Blast mechanism

A blower, centrifugal blower technology, applied in the direction of mechanical equipment, engine components, combustion engines, etc., can solve the problems of high load, affecting cooling efficiency, reducing the economy of working instruments, etc., and achieve the effect of reducing flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

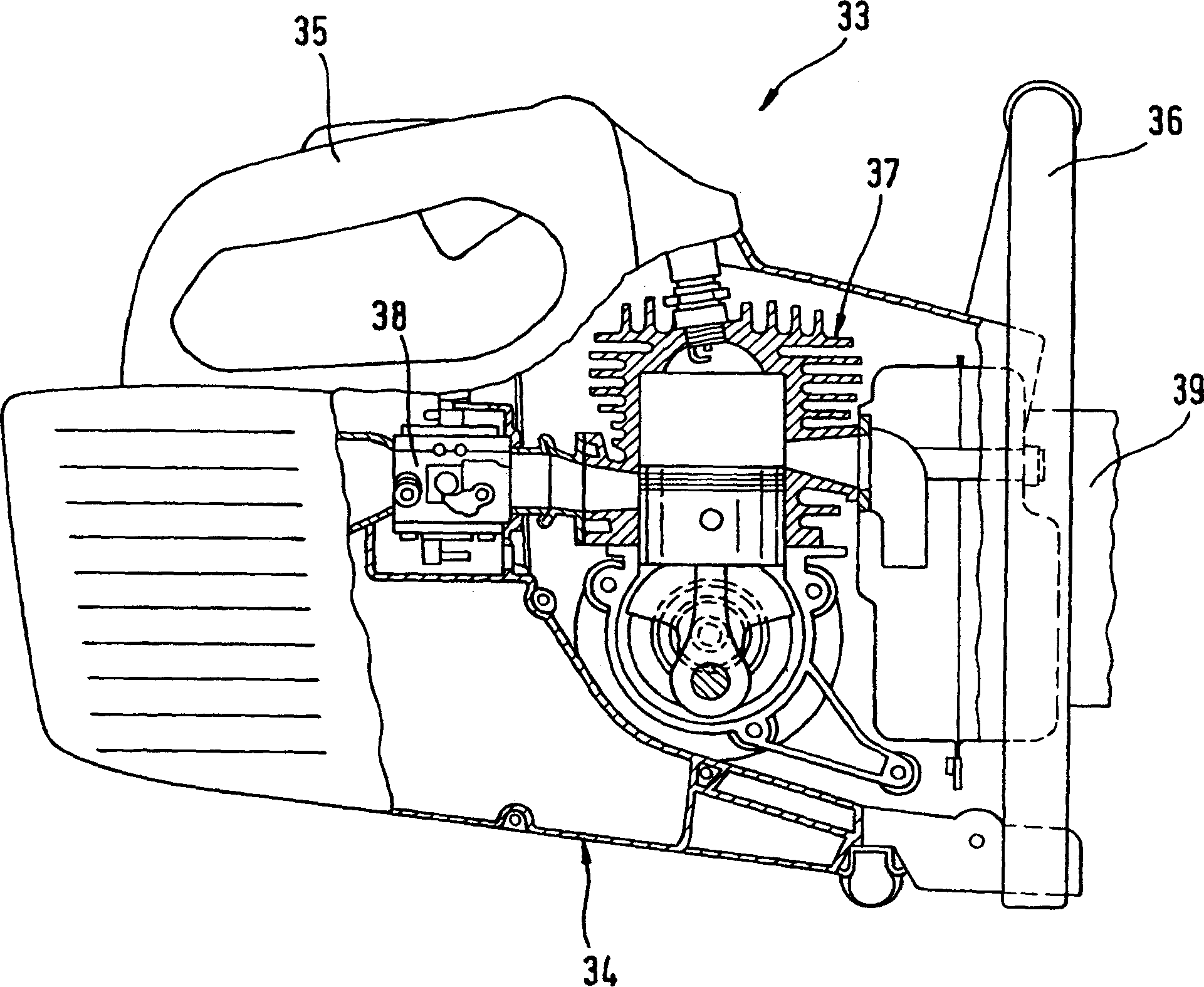

[0022] figure 1 A partial cross-sectional view of a working instrument 33 is shown. The working instrument includes a housing 34 with an internal combustion engine 37 inside and a tool 39 driven by the internal combustion engine. An upper handle 35 and a front handle 36 are provided on the housing. In front of the internal combustion engine 37 is a vaporizer.

