Patents

Literature

43results about How to "Avoid flow loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

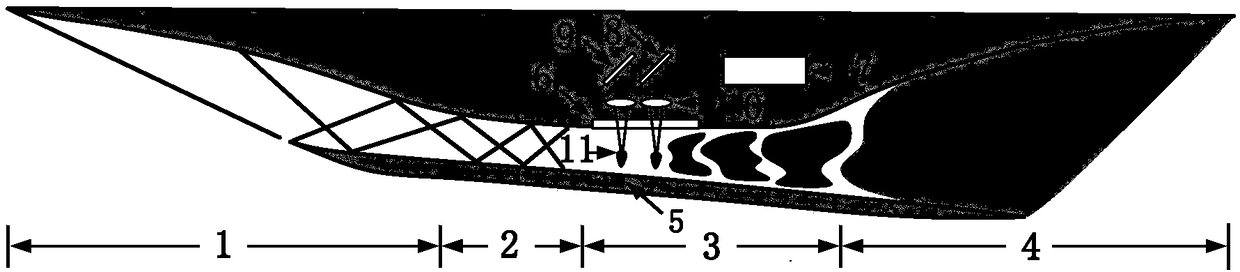

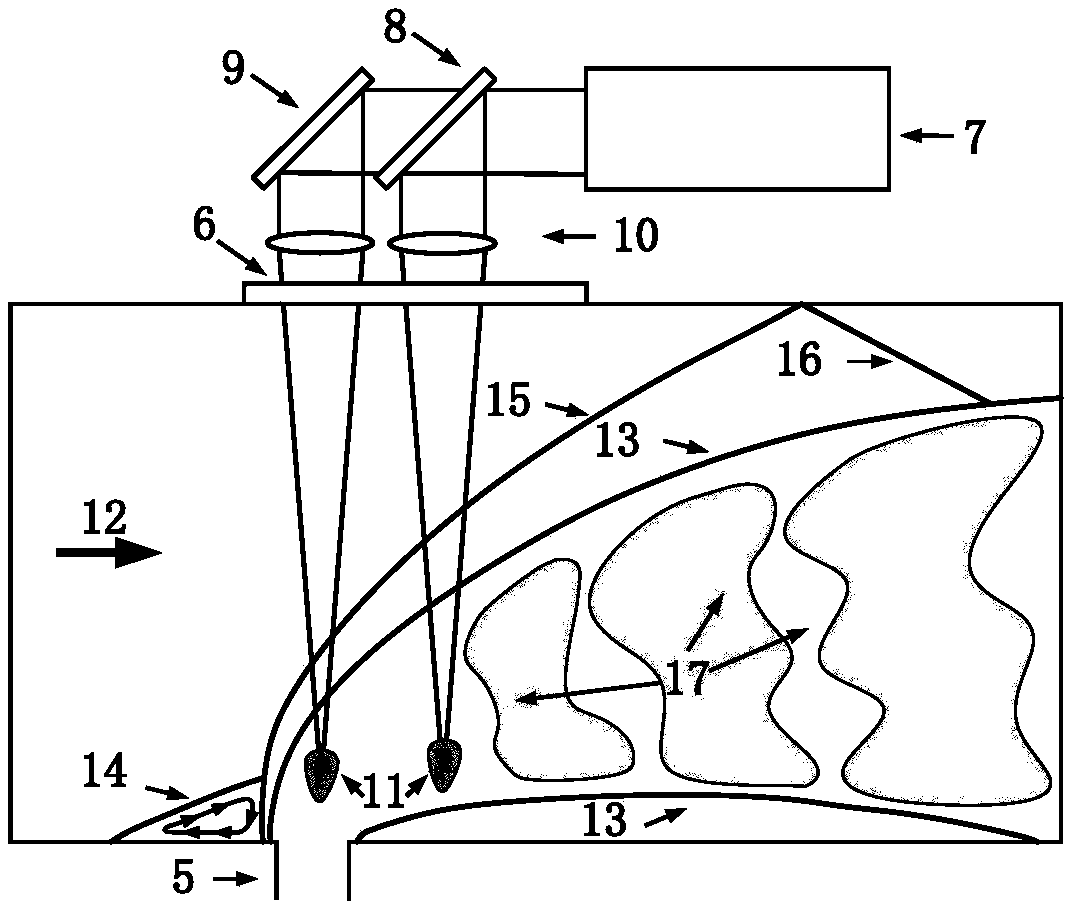

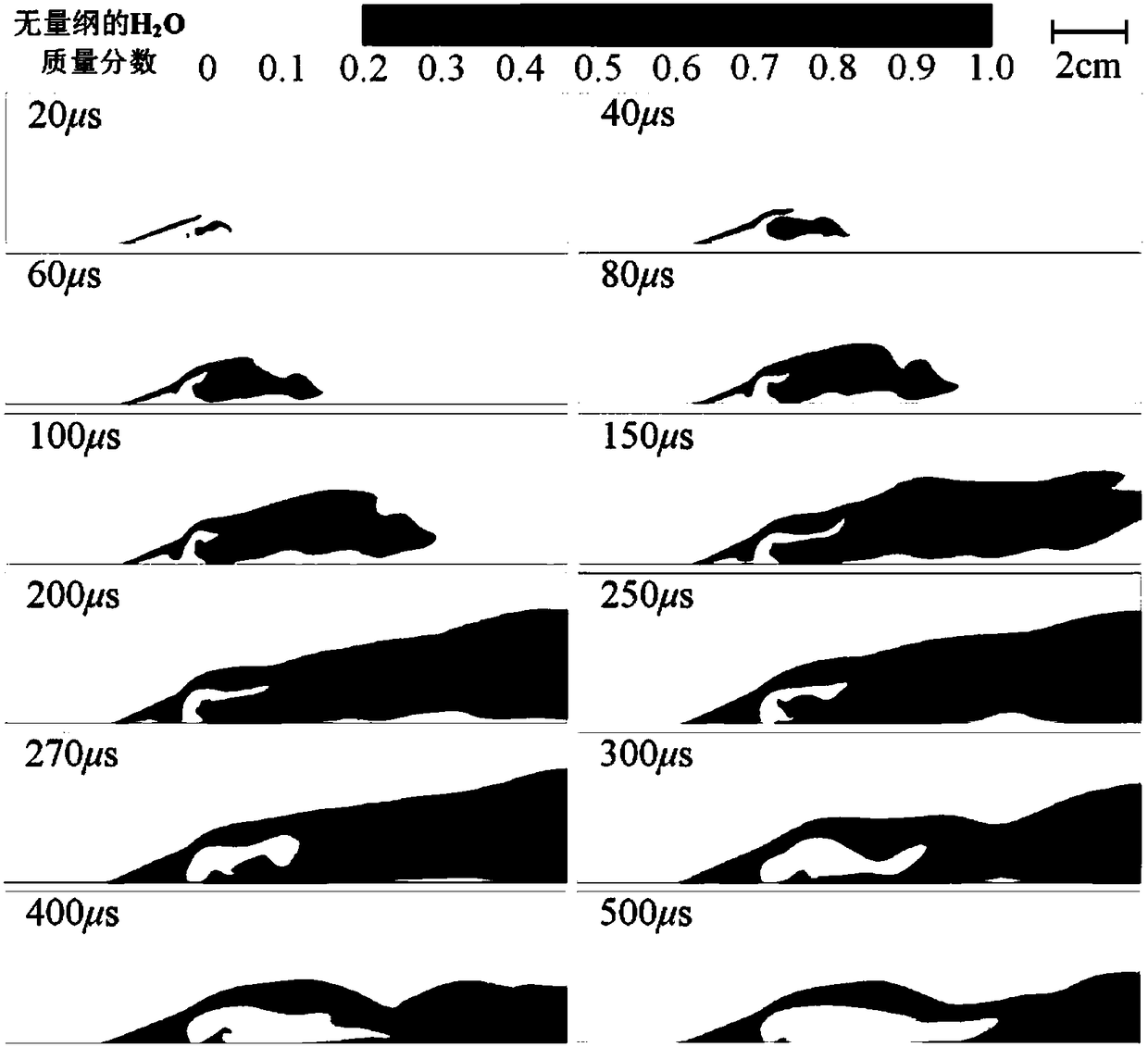

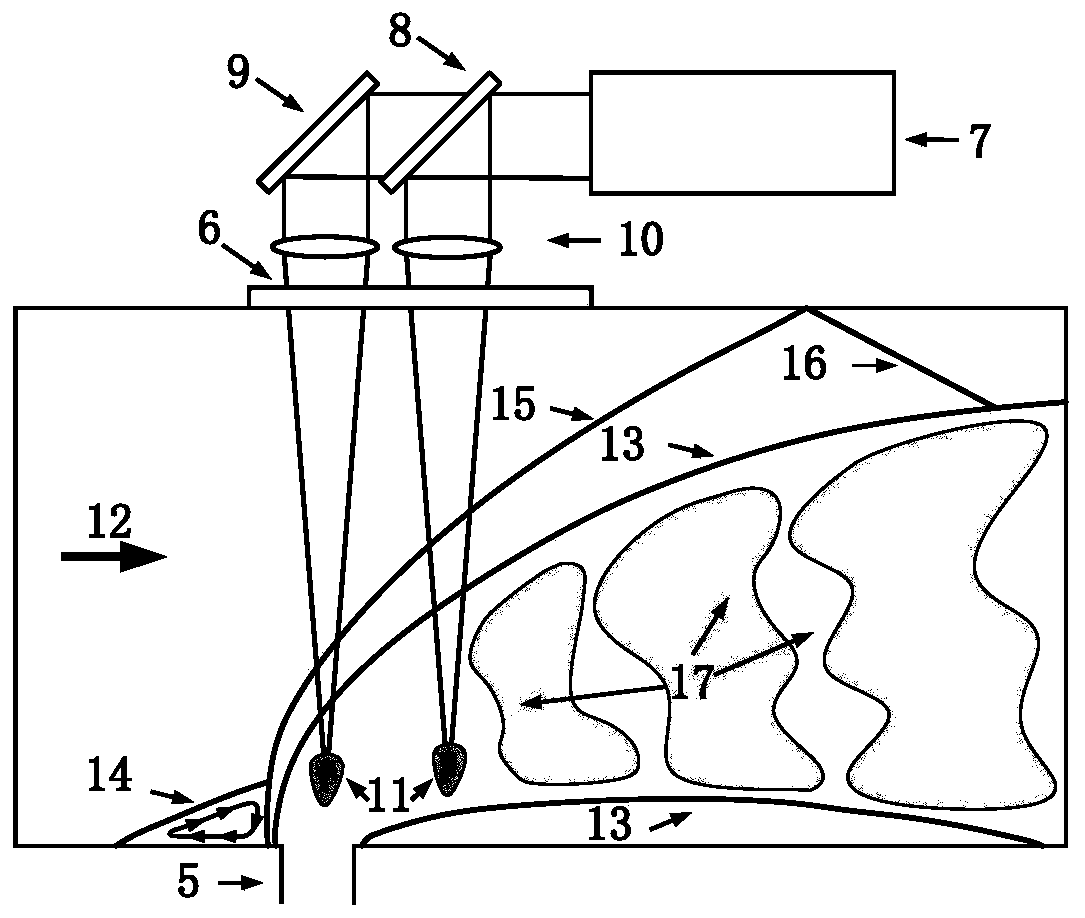

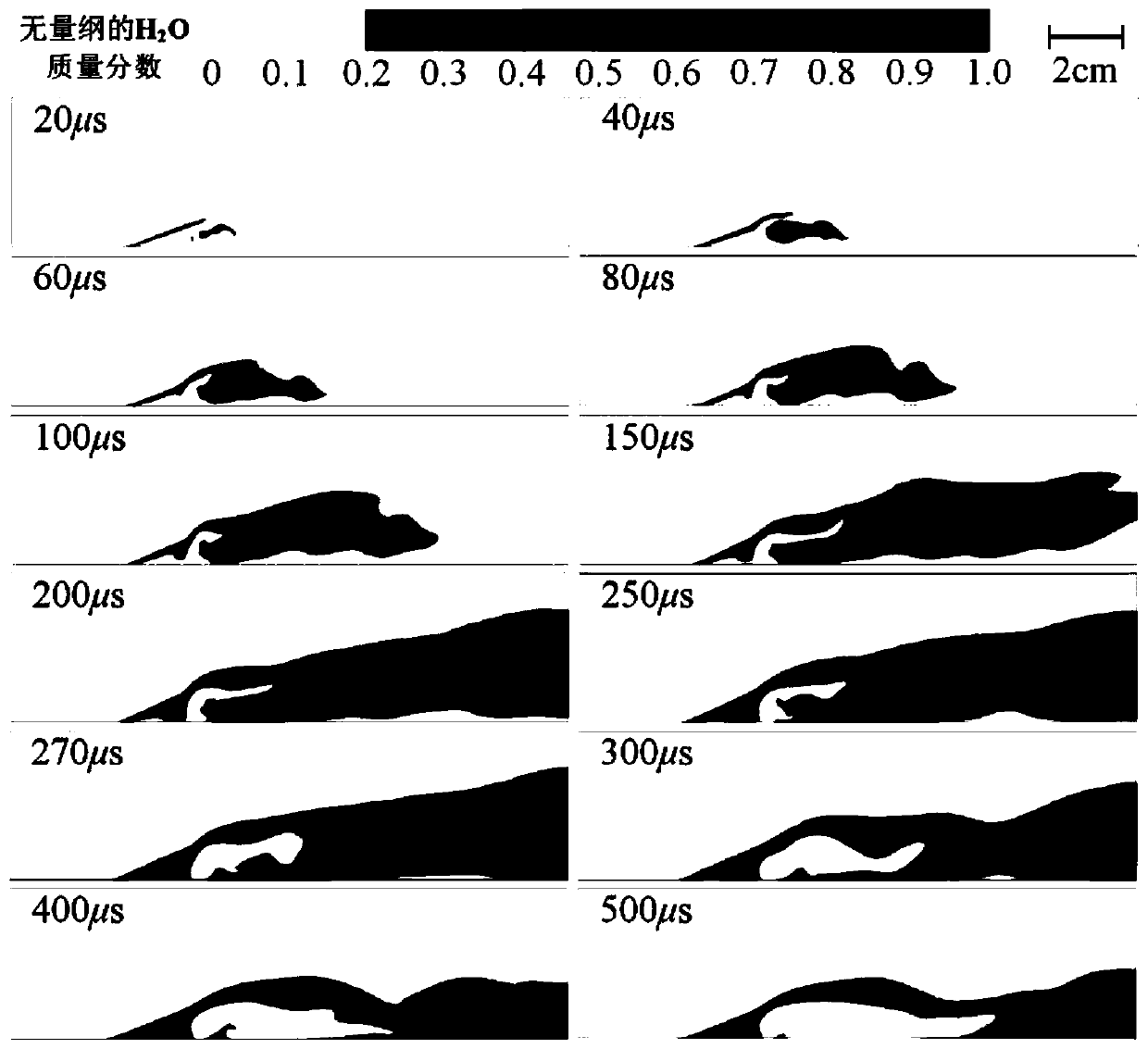

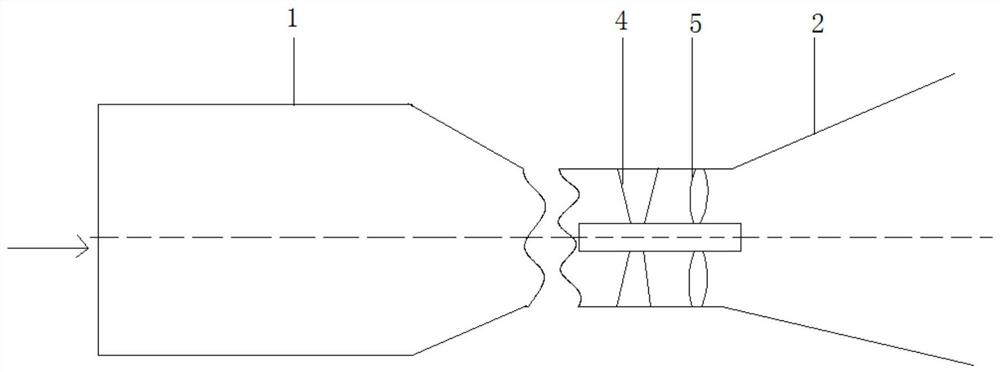

Combustion chamber based on high-repetition-frequency laser and scramjet engine

ActiveCN108443913ASolve electromagnetic interferenceAvoid energy lossContinuous combustion chamberCombustion chamberEngineering

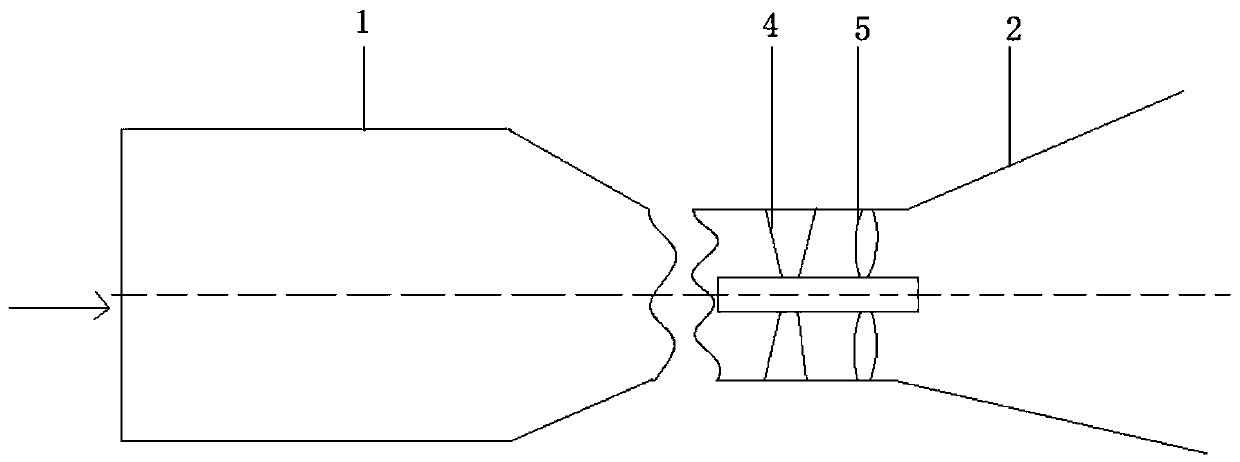

The invention provides a combustion chamber based on high-repetition-frequency laser and a scramjet engine. Stable flame is realized through a method of continuous breakdown of gas in supersonic-velocity gas currents through high-repetition-frequency laser pulse, so that the problems of flowing loss and heat protection caused by a mechanical flame stabilizer are effectively prevented.

