Multi-way valve, fluid circuit and cooling fluid circuit

A technology for cooling fluid and fluid circuits, applied in the field of multi-way valves, which can solve problems such as incomplete radial extension of guides, closure, flow loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

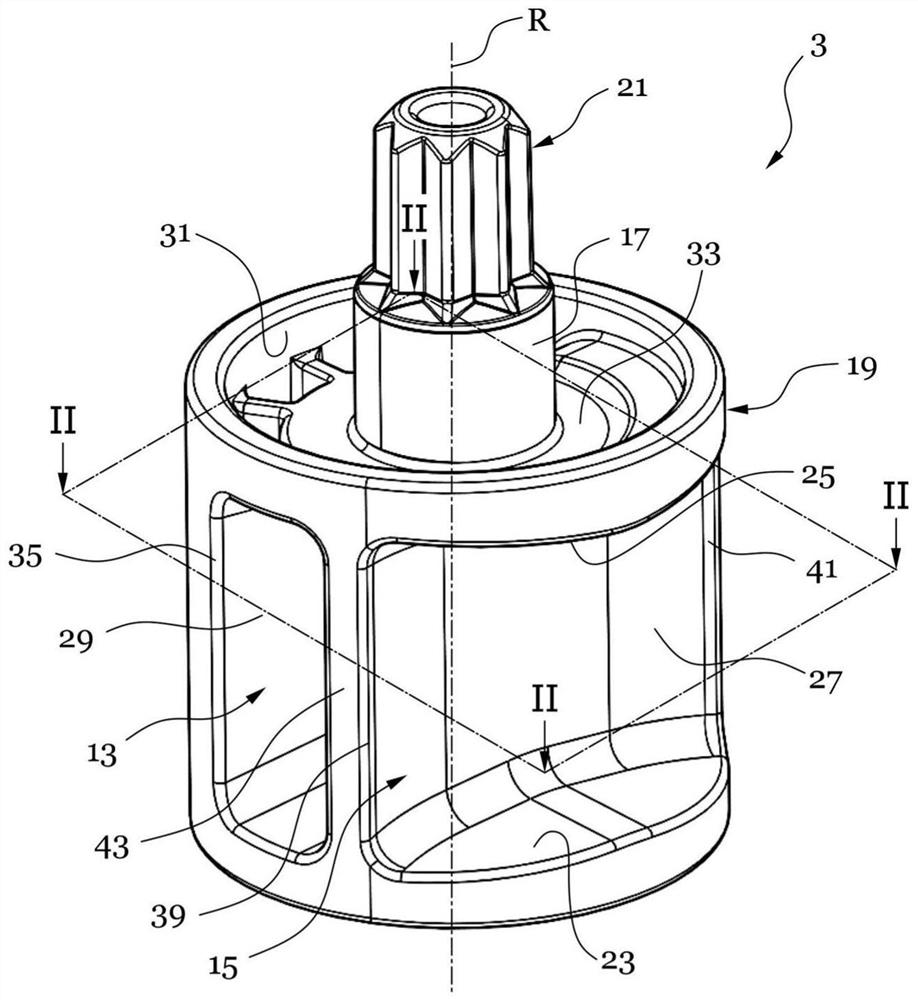

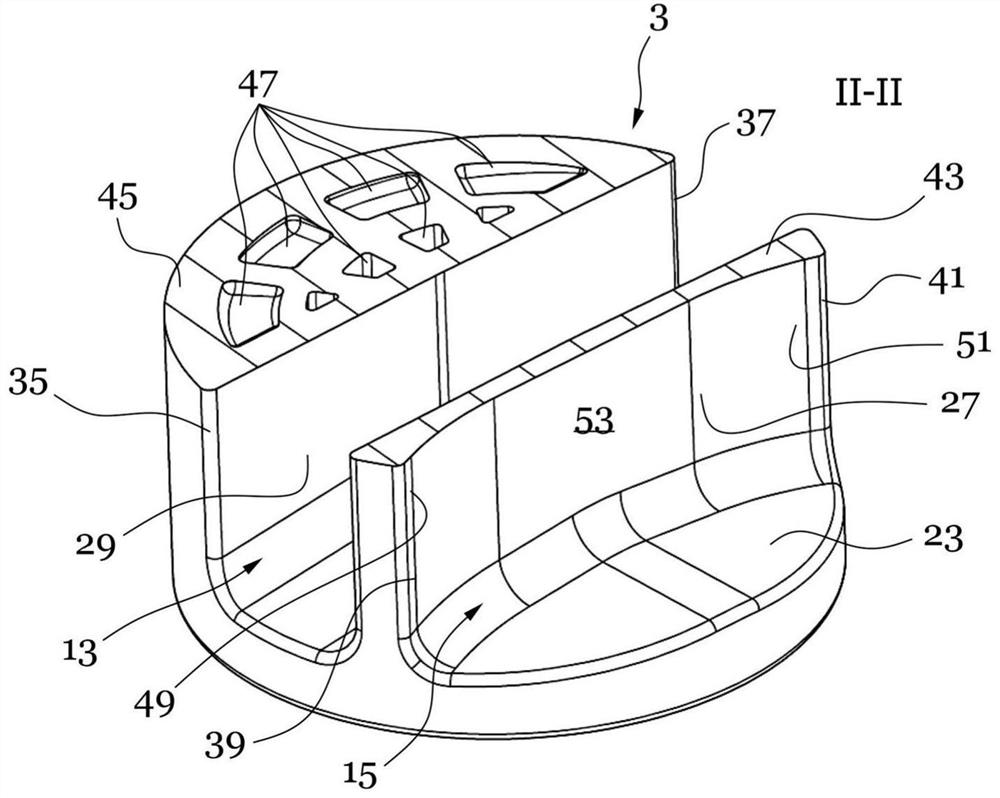

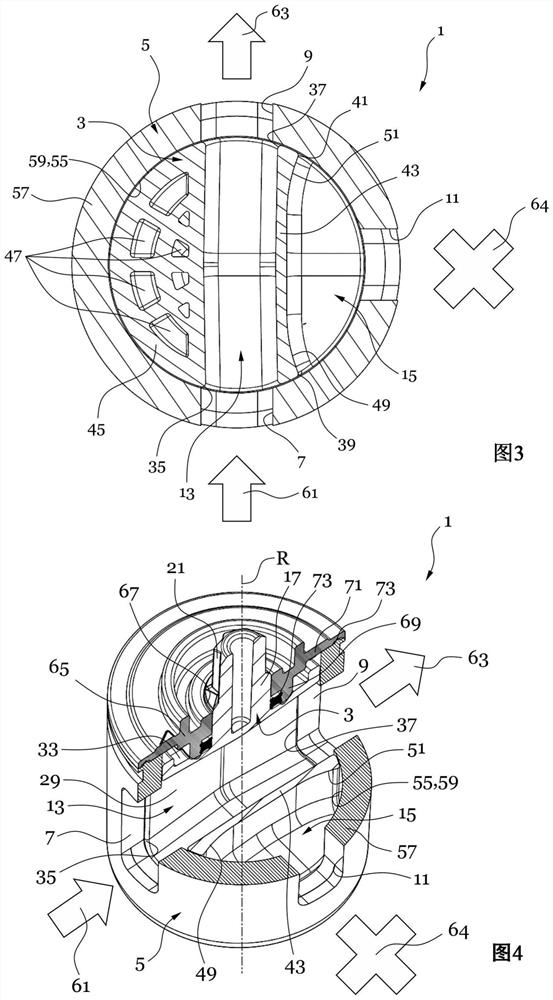

[0035] In the following description of exemplary embodiments of the multiport valve according to the invention and the fluid circuit according to the invention, the multiport valve according to the invention is generally designated with reference numeral 1 , while the fluid circuit according to the invention is generally Reference numeral 100 is provided. according to Figure 1 to Figure 8 The multi-way valve 1 shown in the exemplary embodiment of FIG. 1 is used to control fluid flow in a fluid circuit 100, which may be, for example, a cooling device circuit of a motor vehicle. For example, the multiport valve 1 is preferably produced from plastic by means of a plastic injection molding process. Alternatively, it is conceivable for the multiport valve 1 to be produced, for example, from metal according to known production techniques. Reference basis Figure 1 to Figure 6 An exemplary embodiment of a multiport valve 1 according to the invention is shown. refer to Figure 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com