Fixed-area controllable staggered oriented perforating horizontal well hydraulic fracturing physical simulation method

A technology of directional perforation and physical simulation, applied in the direction of applying stable tension/pressure to test material strength, earthwork drilling, wellbore/well components, etc. Issues such as the influence of perforation azimuth are not considered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

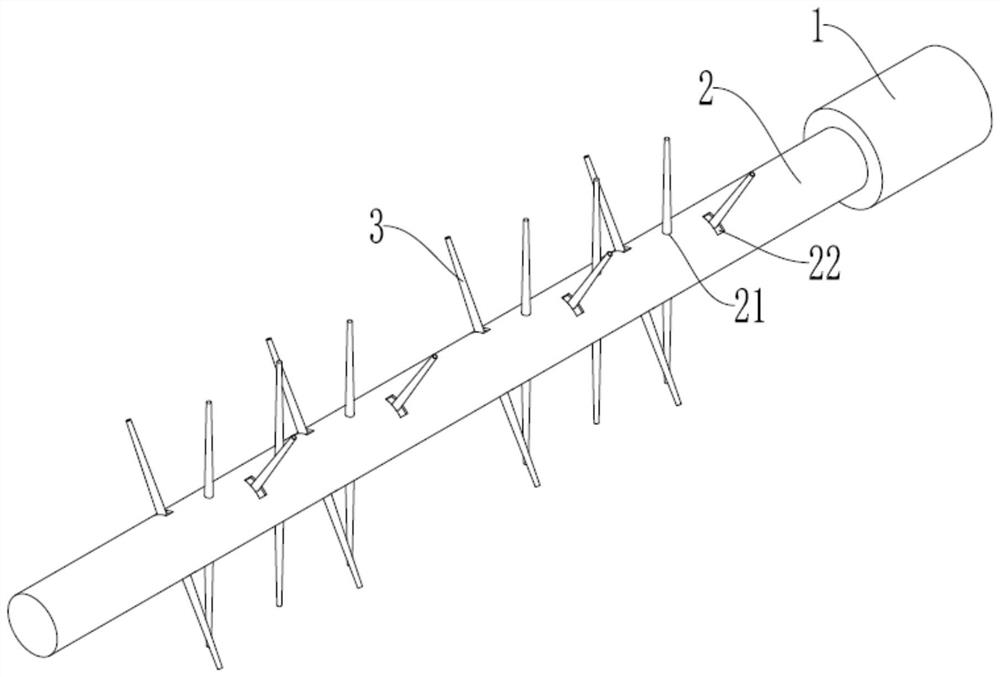

[0051] Such as figure 1 As shown, this embodiment discloses a simulated wellbore, which includes a wellbore head 1 and a wellbore 2 connected to each other. The wellbore 2 is provided with a plurality of perforation groups along its axial direction, wherein the perforation groups are distributed in the simulation The middle position of the wellbore ensures that the part of the wellbore 2 where the perforation holes are opened is located at the center of the artificial core.

[0052] The simulated wellbore also includes a plurality of liquid injection pipes 3, and the liquid injection pipes 3 are partially inserted into the wellbore 2 from the outside to the inside. Each perforation group corresponds to a liquid injection pipe 3, and each liquid injection pipe 3 injects liquid into its corresponding perforation group.

[0053] The outer diameter of the wellbore head 1 is 20mm, the inner diameter is 18mm, and the height is 30mm; the outer diameter of the wellbore 2 is 14mm, the...

Embodiment 2

[0058] This embodiment discloses a physical simulation method for hydraulic fracturing of horizontal wells with controllable staggered directional perforation in a fixed area, which includes the following steps:

[0059] S1. Make a simulated wellbore. A plurality of perforation groups are arranged on the simulated wellbore. Each perforation group corresponds to a liquid injection pipe 3. The perforation group includes a plurality of perforation holes, and the perforation tunnel is made of paper. Inserting the perforation tunnel into the perforation hole;

[0060] S2. Place the simulated wellbore in the mold, pour the mixture of cement and quartz sand into the mold, remove the mold after drying, and obtain the artificial rock core test piece;

[0061] S3, put the test piece and the simulated shaft into the loading chamber of the true triaxial physical simulation testing machine;

[0062] S4. Connect the liquid injection pump to a liquid injection pipe 3 of the simulated wellbo...

Embodiment 3

[0068] This embodiment discloses a physical simulation method for hydraulic fracturing of horizontal wells with controllable staggered directional perforation in a fixed area, which includes the following steps:

[0069] S1. Make a simulated wellbore. The simulated wellbore is provided with multiple perforation groups along its axial direction. Each perforation group corresponds to a liquid injection pipe 3. The perforation group includes multiple perforations, and the perforation group is made of paper. The perforation tunnel is inserted into the perforation hole; the simulated wellbore is the simulated wellbore in Embodiment 1. The length of the perforation tunnel is 20mm-40mm, and the perforation tunnel is inserted into the second perforation hole 22 to adjust and control the angle of the fracturing fluid ejected from the second perforation hole 22 . The perforation tunnel is made of A4 paper.

[0070] S11. Make a mold for the test piece, wherein the size of the mold is se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com