Owner:NAT UNIV OF DEFENSE TECH

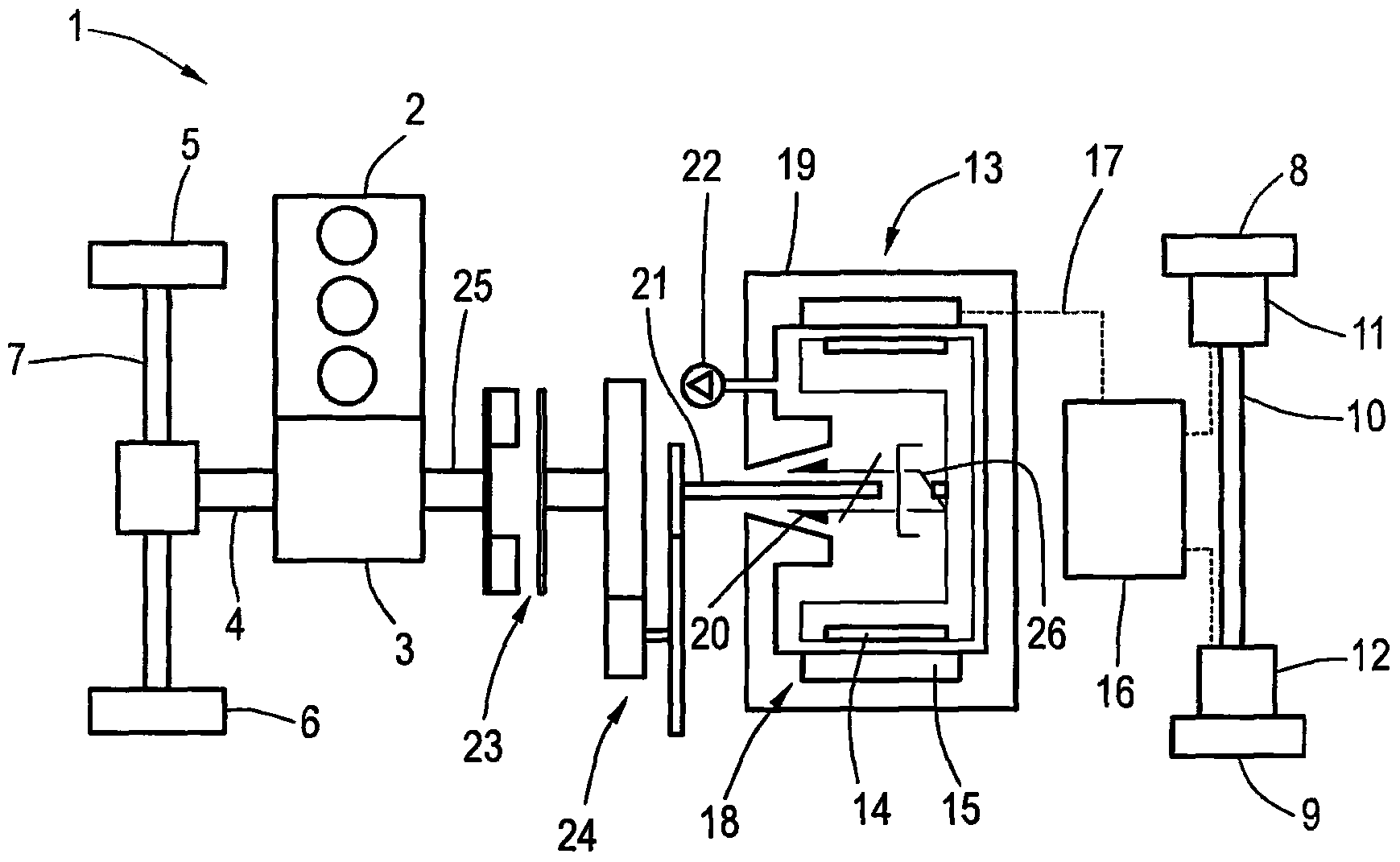

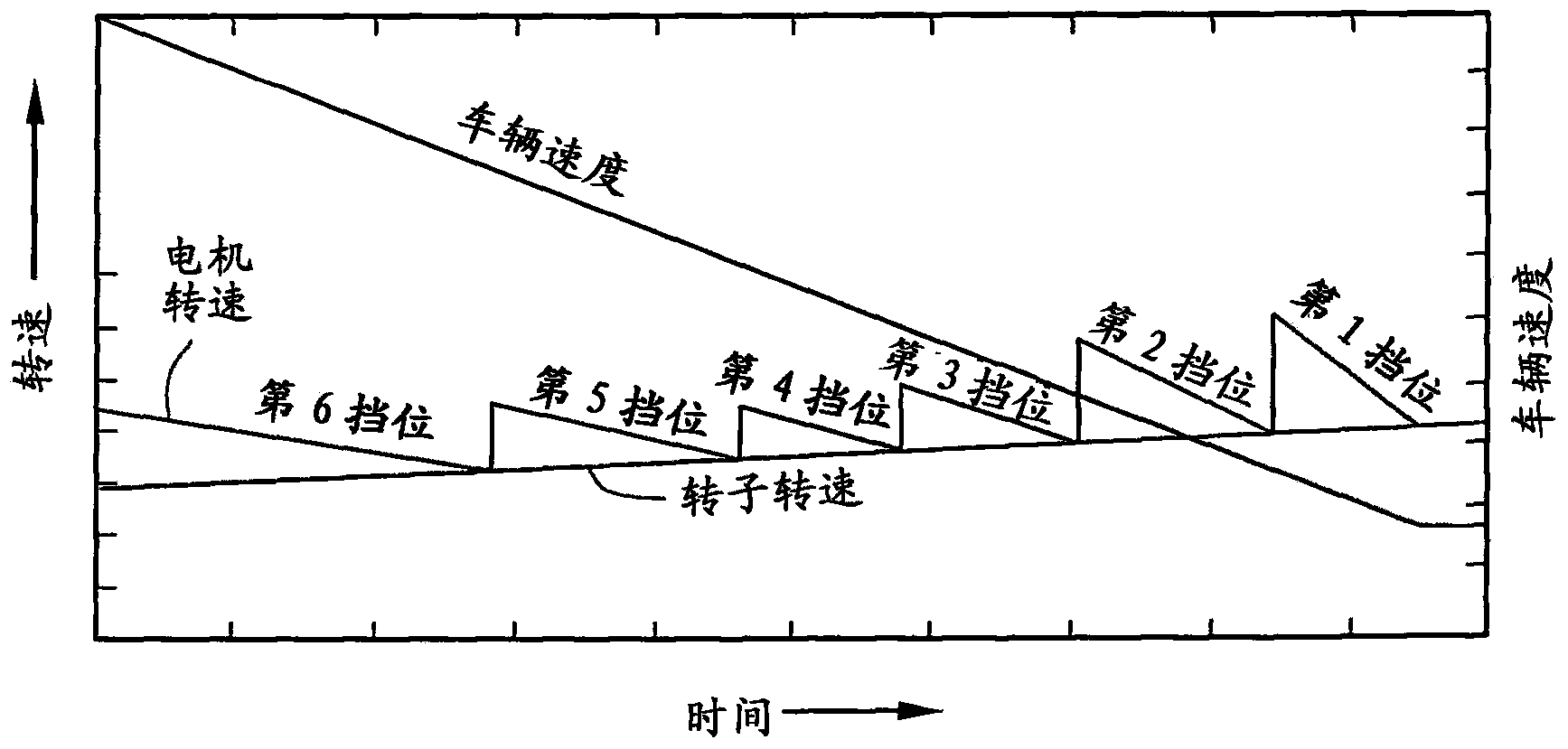

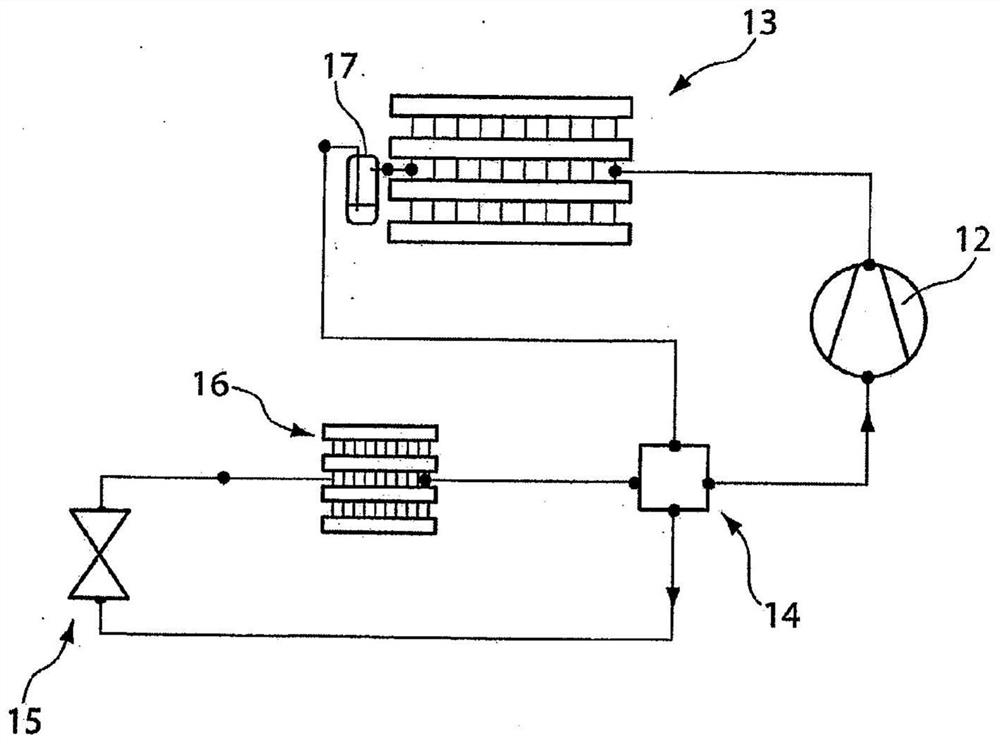

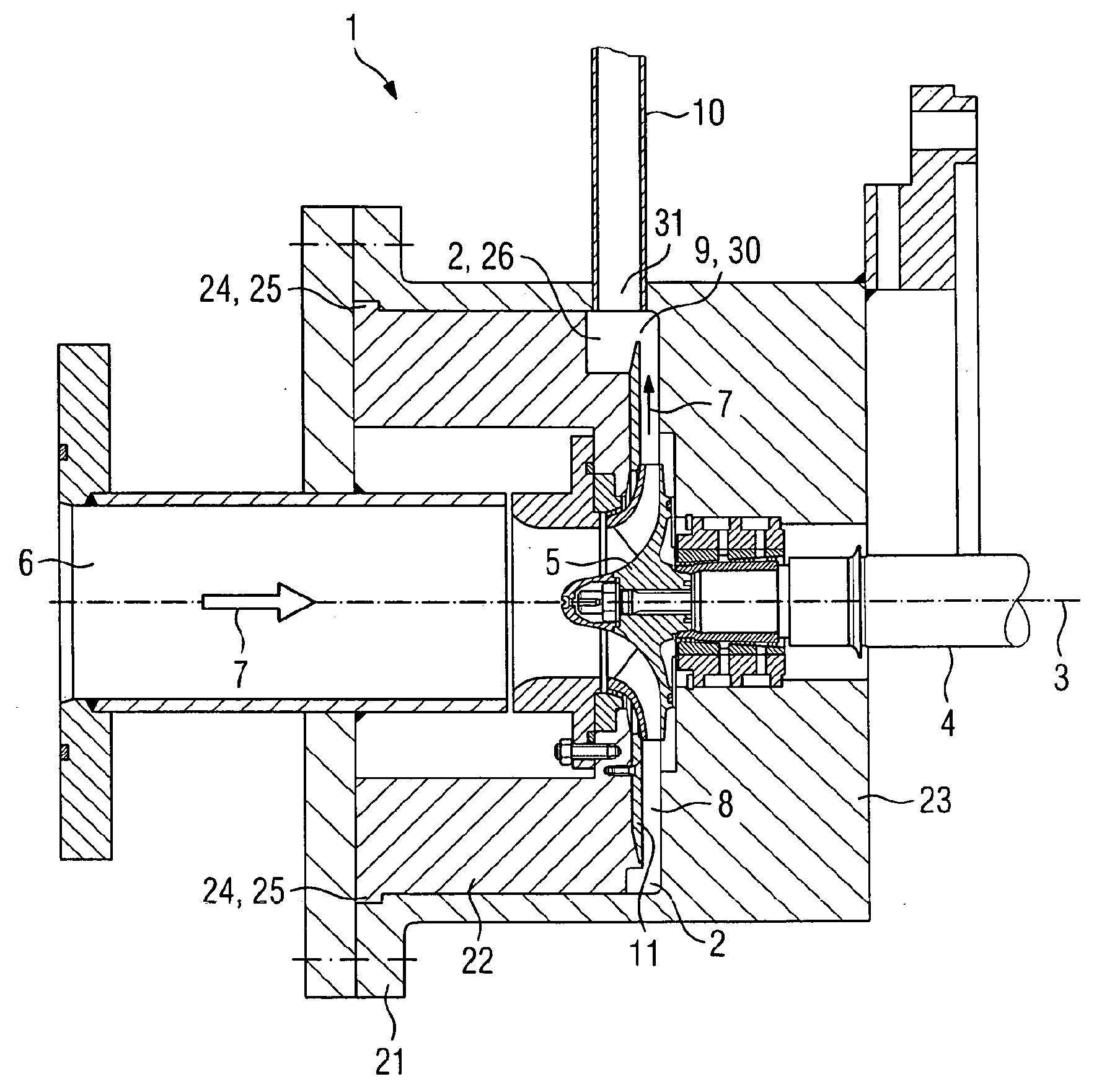

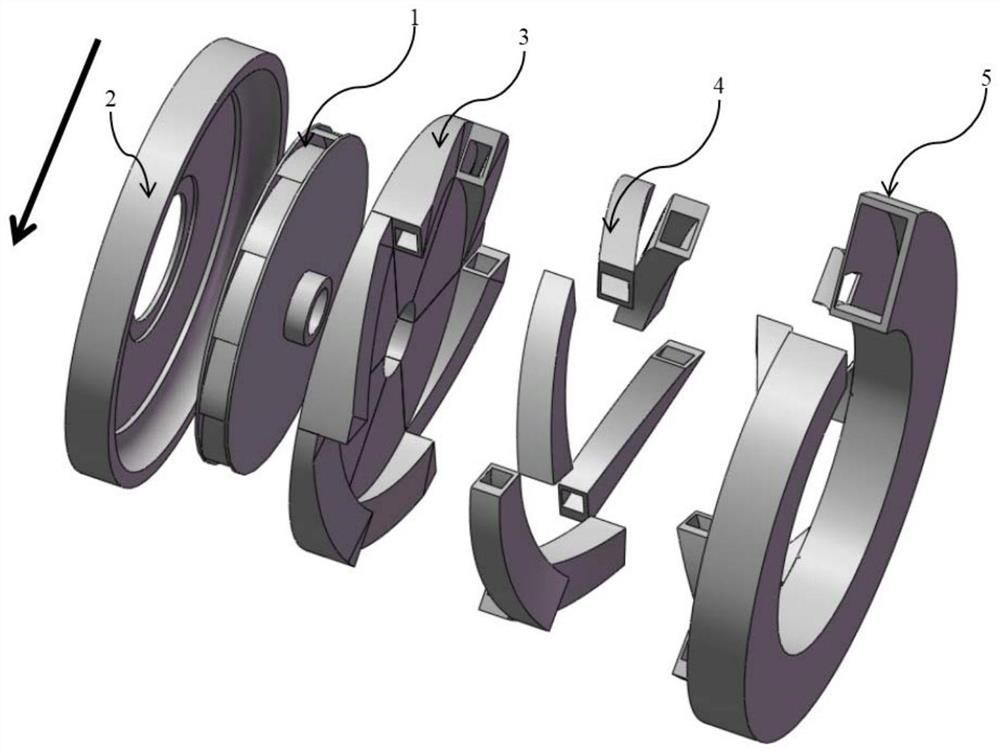

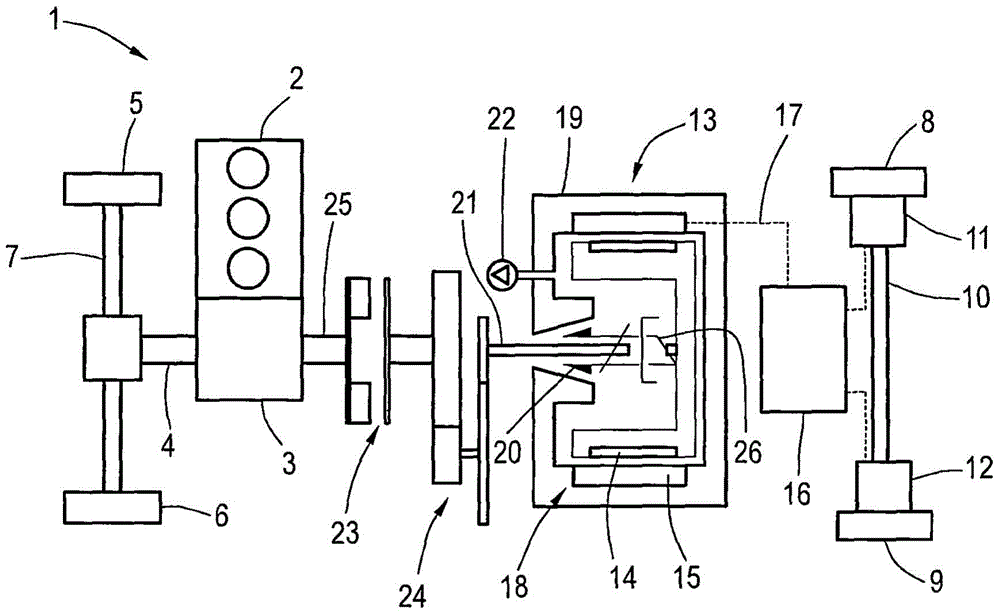

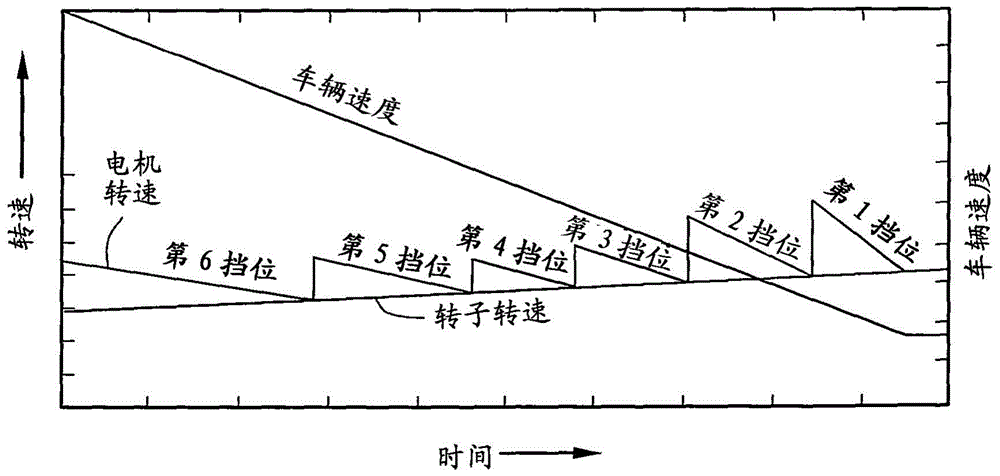

Hybrid vehicle

ActiveCN103842195AIncrease braking energyImprove efficiencyGas pressure propulsion mountingVehicle sub-unit featuresElectric machineExternal combustion engine

The invention relates to a hybrid vehicle comprising an internal combustion engine (2) with a driveshaft (4) for driving the wheels of at least one axle (7) and comprising at least one electric machine (11, 12) for driving the wheels of said axle or at least one other axle (10). The at least one electric machine can be operated as a generator during a braking process and as a motor during an acceleration process. The hybrid vehicle also comprises another electric machine (18) which is coupled to the at least one electric machine and which comprises a flywheel storage that has a rotor (14), said flywheel storage being chargeable during a braking process and dischargeable during an acceleration process. The rotor (14) can be mechanically coupled to the driveshaft (4) of the at least one axle (7) which can be driven by the internal combustion engine via at least one shiftable clutch (23).

Owner:AUDI AG

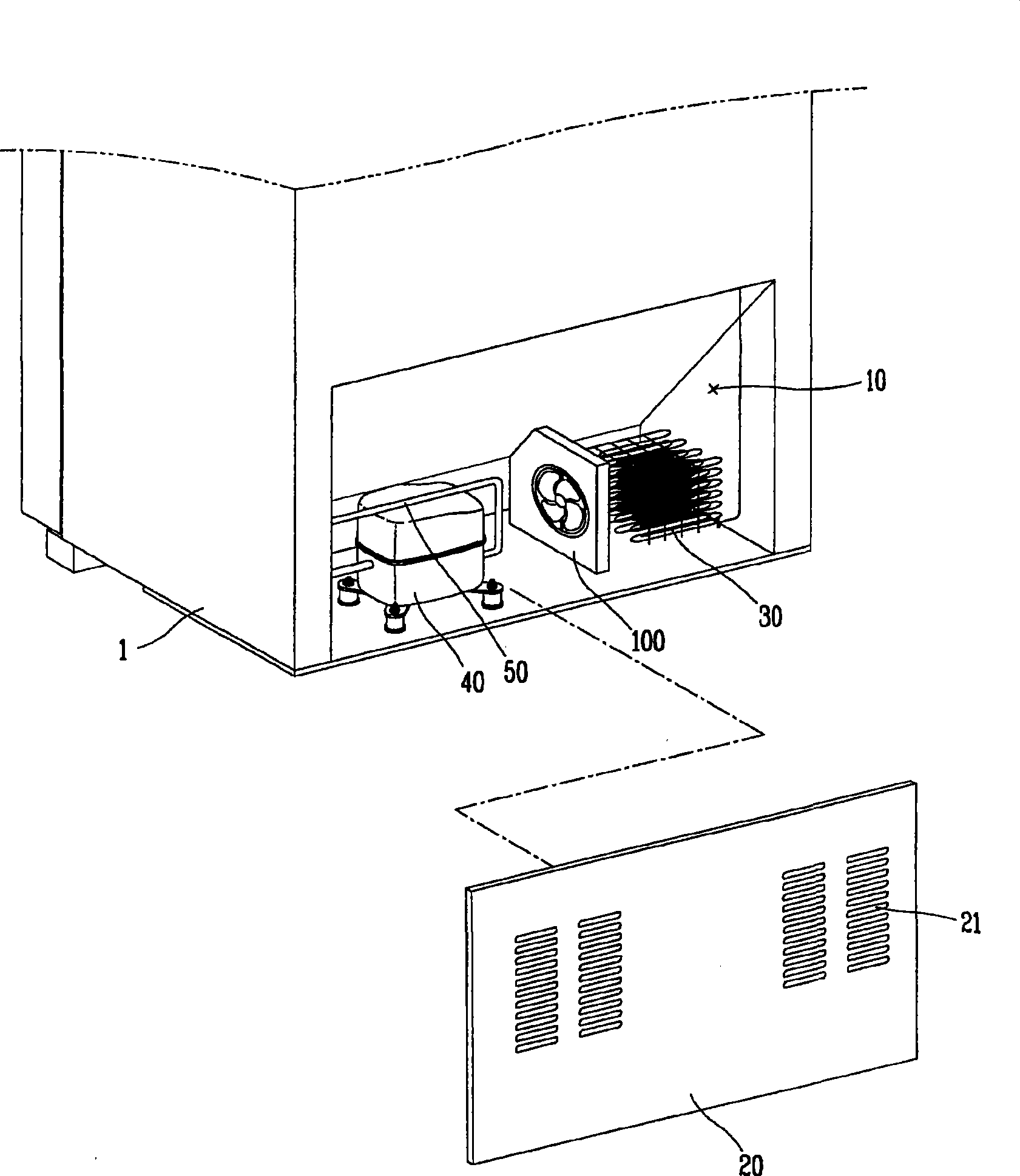

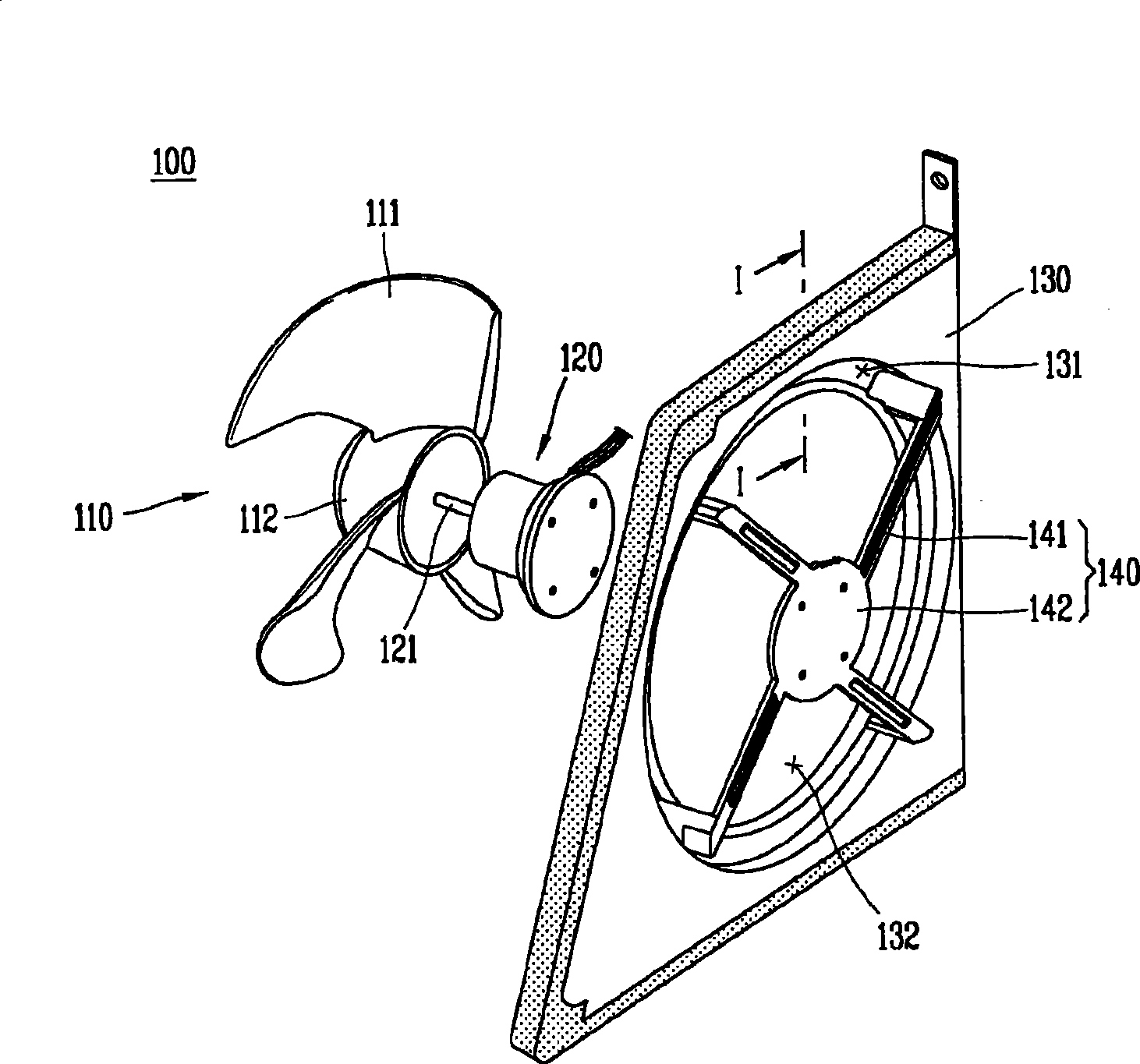

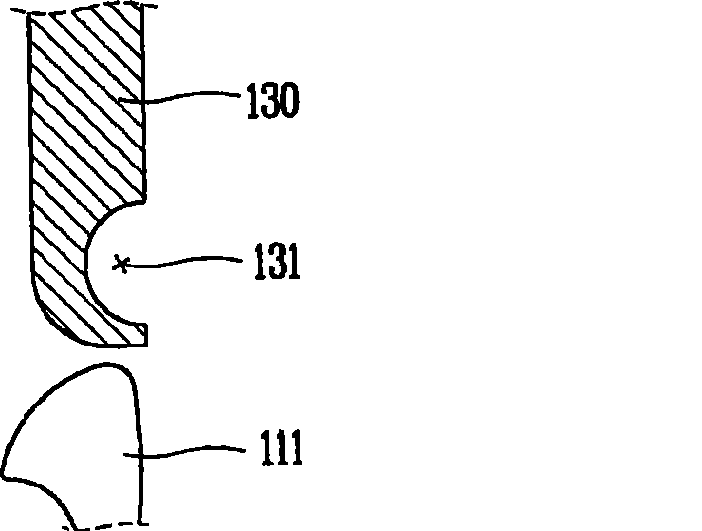

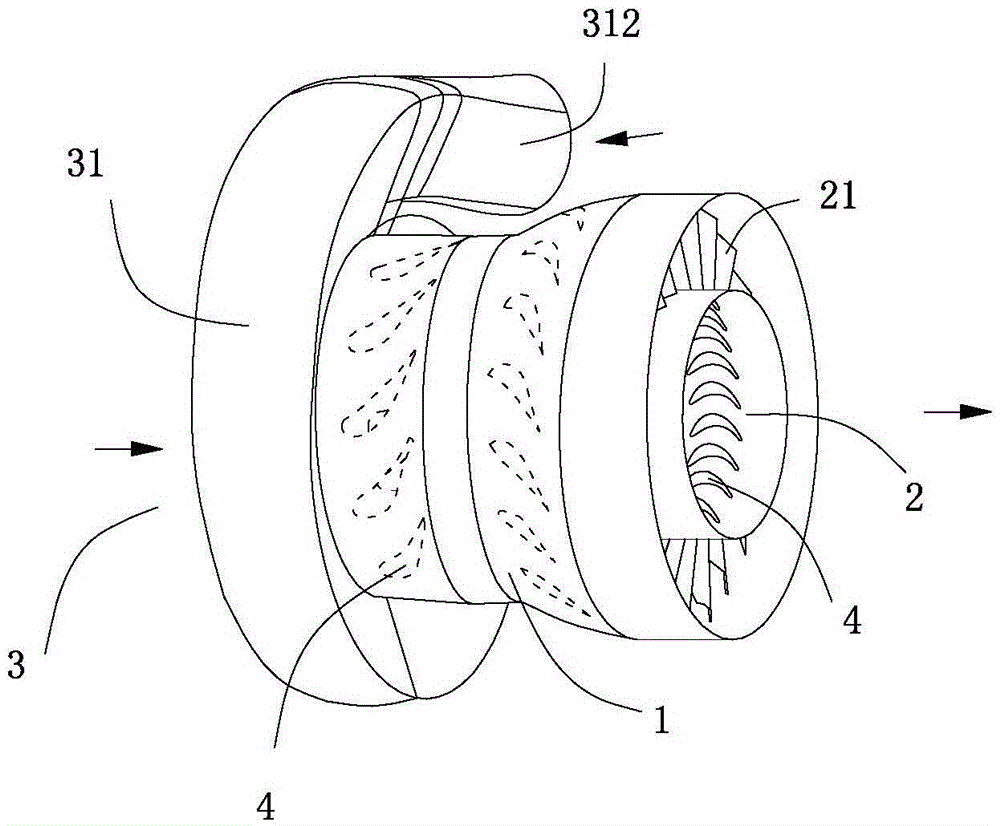

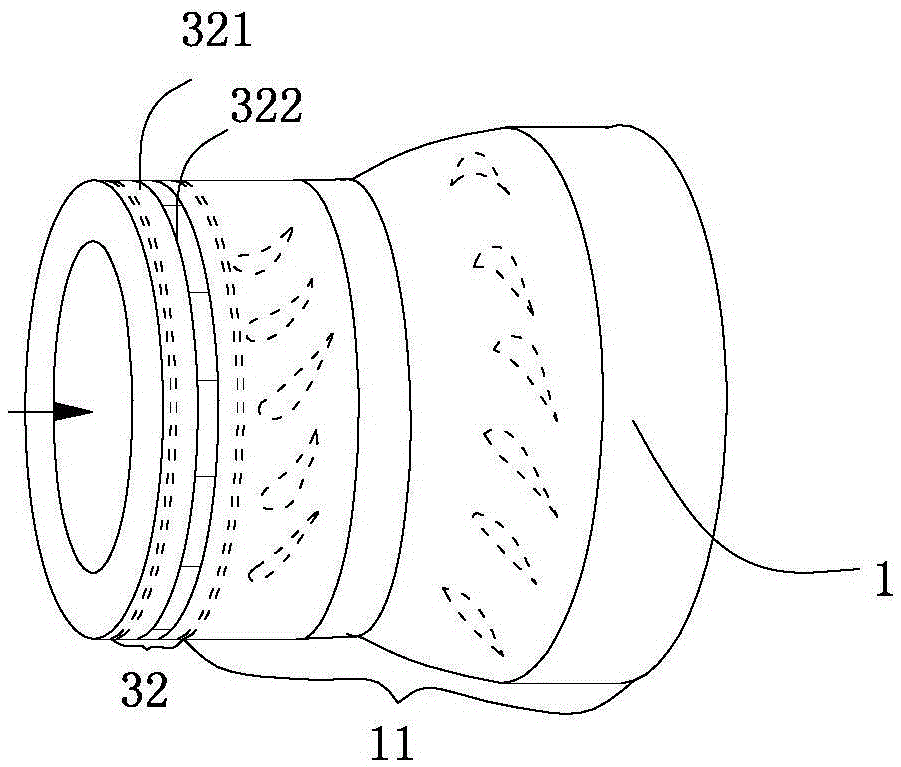

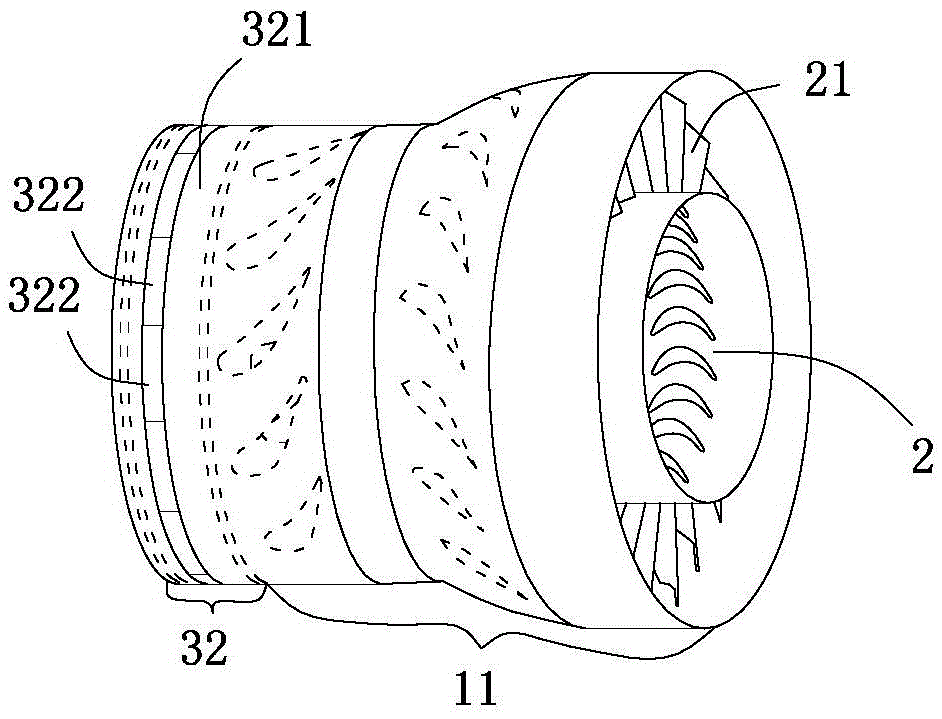

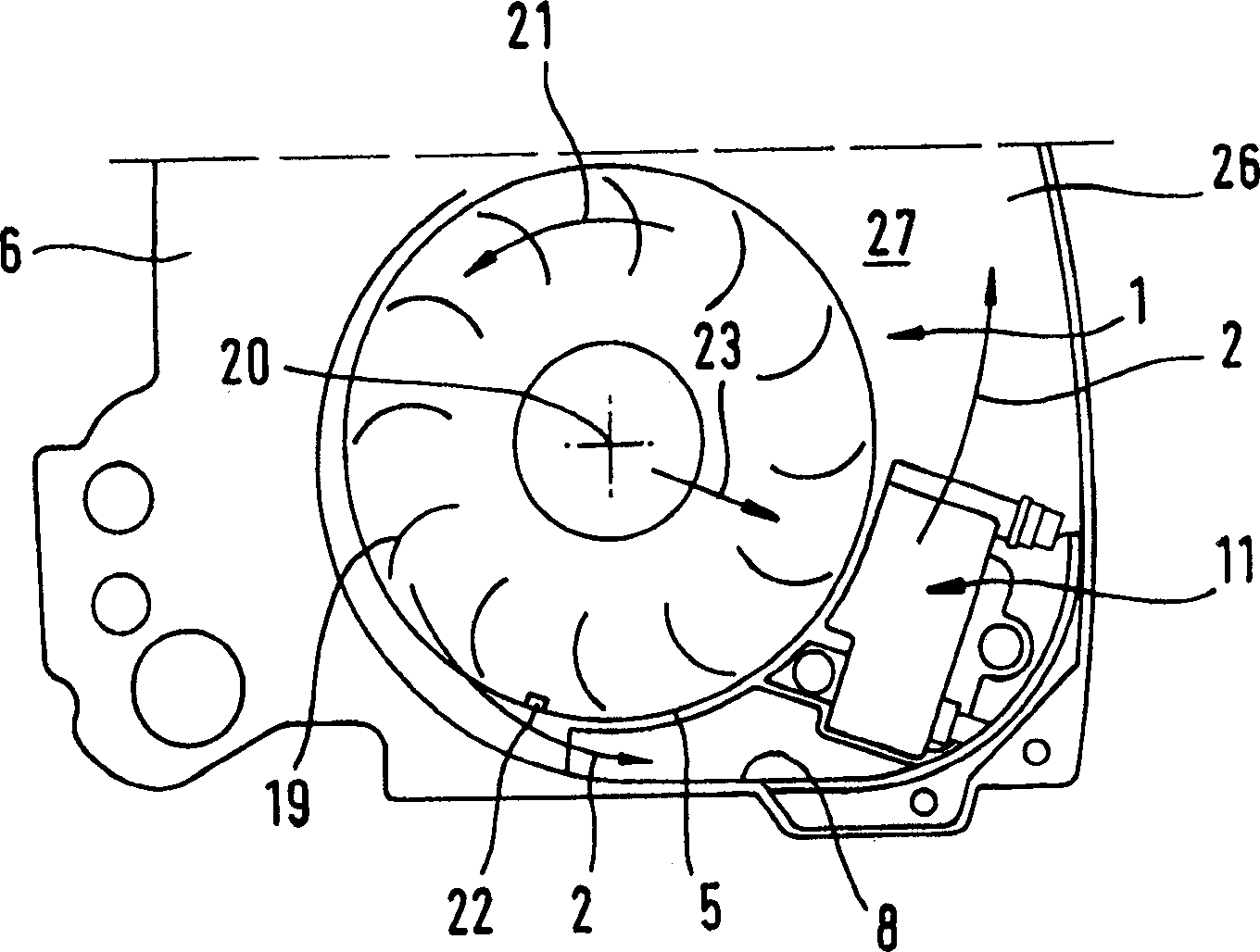

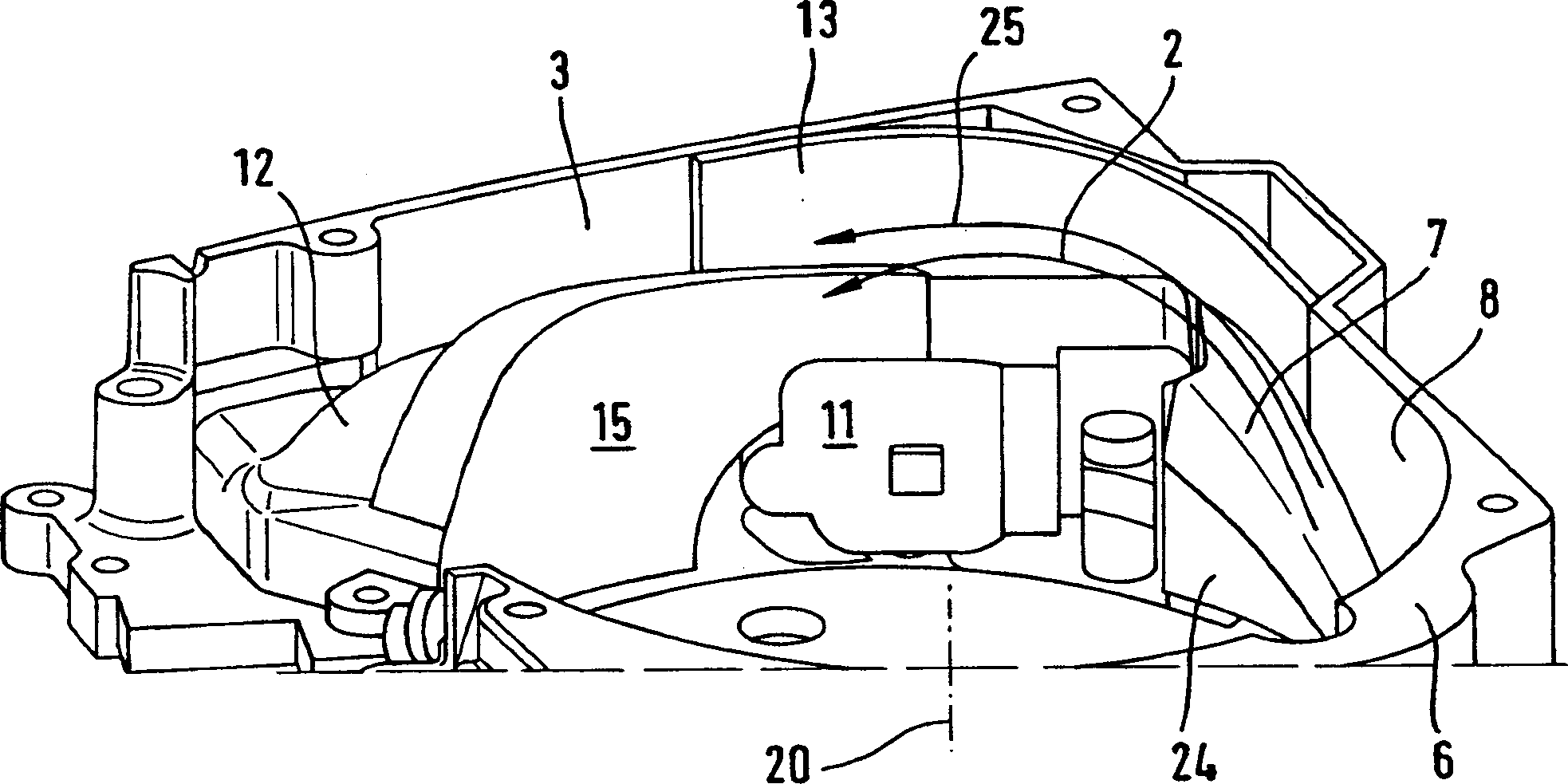

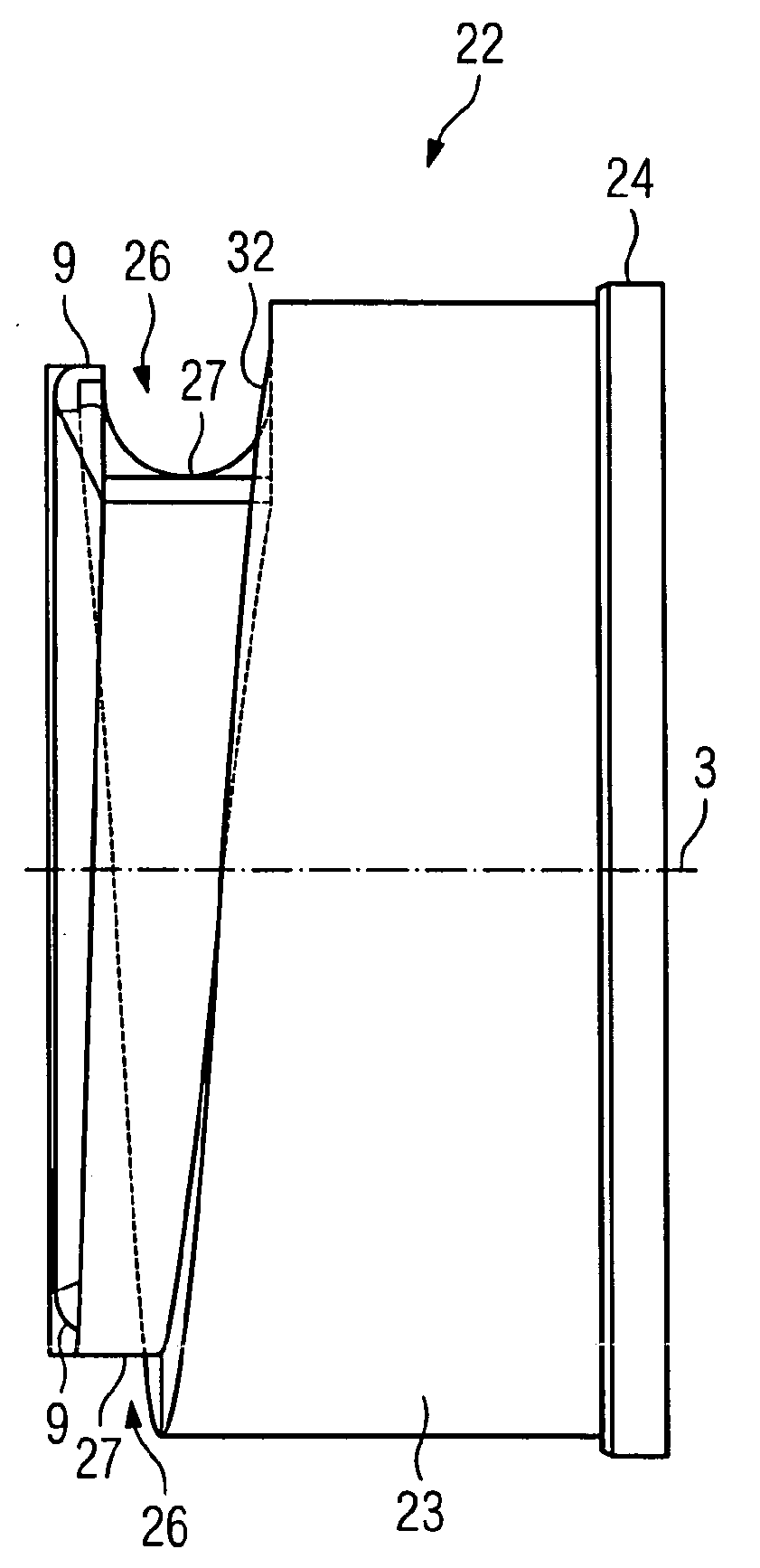

Fan module

InactiveCN101469718AAvoid noiseAvoid flow lossPump componentsLighting and heating apparatusEngineeringComputer engineering

Owner:LG ELECTRONICS INC

Gas introducing device before gas turbine

InactiveCN105569742AIncrease powerIncrease the overall expansion ratioStatorsMachines/enginesInlet pressureProduct gas

The invention provides a gas introducing device before a gas turbine. The gas introducing device before the gas turbine comprises a volute and a bypass gas introducing slot part; the volute comprises junction surfaces and a gas introducing opening; the bypass gas introducing slot part is located at the upper part of a turbine flow passage section along an axial direction, is connected with the turbine flow passage section and is circumferentially connected with the junction surfaces of the volute; a part, within a connection position of the junction surfaces of the volute, of the outer peripheral face of the bypass gas introducing slot part and the volute together form a drainage flow passage circumferentially encircling the bypass gas introducing slot part; gas introducing slot openings which are arranged along a circumferential direction and penetrate through the bypass gas introducing slot part are formed in the part of the outer peripheral face of the bypass gas introducing slot part; the gas introducing slot openings, the drainage flow passage and an inner cavity of the turbine flow passage section communicate. According to the gas introducing device before the gas turbine, provided by the invention, gas discharged from an engine is evenly introduced into the volute, so that flow losses are avoided, power of the gas turbine is increased, an overall expansion ratio of a two-stage turbine is increased, and moreover, influence of gas introducing inlet pressure and gas introducing mixing on performance of the gas turbine and a power turbine is reduced.

