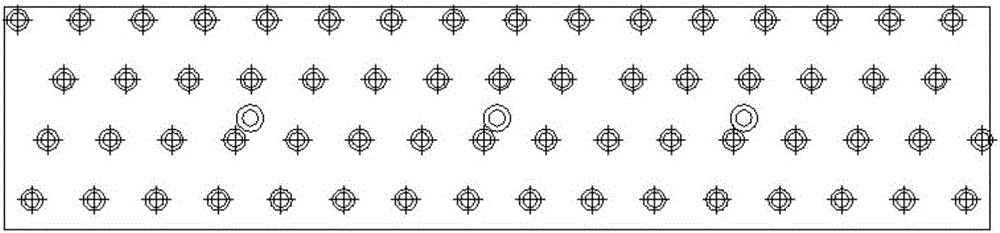

Fixed-area controllable staggered oriented perforating horizontal well hydraulic fracturing physical simulation method

InactiveCN112267865AEffectively press openFracturing goodSurveyMaterial strength using tensile/compressive forcesUnconventional oilFluid migration

The invention relates to the technical field of unconventional oil and gas resource development, and discloses a fixed-area controllable staggered oriented perforating horizontal well hydraulic fracturing physical simulation method. The fixed-area controllable staggered oriented perforating horizontal well hydraulic fracturing physical simulation method comprises the steps that S1, a simulation shaft is manufactured, the simulation shaft is provided with a plurality of perforating hole sets, each set corresponds to a liquid injection pipe, and the simulation shaft comprises a plurality of perforating holes, and perforating hole channels are manufactured and are inserted into the perforating holes; S2, the shaft is put into a mold, and pouring is carried out to obtain an artificial rock core test piece; S3, the artificial rock core test piece is put into a loading chamber; S4, a liquid injection pump is connected to the liquid injection pipe; S5, crustal stress is loaded in the X, Y andZ directions of the test piece, fracturing fluid is injected into the simulation shaft, data are synchronously acquired, and the crustal stress on the test piece is canceled; S6, the liquid injectionpump is connected to the next liquid injection pipe, then the step S5 is repeated till all the liquid injection pipes are injected with liquid, and then the step S7 is carried out; and S7, sectioningis carried out on the test piece, and a fluid migration channel in the test piece is observed to obtain a hydraulic fracturing crack propagation rule.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

