A two-way full-flow turbine

A technology of turbines and flowing water, applied in mechanical equipment, hydroelectric power generation, engine components, etc., can solve the problems of low reverse energy conversion efficiency and large pressure pulsation, so as to improve reverse energy conversion efficiency, reduce pressure arteries, and avoid flow loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

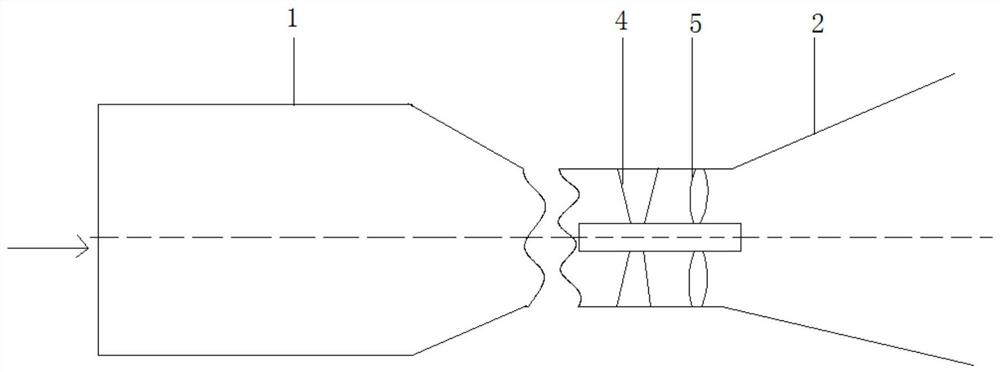

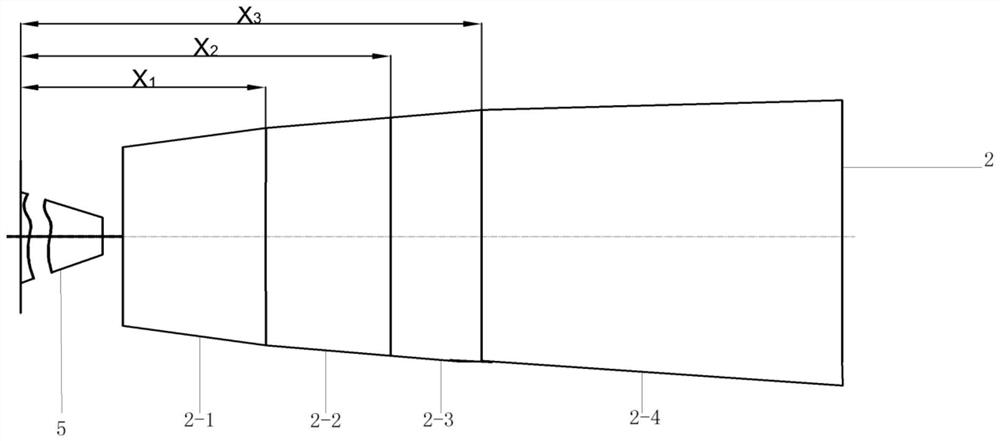

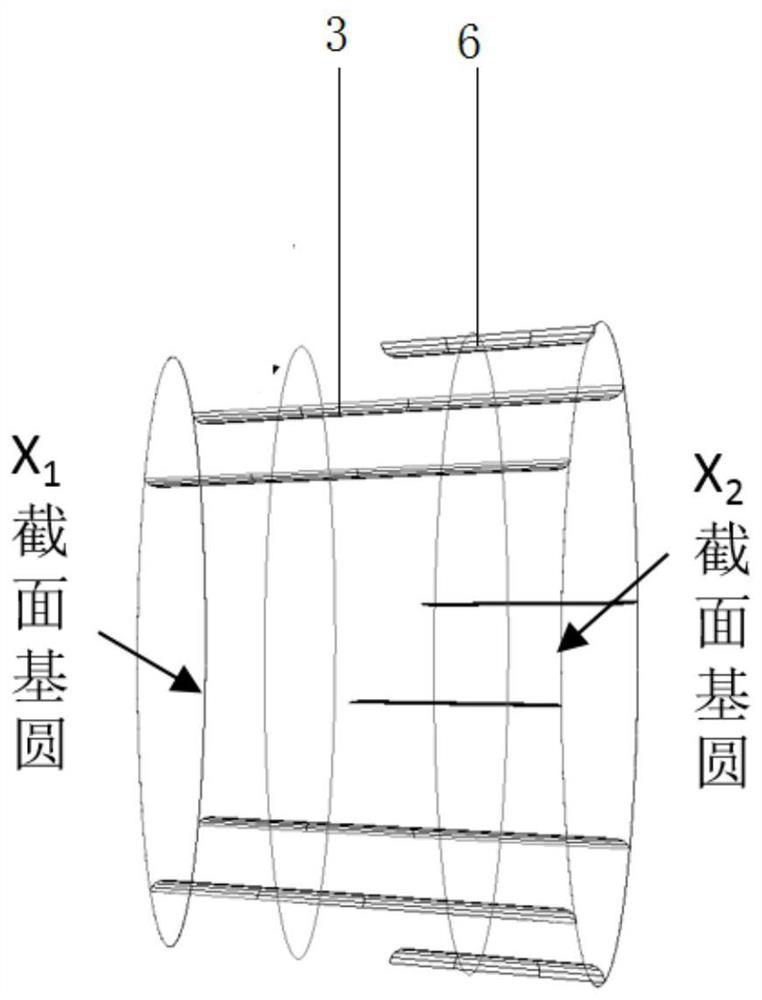

[0019] A two-way full-through flow turbine, such as figure 1 As shown, it includes an inlet pipe 1 and a draft pipe 2 connected in sequence, and movable guide vanes 4 and runners 5 are sequentially arranged on the central axis of the inlet pipe 1 along the direction of water flow; figure 2 As shown, the draft tube 2 includes a first diffuser section 2-1, a second diffuser section 2-2, a third diffuser section 2-3 and a fourth diffuser section 2-4 connected in sequence, as image 3 As shown, the first deflector 3 and the second deflector 6 are connected along the circumference of the inner wall of the second diffusion section 2-2, which is determined by the flow characteristics of the fluid in the draft tube. For draft tubes of different models, The best effect is to place the deflector on the second diffuser section 2-2; the first deflector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com