Owner:TSINGHUA UNIV

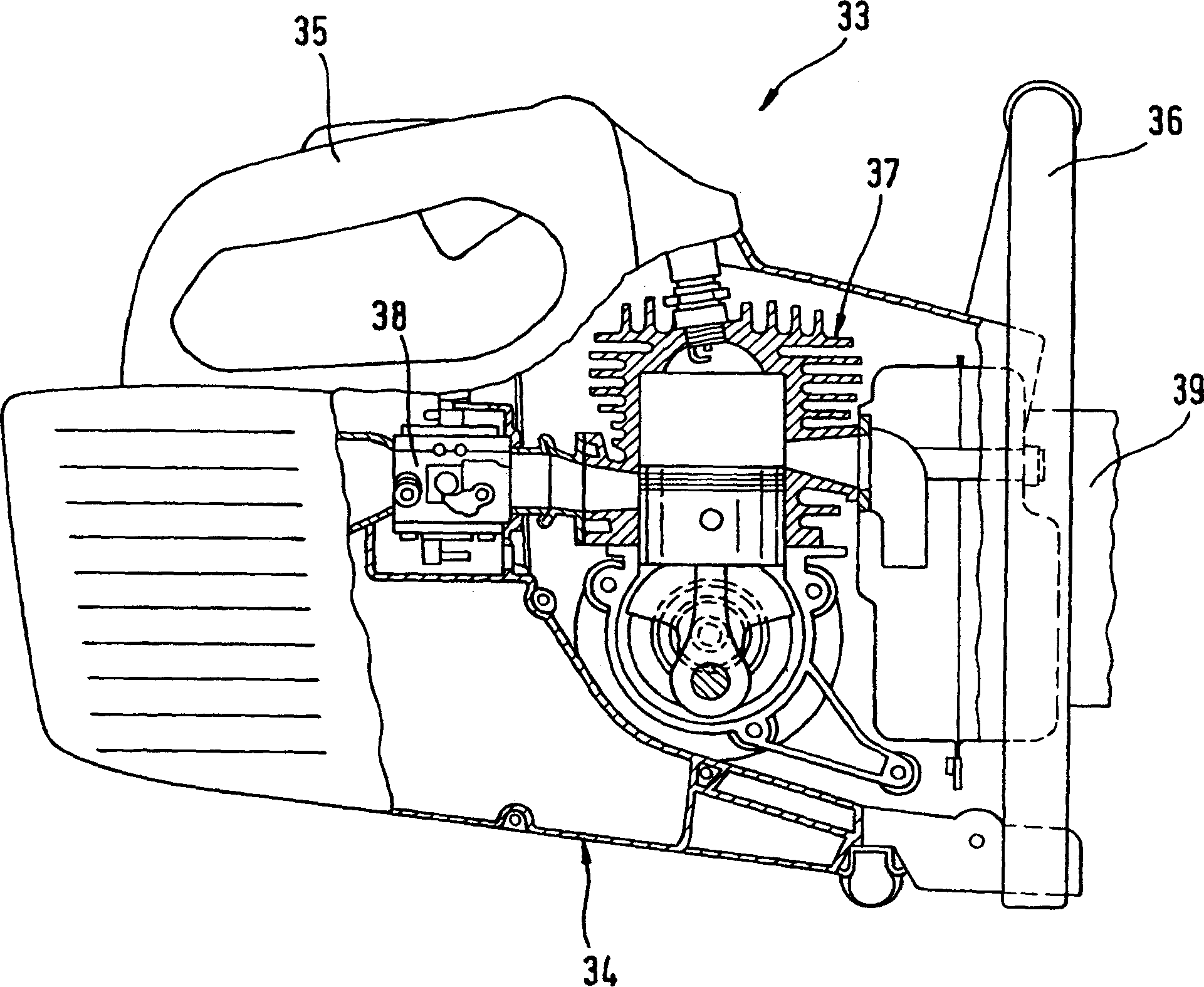

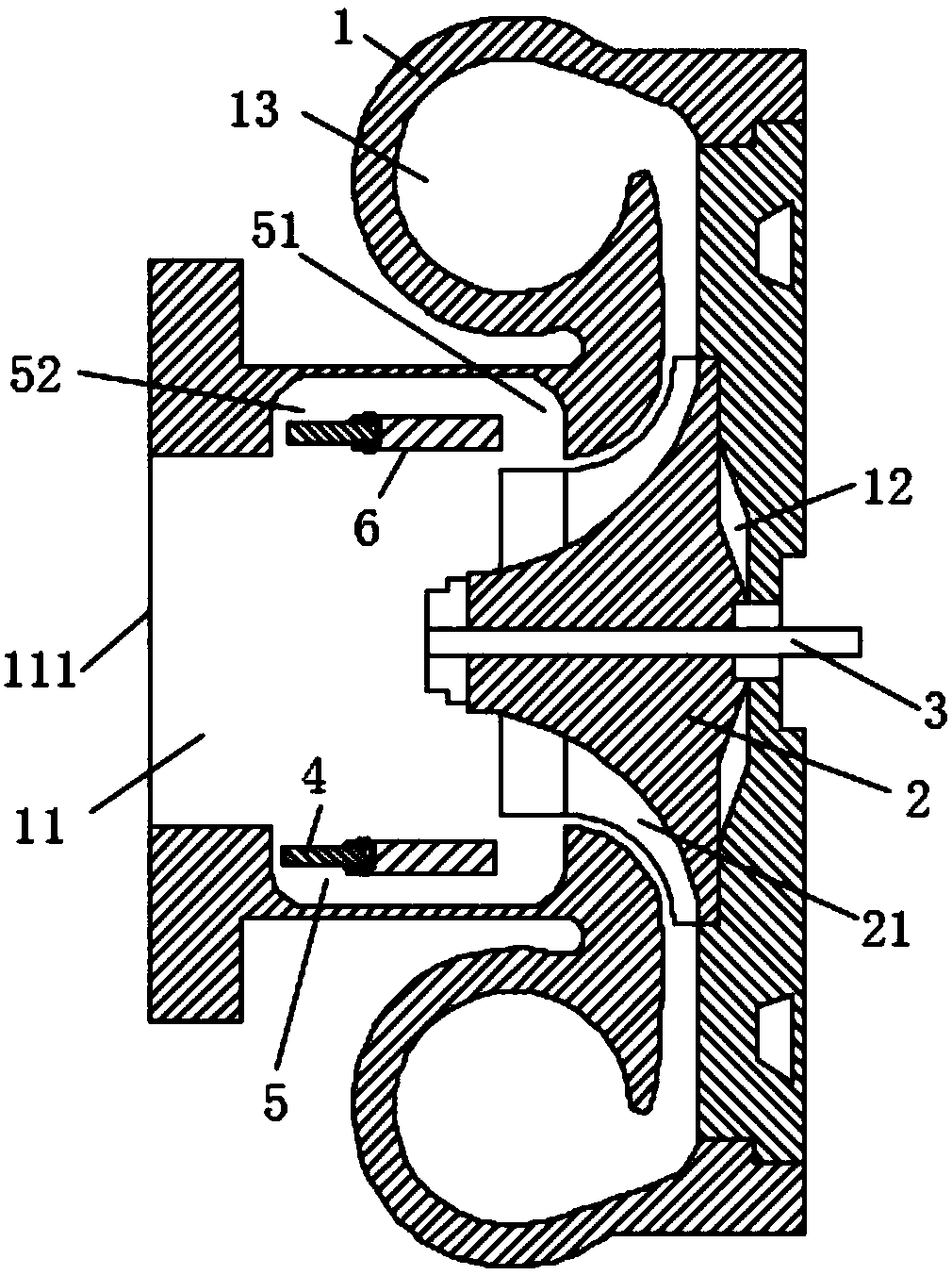

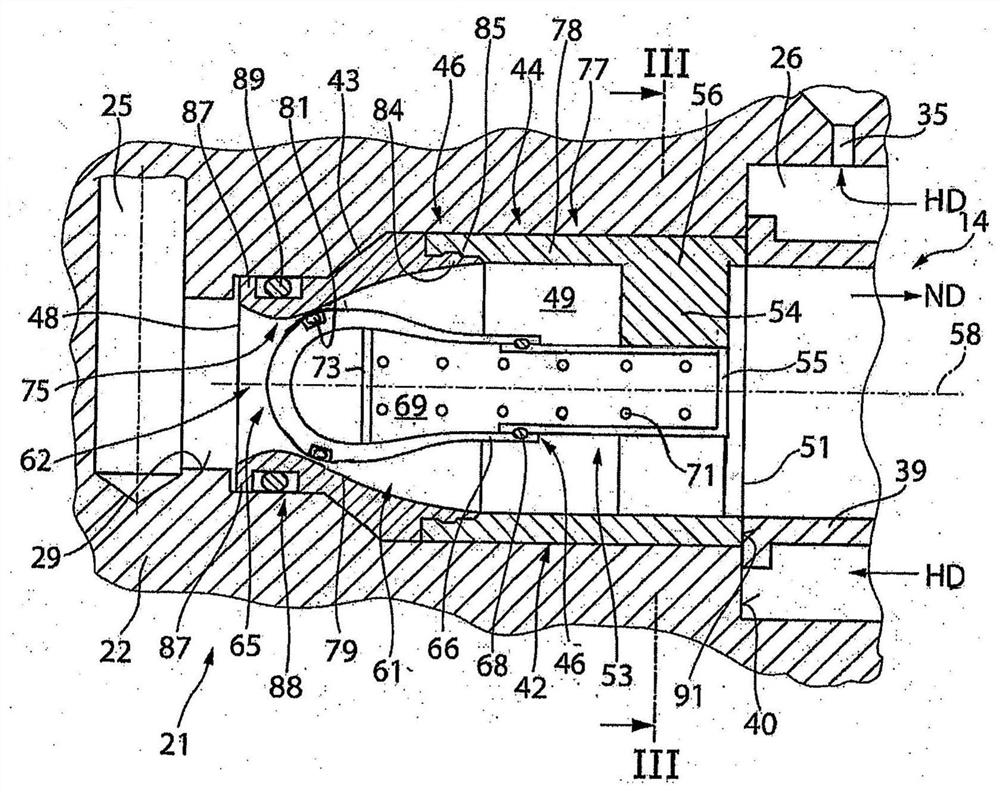

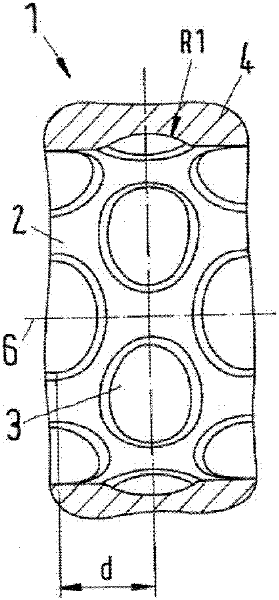

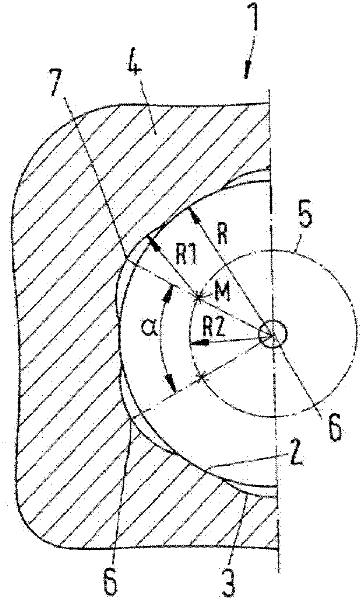

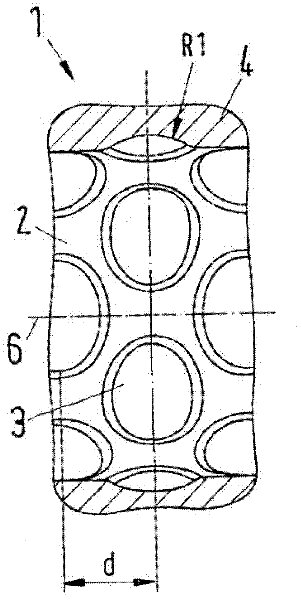

Blast mechanism

InactiveCN1497185AAvoid flow lossImprove efficiencyInternal combustion piston enginesPump componentsCombustionInternal combustion engine

A fan arrangement of a portable handheld work apparatus is driven by an internal combustion engine and includes a radial fan (1) which includes a fan wheel (5) and a spirally-shaped fan housing (6) which encloses the fan wheel (5) at least partially. A take-out opening (3) is provided in the radial fan (1) in the region of the moved air flow (2) for diverting a combustion air flow (4) for the engine. The combustion air flow (4) is branched off from the air flow (2). In the radial direction outside of the fan wheel (5), there is an aerodynamically formed guide ramp (7) provided in the air flow (2) which rises in the axial direction. The take-out opening (3) is arranged downstream of the guide ramp (7).