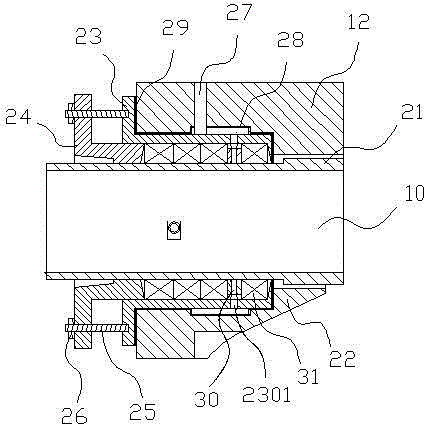

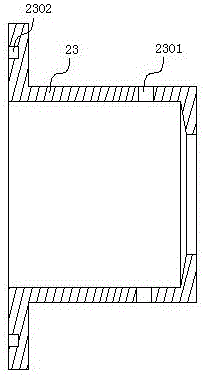

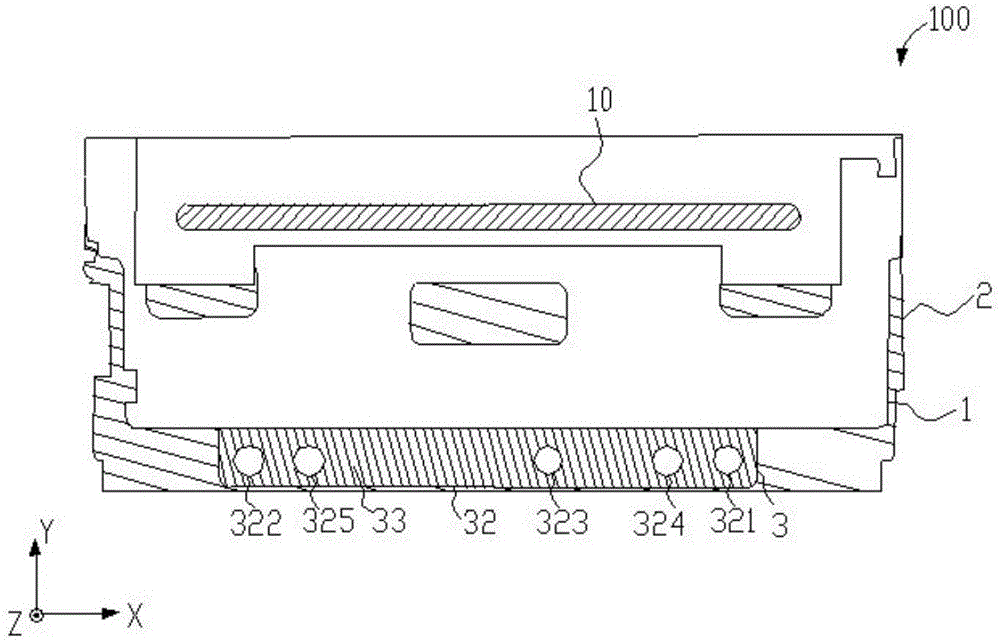

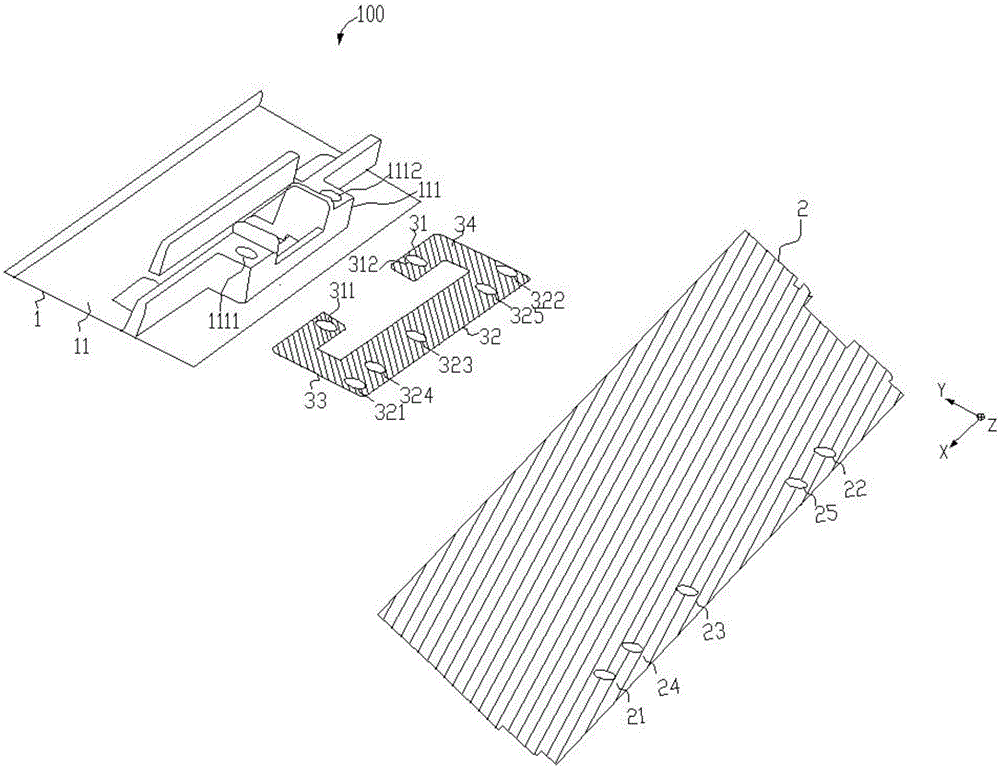

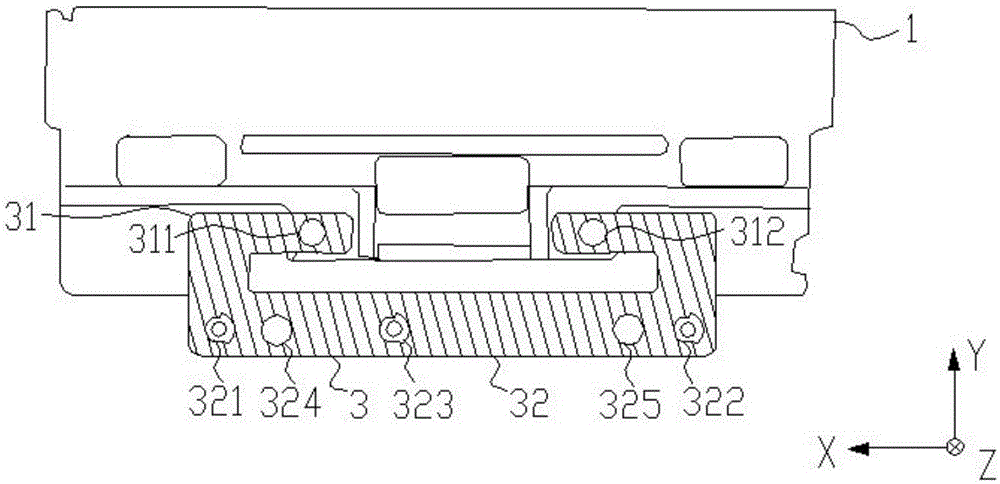

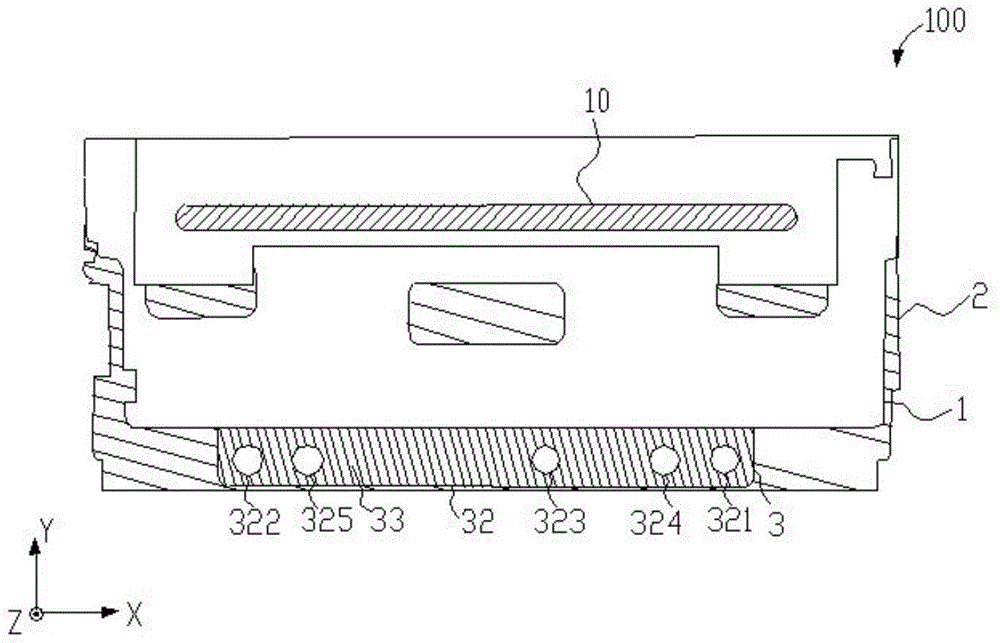

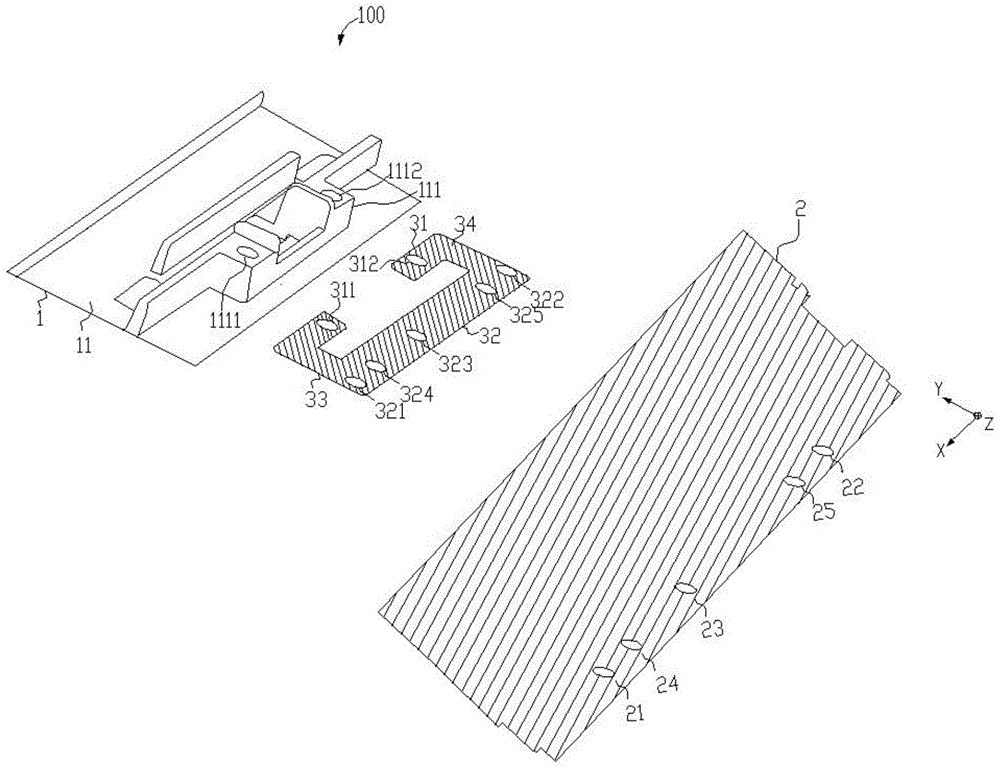

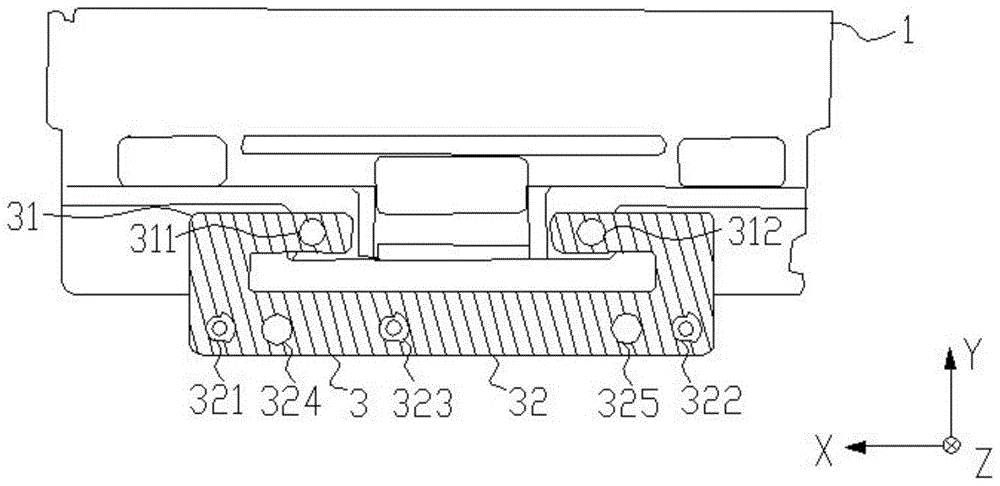

Print head module and label printer

InactiveCN105150686AImprove flatnessGuaranteed deflectionPrintingColor printingBiomedical engineering

The invention discloses a print head module and a label printer. The print head module comprises a flat plate, a fixation frame and a spring sheet. A print head is arranged on the flat plate; and the spring sheet has a first end and a second end which are opposite, wherein the first end realizes fixation connection with the flat plate through combination and fixation of a first fixation portion and a second fixation portion, which are different in position and coplanar, of the first end with a first fixation member and a second fixation member of the flat plate; and the second end realizes fixed combination with the fixation frame through combination and fixation of a third fixation portion and a fourth fixation portion, which are different in position and coplanar, of the second end with a third fixation member and a fourth fixation member of the fixation frame, such that the two ends of the print head are equally stressed, the problems of wrinkling, paper jam and light-color printing due to unequal stress of the print head are prevented, and deflection is guaranteed.

Owner:QISDA OPTRONICS (SUZHOU) CO LTD

Sludge sampling equipment based on unmanned aerial vehicle

PendingCN111964968AImprove sampling efficiencyPrevent rolloverAircraft componentsWithdrawing sample devicesRolloverSludge

The invention discloses sludge sampling equipment based on an unmanned aerial vehicle. The sludge sampling equipment comprises a mounting disc and a mounting cylinder fixedly connected to the top of the mounting disc, and a sampling device is fixedly connected to the bottom of the mounting disc; and a plurality of supporting devices are arranged at the bottom of the mounting disc close to the outer edge of the mounting disc. The supporting devices are mounted at the bottom of the mounting disc, buoyancy balls drive stop levers to move under the buoyancy of water, the stop levers cannot stop the supporting legs, when the supporting legs are located at bumpy positions, the supporting legs can deflect in the direction away from a main sharp cylinder, so that supporting range of the pluralityof supporting legs is enlarged, rollover can be prevented, the main sharp cylinder can be in contact with sludge, the sludge enters the main sharp cylinder through sampling holes, and a driving cylinder drives a pull rod to move towards the mounting disc, so that a suction effect is achieved in a vertical cylinder, the external sludge is sucked into the sharp cylinder, the sludge sampling efficiency is improved, the overall stability is guaranteed, and the sampling efficiency is improved.

