Shuffling device and transferring method for turnout switch rails and stock rail assemblies on bridge

A technology of sliding device and transfer method, which is applied in roads, tracks, laying tracks, etc., and can solve problems such as difficult control of deflection deformation, hidden quality problems, and increased difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

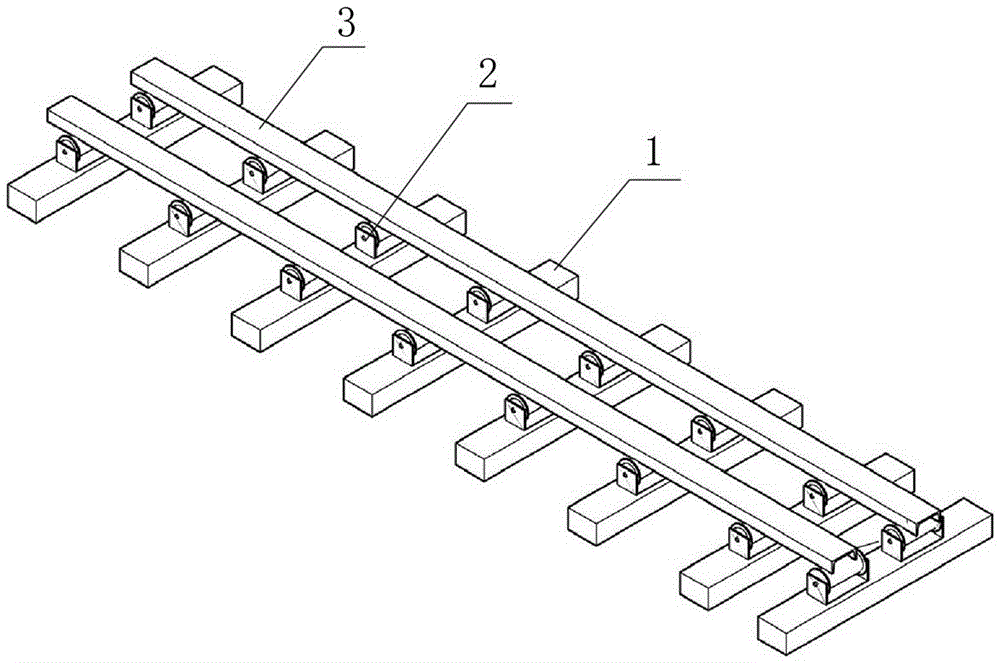

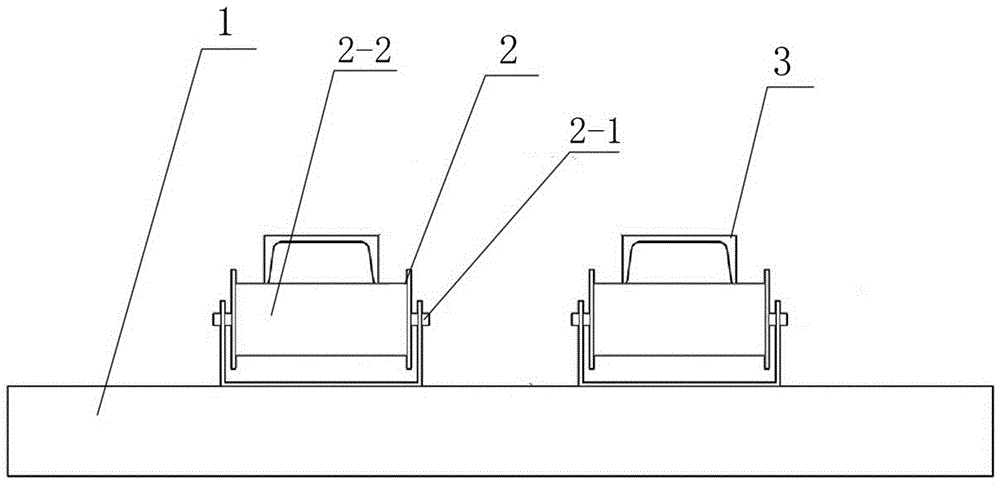

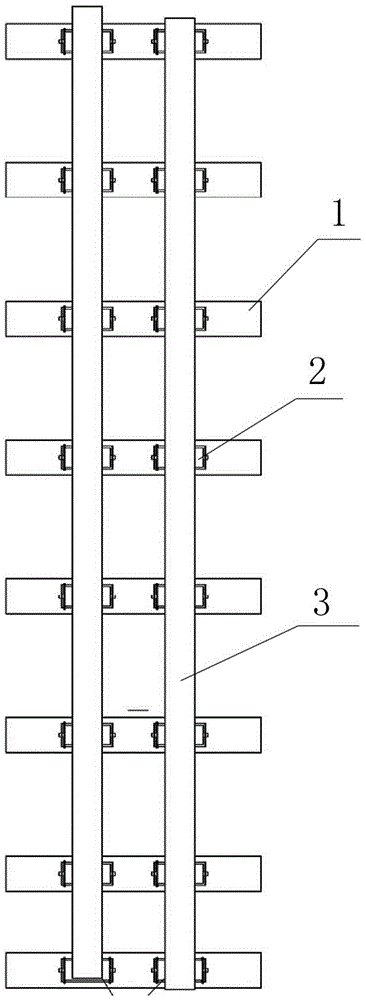

[0025] like figure 1 , figure 2 , image 3 , Figure 4 Shown, the present invention is to set its length direction vertically with the track vertical some square wood 1 on the bridge turnout construction working face, and every square wood 1 is all provided with two roller assemblies 2 above the length direction, all square woods 1 The two roller assemblies 2 on the wood 1 are equally spaced and have consistent margins. The roller shafts 2-1 of the two roller assemblies 2 on a square log 1 are coaxial and the axis is at the centerline of the length direction of the square log 1 . The roller assemblies 2 on all square logs 1 are arranged in two rows by the longitudinal straight line of the track. A sliding steel beam 3 is respectively overlapped on the rollers 2-2 of the two rows of roller assemblies 2 . All square logs 1 and the roller assembly 2 installed thereon form a rolling structure. Two sliding steel beams form the mobile platform. The rolling structure and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com