Owner:ANDREAS STIHL AG & CO KG

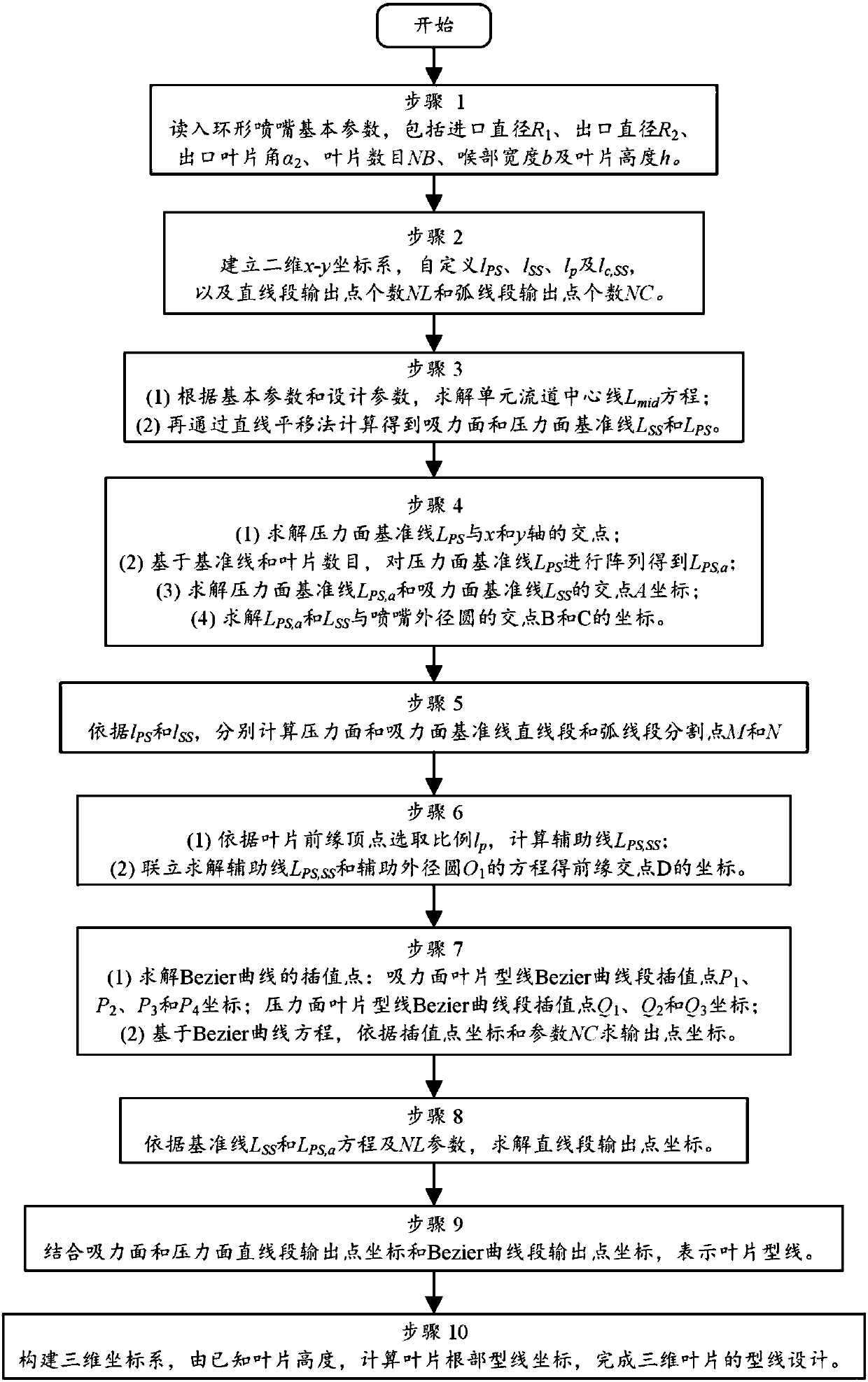

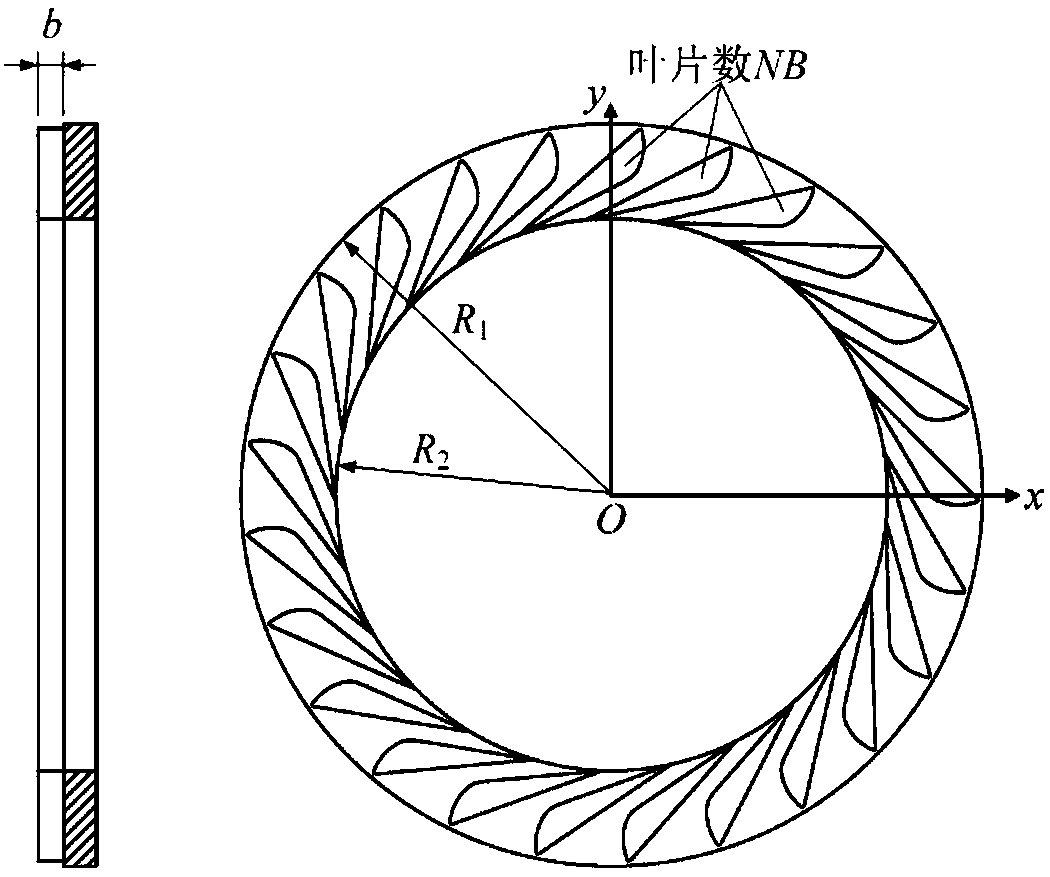

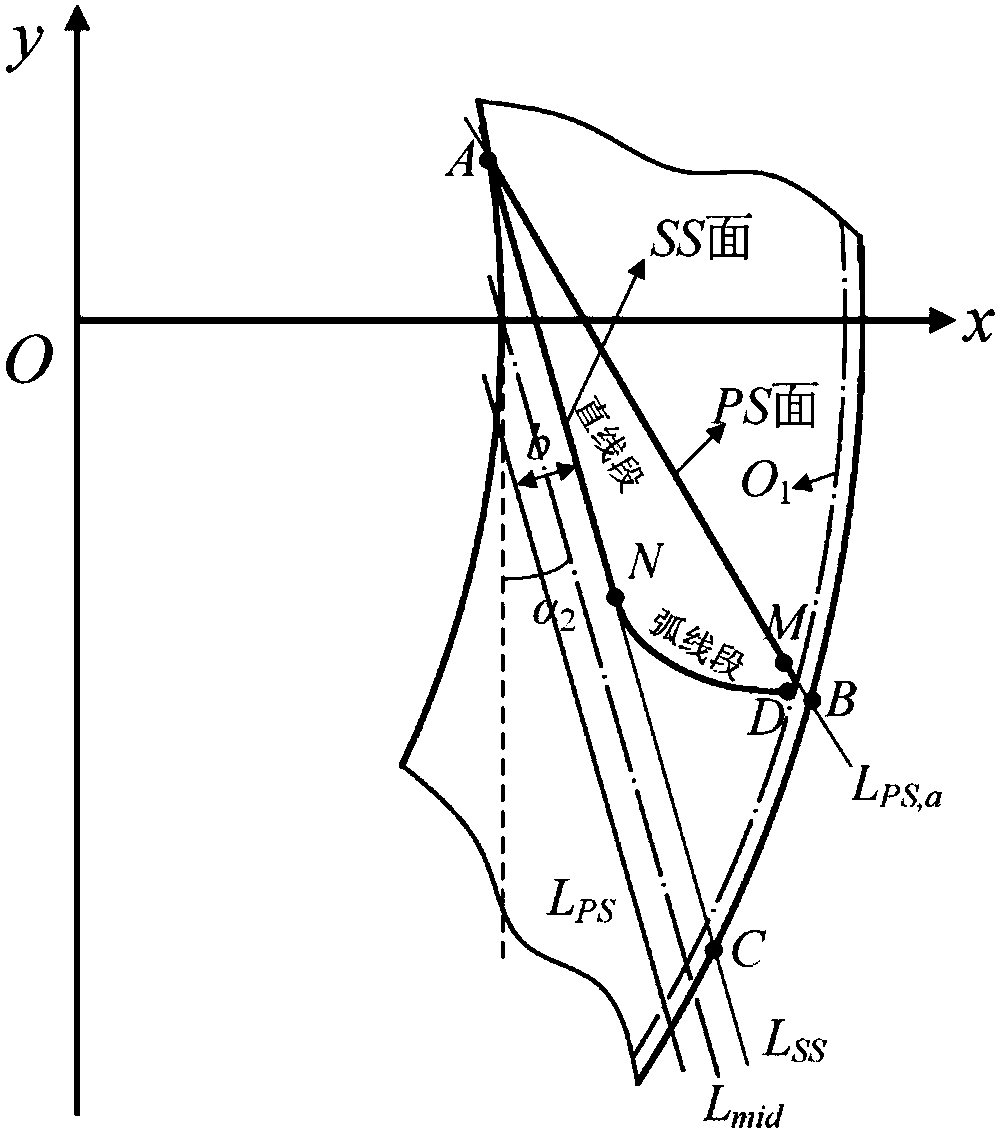

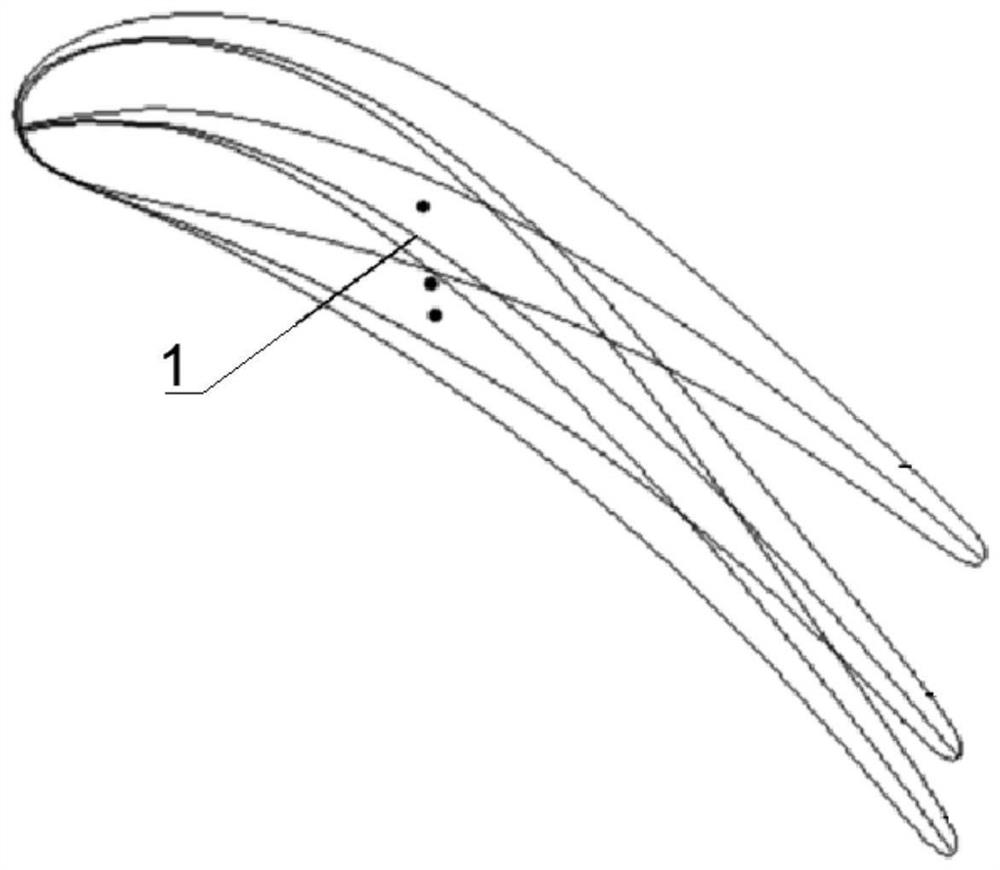

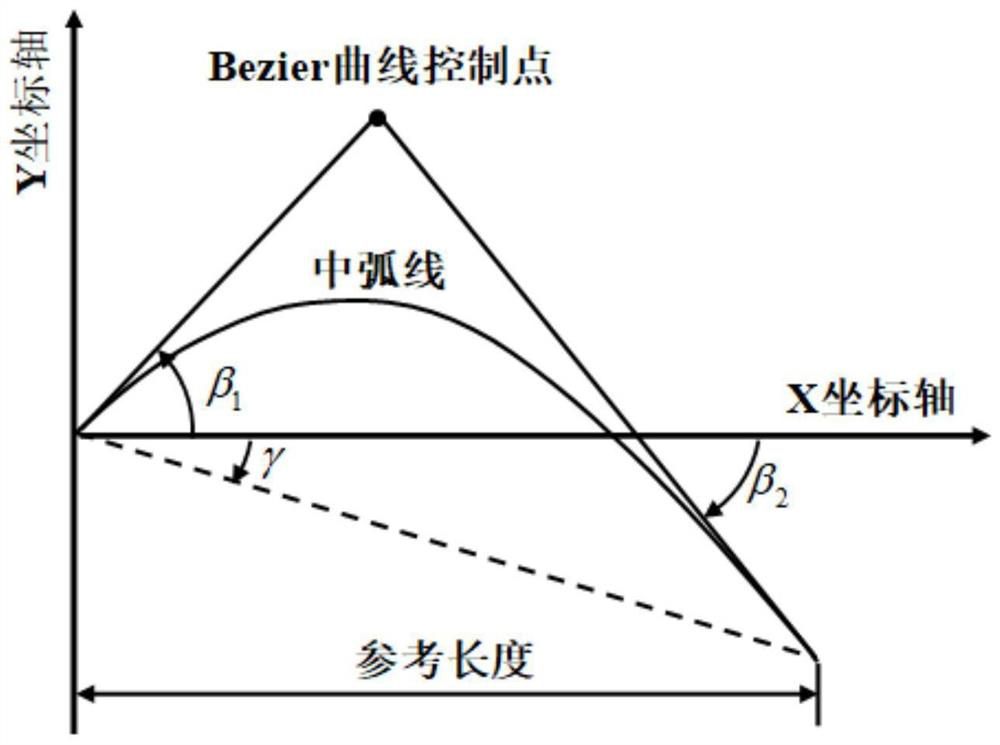

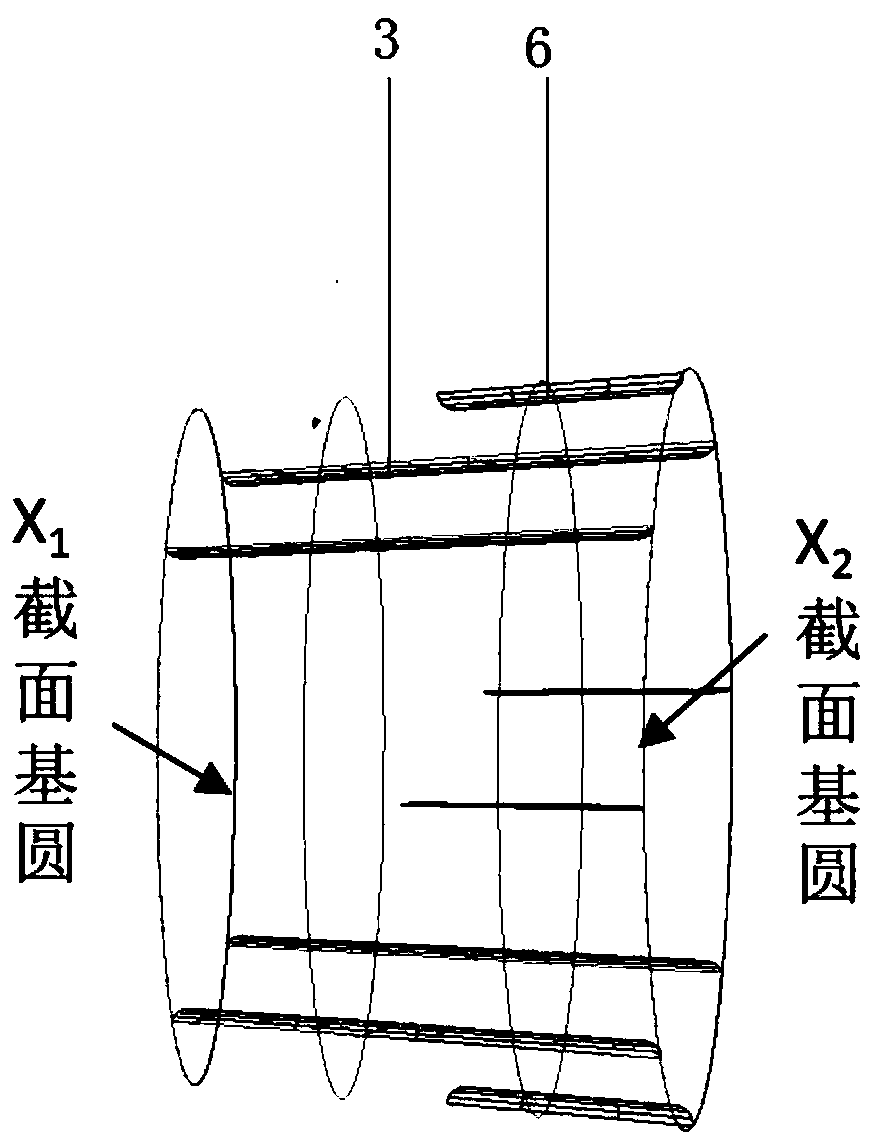

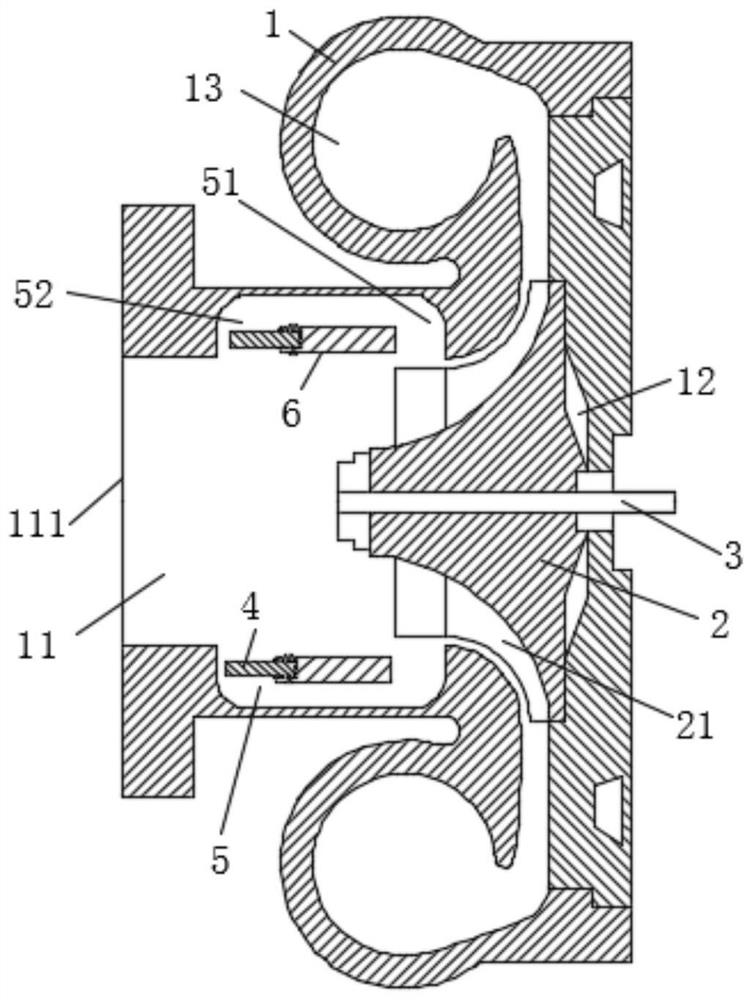

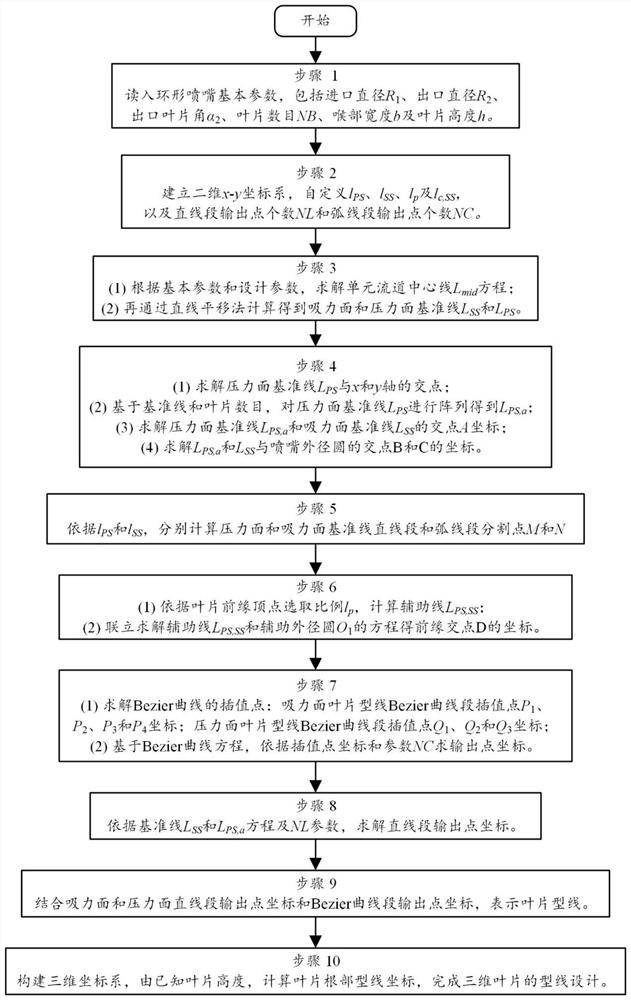

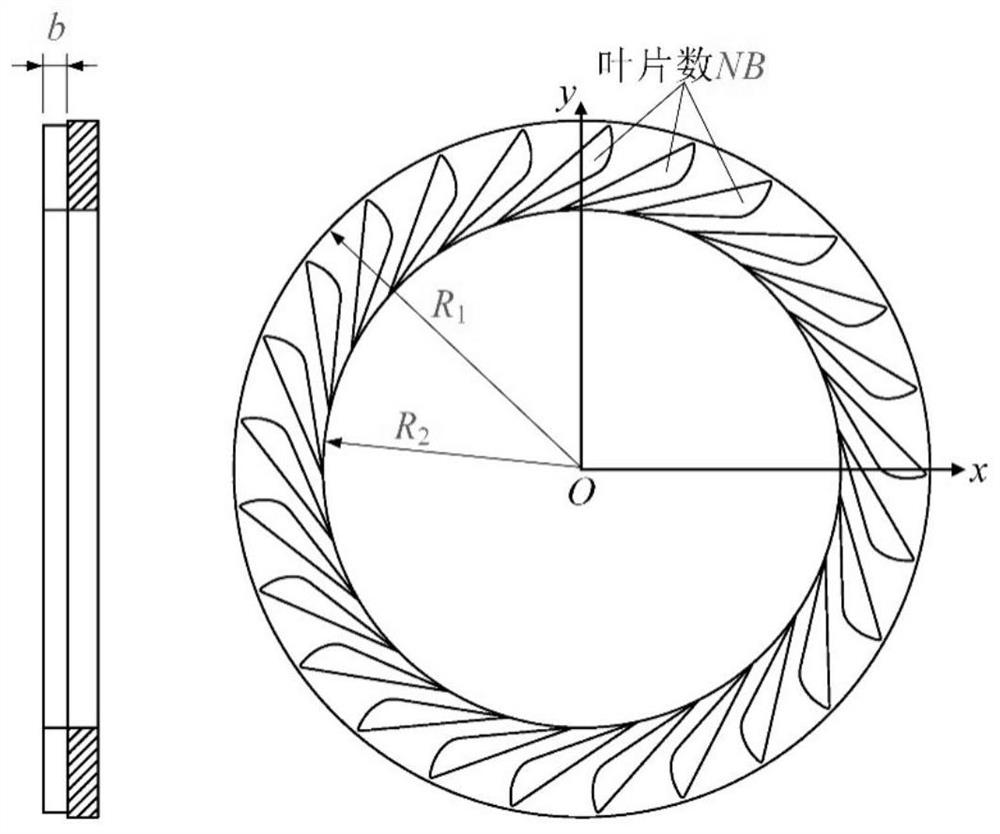

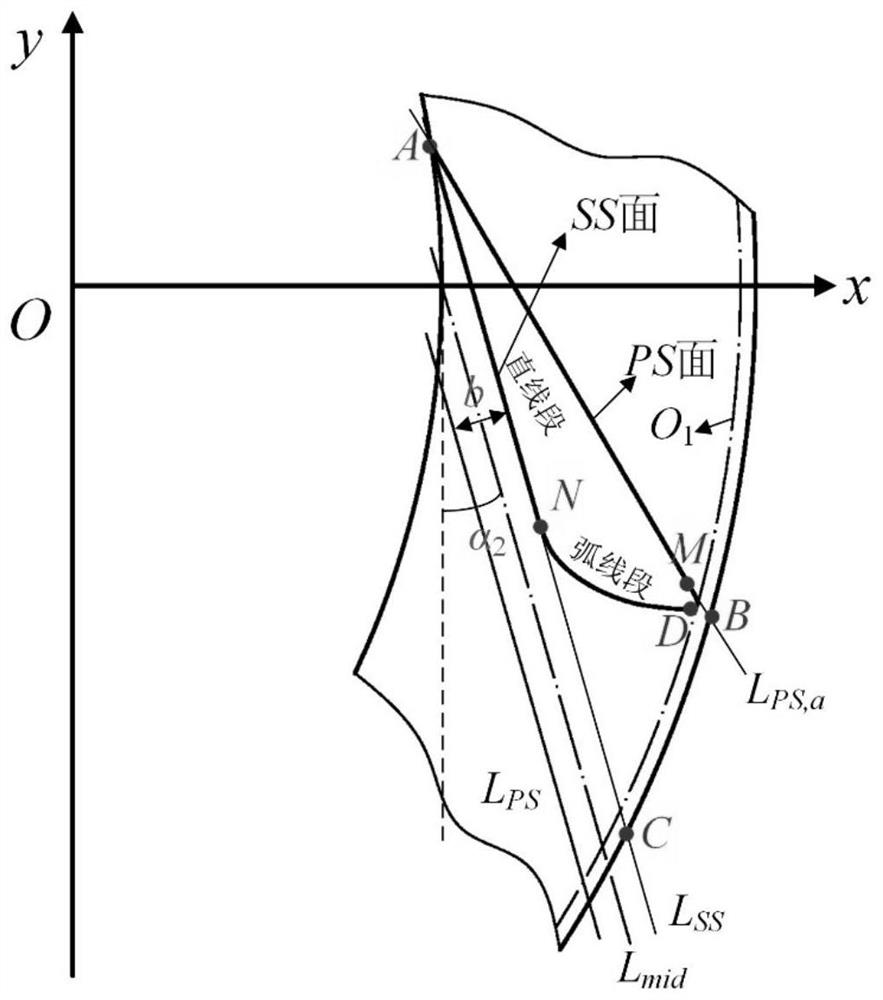

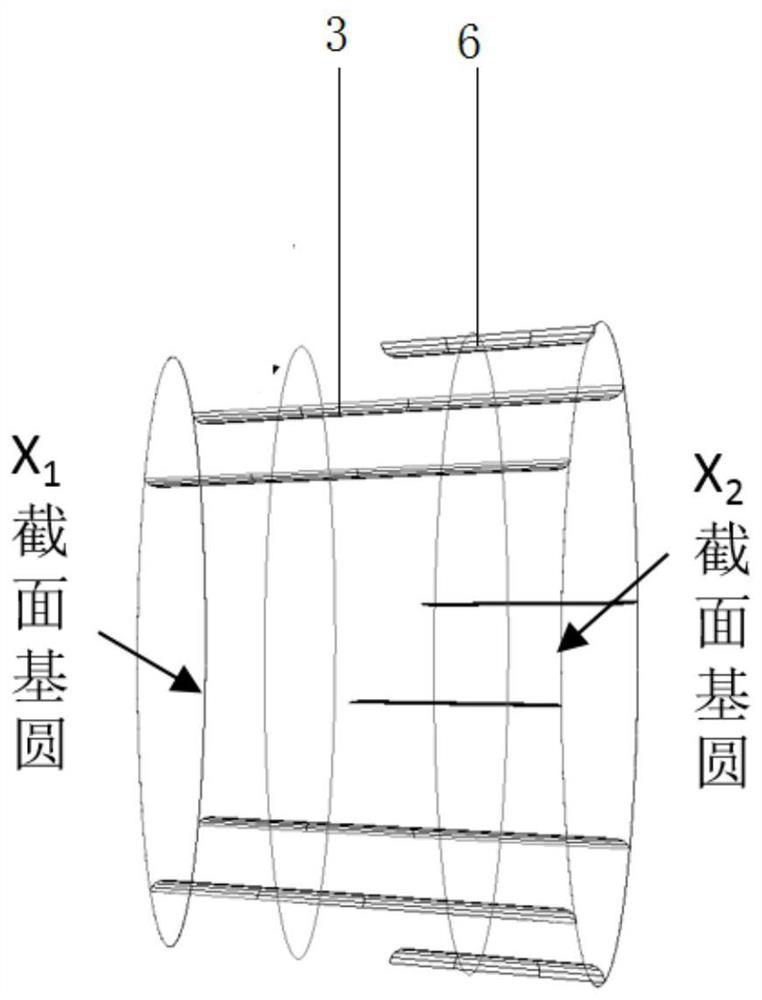

Annular-nozzle straight-line-arc-line blade profile line design method

ActiveCN107862104AGuaranteed geometric curvature continuityEasy to processGeometric CADDesign optimisation/simulationSpray nozzleEngineering

The invention discloses a method used for annular-nozzle straight-line-arc-line blade profile line design of a radial-axial-flow-type turboexpander. The method includes: dividing a blade into two parts of a suction surface and a pressure surface, also dividing a blade profile line of each part into a straight-line segment and an arc-line segment, and utilizing mathematical expressions to carry outcoordinate solving on the straight-line segment and the arc-line segment through programming. According to the method, a Bezier curve is adopted for solving for arc-line segment coordinates to realize smooth transition of the straight-line segment and the arc-line segment, thus geometric curvature continuity of the nozzle blade profile line can be well guaranteed, and more flow losses can be avoided; and in addition, the blade profile line is divided into the straight-line segment and the arc-line segment through programming, the mathematical expressions are respectively used for representation, a design process is simpler, more convenient and faster, and subsequent work processes of machining manufacturing, numerical simulation, optimization design and the like on the nozzle blade profile line are facilitated.

Owner:CHONGQING UNIV

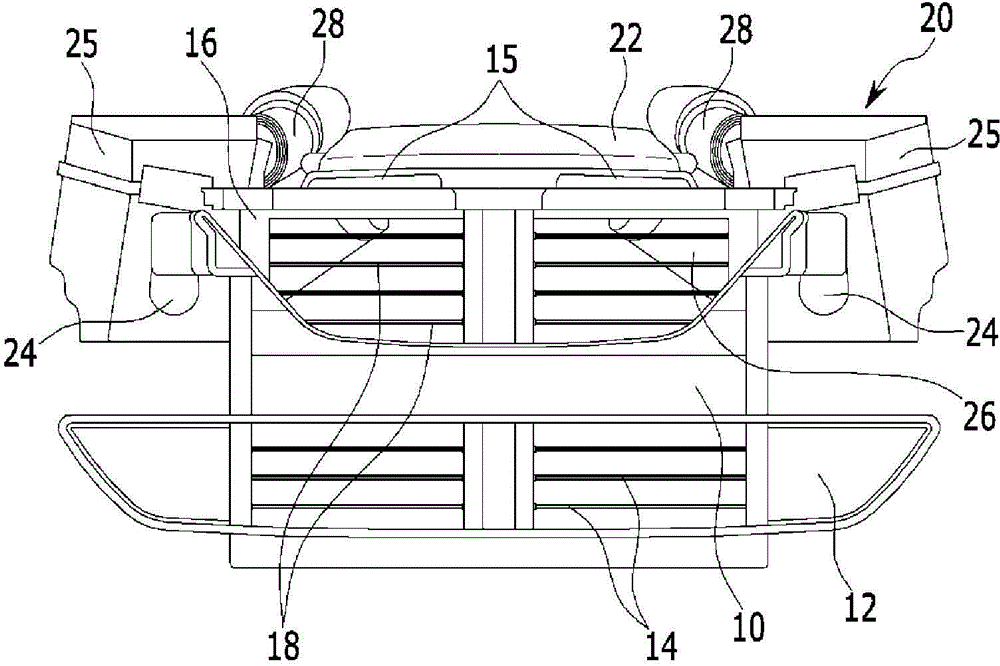

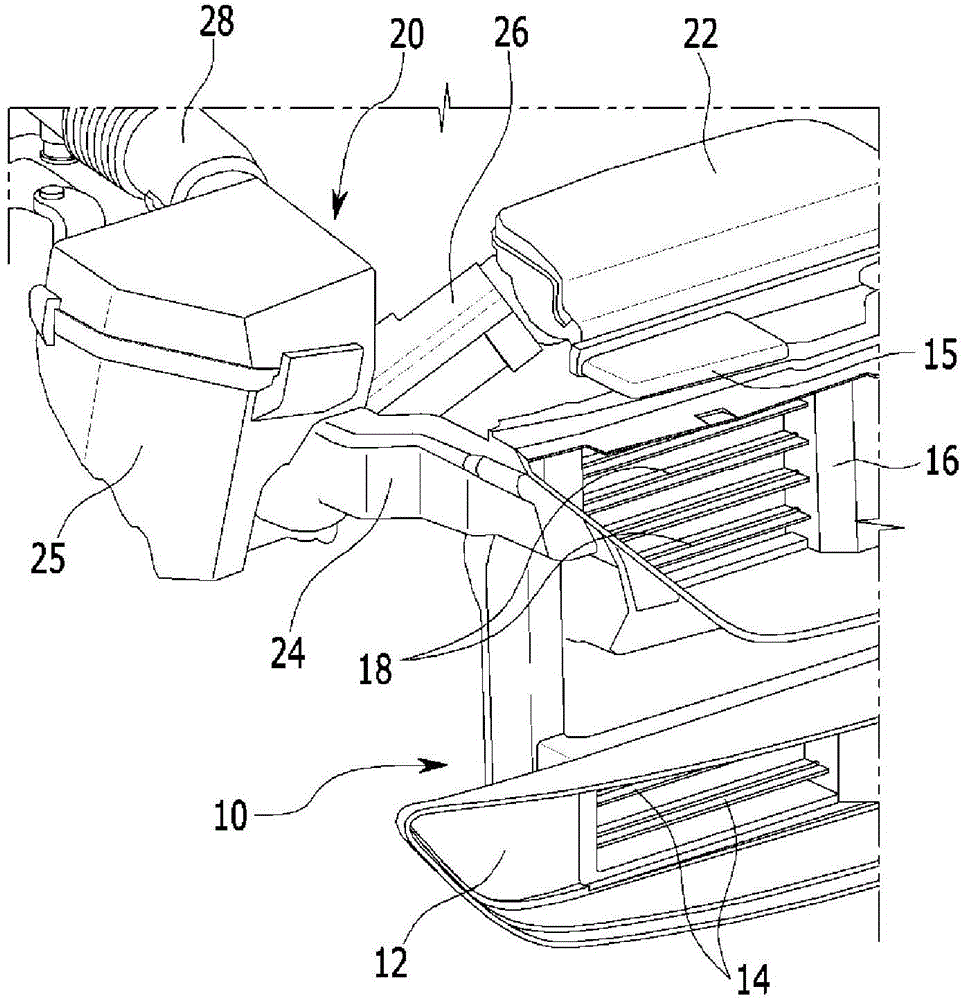

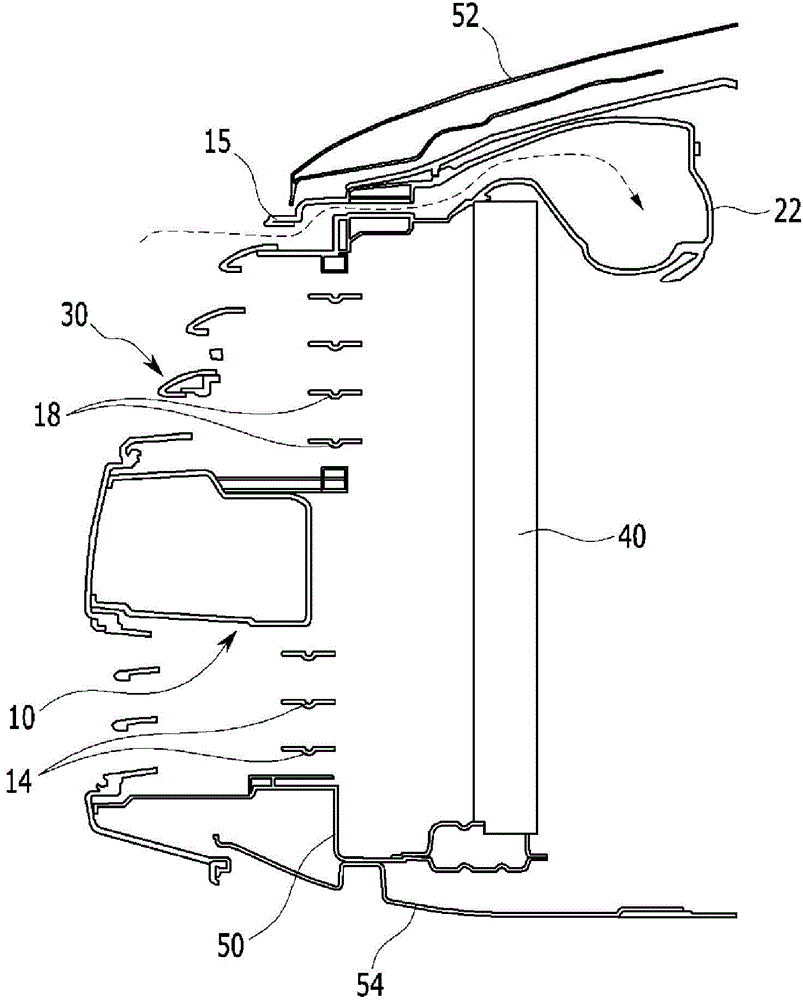

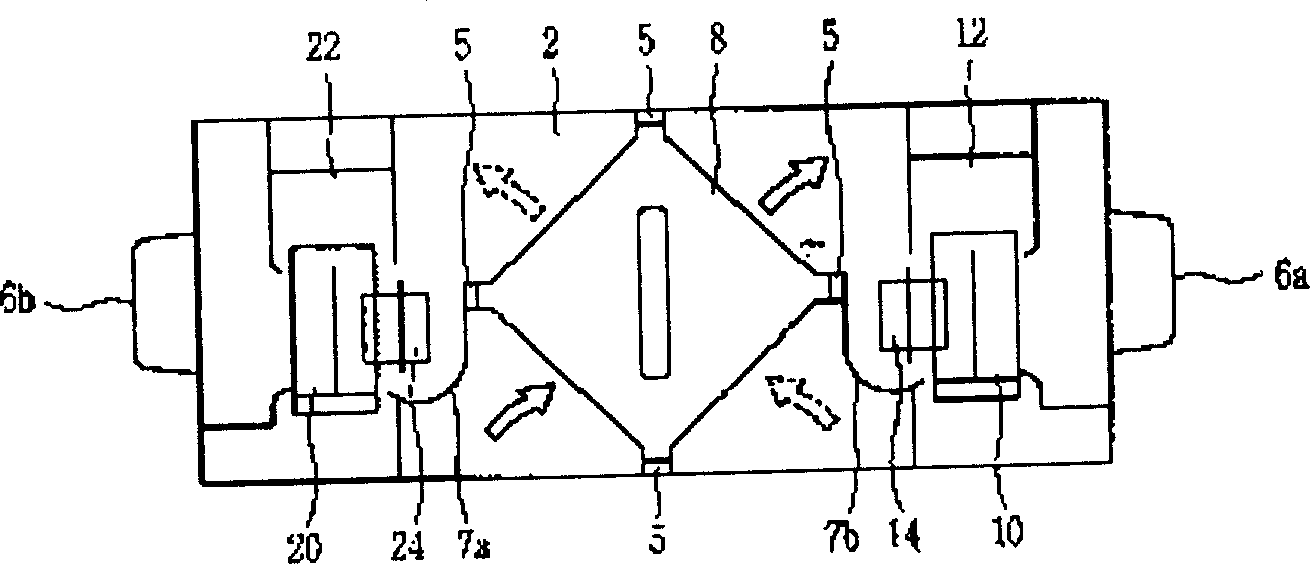

Airflow guiding system for vehicle

InactiveCN104553751AAvoid flow lossImprove NVH performanceInternal combustion piston enginesAir coolingAirflowAerospace engineering

An airflow guiding system for a vehicle may include an air flap module with air flaps that are selectively opened / closed so that an engine compartment selectively receives external air from a front of the vehicle in accordance with a driving state of an engine, air holes that are formed through the air flap module, at an upper portion of the air flap module, and are kept open, and air ducts that supply air passed through the air holes or air from a front of the air flap module as intake air for the engine. The air passed through the air holes or the air from the front of the air flap module may be supplied as the intake air for the engine, even if the air flaps are closed.