Owner:徐马招

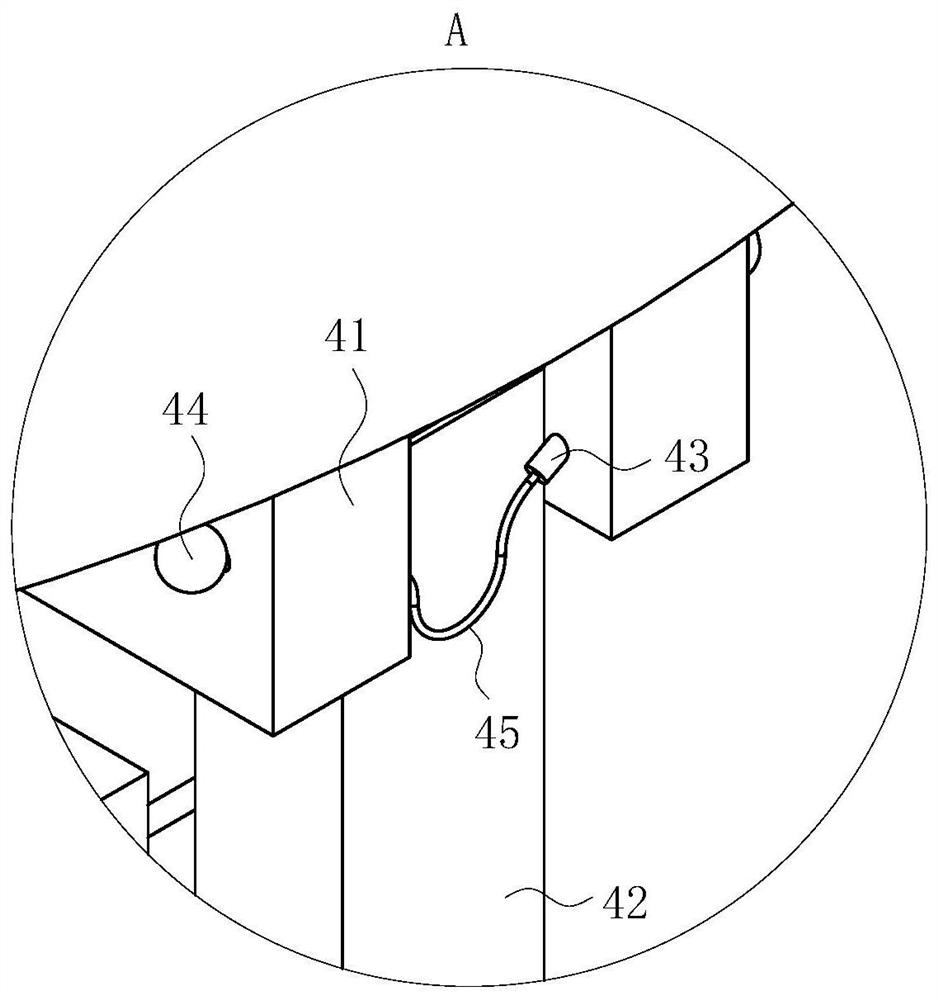

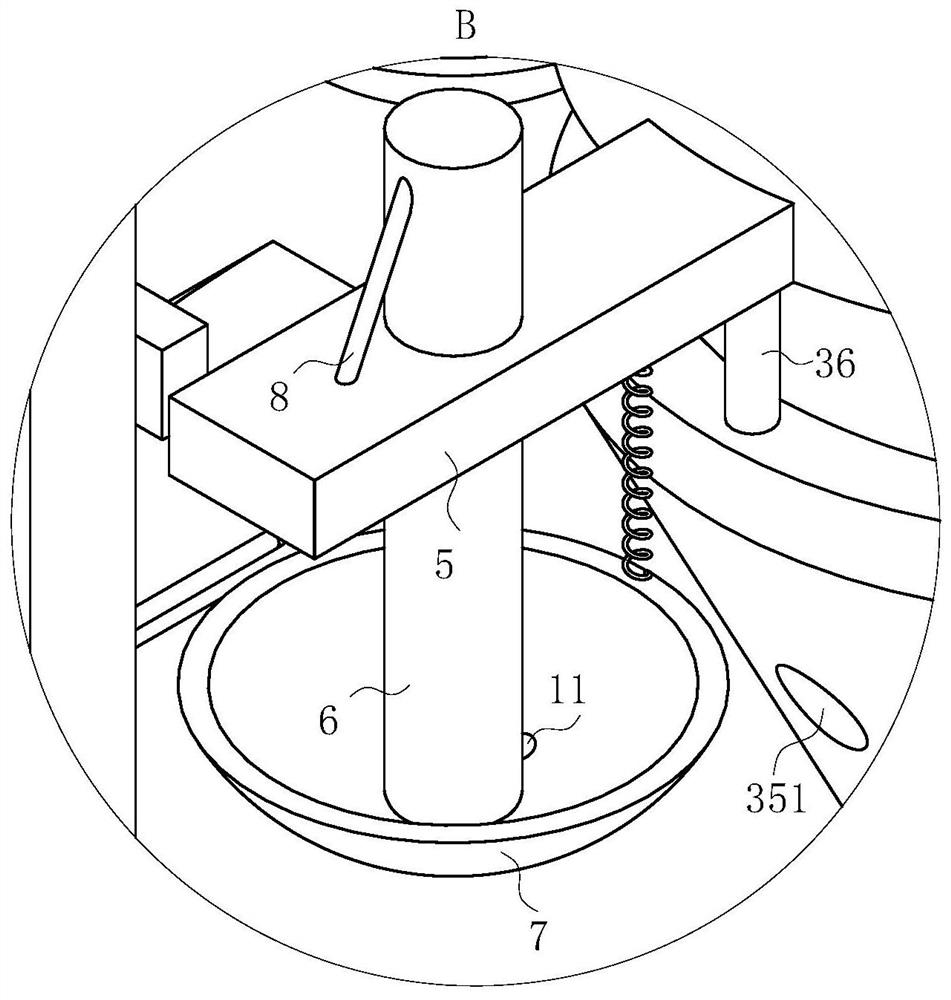

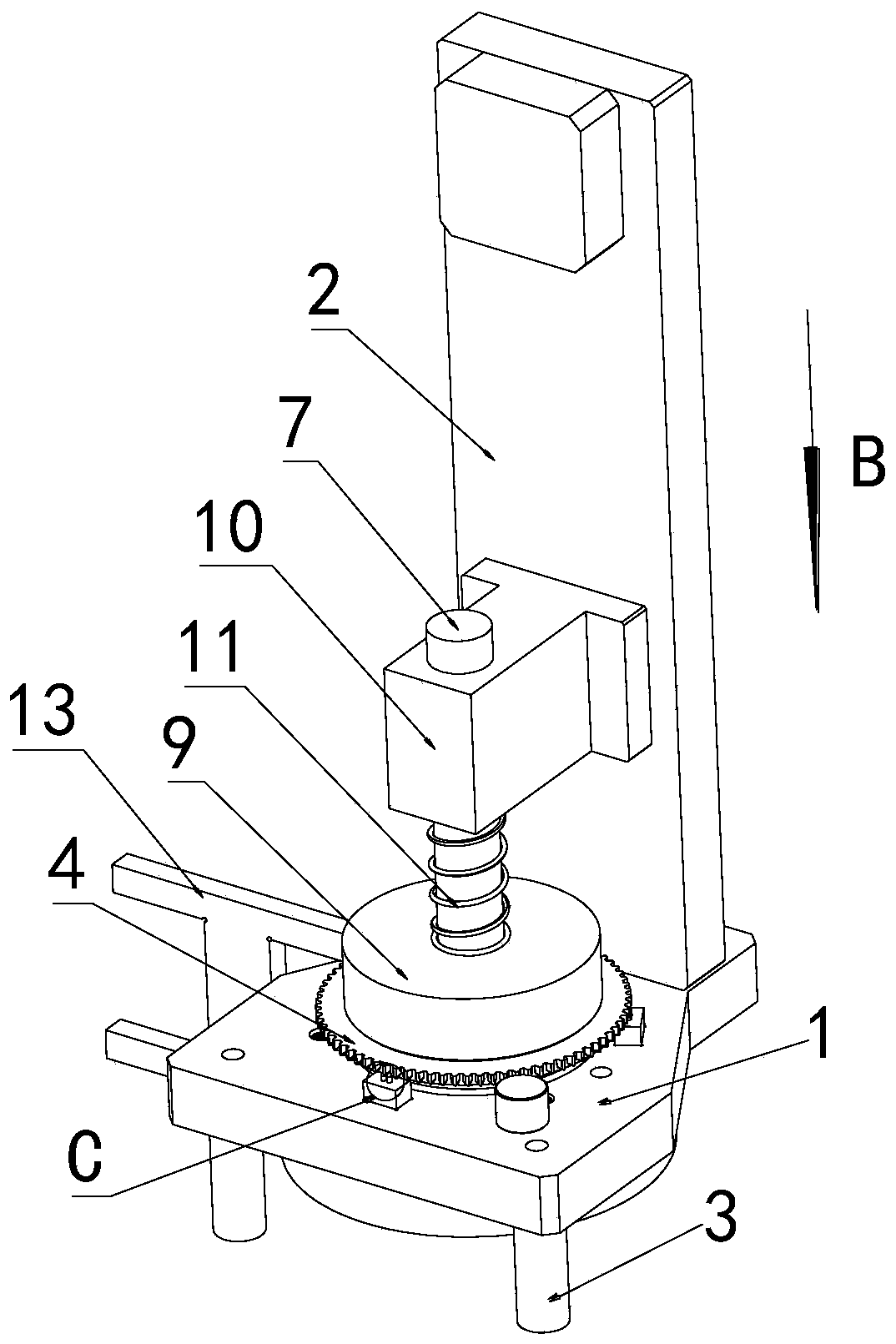

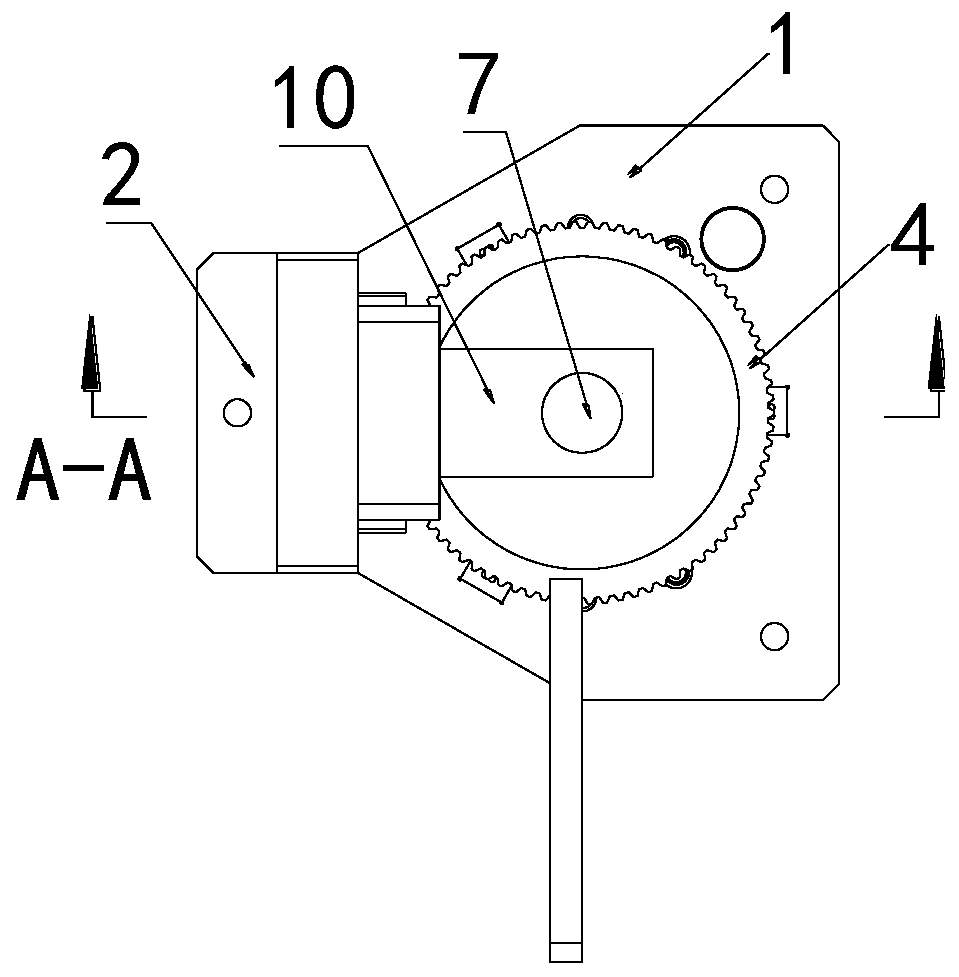

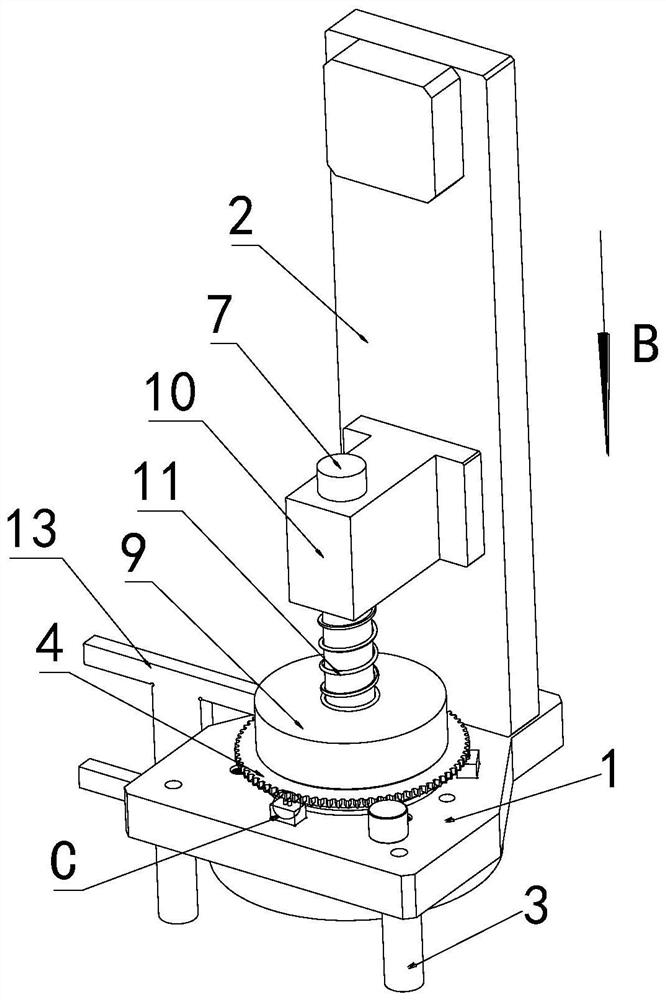

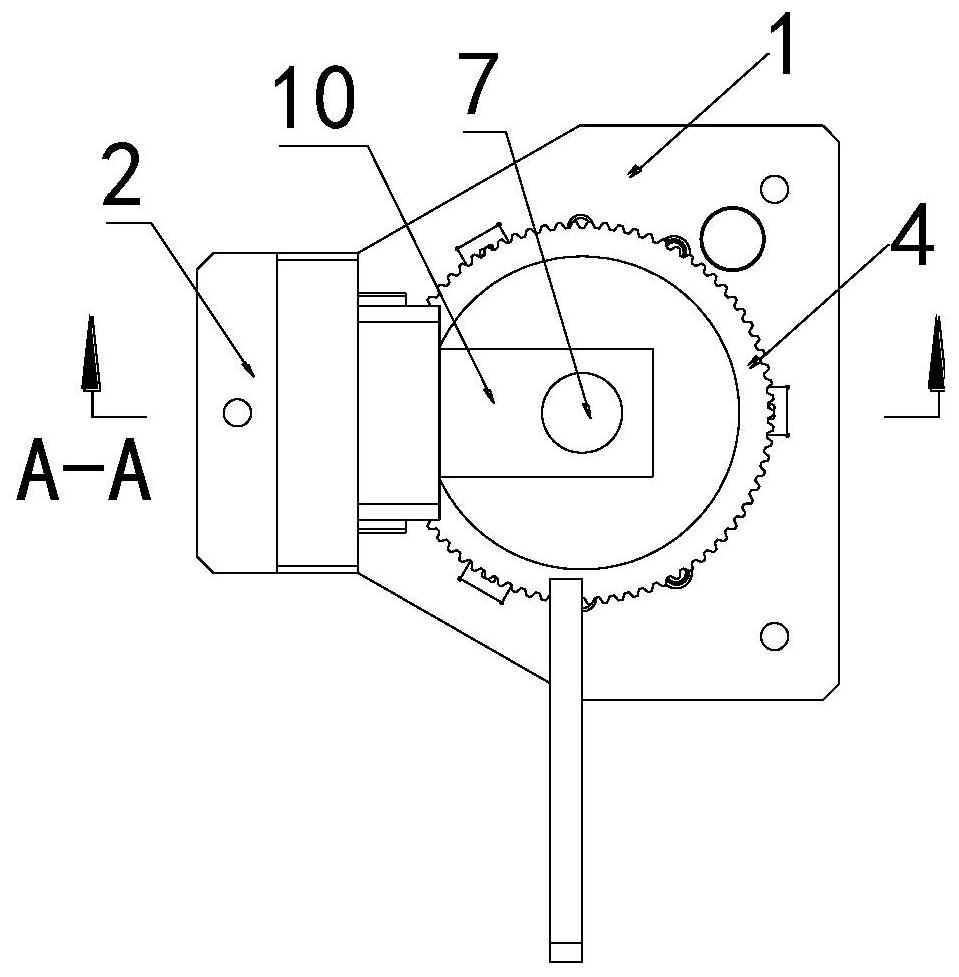

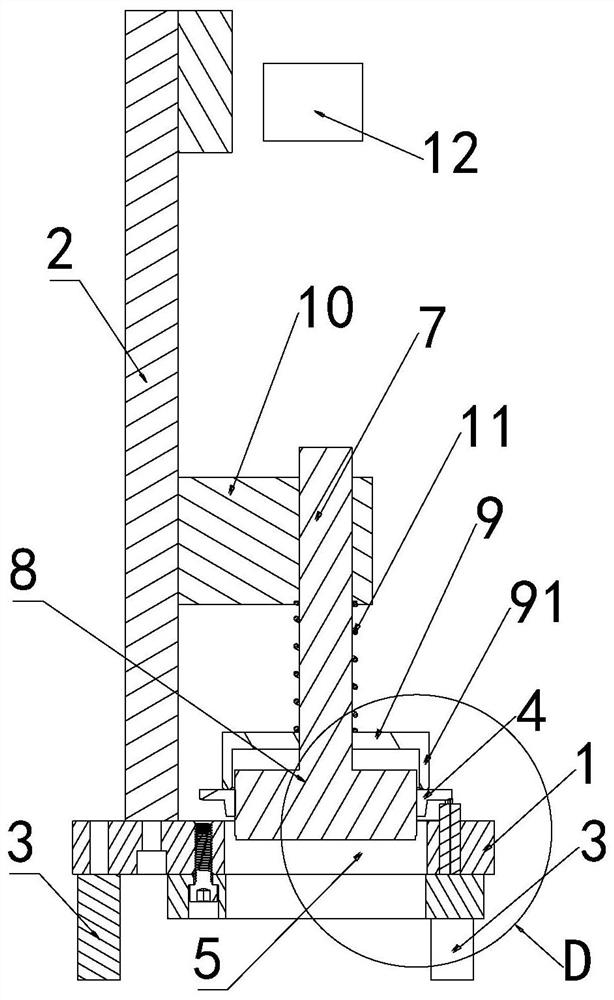

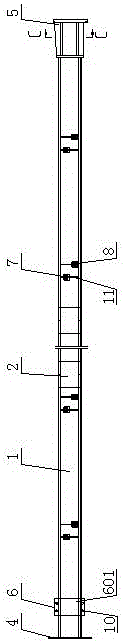

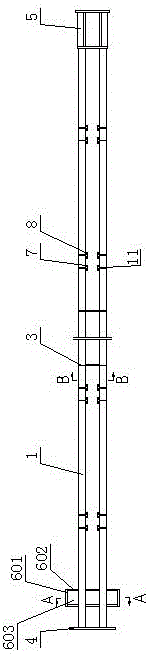

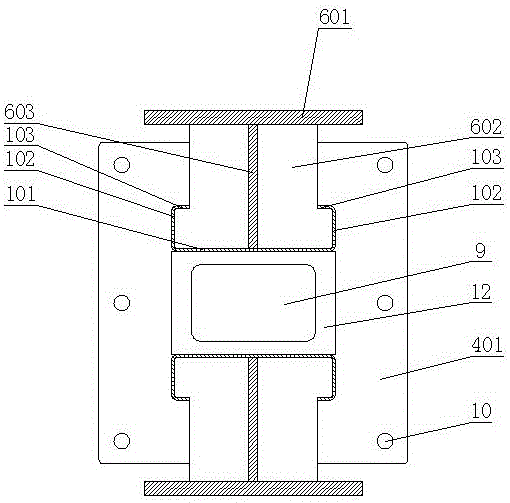

Tooth chamfer tester of tooth ring

ActiveCN110411306AGuaranteed deflectionShorten the timeMechanical clearance measurementsOrthodonticsTooth chamber

The invention relates to a tooth chamfer tester of a tooth ring, and belongs to the technical field of tooth rings. The tester comprises a column arranged on a pedestal, the pedestal is supported by supporting legs, the pedestal is provided with a through hole