Annular-nozzle straight-line-arc-line blade profile line design method

A technology of annular nozzle and blade profile, which is applied in the field of annular nozzle blade profile design, can solve the problems that are not conducive to blade profile processing and manufacturing, numerical simulation and optimal design, the process of modifying profile is cumbersome and complicated, and it is difficult to ensure the straight line and Problems such as smooth transition of arc segments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] Below in conjunction with embodiment the present invention will be further described, but should not be interpreted as the above-mentioned scope of the present invention is limited to following embodiment. Without departing from the above-mentioned technical idea of the present invention, various replacements and changes can be made according to common technical knowledge and customary means in this field, and all should be included in the protection scope of the present invention.

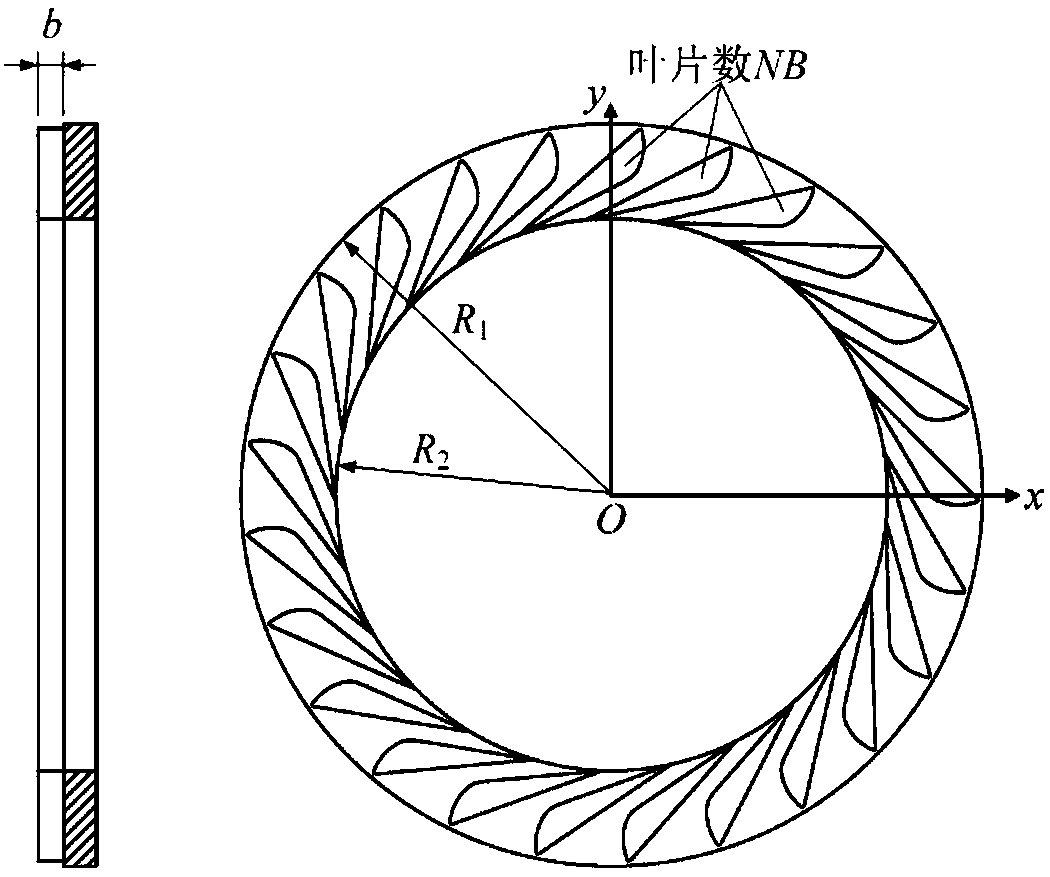

[0080] This embodiment takes a turboexpander supporting a certain low-pressure air separation process as an example. The design parameters of the turboexpander and the main structural dimensions of the impeller are shown in Table 1, and the gas is discharged in the axial direction.