Owner:HYUNDAI MOTOR CO LTD

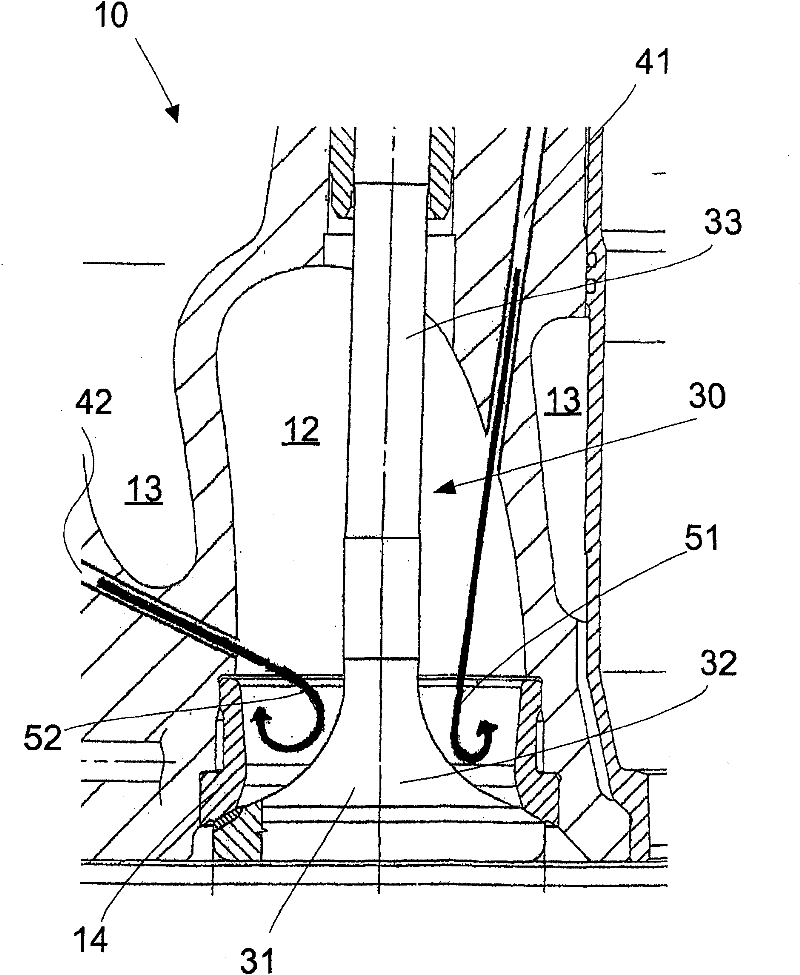

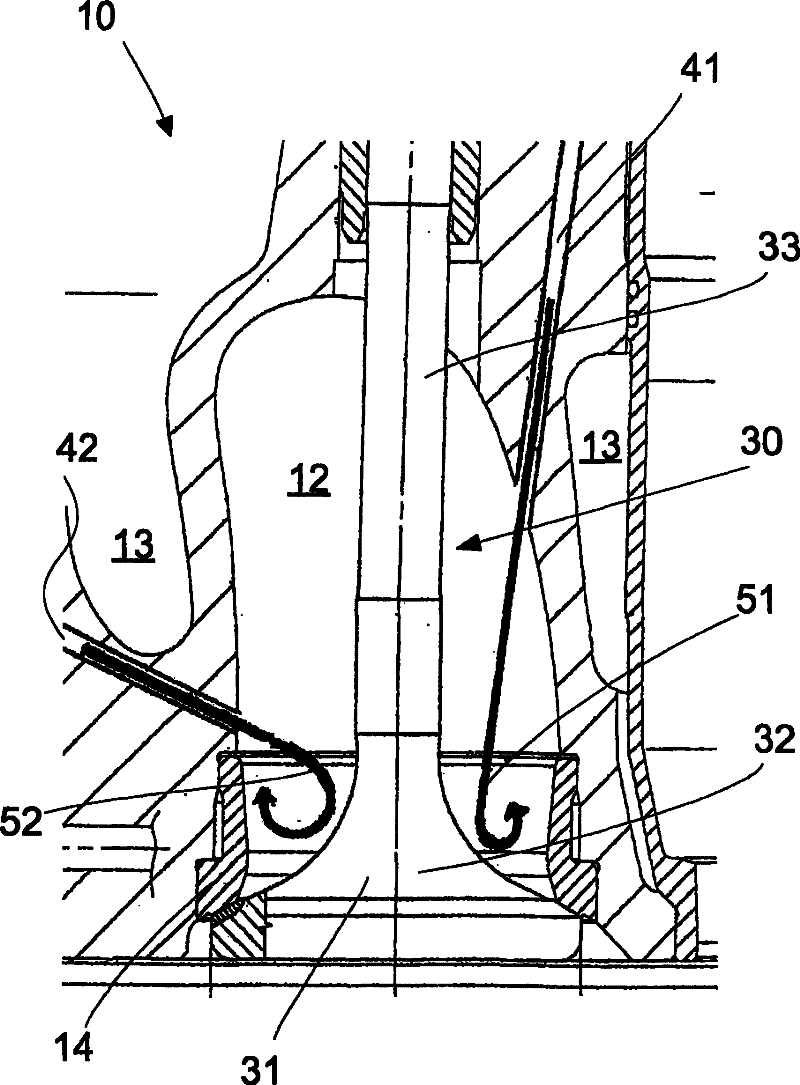

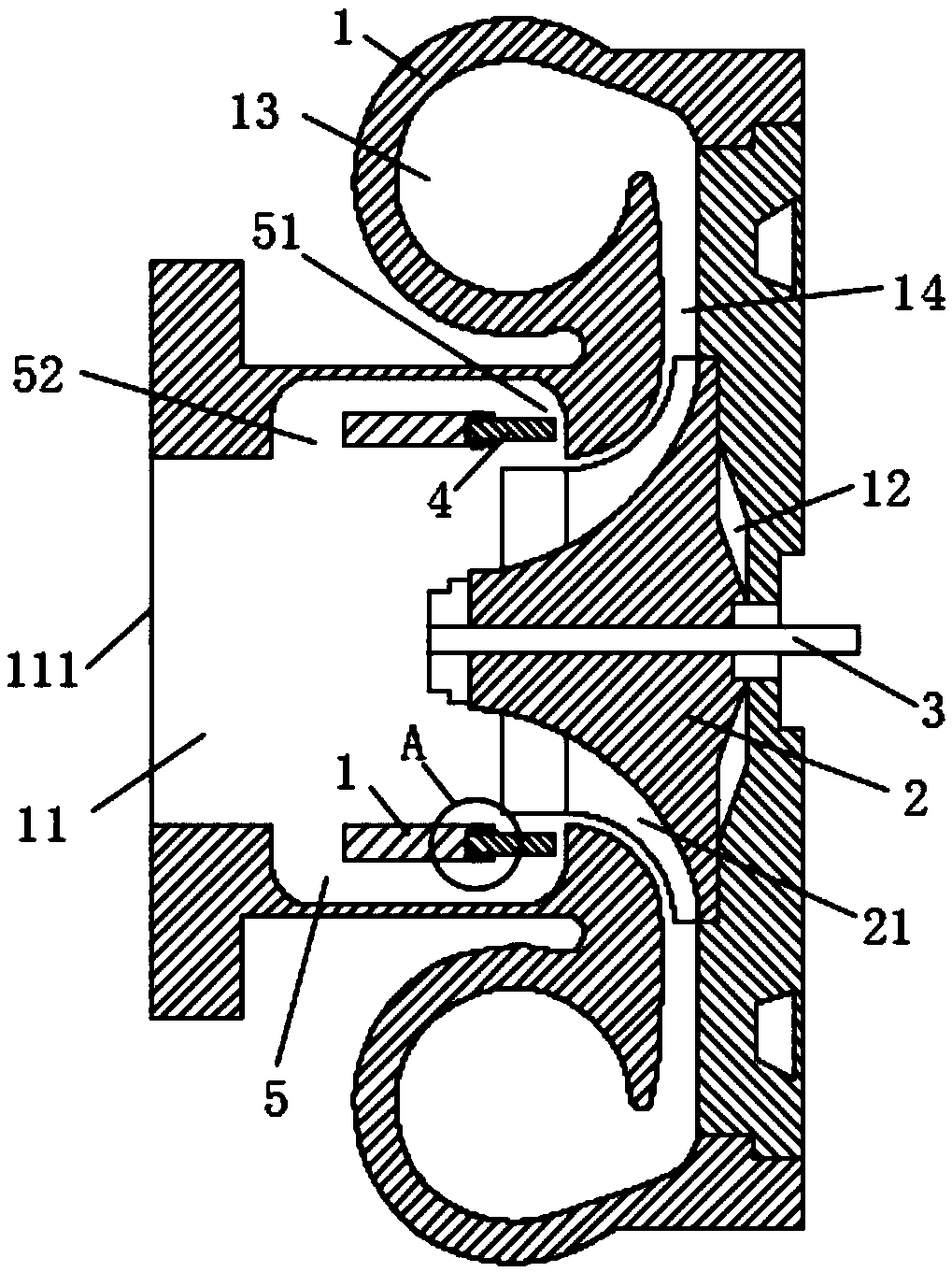

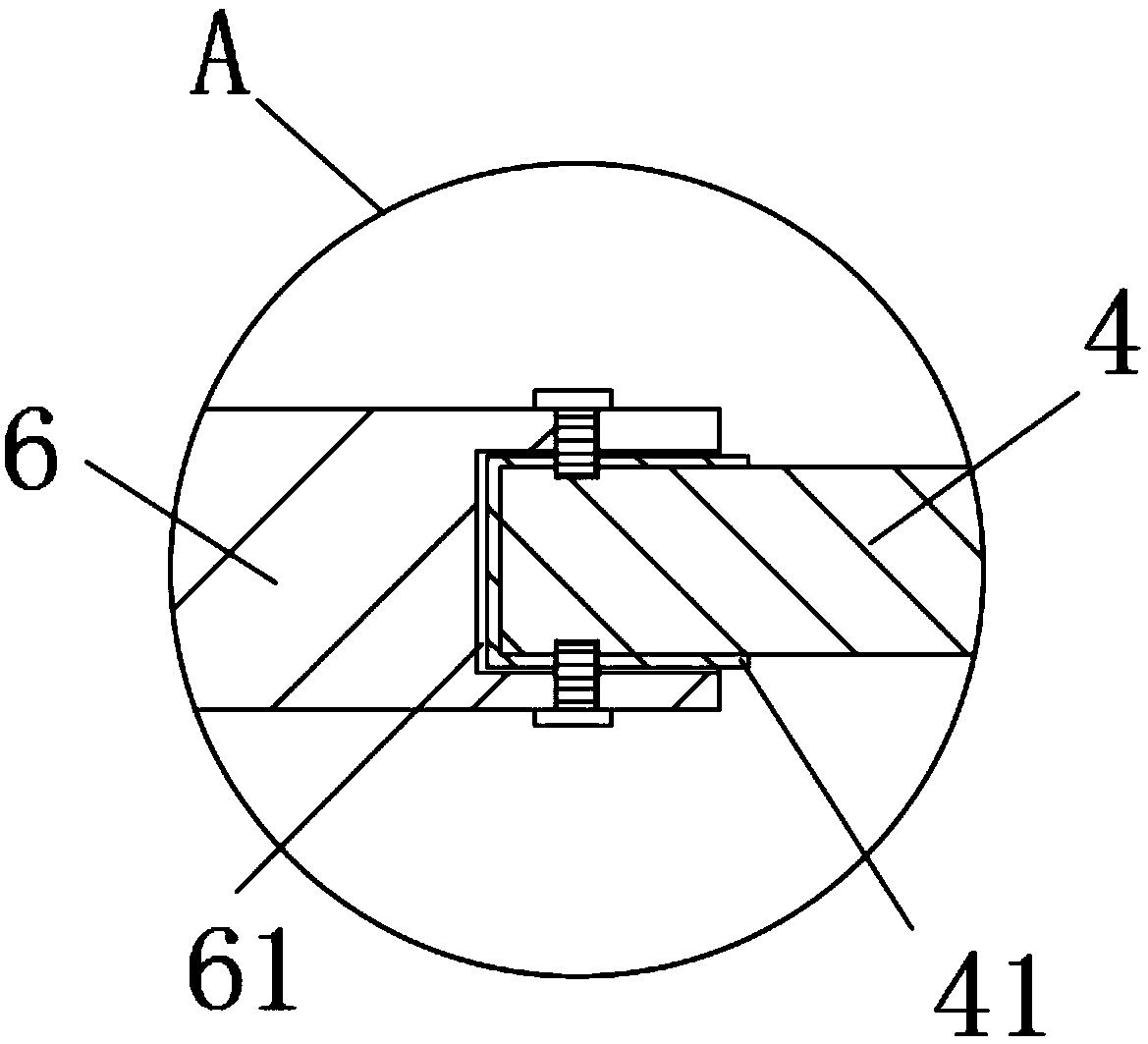

Cylinder head for a self-igniting internal combustion engine

The invention relates to a cylinder head for a self-igniting internal combustion engine, specifically, the cylinder head (10) has at least one exhaust channel (12) capable of being closed by an exhaust valve (30), and comprises a cooling air duct assembly having at least one cooling air duct (41, 42) for loading the cold air to the exhaust valve. The cooling air duct of the cooling air duct assembly in the cylinder head is configured to have approximately linear and / or approximately constant or continuously increased cross section.

Owner:MAN B & W DIESEL AS

Flexible casing treatment centrifugal compressor

InactiveCN109356866AImprove stable working rangeLow efficiencyPump componentsPump controlInlet channelEngineering

The invention discloses a flexible casing treatment centrifugal compressor. The flexible casing treatment centrifugal compressor comprises a volute and an impeller, air outlet channels are formed in the two side ends in the volute, an air inlet is formed in the position, on an air inlet channel, of the front side surface of the volute, air outlets are formed in the positions, on the air outlet channels, of the two side ends in the volute, an impeller mounting cavity communicates with the air inlet channel and the air outlet channels, casing grooves are formed in the two side walls of the air inlet channel, partition boards are transversely and fixedly arranged in the casing grooves, flexible baffles are arranged on the side surfaces of the partition boards, and gaps are formed between theouter side ends of the flexible baffles and the bottom surfaces of the casing grooves. The compressor carries out operation on the basis of not changing an original centrifugal compressor volute casing treatment mechanism, the compressor is simple and convenient, flowing losses are avoided to a certain degree while the stable work range of the centrifugal compressor is further widened, and the reduction of the efficiency of the centrifugal compressor is effectively prevented.

Owner:汪陈芳

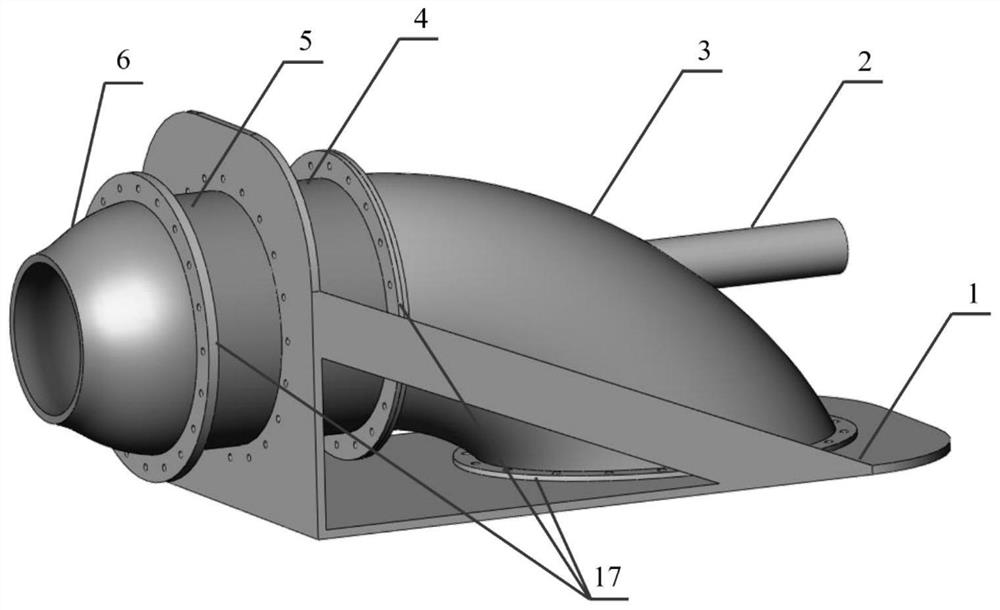

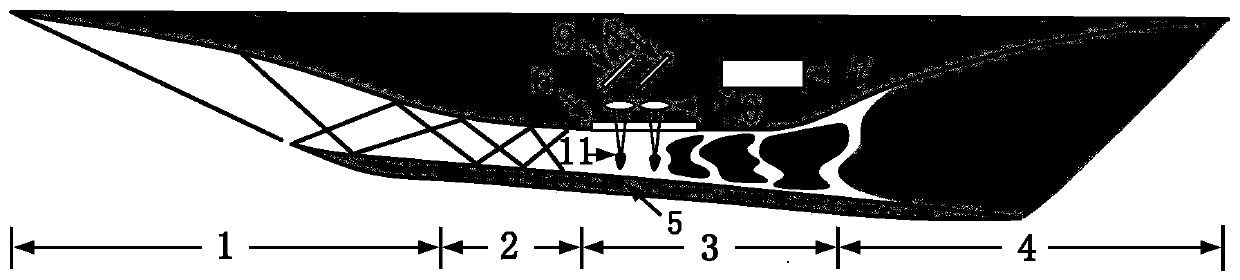

Axial-flow type double-duct water-jet propeller

The invention relates to an axial-flow type double-duct water-jet propeller, and belongs to the field of fluid mechanical engineering and ship propulsion. The invention aims to solve the problem that an existing axial flow type water-jet propeller is low in lift. The propeller is composed of a support, an outer duct transmission shaft, a water inlet runner, an outer duct impeller chamber, an outer duct guide vane chamber, a nozzle, an outer ducted impeller hub, outer ducted impeller blades, outer ducted guide vane blades, an inner ducted transmission shaft, an inner ducted impeller hub, an inner ducted guide vane hub, an inner ducted impeller chamber, an inner ducted guide vane chamber, inner ducted impeller blades, inner ducted guide vane blades and a flange plate. According to the axial-flow type double-duct water-jet propeller, on the premise that large flow is guaranteed, the lift of the water-jet propeller can be improved, the cavitation resistance is improved, the axial-flow type water-jet propeller can be applied to propelling of a high-speed navigation body, and meanwhile the defects that a multi-stage water-jet propeller is large in weight, large in space size and the like are overcome through the axial-flow type double-duct water-jet propeller.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

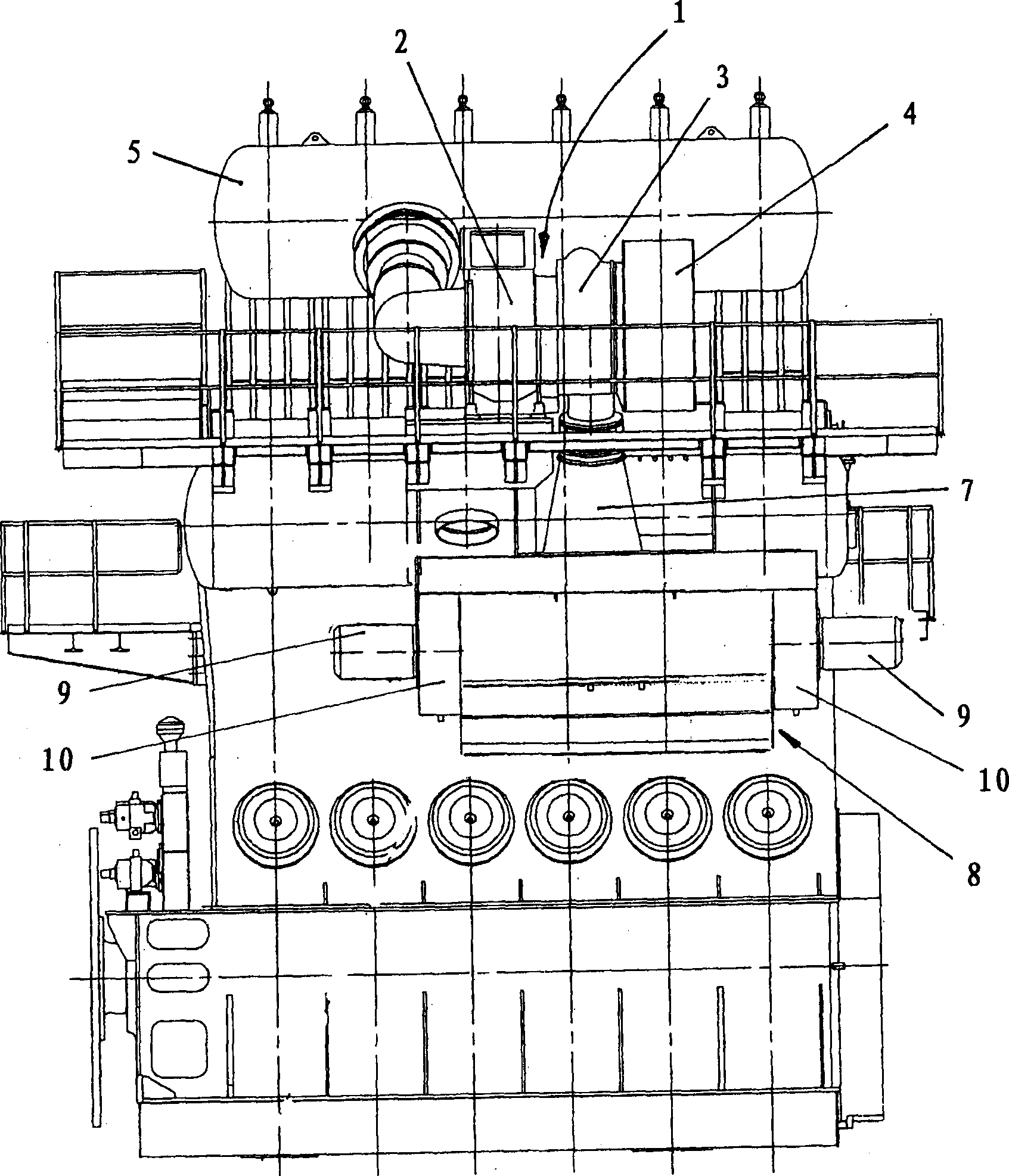

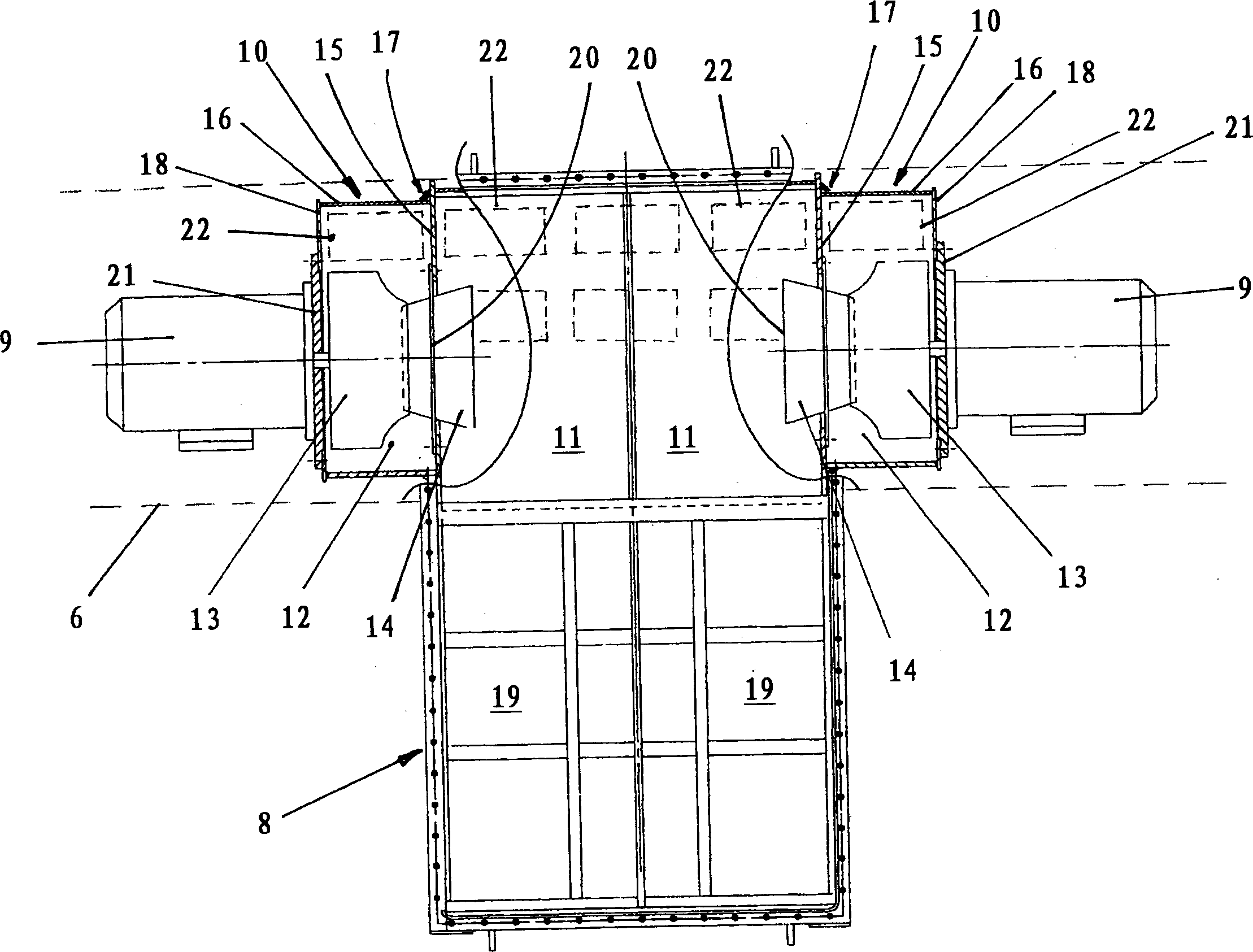

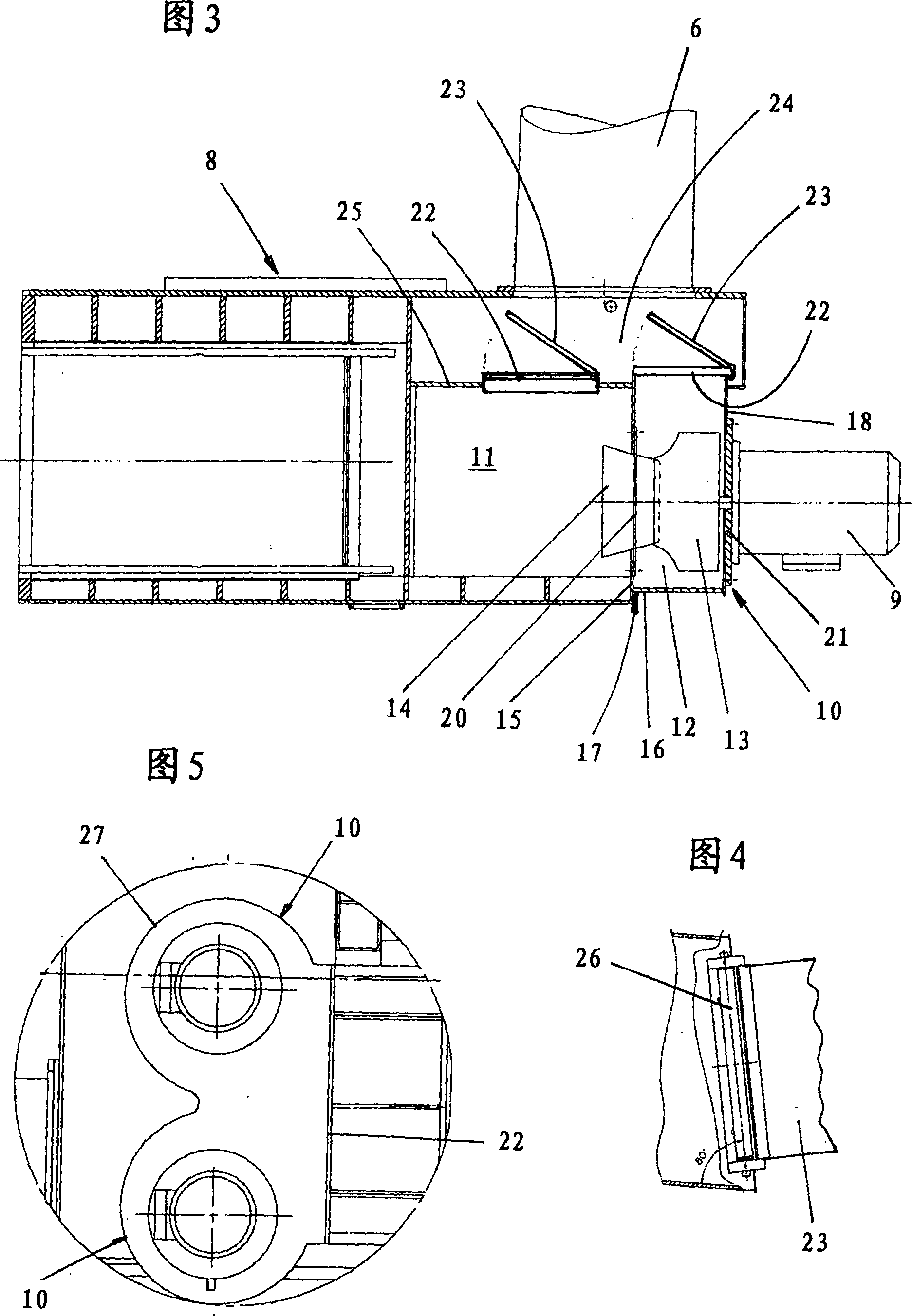

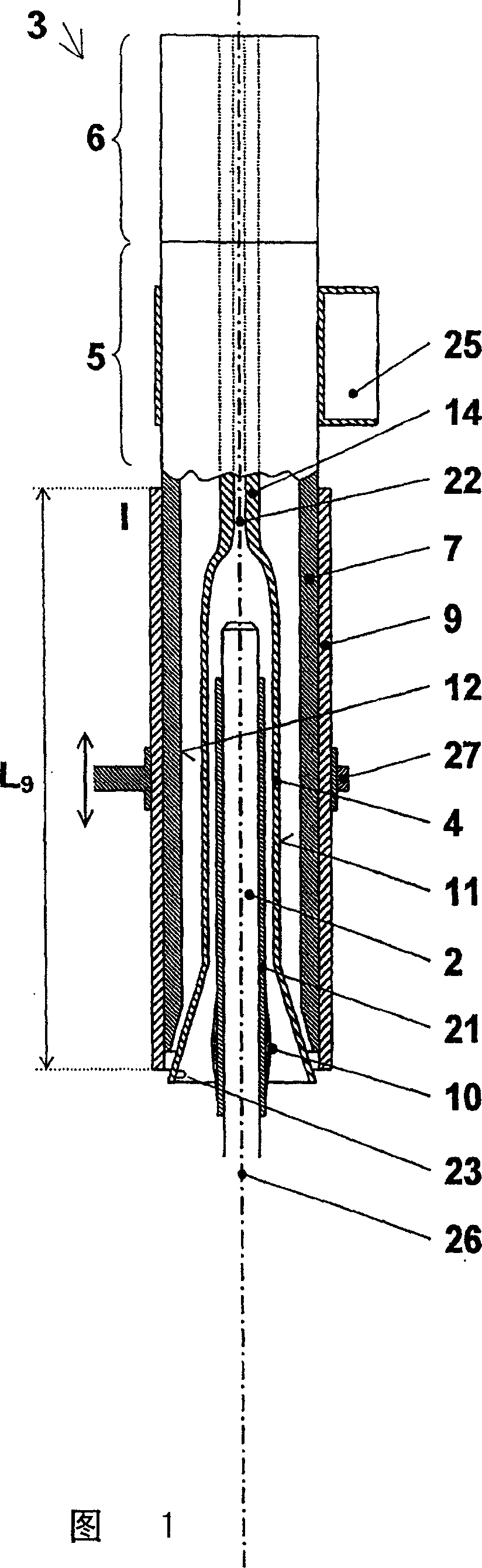

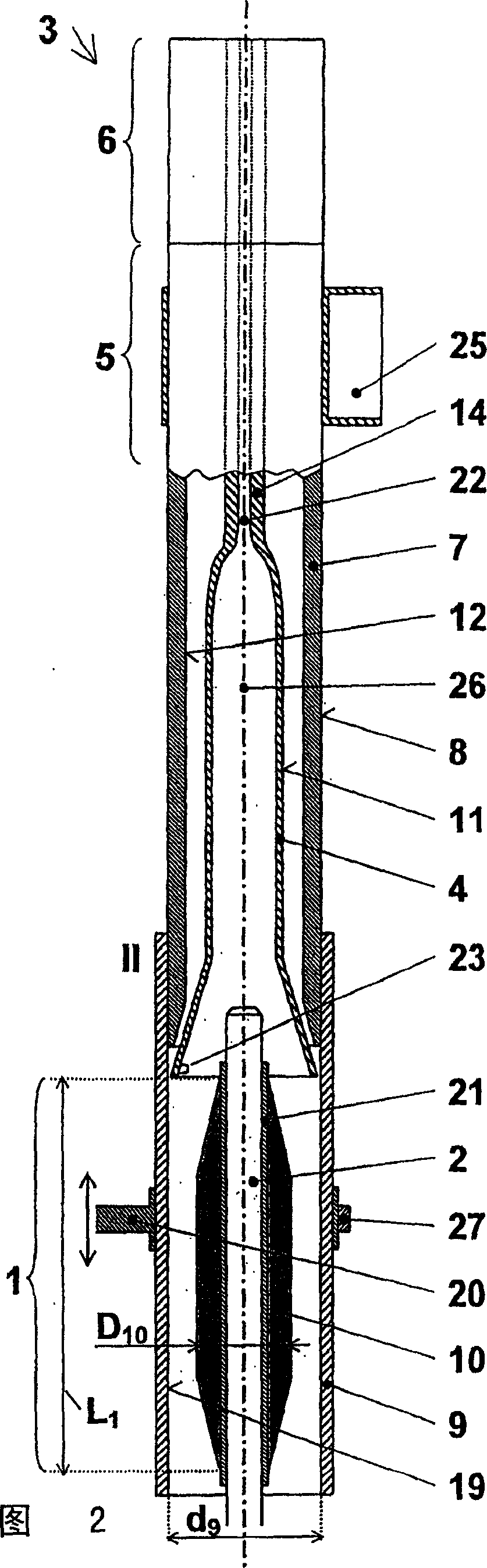

Large-scale engine

ActiveCN1847639AImprove rigidityImprove stabilityInternal combustion piston enginesCombustion-air/fuel-air treatmentImpellerTurbocharger

A large engine with a charge air container (6) which can be operated by means of an exhaust gas turbocharger (1) and / or by means of at least one blower with a motor (9) The auxiliary blower (10) of the impeller (13) is supplied with charge air, which can be conditioned by means of a charge air cooler with a downstream droplet separator and with a Regulating housing (8) behind the device (1), which has at least one compartment (19) for a charge air cooler and at least one compartment (11) for a droplet separator, an auxiliary At least one blower chamber (12) of the blower (10) is connected to it on the inlet side, in such a large engine a very compact and vibration-resistant construction can be achieved in such a way that each blower chamber (12 ) and corresponding adjacent compartments (11) have at least one common wall (15) containing the inlet of the blower chamber (12).