for placing the tooth ring and at least three groups of spherical supporters, each group of spherical supporters supports the two side surfaces of a chamfer of the same tooth in the tooth ring, a positioning mandrel is further included, one end of the positioning mandrel is provided with a positioning cylinder matching the inner ring ofthe tooth ring, and the positioning mandrel and the positioning cylinder are arranged on the column in an up-down sliding way. Thus, detection time for the tooth chamber is shortened, the detection efficiency is improved, and the cost is reduced.

Owner:CHONGQING LANDAI POWER TRANSMISSION MACHINERY

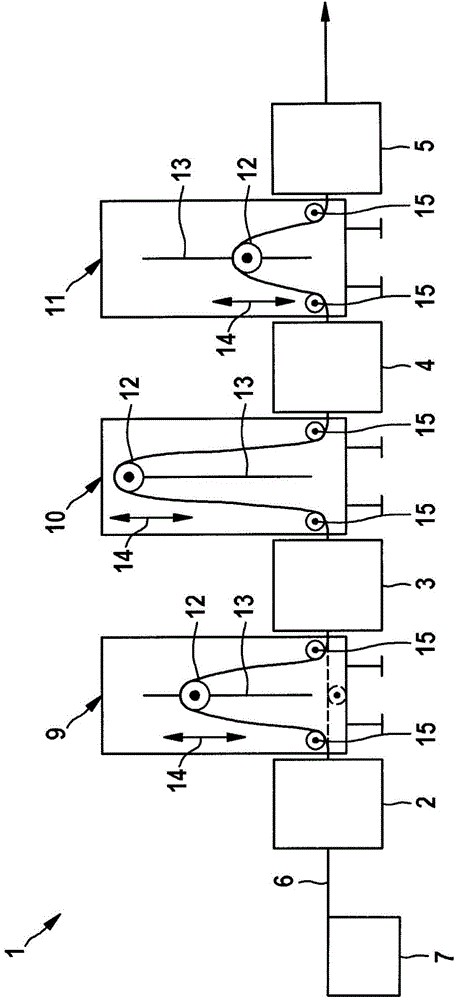

Device and Method for Manufacturing Cable Sensors

InactiveCN104646571AGuaranteed high flexibilityShorten the manufacturing cycleMeasurement apparatus componentsFilament handlingLine sensorEngineering

A device for the production of cable sensors that each have at least one sensor and a cable trimmed to a variably pre-definable length includes at least two processing units, and at least one conveying unit. The processing units are configured to load and cut a cable blank, and are further configured to sequentially convey the cable blank along a pre-defined motion track. At least one deflection unit is positioned between adjacent processing units. Each deflection unit includes at least one deflection element that is in contact with or is configured to contact the cable blank. A displacement unit is assigned to and is configured to modify a position of the deflection element in order to influence a length of the motion track of the cable blank so as to obtain variable lengths of cable.