[0081] Table 1 Turboexpander design parameters and main structural dimensions of the impeller

[0082]

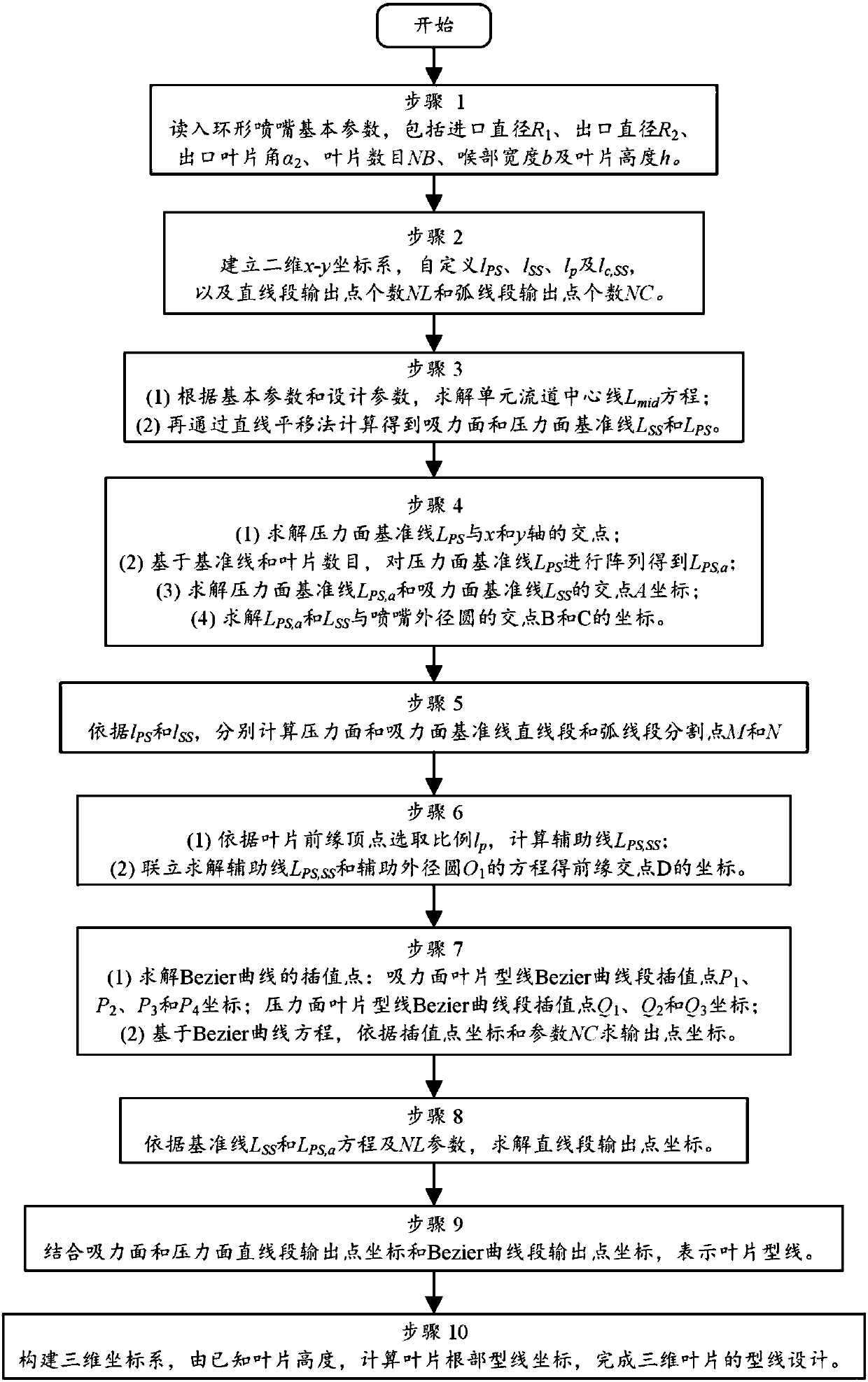

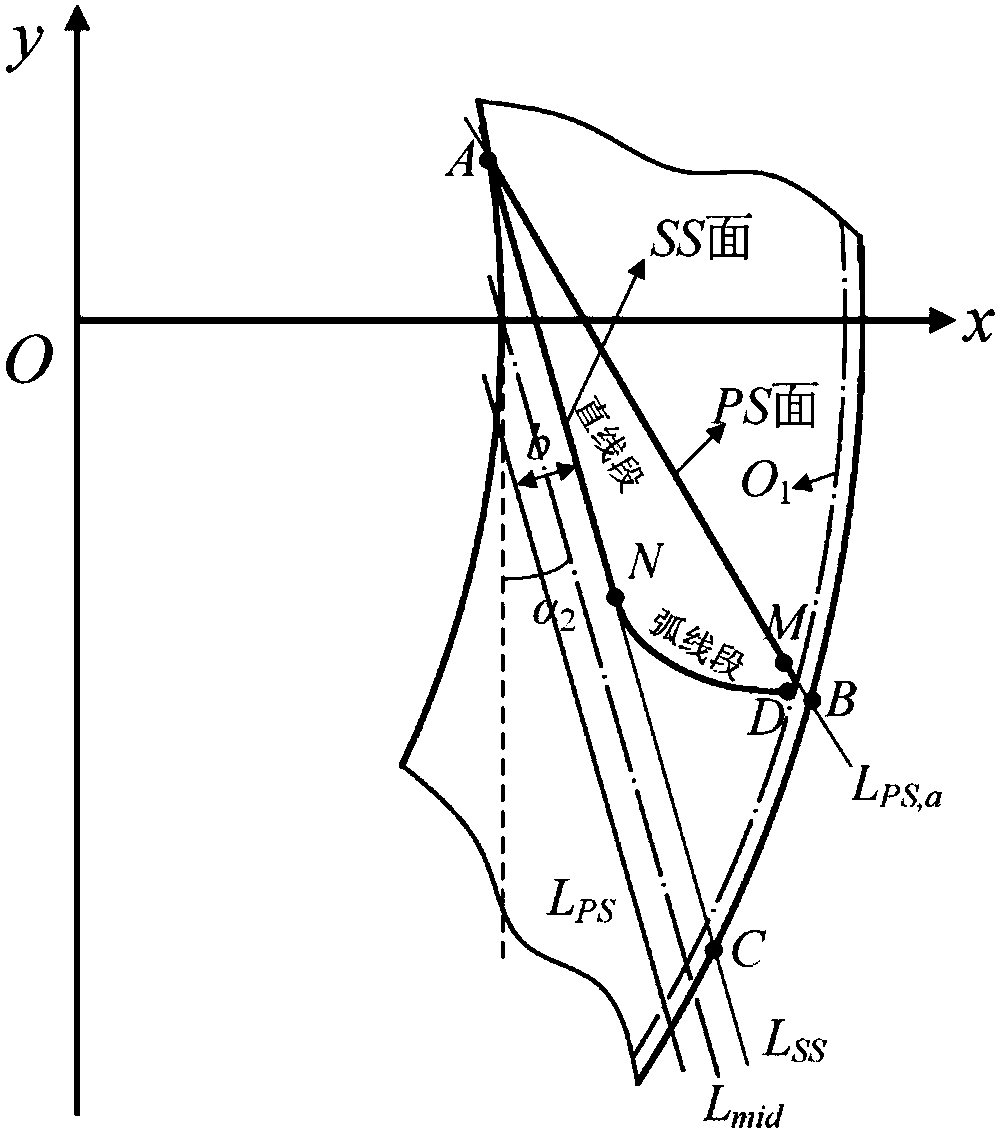

[0083] Design according to the following steps (in the parameters, use "1" to indicate the inlet, "2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com