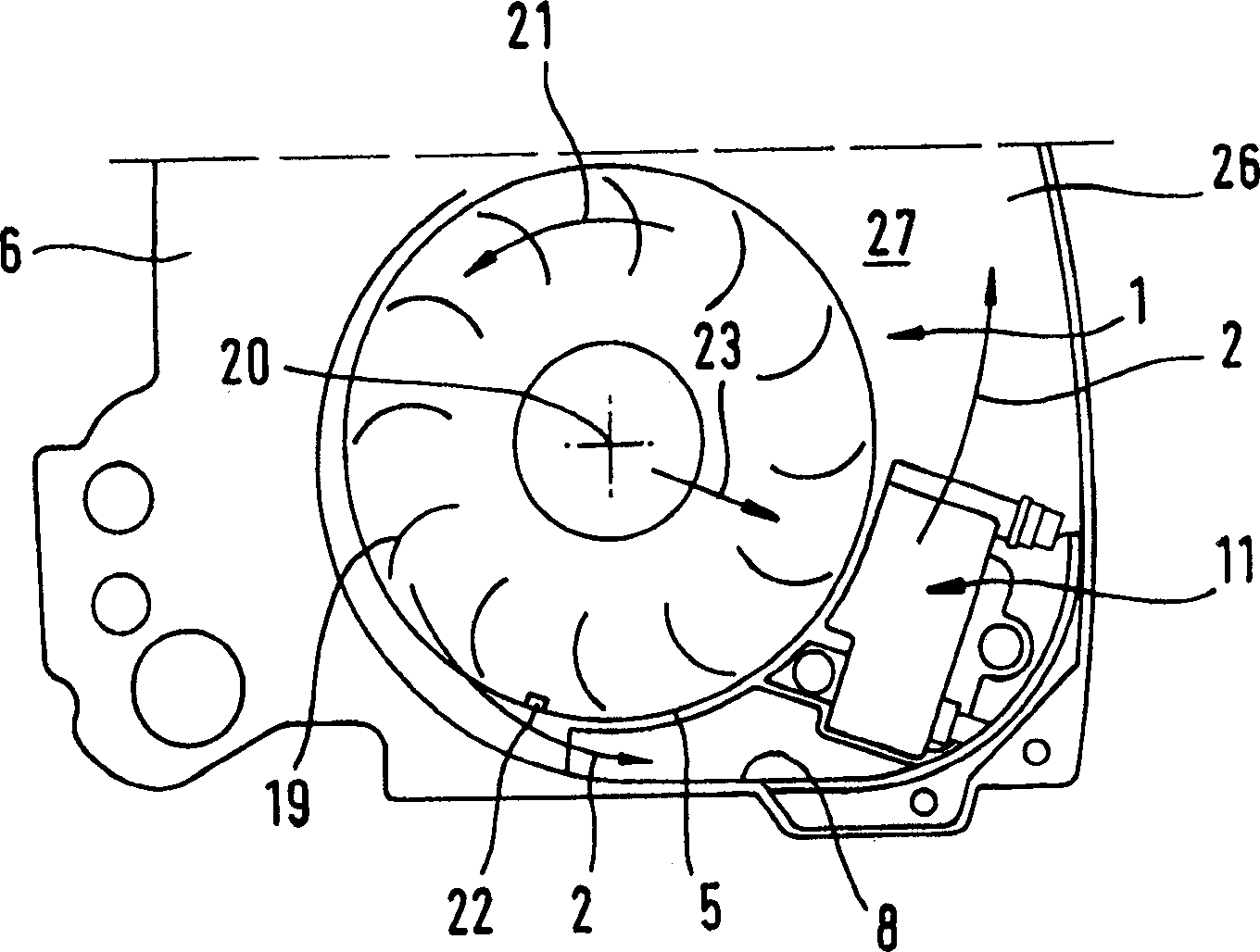

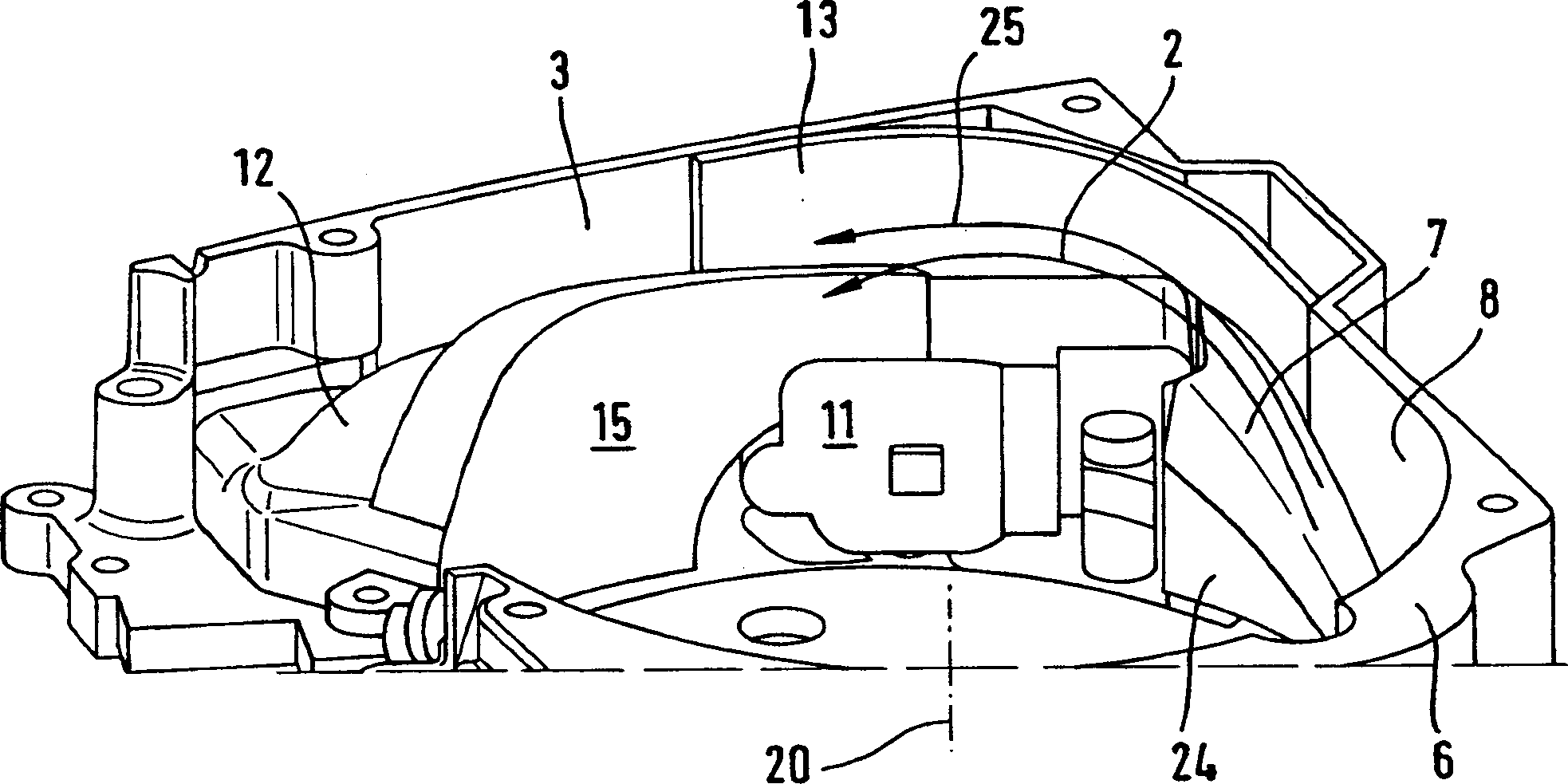

[0023] figure 2 A schematic diagram of the main components of a centrifugal blower 1 is shown. The centrifugal blower includes a blower wheel 5 and a spiral blower housing 6 that at least partially surrounds the blower wheel 5. For the sake of clarity, only an open half shell is shown for the blower housing 6, which constitutes an end wall 27 located in the plane of the blower wheel 5 and a spiral shape located radially outside of the blower wheel 5. Expanded peripheral wall 8.

[0024] The blower wheel 5 has a plurality of blades 19 and is rotatably supported around a rotating shaft 20. Through the rotation of the blow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com