Owner:MAN DIESEL & TURBO FILIAL AF MAN DIESEL & TURBO SE TYSKLAND

Funnel spinning device with funnel and sinning part

InactiveCN1752310AReduce energy consumptionAvoid flow lossContinuous wound-up machinesYarnEngineering

The result of the invention is: to maintain low driving energy loss of the funnel spinning apparatus caused by flow resistance as much as possible and enabling approach a spinning site of the funnel spinning apparatus as simply as possible, especially for starting spinning, doffing or on the breakage of a yarn.

Owner:MASCHINENFABRIK RIETER AG

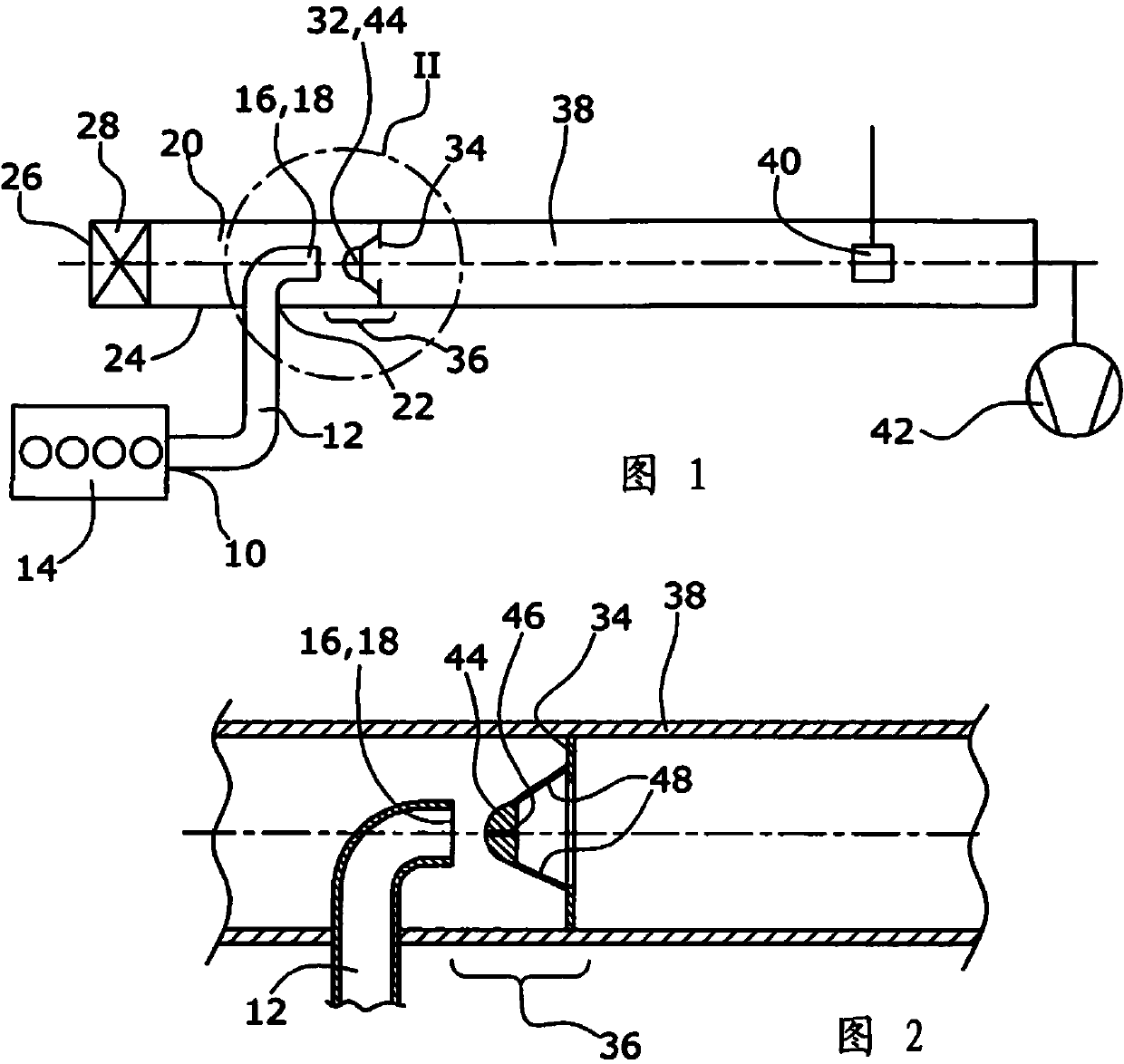

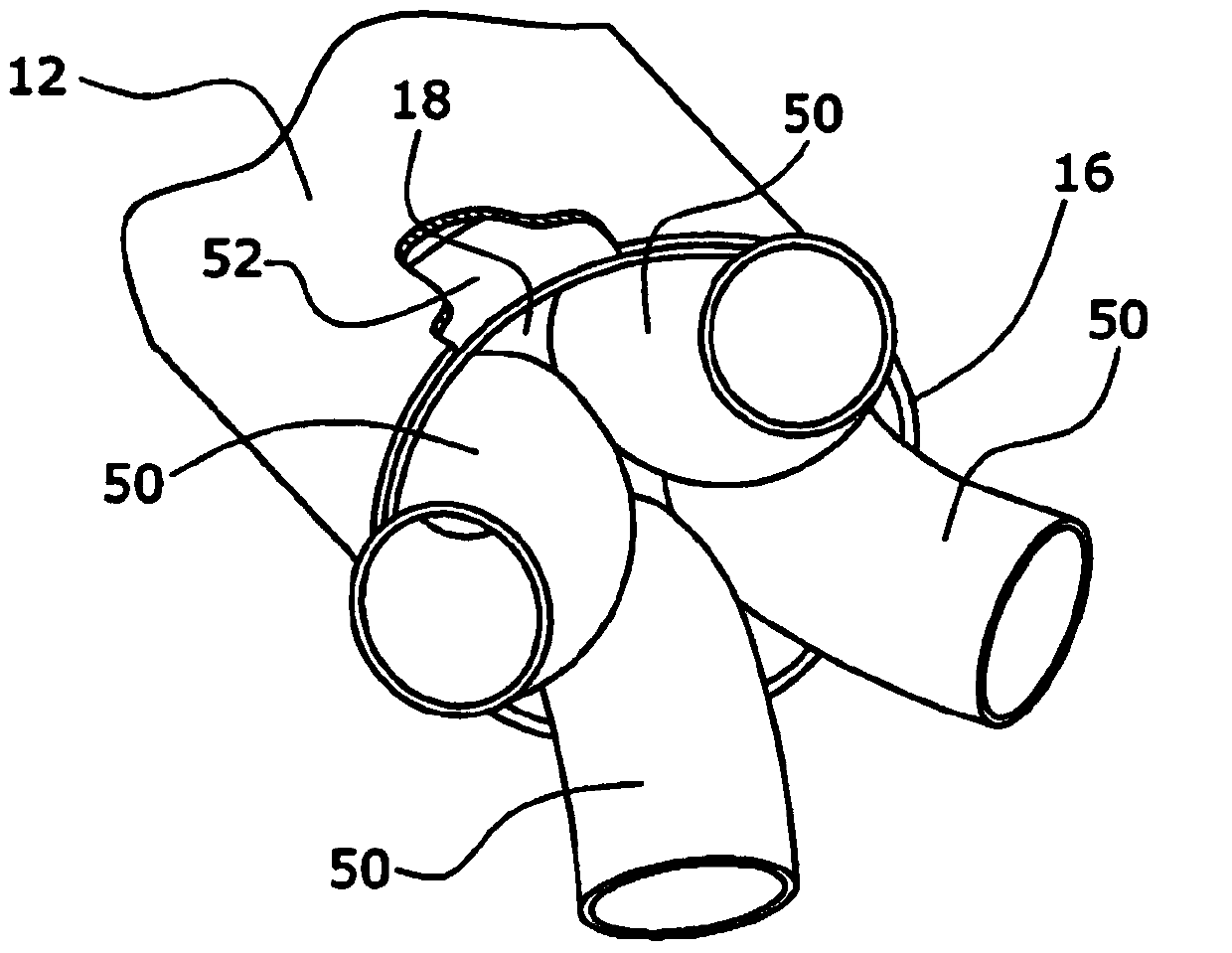

System for removing exhaust gas samples from internal combustion engines

ActiveCN104220860AHigh speedWell mixedEngine testingWithdrawing sample devicesCombustionExternal combustion engine

Systems for removing exhaust gas samples from internal combustion engines are know, said systems comprising: an exhaust gas duct (12) having fluid communication with an exhaust gas source (14) via an exhaust gas inlet (10); an air duct (20) into which ambient air can be suctioned via an air filter (28); a fusion zone (36) arranged downstream of an outflow cross section (18) of the exhaust gas duct (12); and a dilution tunnel (38), through which the exhaust gas / air mixture flows, wherein the outflow cross section (18) of the exhaust gas duct (12) is arranged substantially concentric in the air duct (20) and an annular orifice (34) is arranged downstream of the outflow cross section (18) of the exhaust gas duct (12) in the dilution tunnel (38). However, the two gas flows are often inadequately mixed. In order to ensure good mixing and representative sampling, the invention therefore proposes that means (32, 44, 50) are arranged upstream of the orifice (34) and downstream of the outflow cross section (18) of the exhaust gas channel (12), via which means the exhaust gas flow is deflected in such a manner that the exhaust gas flow is removed directly upstream of the means (32, 44, 50) and asymmetrically from the centre axis of the dilution tunnel (38).

Owner:AVL EMISSION TEST SYST GMBH

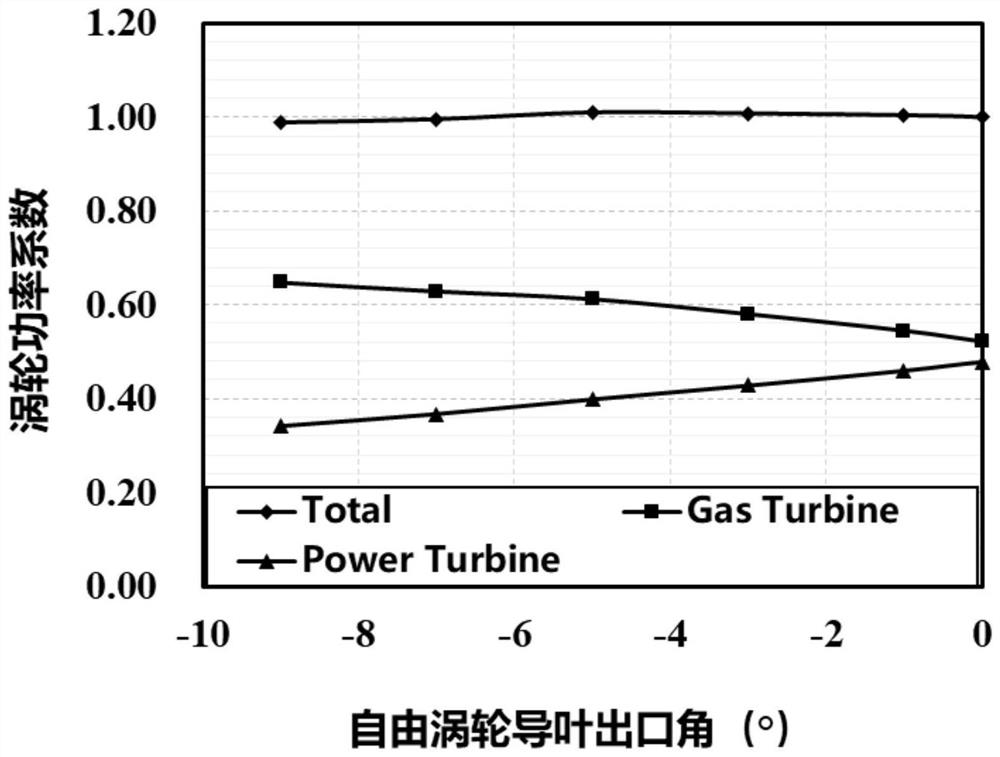

Method and device for determining outlet metal angle of guide vane blade

The invention provides a method and device for determining an outlet metal angle of a guide vane blade. The method and device are used for power equipment with a gas turbine and a free turbine. The free turbine is provided with the guide vane blade. The method comprises the steps that the target power coefficient of the free turbine is determined based on a power matching relation of the gas turbine and the free turbine; and the outlet metal angle of the guide vane blade is determined based on the target power coefficient of the free turbine. Compared with a traditional scheme of adjusting a mounting angle, the internal flow loss of the free turbine can be prevented from being greatly improved, and therefore, efficient matching of the output power of the gas turbine and the output power of the free turbine can be achieved under the condition that the aerodynamic efficiency of the whole-stage turbine is kept.

Owner:BEIHANG UNIV

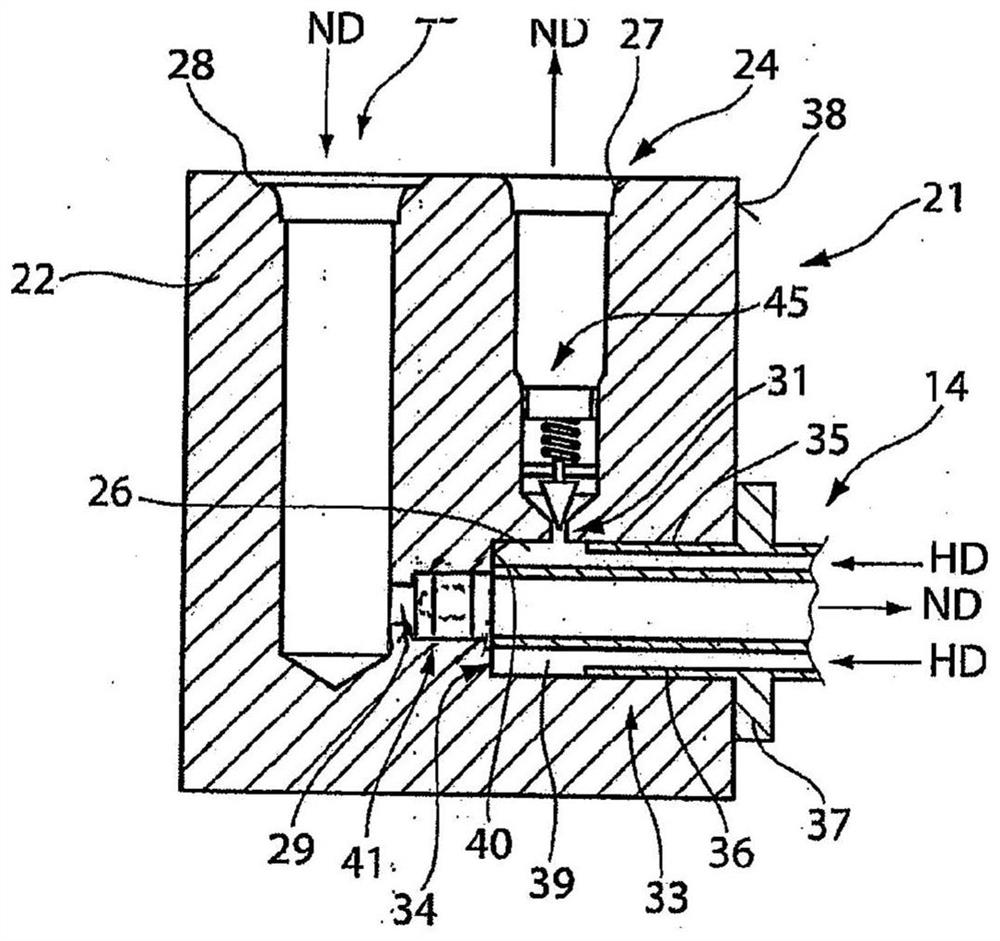

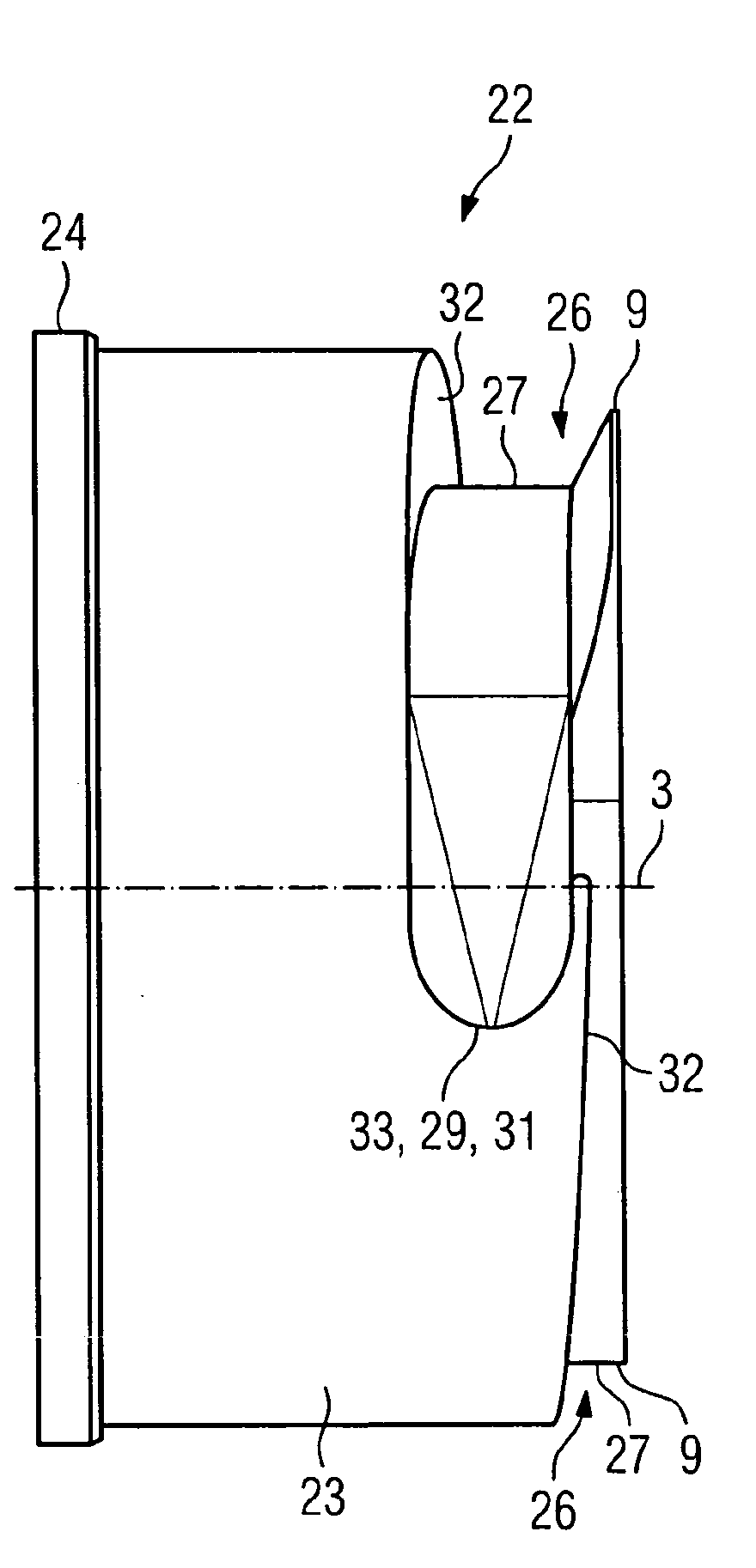

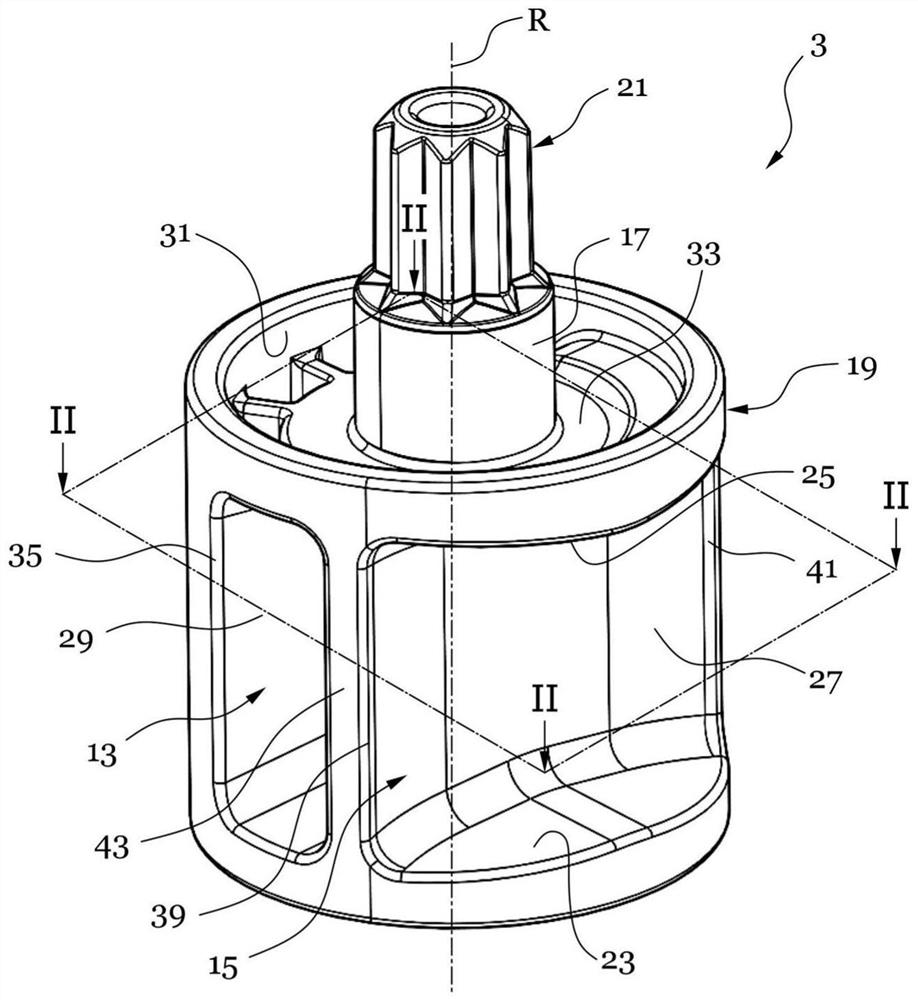

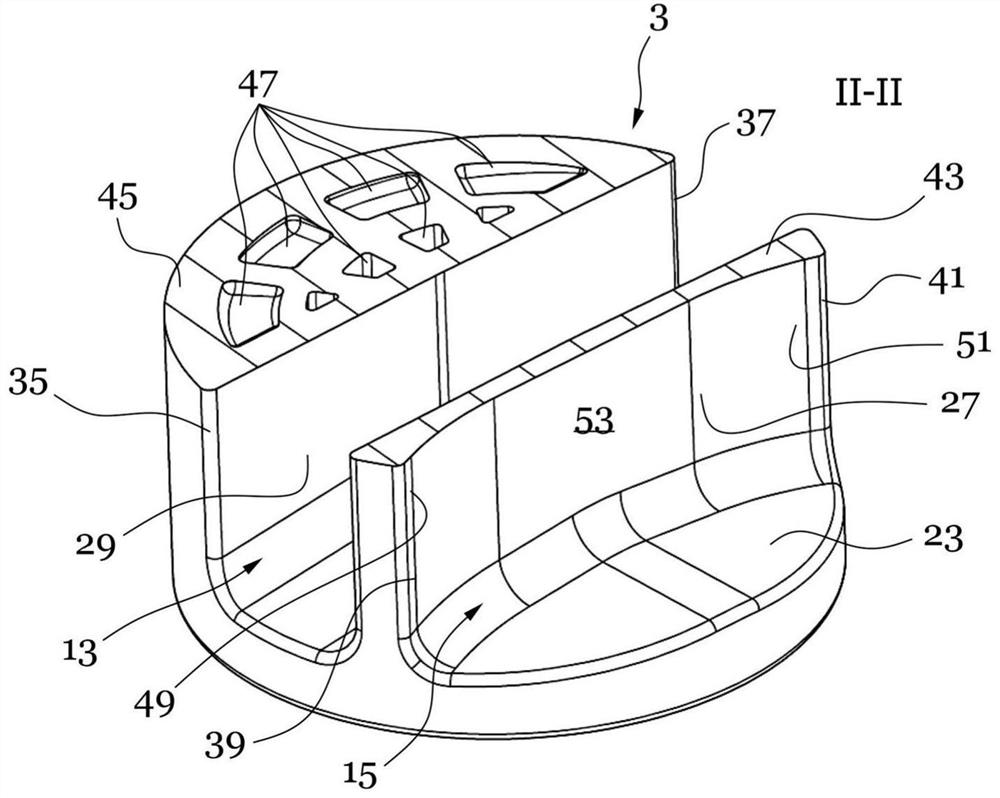

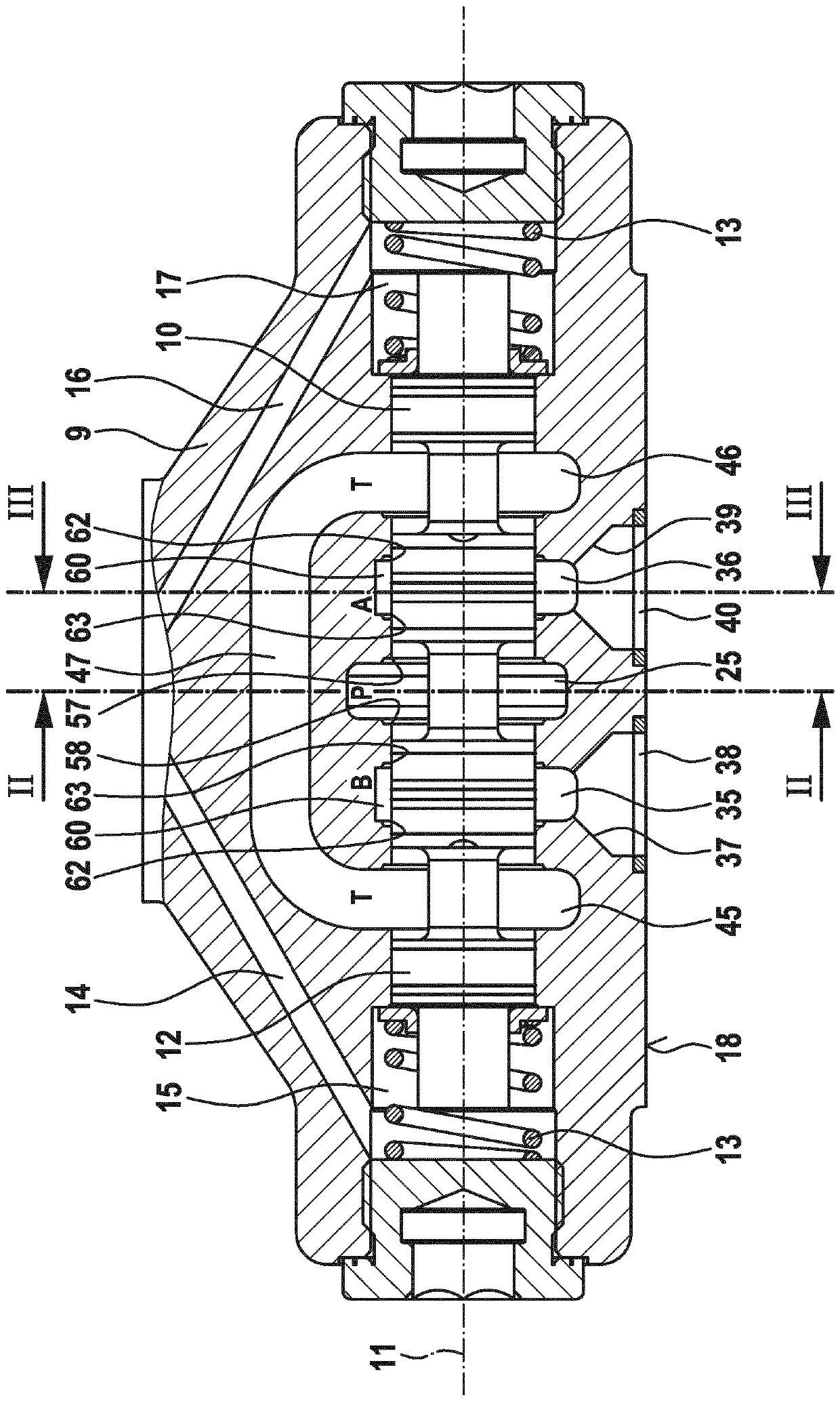

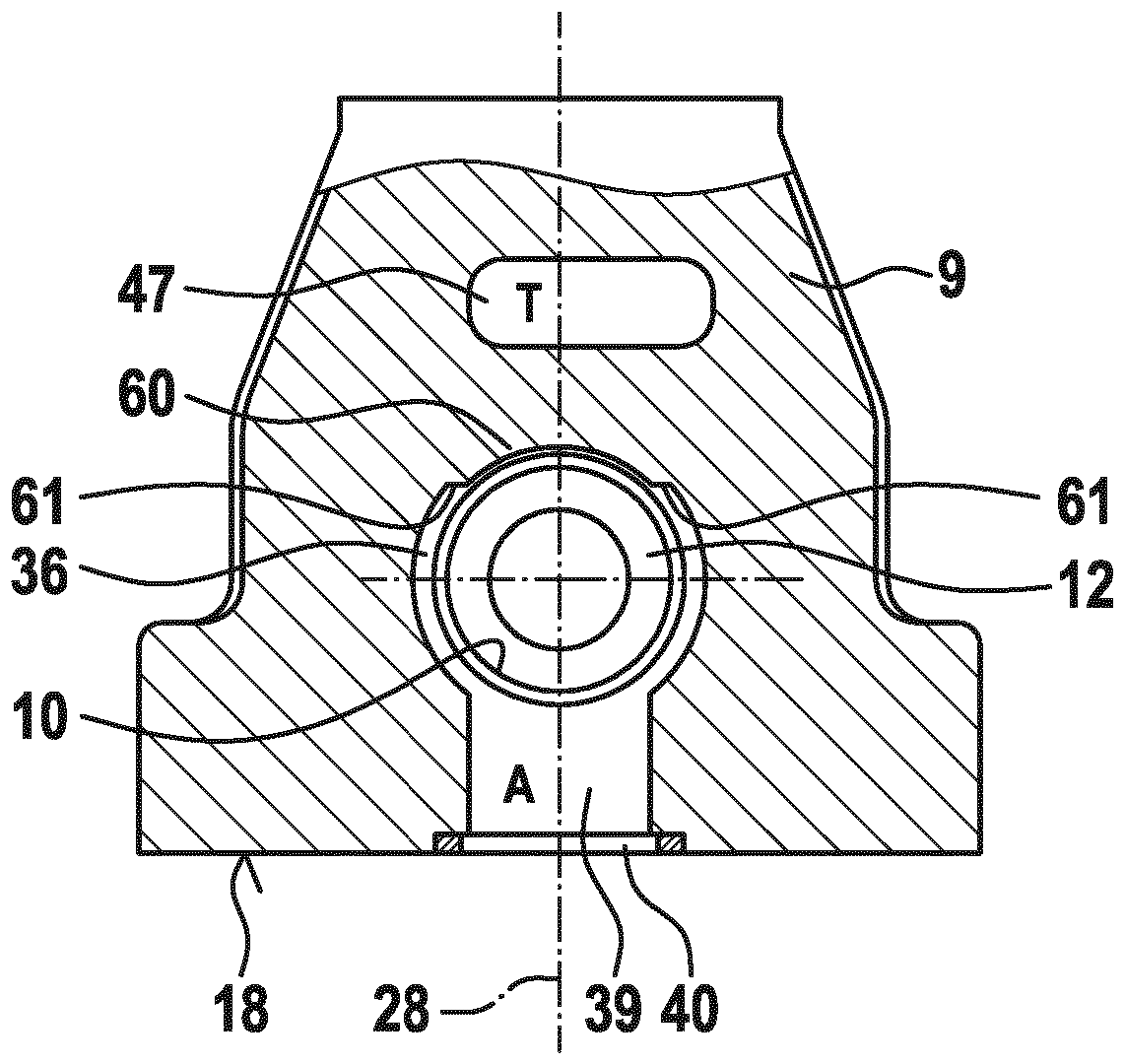

Non-return valve, in particular for a refrigeration or heat circuit

ActiveCN112166271AAvoid flow lossAvoid vortexCheck valvesHeat exchanger casingsEngineeringCheck valve

The invention relates to a non-return valve, in particular for a refrigeration or heat circuit, which valve can be inserted into a connection opening (26, 27, 28, 29) of a connection device (21) or ofa pipe (39) and comprises: - a one-part or multi-part housing (42) which comprises at least one main housing (44), a feed opening (48) being provided on the inlet side and a discharge opening (51) being provided on the outlet side of the main housing (44), the feed opening and the discharge opening being interconnected by a flow channel (49); - a guide element (53) which is provided on the main housing (44) and by means of which a valve closing element (61) is guided slidably relative to the main housing (44), the valve closing element (61) being arranged in a starting position (42) by meansof an energy accumulator (71) and the valve closing element (61) being slidable toward the discharge opening (51) against an actuating force of the energy accumulator (71) in order to be transferred into a working position (63), and the energy accumulator (71) being provided between the valve closing element (75) and the main housing (44), the guide element (53) of the main housing (44) having atleast one through-hole (57) and at least one guide rod (59) being guided in said at least one through-hole (57), which rod at least extends from the valve closing element (61) through the at least onethrough-hole (57) and is secured against release from the through-hole (57), or the guide element (53) being designed as a sleeve (54) having a bottom (55), which is associated with the discharge opening (51), and the valve closing element (61) having a guide portion (66) which acts on the sleeve (54).

