Equipment for obtaining exhaust gas samples from internal combustion engines

A technology of internal combustion engine and exhaust gas, applied in the direction of sampling, sampling device, engine test, etc., to achieve the effect of simple installation, cheap manufacture and operation, and reduced pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

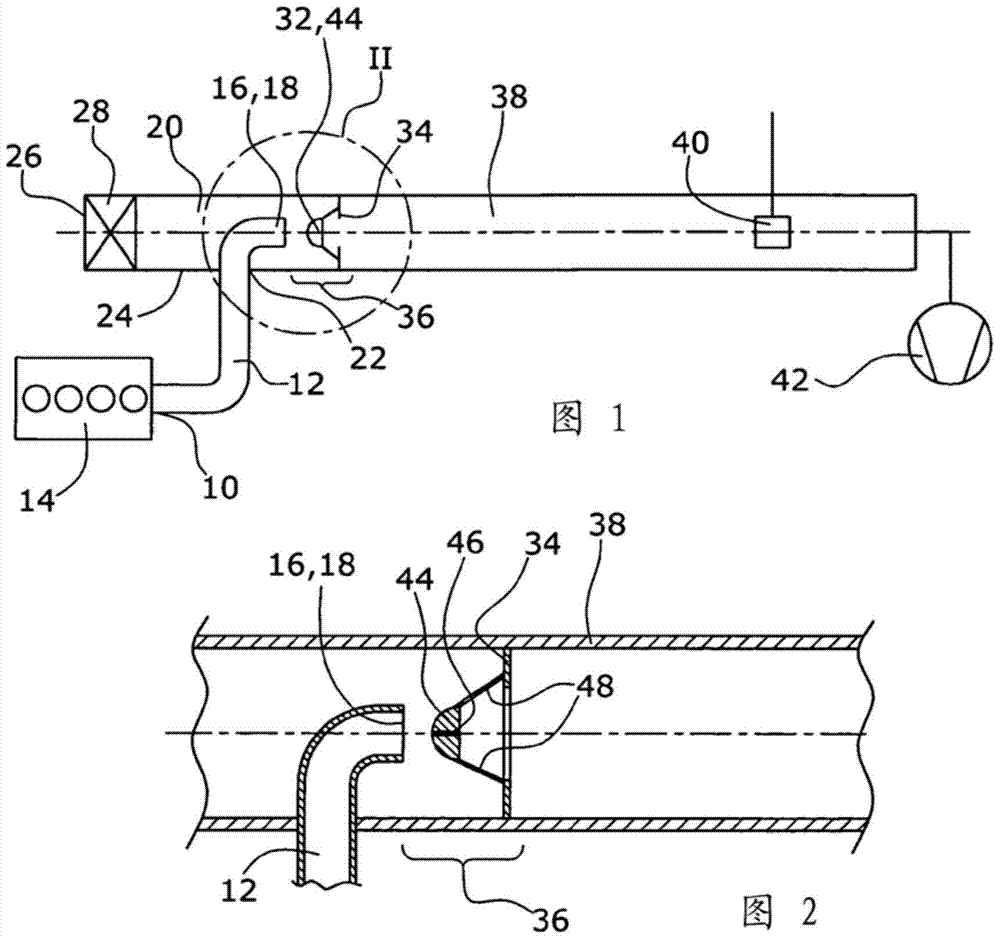

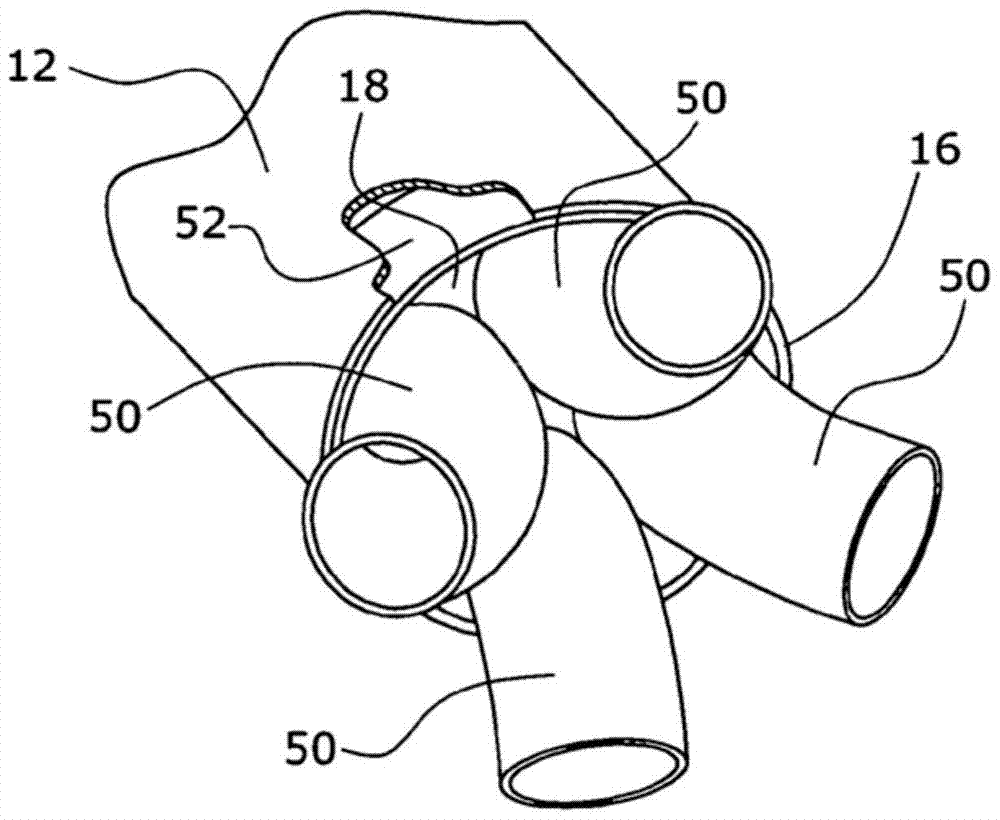

[0026] The device according to the invention for obtaining exhaust gas samples from an internal combustion engine of a diesel or gasoline engine comprises an exhaust gas inlet 10 through which an exhaust gas channel 12 is in fluid communication with an exhaust gas source 14 formed by the internal combustion engine of a vehicle.

[0027] The exhaust gas channel 12 has an end 16 with an outflow cross section 18 which opens concentrically in an air channel 20 . For this purpose, this air channel 20 has in its boundary wall 24 an opening 22 through which the exhaust gas channel 12 protrudes vertically into the air channel 20 . In order to open concentrically in the air channel 20 , the exhaust gas channel 12 has a deflection of 90°.

[0028] Upstream of the flow of the exhaust gas channel 12, the air channel 20 has an inlet 26, on which a first air filter 28, usually formed by three filters, is arranged, through which air can be sucked into the Inside the air channel 20. The def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com