Owner:ROBERT BOSCH GMBH

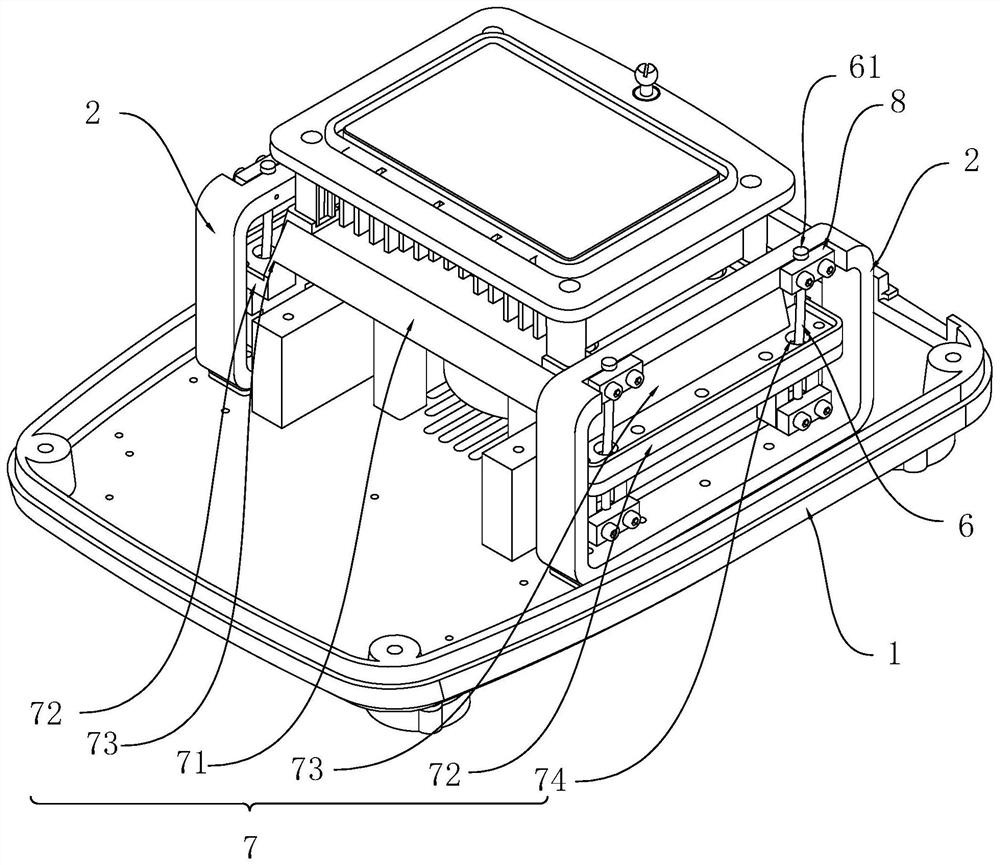

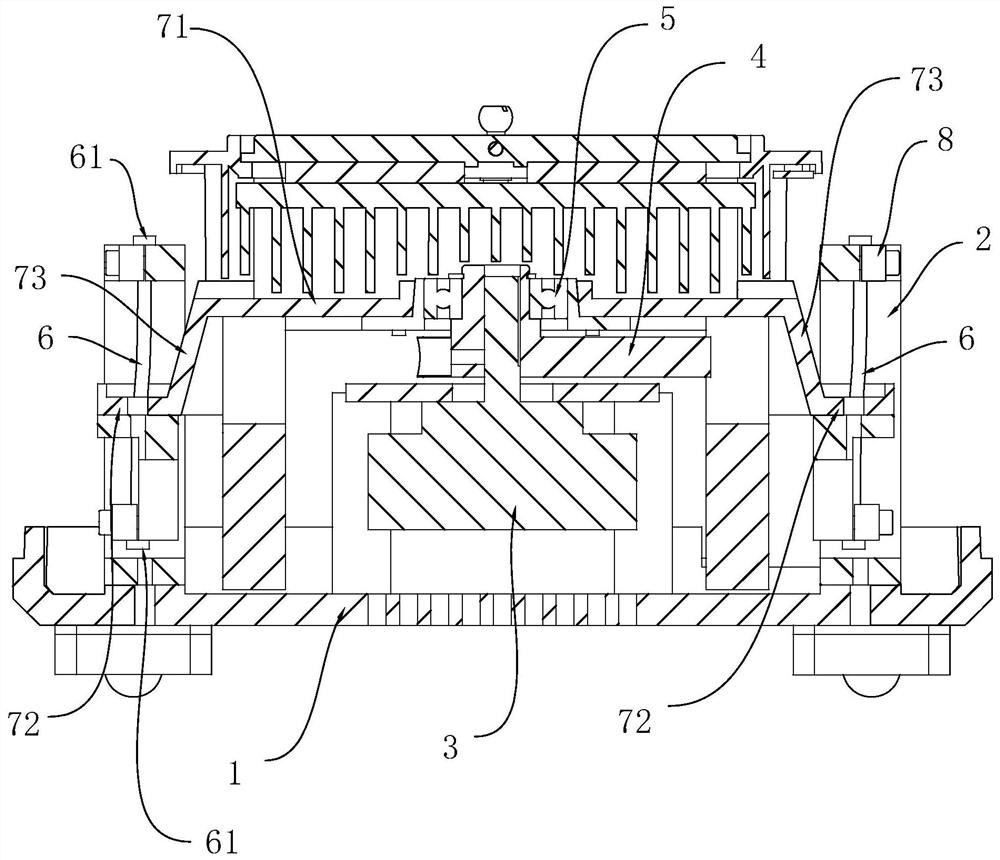

Chassis assembling tool and method

ActiveCN114260634AGuaranteed disc distanceGuaranteed deflectionWelding/cutting auxillary devicesAuxillary welding devicesTruckRailway freight car

The invention discloses a chassis assembling tool and method, and belongs to the technical field of railway wagons. According to the chassis assembling tool, two traction beam supporting frames are both fixedly arranged on an assembling datum platform, and two sleeper beam supporting frames are arranged between the two traction beam supporting frames; the two sleeper beam supporting frames are both fixedly arranged on the assembling reference platform, and the distance between the two sleeper beam supporting frames is set. Two positioning plates are arranged on the sleeper beam supporting frame, the distance between the two positioning plates is set, two positioning pieces are arranged on the positioning plates, and the distance between the two positioning pieces is set; the plurality of main beam supporting frames are fixedly arranged on the assembly reference platform, and the plurality of main beam supporting frames are arranged between the two sleeper beam supporting frames; two limiting plates are arranged on the main beam supporting frame, and the distance between the two limiting plates is set. Two side beam supporting plates are arranged on the main beam supporting frame, and the heights of the side beam supporting plates are set. According to the chassis assembly tool and the assembly method, the size precision can be guaranteed, and the production efficiency is improved.