Owner:OTTO EGELHOF GMBH & CO KG

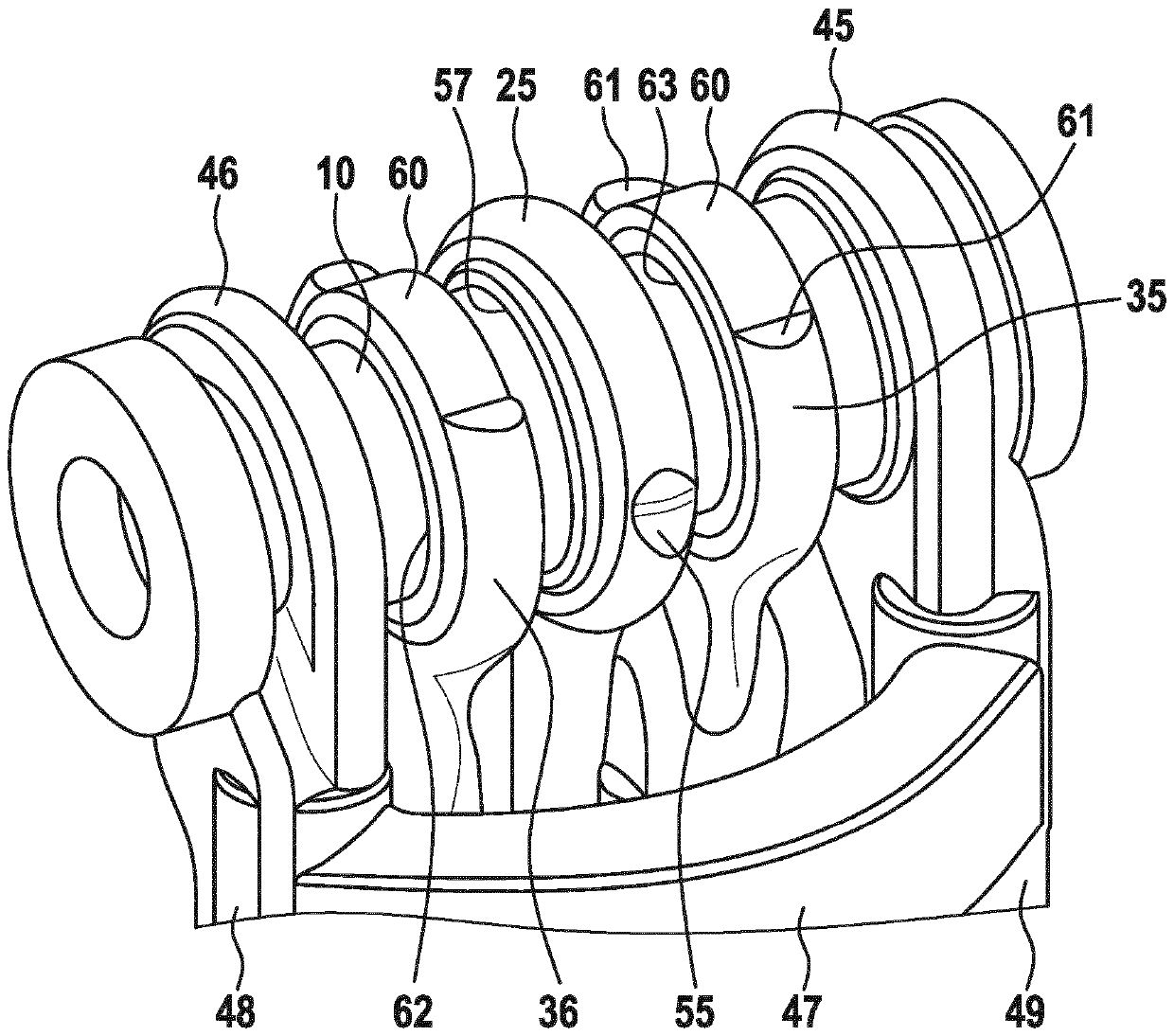

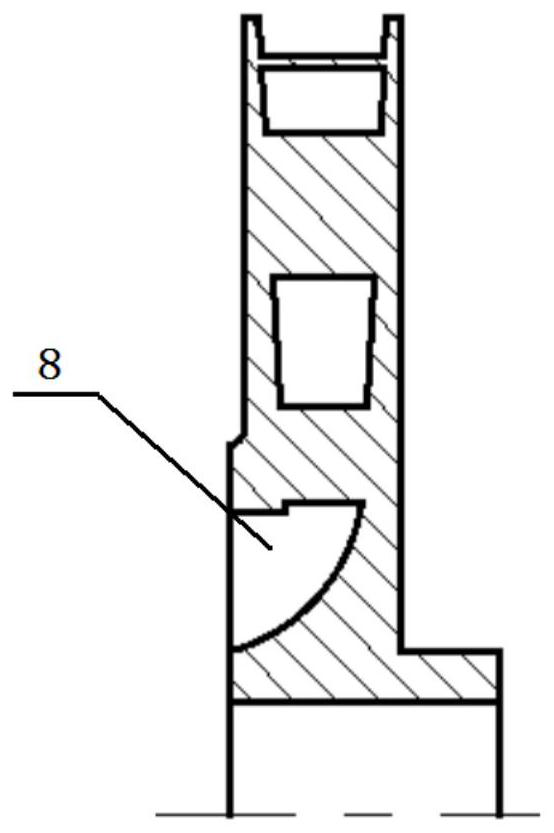

Collecting chamber and method of production

InactiveCN102105698AGood for flow distributionApplicable inflow situationPump componentsRadial flow pumpsMethods of productionMechanical engineering

The invention relates to a collecting chamber (2) of a flow machine (condenser 1), which expands in the direction of circumference, comprising at least one outer shell part (21) and a contour insert (22), wherein the contour insert (22) is provided with a groove (26) which extends in the circumferential direction and is preferably configured as a helical spiral. According to the invention, the contour insert (22) is cut from a whole unit and is delimited at one end in the circumferential direction by a bent edge (33) so that the flow losses are minimized during the passage from the collecting chamber into a subsequent diffuser (10).

Owner:SIEMENS AG

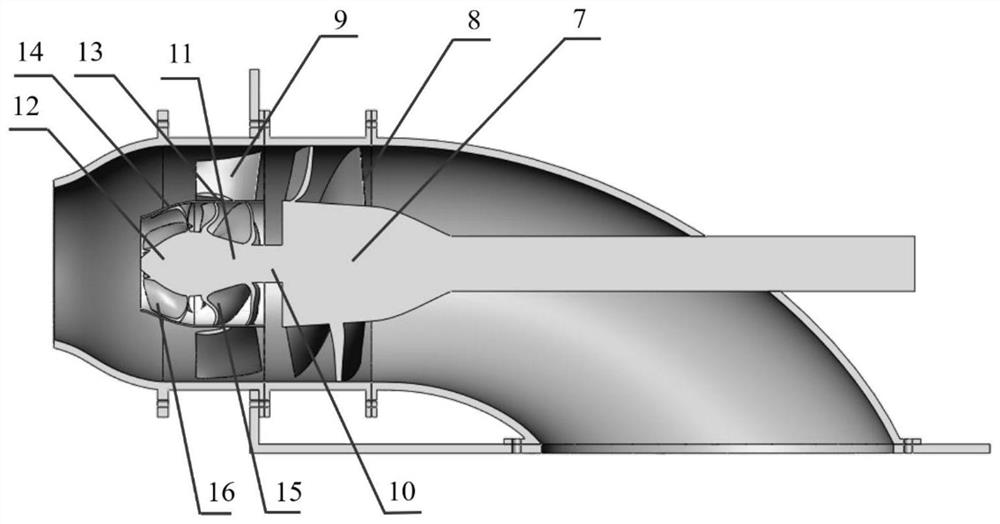

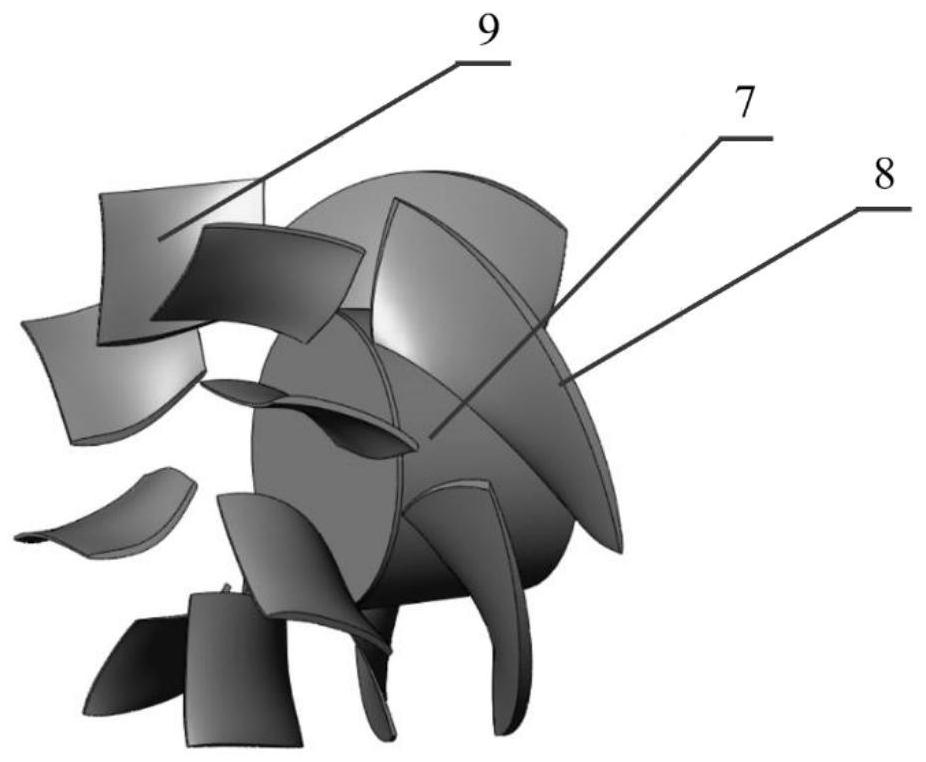

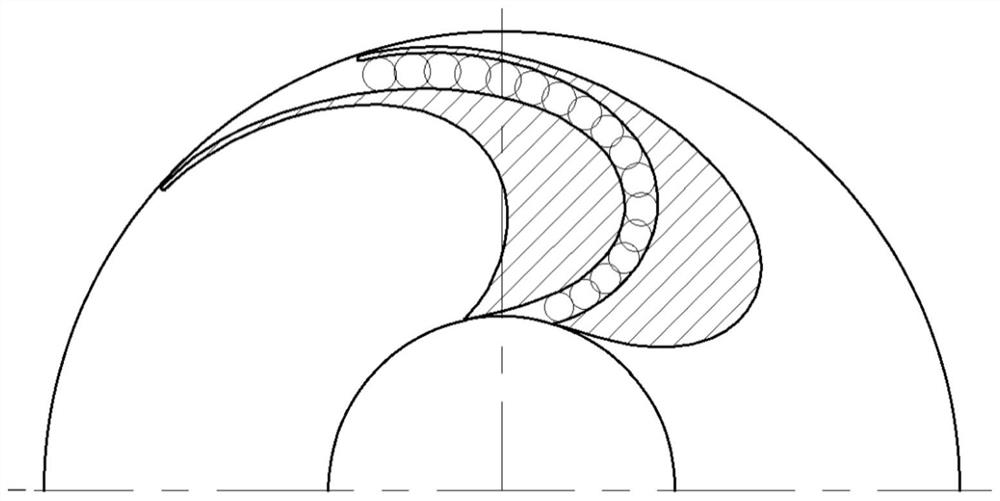

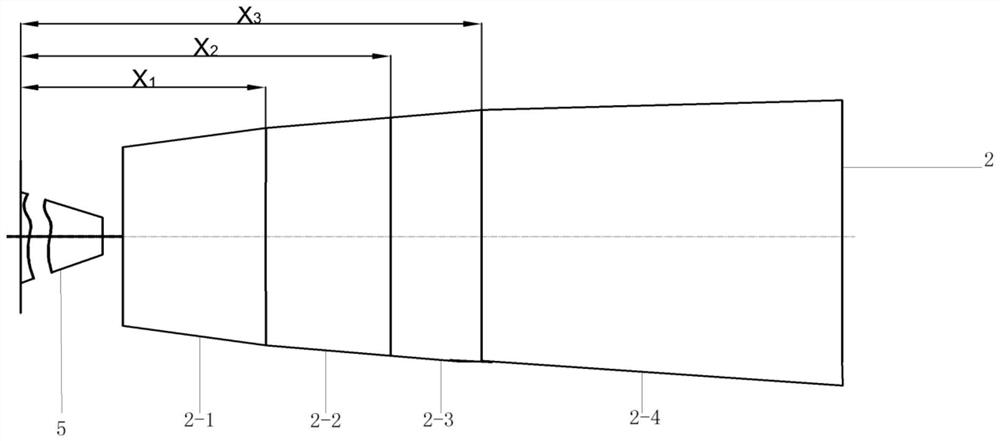

High-performance two-way full cross flow turbine

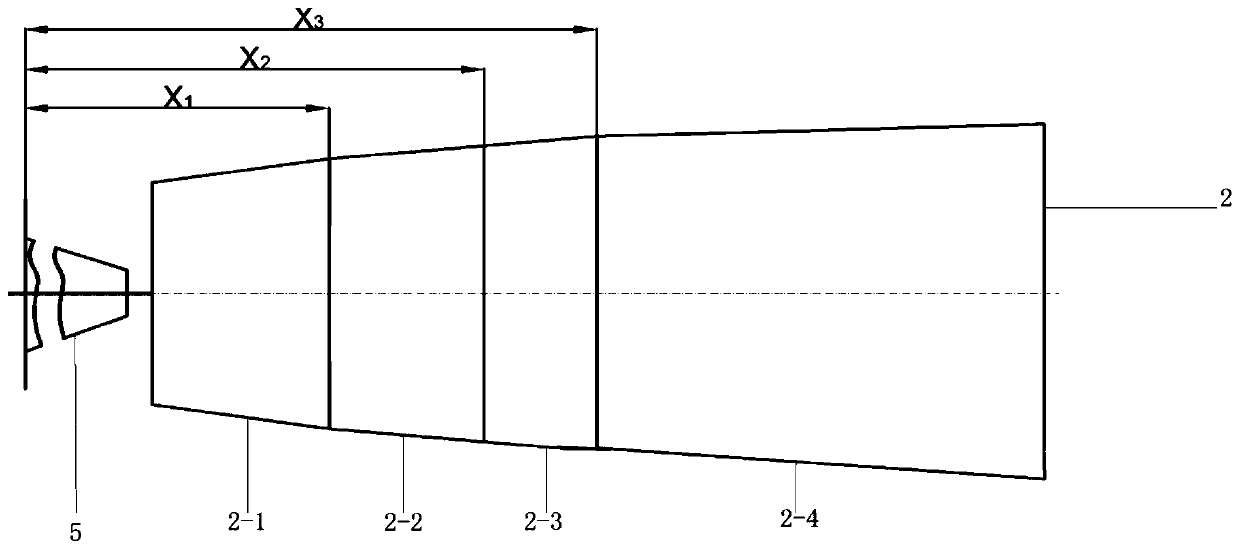

ActiveCN110296032AGuaranteed uniformityWeaken CircumferenceHydro energy generationReaction enginesImpellerWater flow

The invention discloses a high-performance two-way full cross flow turbine, which comprises an inlet pipe and a draft pipe connected in sequence, wherein a movable guide vane and a runner are sequentially arranged along a water flow direction on a central axis in the inlet pipe; the draft pipe comprises a first diffusion section, a second diffusion section, a third diffusion section and a fourth diffusion section, which are connected in sequence; a first deflector and a second deflector are connected along the circumference of the inner wall of the second diffusion section, and are equally spaced; the length of the first deflector is equal to that of the second diffusion section, and is greater than that of the second deflector; one end of the second deflector is located at the exit section of the second diffusion section. Unnecessary flow loss is avoided; the second deflector is away from the exit side of the runner, thus preventing from affecting stable operation caused by strong dynamic and static interference between the deflector and an impeller.

