A tooth chamfering inspection tool for a ring gear

A ring gear and chamfering technology, applied in the ring gear field, can solve the problems of long detection time and low detection efficiency of ring gear chamfering, and achieve the effects of saving detection time, reducing costs and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

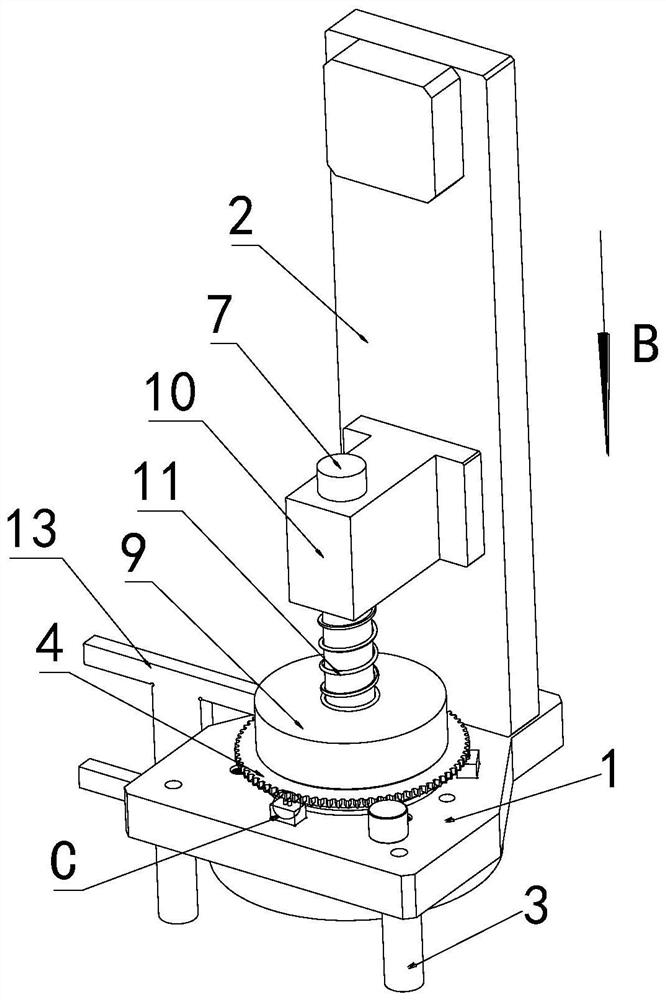

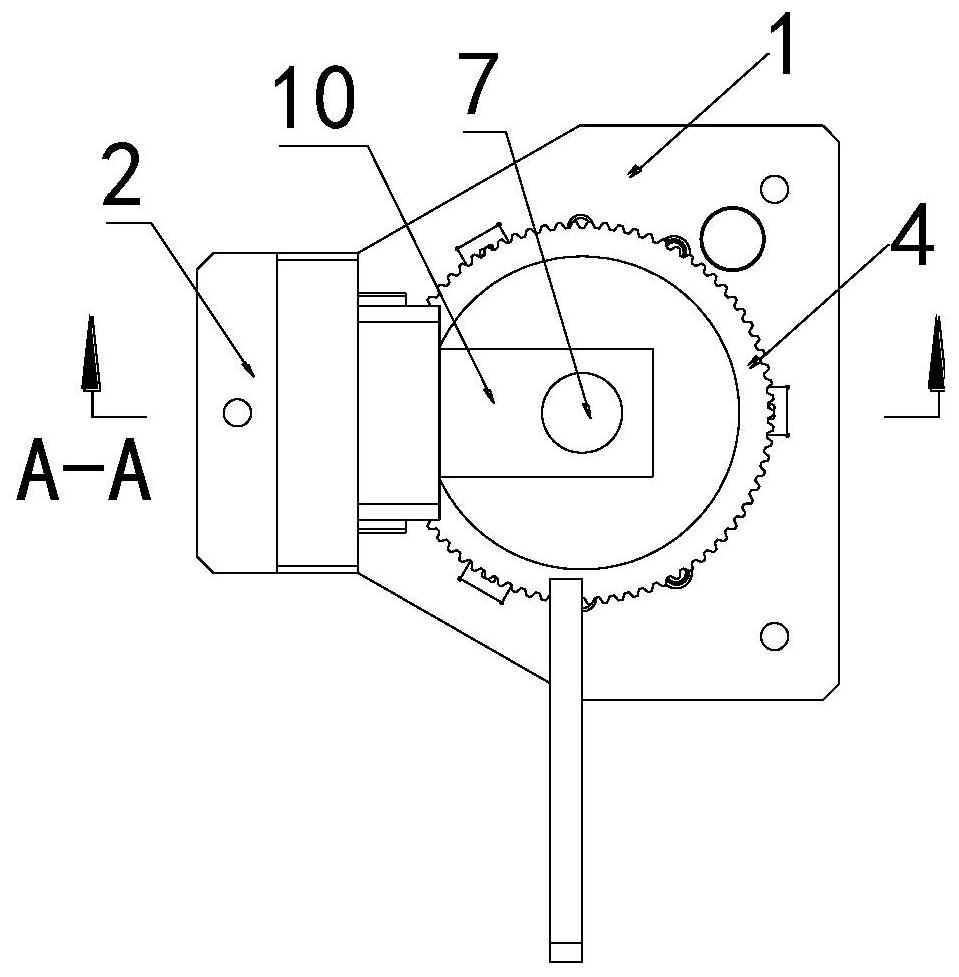

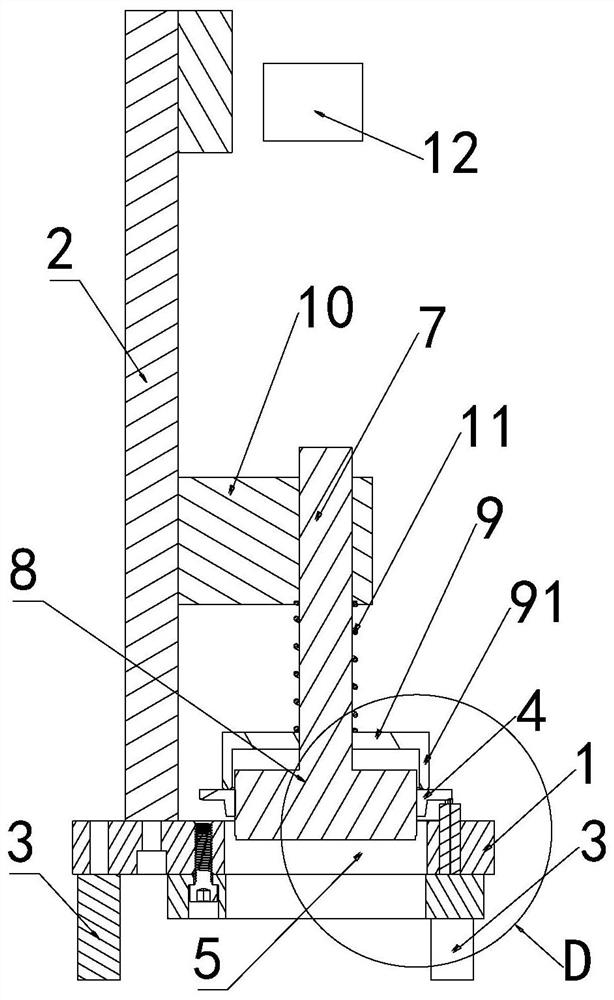

[0024] Such as Figure 1 to Figure 6 As shown, a tooth chamfering inspection tool for a ring gear includes a column 2 arranged on a base 1; Hole 5, said base 1 is provided with at least three spherical support devices 6, each of said spherical support devices 6 supports the two sides of the chamfer of the same tooth in said ring gear 4; also includes a positioning mandrel 7, One end of the positioning mandrel 7 is provided with a positioning cylinder 8 that matches the inner ring of the ring gear 4, the positioning mandrel 7 is fixedly connected to the positioning cylinder 8, and the positioning mandrel 7 slides up and down on the column 2, in this embodiment, the positioning mandrel 7 is welded or bolted to the positioning cylinder 8.

[0025] Such as Figure 4 As shown, in this embodiment, the spherical support device 6 is arranged between the outer diameter and the inner diameter of the teeth of the ring gear 4, the spherical support device 6 includes two spherical suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com