Owner:CRRC ZHUZHOU ROLLING CO LTD

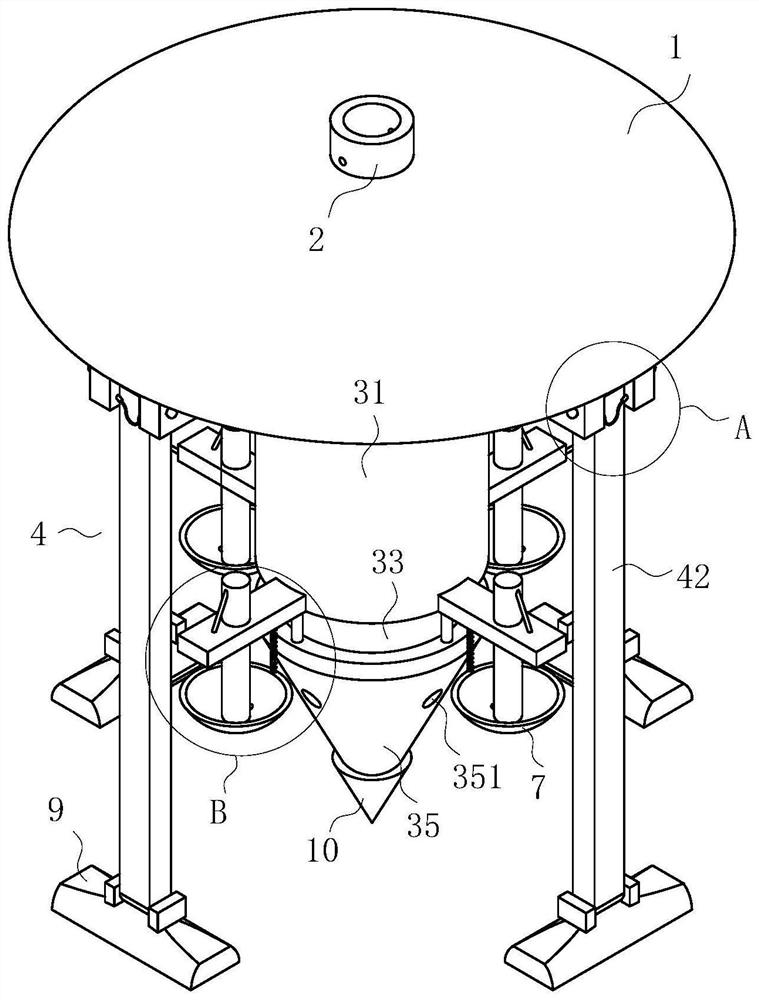

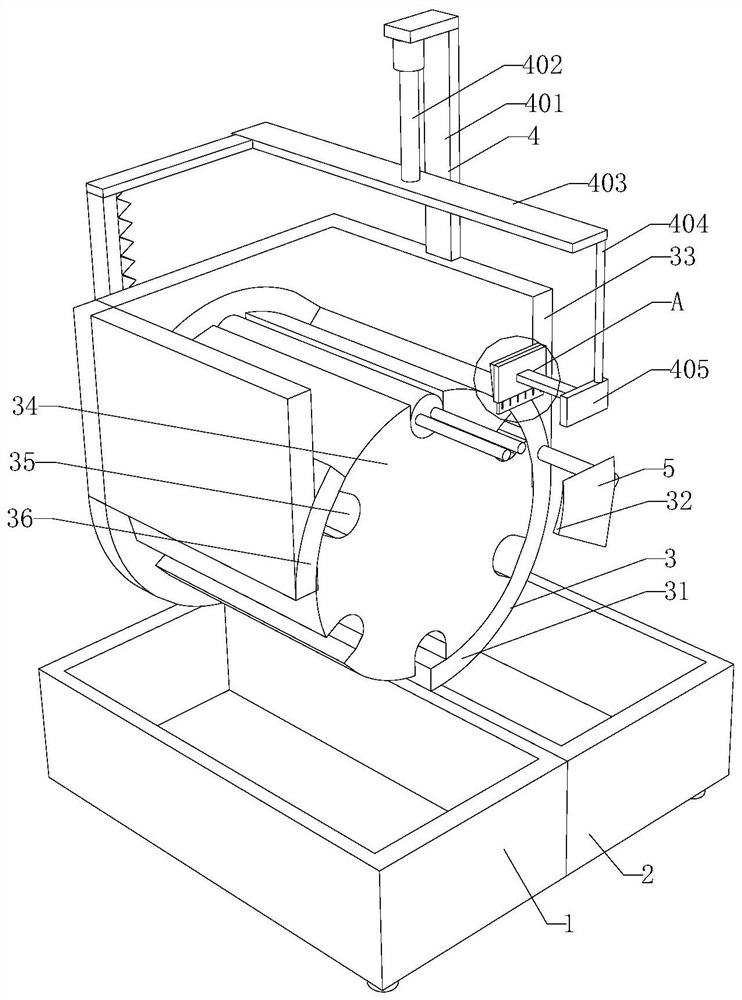

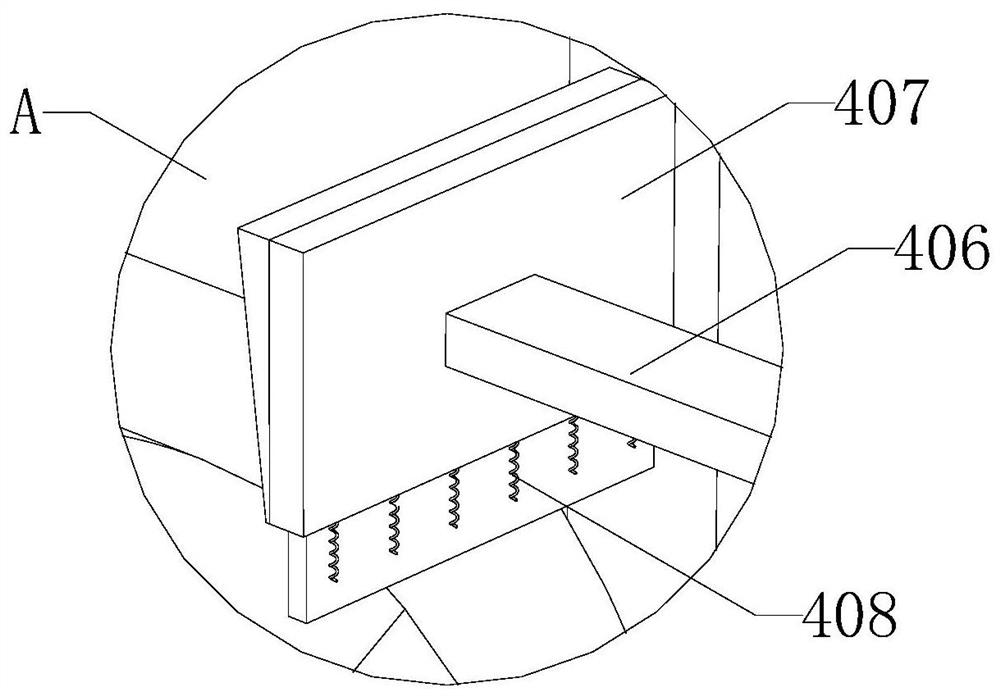

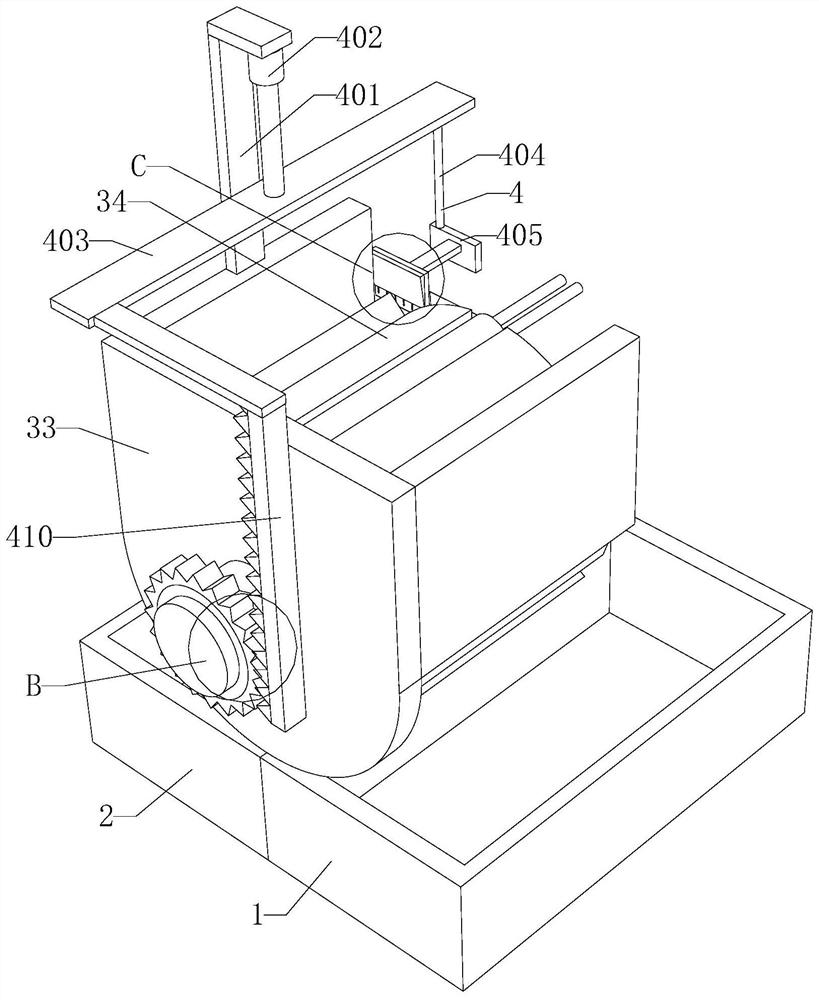

Spring rod suspension type oscillation blending device

PendingCN112473492APrevent rotationOvercome Oscillating ImbalancesShaking/oscillating/vibrating mixersTransportation and packagingElectric machineryEngineering

The invention relates to a spring rod suspension type oscillation blending device, which solves the problems of non-uniform oscillation, large noise, poor blending effect and the like in the prior art, and adopts the technical scheme that a plurality of spring rods are arranged on a base, the lower ends of the spring rods are limited on the base, and the upper ends of the spring rods are matched with an oscillation disc; and the spring rod is used for enabling the oscillating disc to oscillate stably on an annular track. The device has the effects that the spring rod is additionally arranged on the base and is matched with the oscillating disc, so that the oscillating disc is stressed to oscillate uniformly under the action of the motor, the noise is reduced, and the uniform mixing effectis improved.