Owner:XIAN UNIV OF TECH

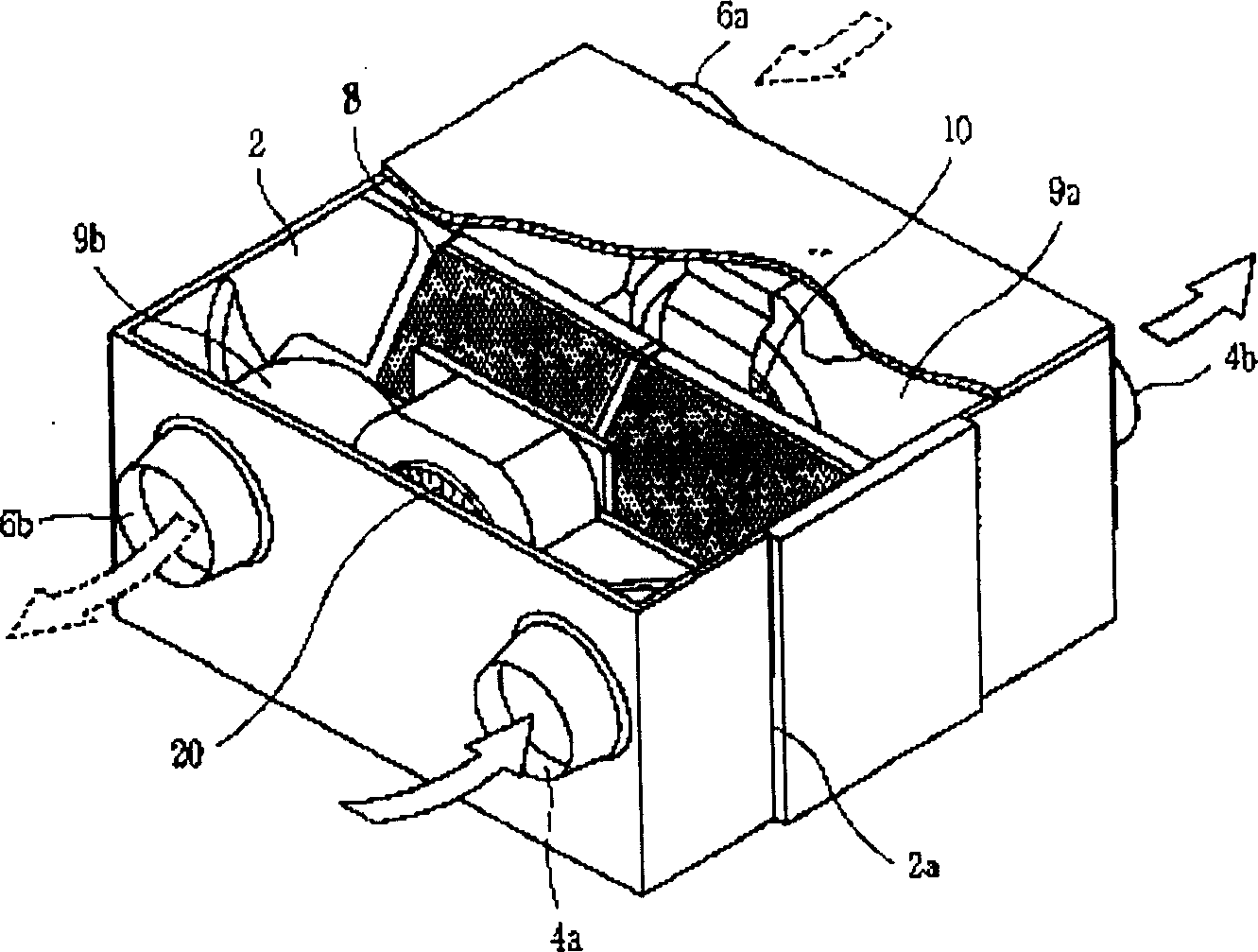

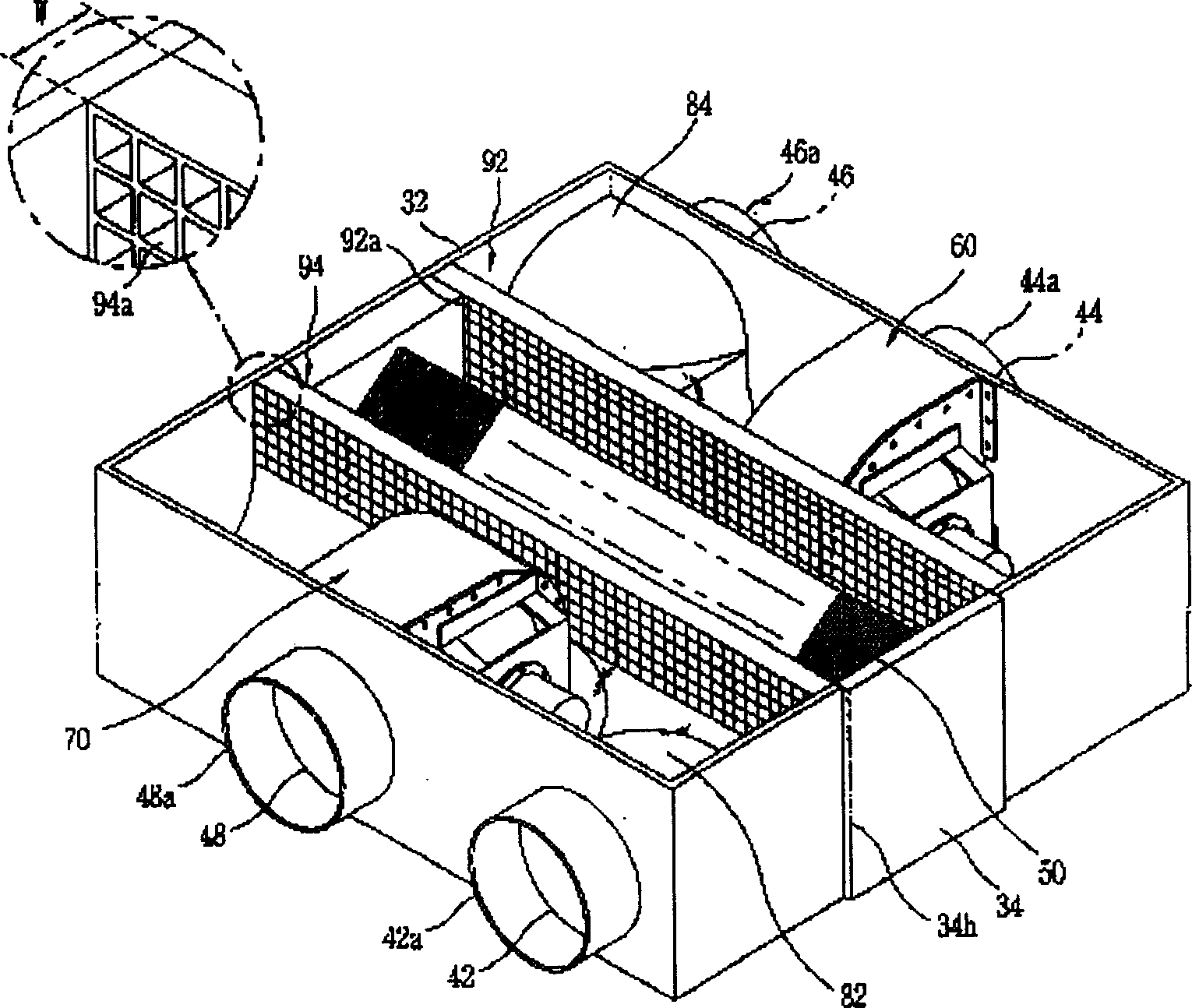

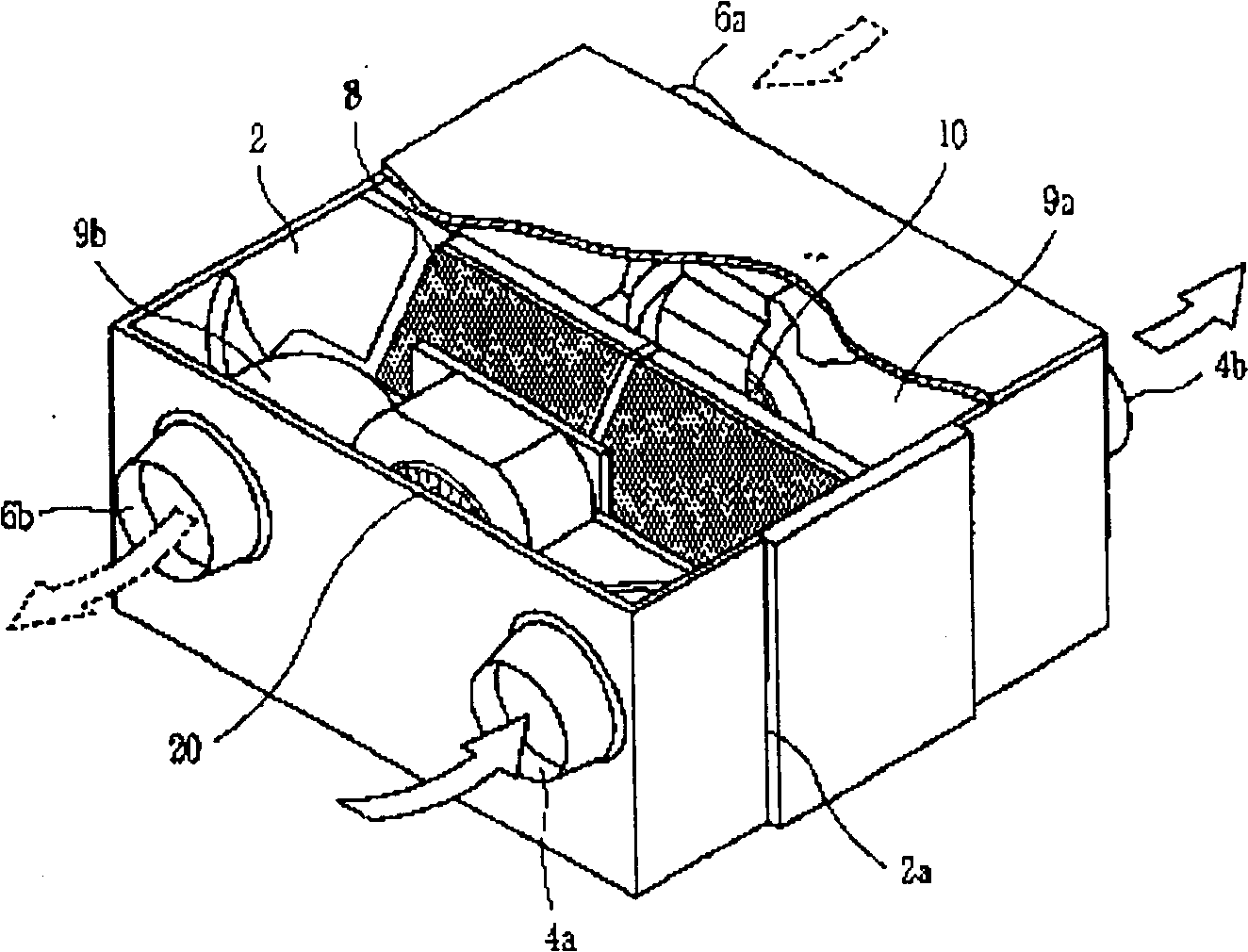

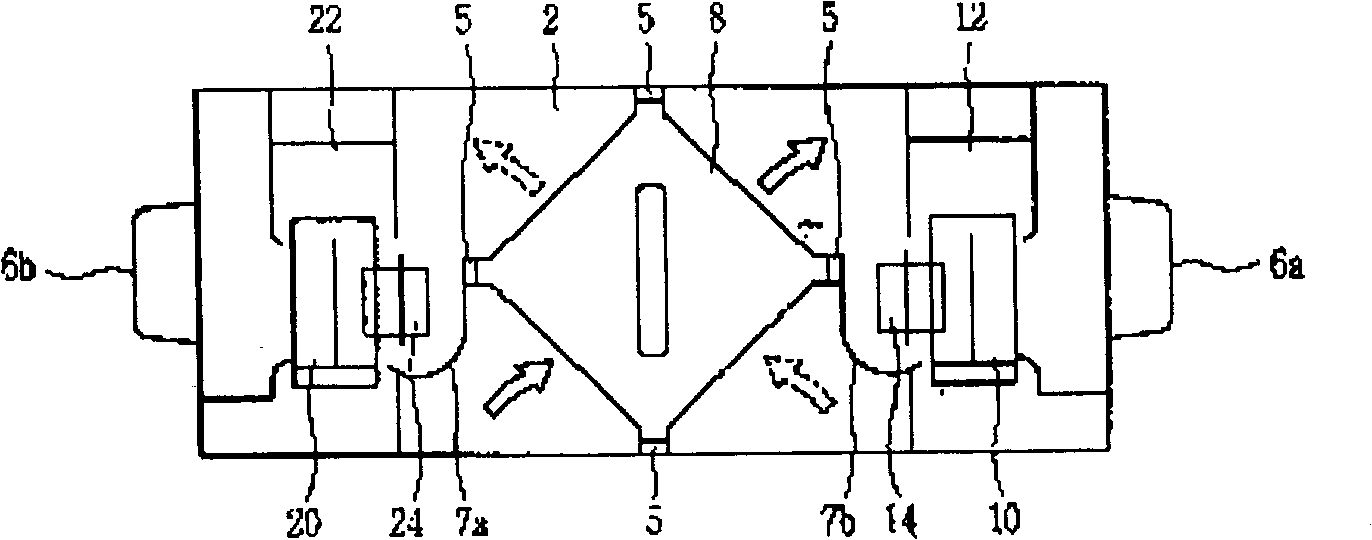

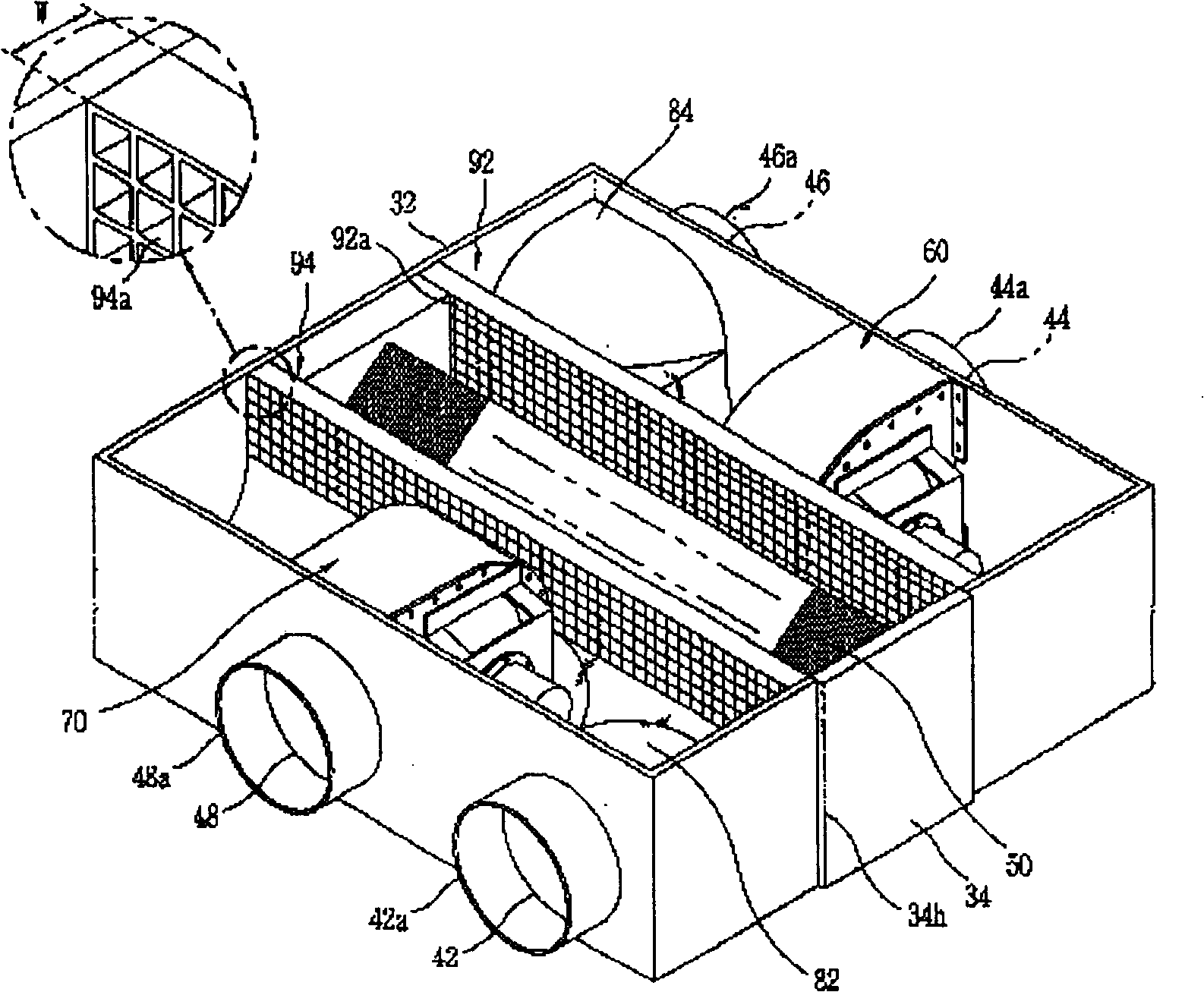

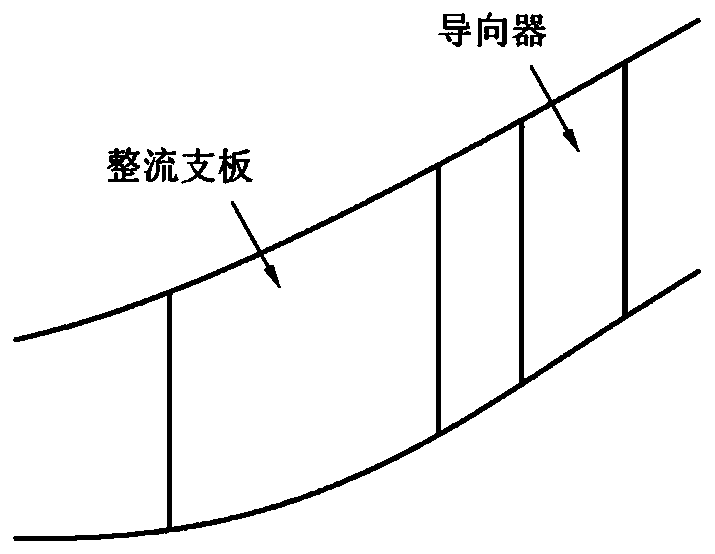

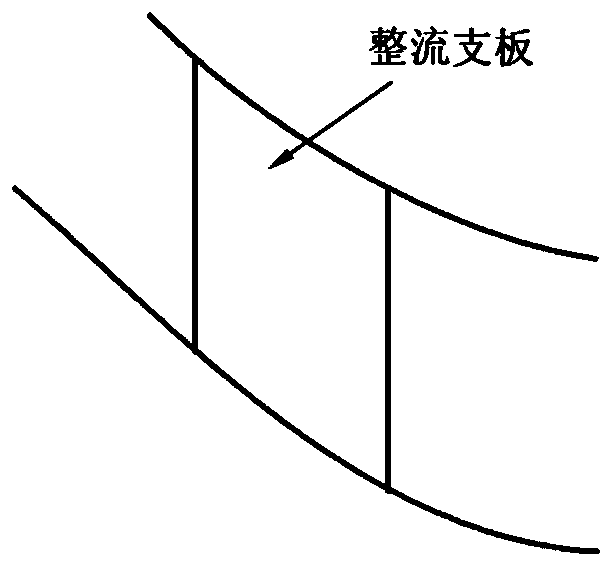

Ventilator

InactiveCN1707187ASpeed up the flowAvoid flow lossLighting and heating apparatusVentilation systemsPlate heat exchangerEngineering

The present invention relates to one kind of air exchange device. In the space exhausting outdoor air or indoor air from the heat exchanger inside the casing, one flow stabilizer is set to change the flow of the outdoor air or indoor air from the heat exchanger into laminar flow so as to homogenize the flow of outdoor air or indoor air in the heat exchanger and to raise heat exchange efficiency.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

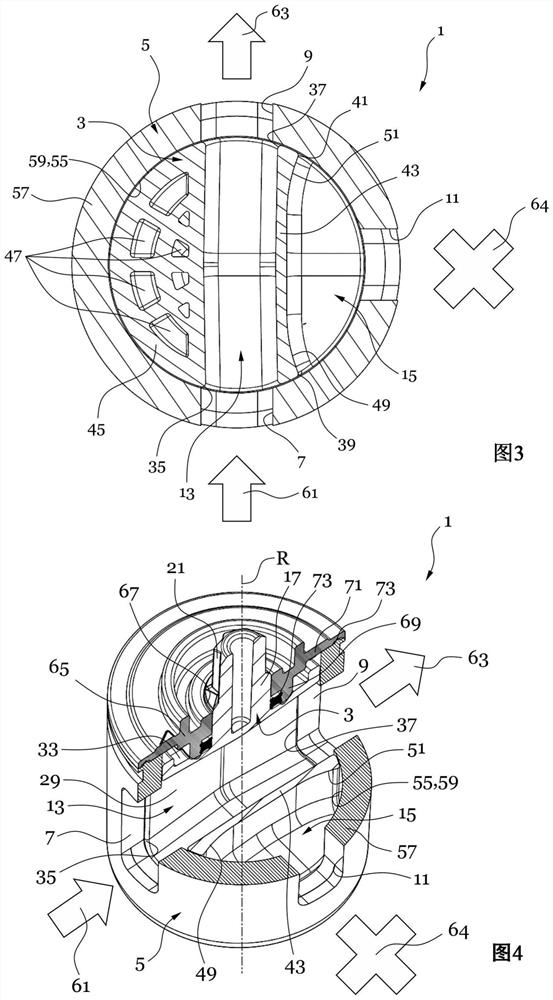

Multi-way valve, fluid circuit and cooling fluid circuit

PendingCN112709843AFlow cross-section limitationLow powerAir-treating devicesCoolant flow controlRotational axisSpool valve

A multi-way valve for controlling a fluid flow in a fluid circuit, such as a cooling fluid circuit of a motor vehicle, may include a valve housing having at least three fluid connections and a rotary slide for setting the fluid flow. The rotary slide includes at least two fluid channels and is configured to connect two respective fluid connections fluidly via one fluid channel dependent upon its rotary position in relation to its rotational axis. The at least three fluid connections and the at least two fluid channels overlap in relation to a crosswise direction oriented crosswise relative to the rotational axis.

Owner:WOCO INDTECHN

Hydraulic spool valve

ActiveCN111183307APremium Control EdgeLow flow resistanceOperating means/releasing devices for valvesServomotor componentsPhysicsPiston

The invention relates to a hydraulic spool valve comprising a valve housing (9) which comprises a valve bore (10) having two control chambers (25), which directly follow one after the other axially ata distance and extend beyond the diameter of the valve bore. The valve housing also has, in a connection surface, a pump connection opening (27), which is connected by means of a first fluid channel(26) to a first of the two control chambers, and a consumer connection opening, which is connected by means of a second fluid channel to a second of the two control chambers. The hydraulic spool valvealso comprises a control piston (12), which is guided so as to be moveable back and forth in the valve bore to fluidically connect the two control chambers with each other and separate said control chambers from each other. A radial web (55) of the valve housing projects into each control chamber, the extension of said web being delimited in the circumferential direction. To particularly effectively avoid annular flows in the control chambers and flow losses associated therewith, the second web in the second control chamber is longer in the circumferential direction than the first web in thefirst control chamber.

Owner:ROBERT BOSCH GMBH

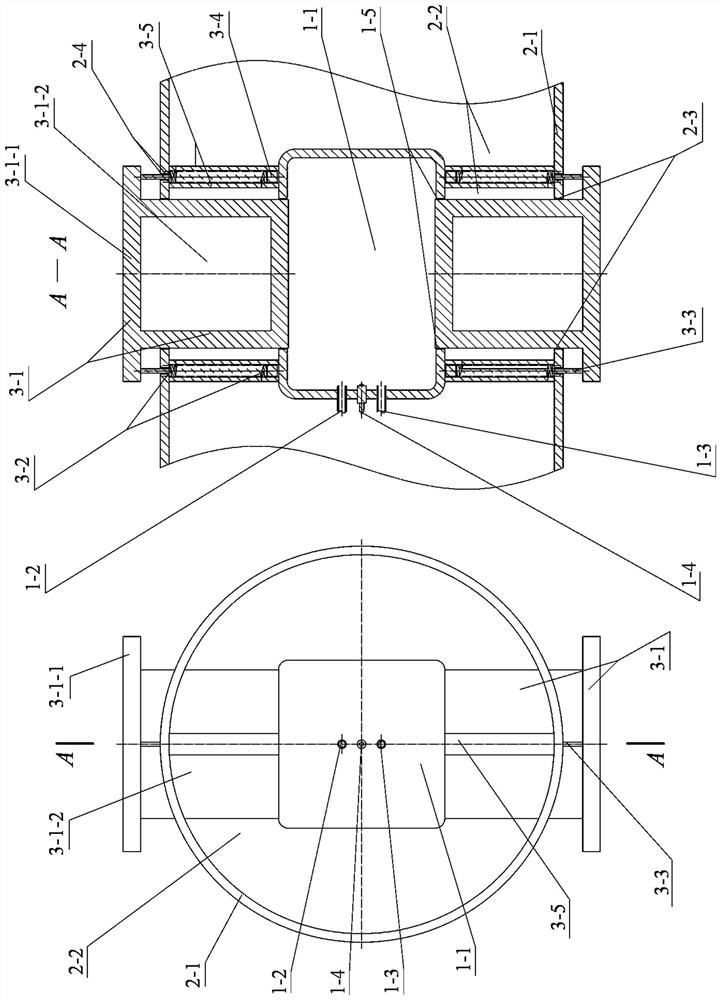

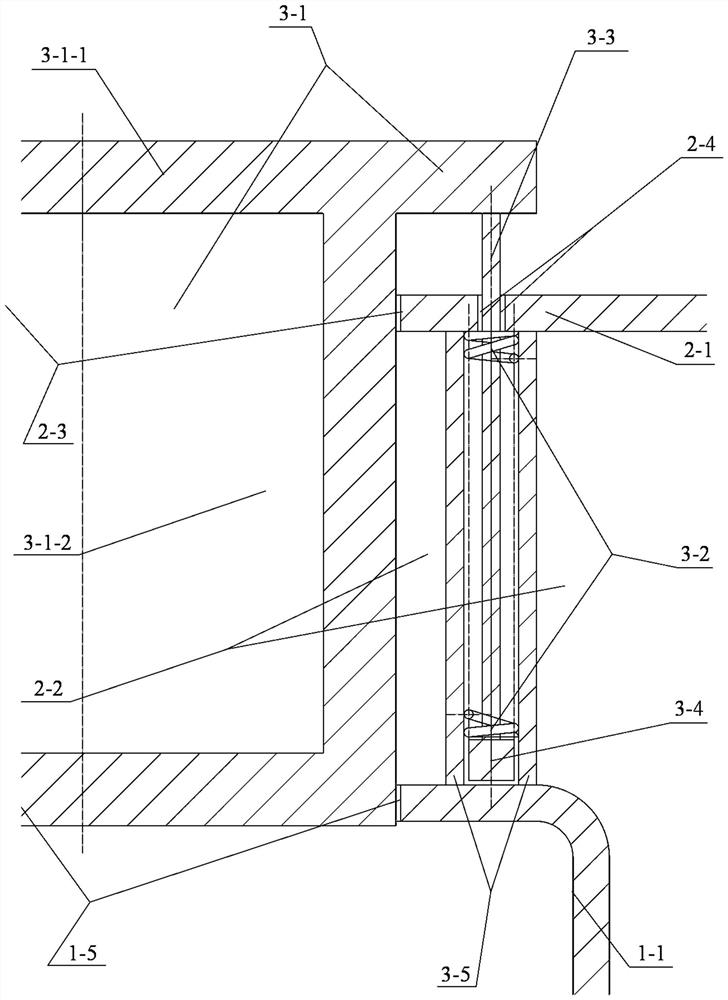

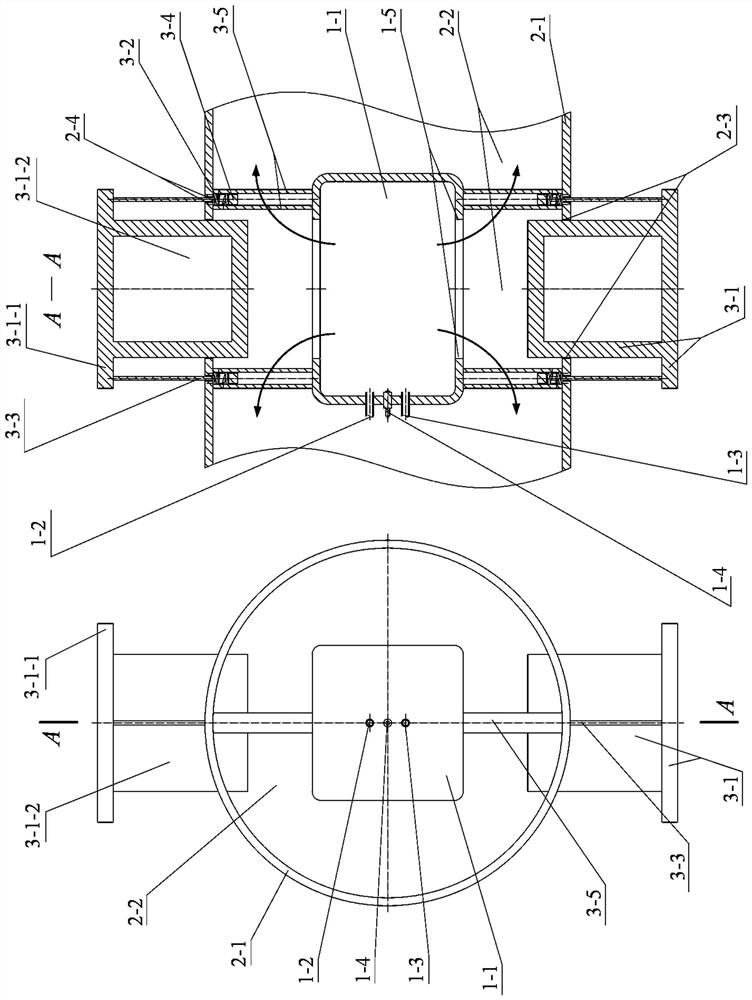

A device for low-energy ignition initiation detonation wave

ActiveCN109184950BOptimize the fuselage designIncrease the maximum operating frequencyIntermittent jet plantsDetonationEngineering

The invention provides a device for igniting detonation waves at low energies. The device comprises a pre-detonation chamber, a main detonation chamber and a piston spring actuation system. The pre-explosion chamber is composed of a cavity, an oxygen and explosive fuel injection device and a low-energy pulse igniter. Two drainage holes are formed in the wall face of the pre-explosion chamber. Themain detonation chamber surrounds the pre-detonation chamber, and two piston actuating holes are formed in the wall face of the main detonation chamber, corresponding to the positions of the drainageholes and having the same aperture; and the piston spring actuation system is arranged on the outside of the drainage holes and consists of a piston, a spring, a connecting post, a limit block and a protective sleeve, and the piston moves up and down in translation by clinging to the hole walls of the drainage holes and the piston actuation holes. According to the invention, the communication andisolation between the pre-detonation chamber and the main detonation chamber are controlled by adjusting the relative magnitude of the pressure difference between the inner and outer sides of the piston and the spring force. The detonation waves generated by low energy ignition of pure oxygen and explosive fuel in the pre-detonation chamber are transmitted into the main detonation chamber throughthe drainage holes which are opened after the piston moves upward, so as to initiate the detonation waves in the explosive mixture of the main detonation chamber.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Scramjet engine and its combustion chamber based on high repetition rate laser

ActiveCN108443913BAvoid flow lossAvoid protectionContinuous combustion chamberRamjetCombustion chamber

The invention provides a combustion chamber based on high-repetition-frequency laser and a scramjet engine. Stable flame is realized through a method of continuous breakdown of gas in supersonic-velocity gas currents through high-repetition-frequency laser pulse, so that the problems of flowing loss and heat protection caused by a mechanical flame stabilizer are effectively prevented.

Owner:NAT UNIV OF DEFENSE TECH

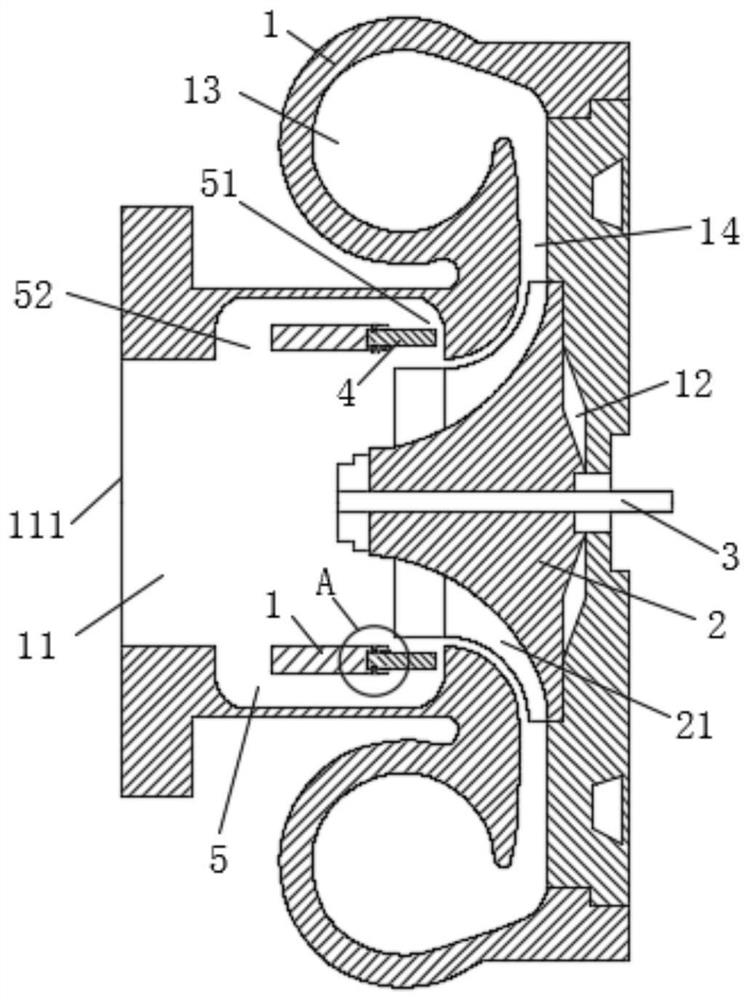

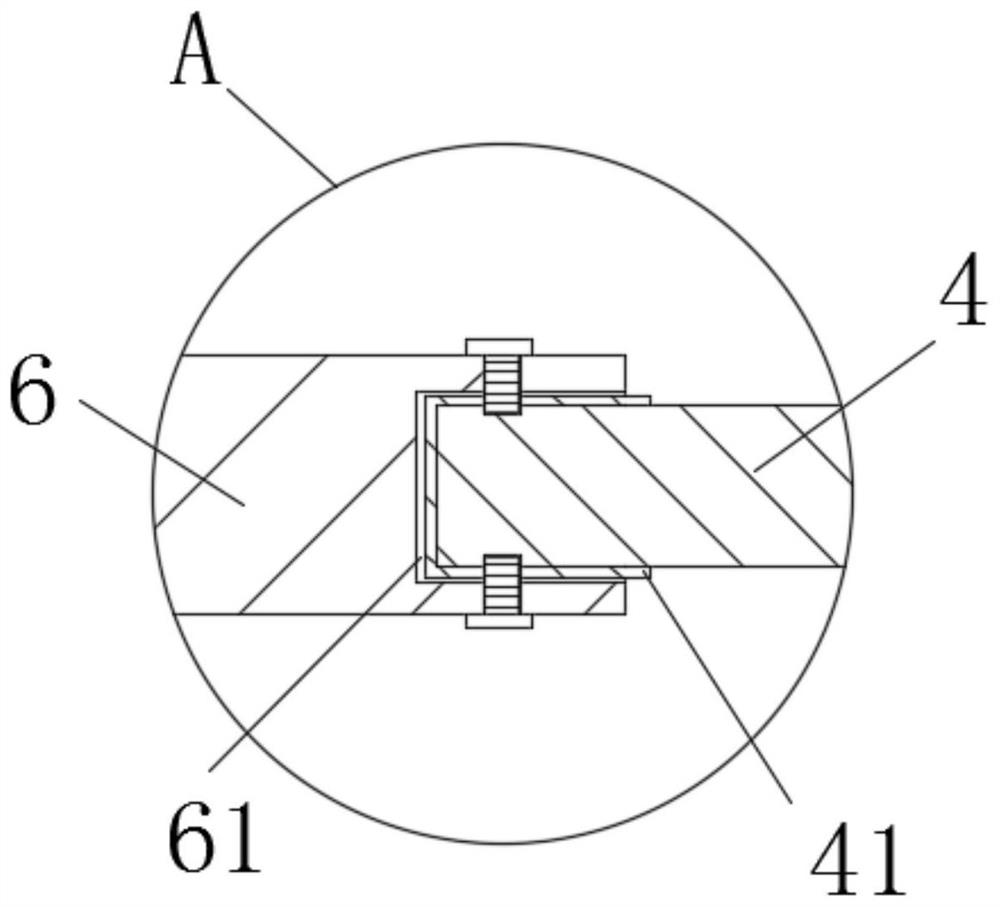

A flexible case handles a centrifugal compressor

InactiveCN109356866BImprove stable working rangeLow efficiencyPump componentsPump controlEngineeringStructural engineering

The invention discloses a flexible casing treatment centrifugal compressor. The flexible casing treatment centrifugal compressor comprises a volute and an impeller, air outlet channels are formed in the two side ends in the volute, an air inlet is formed in the position, on an air inlet channel, of the front side surface of the volute, air outlets are formed in the positions, on the air outlet channels, of the two side ends in the volute, an impeller mounting cavity communicates with the air inlet channel and the air outlet channels, casing grooves are formed in the two side walls of the air inlet channel, partition boards are transversely and fixedly arranged in the casing grooves, flexible baffles are arranged on the side surfaces of the partition boards, and gaps are formed between theouter side ends of the flexible baffles and the bottom surfaces of the casing grooves. The compressor carries out operation on the basis of not changing an original centrifugal compressor volute casing treatment mechanism, the compressor is simple and convenient, flowing losses are avoided to a certain degree while the stable work range of the centrifugal compressor is further widened, and the reduction of the efficiency of the centrifugal compressor is effectively prevented.

Owner:汪陈芳

A Design Method of Straight-arc Blade Profile of Annular Nozzle

ActiveCN107862104BGuaranteed geometric curvature continuityEasy to processGeometric CADDesign optimisation/simulationSuction forceStructural engineering

The invention discloses a method used for annular-nozzle straight-line-arc-line blade profile line design of a radial-axial-flow-type turboexpander. The method includes: dividing a blade into two parts of a suction surface and a pressure surface, also dividing a blade profile line of each part into a straight-line segment and an arc-line segment, and utilizing mathematical expressions to carry outcoordinate solving on the straight-line segment and the arc-line segment through programming. According to the method, a Bezier curve is adopted for solving for arc-line segment coordinates to realize smooth transition of the straight-line segment and the arc-line segment, thus geometric curvature continuity of the nozzle blade profile line can be well guaranteed, and more flow losses can be avoided; and in addition, the blade profile line is divided into the straight-line segment and the arc-line segment through programming, the mathematical expressions are respectively used for representation, a design process is simpler, more convenient and faster, and subsequent work processes of machining manufacturing, numerical simulation, optimization design and the like on the nozzle blade profile line are facilitated.

Owner:CHONGQING UNIV

A compact low-speed centrifugal compressor

ActiveCN112922861BSmall sizeIncrease pressure ratioPump componentsRadial flow pumpsEngineeringMechanical engineering

The invention discloses a compact low-speed centrifugal compressor, one diffuser cover plate channel corresponds to a diffuser spiral channel, and the diffuser cover plate channel is connected with the entrance of the corresponding diffuser spiral channel, and the diffuser collector A number of diffuser collector inlet channels are arranged on the inner side of the diffuser collector, one diffuser collector inlet channel corresponds to a diffuser helical channel, and one end of each diffuser collector inlet channel is connected with the outlet of the corresponding diffuser helical channel. The pressure collector is a hollow structure, and the other end of the inlet channel of the diffuser collector is connected with the diffuser collector; along the flow direction of the airflow, the cross-sectional area of the diffuser spiral channel gradually increases, and the cross-sectional area of the cover plate channel after the diffuser The area gradually increases; the diffuser collector is an equiangular helical structure, and along the spiral direction, the cross-sectional area of the diffuser collector gradually increases, and the compressor can have the characteristics of high boost and small size.

Owner:XI AN JIAOTONG UNIV

Flow- optimized fluid line

InactiveCN102679046ALow flow resistanceReduce flow lossFluid dynamicsPipe elementsSpherical sectorBiomedical engineering

Owner:NORMA GERMANY GMBH

A two-way full-flow turbine

ActiveCN110296032BGuaranteed uniformityWeaken CircumferenceHydro energy generationReaction enginesImpellerWater turbine

The invention discloses a high-performance two-way full cross flow turbine, which comprises an inlet pipe and a draft pipe connected in sequence, wherein a movable guide vane and a runner are sequentially arranged along a water flow direction on a central axis in the inlet pipe; the draft pipe comprises a first diffusion section, a second diffusion section, a third diffusion section and a fourth diffusion section, which are connected in sequence; a first deflector and a second deflector are connected along the circumference of the inner wall of the second diffusion section, and are equally spaced; the length of the first deflector is equal to that of the second diffusion section, and is greater than that of the second deflector; one end of the second deflector is located at the exit section of the second diffusion section. Unnecessary flow loss is avoided; the second deflector is away from the exit side of the runner, thus preventing from affecting stable operation caused by strong dynamic and static interference between the deflector and an impeller.

Owner:XIAN UNIV OF TECH

Ventilator

InactiveCN100434819CSpeed up the flowAvoid flow lossLighting and heating apparatusAir-flow control membersPlate heat exchangerEngineering

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

hybrid car

ActiveCN103842195BIncrease braking energyImprove efficiencyHybrid vehiclesGas pressure propulsion mountingHybrid carCombustion

A hybrid electric vehicle comprising an engine (2) together with a drive shaft (4) for driving wheels of at least one axle (7) and at least one electric motor (11, 12) for driving the vehicle A wheel of an axle or a wheel of at least one further axle (10), wherein the at least one electric machine can operate as a generator during braking and as a motor during acceleration, the hybrid vehicle also includes and A further electric machine (18) coupled to the at least one electric machine, comprising a flywheel accumulator with a rotor (14), which can be charged during braking and can be charged during acceleration is unloaded, wherein the rotor (14) can be mechanically coupled to the drive shaft (4) of the at least one axle (7) that can be driven by the engine via at least one switchable coupling device (23).

Owner:AUDI AG

Construction method of gas compressor/turbine transition runner with support plate

InactiveCN110210080APrecise constructionImprove practicalityGeometric CADSpecial data processing applicationsAxial compressorBlock effect

The invention provides a construction method of a gas compressor / turbine transition runner with a support plate. The construction method includes the steps: determining inlet and outlet arcs of the transition runner expansion surface profile according to the runner inlet and outlet states, and finding out an inscribed line of a circle where the two arcs are located to serve as a straight line section of the expansion surface profile, wherein the inlet and outlet arcs and the middle straight line section jointly form the expansion surface profile of the runner; giving normal height distributionof the runner through the height of an inlet and an outlet, then solving coordinates of corresponding points on a shrinkage surface profile till convergence is achieved, and obtaining an initial shrinkage surface profile of the runner; and finally, considering the blocking effect of the support plate, calculating the blocking area of the support plate, increasing the height of the runner to compensate the blocking of the support plate, and obtaining the corrected runner shrinkage surface line. The gas compressor / turbine transition runner with the support plate solves the problems that a construction method in the prior art is poor in practicability and not suitable for a sudden expansion type runner with an overlarge expansion angle.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com