Device and Method for Manufacturing Cable Sensors

A sensor and cable technology, which is applied in the field of manufacturing multiple cable sensors, can solve the problems of long cycle time and achieve the effect of shortening the manufacturing cycle and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

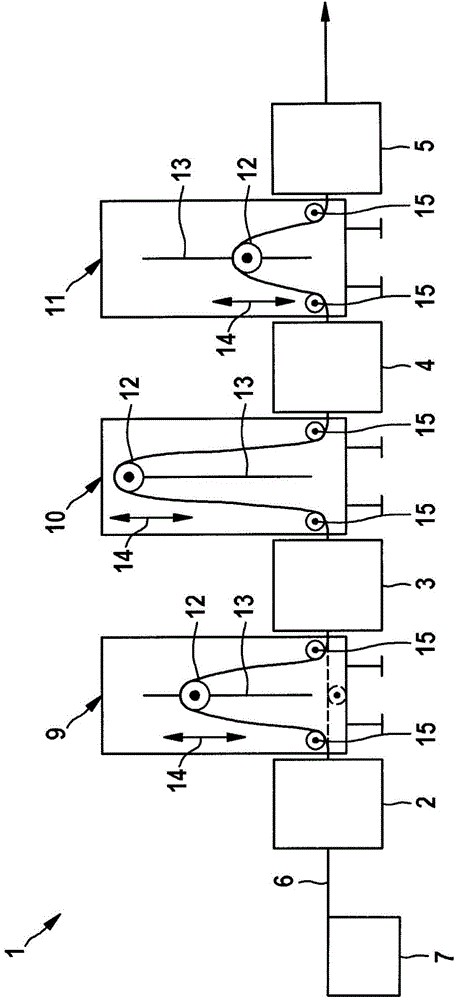

[0019] figure 1 A device 1 for producing a plurality of cable sensors is shown in a simplified illustration. The device 1 is designed as a production line with a plurality of processing devices 2 , 3 , 4 and 5 . A cable raw material 6 , supplied for example by a cable feeder 7 with a cable drum, travels through these processing devices 2 to 5 . The cable raw material 6 runs sequentially, ie according to a sequence, through the processing devices 2 to 5 . In addition, a conveying device 8 is integrated into the processing devices 2 to 5 in the direction of the conveying direction looking at the last processing device 5 , by means of which conveying device 8 a pulling force can be exerted on the cable 6 for conveying the cable raw material 6 through processing units 2 to 5.

[0020] The processing devices 2 to 5 also have a plurality of guide elements for purposefully guiding the cable raw material 6 along a predetermined movement path. These guide elements are advantageousl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com