Owner:HANGZHOU ALLSHENG INSTR

Print head module and label printer

InactiveCN105150686BImprove flatnessGuaranteed deflectionPrintingColor printingBiomedical engineering

The invention discloses a print head module and a label printer. The print head module comprises a flat plate, a fixation frame and a spring sheet. A print head is arranged on the flat plate; and the spring sheet has a first end and a second end which are opposite, wherein the first end realizes fixation connection with the flat plate through combination and fixation of a first fixation portion and a second fixation portion, which are different in position and coplanar, of the first end with a first fixation member and a second fixation member of the flat plate; and the second end realizes fixed combination with the fixation frame through combination and fixation of a third fixation portion and a fourth fixation portion, which are different in position and coplanar, of the second end with a third fixation member and a fourth fixation member of the fixation frame, such that the two ends of the print head are equally stressed, the problems of wrinkling, paper jam and light-color printing due to unequal stress of the print head are prevented, and deflection is guaranteed.

Owner:QISDA OPTRONICS (SUZHOU) CO LTD

A tooth chamfering inspection tool for a ring gear

ActiveCN110411306BGuaranteed deflectionShorten the timeMechanical clearance measurementsEngineeringPhysics

The invention relates to a tooth chamfer tester of a tooth ring, and belongs to the technical field of tooth rings. The tester comprises a column arranged on a pedestal, the pedestal is supported by supporting legs, the pedestal is provided with a through hole for placing the tooth ring and at least three groups of spherical supporters, each group of spherical supporters supports the two side surfaces of a chamfer of the same tooth in the tooth ring, a positioning mandrel is further included, one end of the positioning mandrel is provided with a positioning cylinder matching the inner ring ofthe tooth ring, and the positioning mandrel and the positioning cylinder are arranged on the column in an up-down sliding way. Thus, detection time for the tooth chamber is shortened, the detection efficiency is improved, and the cost is reduced.

Owner:CHONGQING LANDAI POWER TRANSMISSION MACHINERY

Pin shearing device with rapid fixing function for electronic component processing

The invention relates to the field of electronic component processing. The invention discloses a pin shearing device with a rapid fixing function for electronic component processing and aims to solve the problem that the operation is troublesome when an electronic component is fixed through a clamp. When the device is used for cutting an electronic component, it is difficult to ensure that the exposed lengths of pins of the electronic component are equal, and it is difficult to ensure the quality of the cut electronic component. After the device cuts the pins of the electronic components, waste materials of the pins of the electronic components are inconvenient to collect. The pin shearing device is composed of a feeding mechanism and a cutting mechanism. For the pin shearing device with the rapid fixing function for electronic component processing, by putting the electronic component in the inner side of a frame, the electronic component is promoted to be clamped into a groove, then an air cylinder shrinks to drive a driven gear to rotate, then a one-way bearing is matched to promote a connecting rod to drive a cylinder to rotate clockwise, and the cylinder is promoted to drive the electronic component in the groove on the side surface to rotate clockwise.

Owner:郑阳平

Fitting-up fastenr driving tool

InactiveCN1328014CGuaranteed deflectionOpen fullyStapling toolsDispensing apparatusEngineeringFastener

A powered tool constructed to drive a fastener into a workpiece includes a nosepiece assembly including a back plate and a front plate combining to define a path for a driver blade, the front plate being pivotally movable relative to the back plate between a closed position, in which the front plate and the back plate are in contact with each other, and an open position. The front plate is movable to an interim deflecting position between the closed position and the open position. A handle portion has an outer surface at least partially defining a grip, and an inner surface at least partially defining a chamber. The handle portion includes a substrate having at least one aperture, and an overmold configured for forming a gripping surface on the outer surface and for extending through the apertures into the chamber for forming a resilient mounting point.

Owner:ILLINOIS TOOL WORKS INC

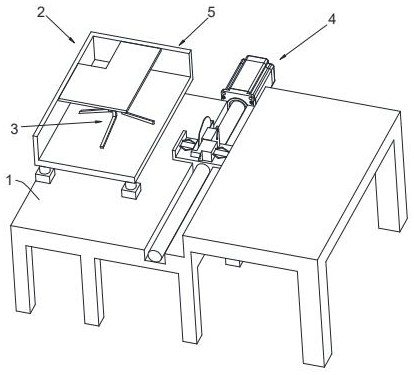

A method for cutting and processing aluminum-plastic panels for building curtain walls

ActiveCN112571499BEasy to operateSuitable for mass productionMetal working apparatusMaterials preparationMechanical engineering

Owner:深圳市成豪建设集团有限公司

A kind of lint opening device

InactiveCN104695062BGuaranteed deflectionFibre cleaning/opening by toothed membersFibre cleaning/opening machinesFiberEngineering

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Conveying bracket of small-diameter steel pipe inner wall shot blasting machine

ActiveCN106625280AAdapt to cleaning requirementsImprove carrying capacityAbrasive machine appurtenancesAbrasive blasting machinesEngineeringBilateral symmetry

The invention relates to a conveying bracket of a small-diameter steel pipe inner wall shot blasting machine. The conveying bracket comprises multiple groups of bearing monomers, wherein each group of bearing monomers comprises two outer bending plates in bilateral symmetry; the two outer bending plates are connected through multiple spaced reinforcing plates; adjacent two groups of bearing monomers are connected through two inner bending plates in bilateral symmetry; the outer end of the bearing monomer at the leftmost end is fixedly connected with a first connecting piece; the outer end of the bearing monomer at the rightmost end is fixedly connected with a second connecting piece; a third connecting piece is arranged on the bearing monomer at the leftmost end; multiple upper support roller racks in bilateral symmetry are mounted on the two sides of the upper part of each group of bearing monomers; multiple lower support roller racks in bilateral symmetry are mounted on the two sides of the lower part of each group of bearing monomers; and support rollers are arranged on the upper support roller racks and lower support roller racks. The conveying bracket provided by the invention is reasonable in structure design and convenient to use, improves the rigidity and deflection and meets the requirement for inner wall shot blasting of a small-diameter steel pipe.

Owner:SHANDONG KAITAI SHOT BLASTING MACHINERY

Equipment for obtaining exhaust gas samples from internal combustion engines

Owner:AVL EMISSION TEST SYST GMBH

A trash can cleaning system

The invention discloses a rubbish can cleaning system and belongs to the technical field of environmental sanitation equipment. The rubbish can cleaning system comprises a driving source, a power spindle, a rotating arm, a rinsing assembly and a spraying mechanism. The rinsing assembly comprises a driving motor, a fixed base, a rotating shaft and a cleaning brush. The axis of the rotating shaft is perpendicular to the extension direction of the rotating arm. A fixed clamping sleeve is fixedly mounted at the end of the rotating arm, and a deflection assembly is fixedly sleeved with the fixed clamping sleeve. The fixed base is fixedly connected with a pair of connecting lug plates. The deflection assembly comprises a central spindle and an outer sleeve body, and the outer sleeve body is sleeved with the fixed clamping sleeve. The cross section of a hollow cavity of the outer sleeve body is square, and the four side faces of the central spindle right face the four corner sides of the hollow cavity of the outer sleeve body. Rubber bodies are plugged between the side faces of the central spindle and the corner sides of the hollow cavity of the outer sleeve body. The two ends of the central spindle are detachably connected with the connecting lug plates. The rubbish can cleaning system can ensure that the cleaning brush has deflection capacity, and accordingly the phenomenon that the outer wall of a rubbish can is abraded due to overlarge contact acting force between the cleaning brush and the outer wall of the rubbish can is avoided.

Owner:YANGZHOU JINWEI ENVIRONMENTAL PROTECTION TECH CO LTD

Filling and sealing structure of axially split pump

The invention relates to the sealing field of split pumps, in particular to a filling and sealing structure of split pumps, which includes a shaft sleeve arranged on a shaft, a pump body is arranged on the shaft sleeve, and a There is a packing retainer docked with the outside of the pump body, the packing retainer is connected with a packing gland matching it, and a sealing cavity is formed between the packing gland and the packing retaining sleeve, and a packing ring is arranged in the sealing cavity and packing, the packing ring and the flushing hole provided on the stuffing retainer butt, the outer side of the packing retaining sleeve is provided with a water tank communicating with the flushing hole, and the water tank communicates with the flushing pipe; the purpose of the present invention is Provide a filling and sealing structure for split pumps, set a cylindrical packing retainer, and set a water tank connected to it on the outside of the packing retainer, and connect the water tank to the washing pipe to make the position of the sealing chamber closer The impeller is improved, the bearing span is reduced, and the deflection of the shaft is guaranteed to be in a safe range.

Owner:王道红

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com