Blade profile receiving hole structure for prewhirl cooling system

A cooling system and hole structure technology, applied in the cooling of the engine, the cooling of the turbine/propulsion device, the engine components, etc., can solve the problem that the flow coefficient of the downstream blade air supply holes is reduced, the flow loss is large, the flow coefficient is low, and the temperature drop of the pre-swirl system. The problem of deterioration of characteristics, etc., can achieve the effect of increasing nozzle pressure ratio, reducing flow loss and reducing flow loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

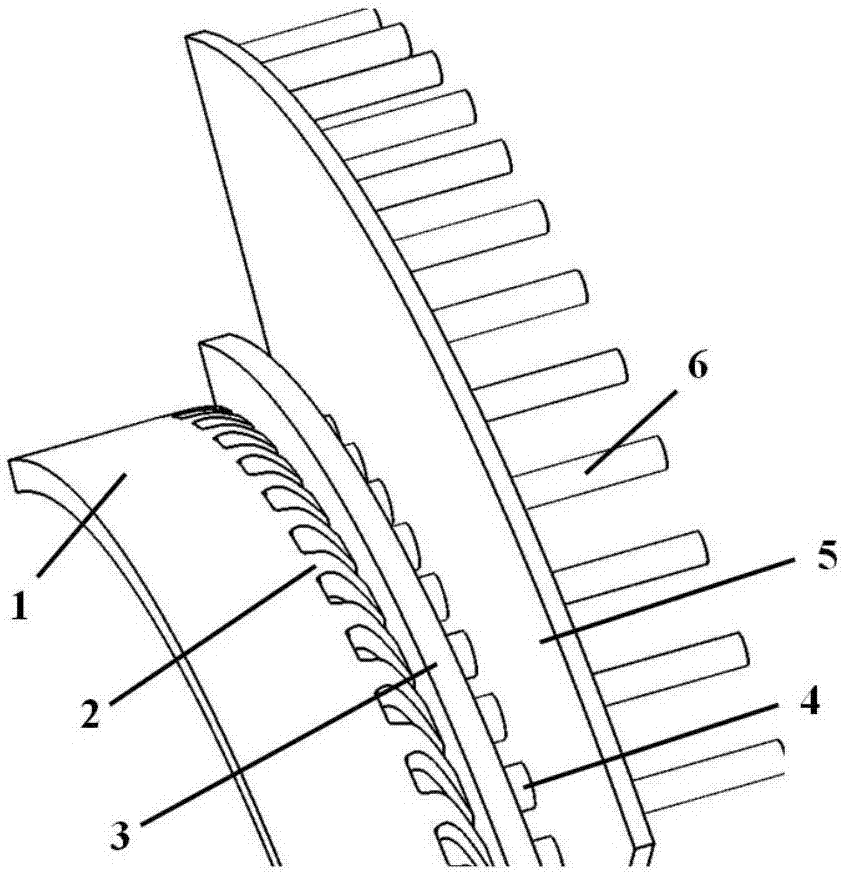

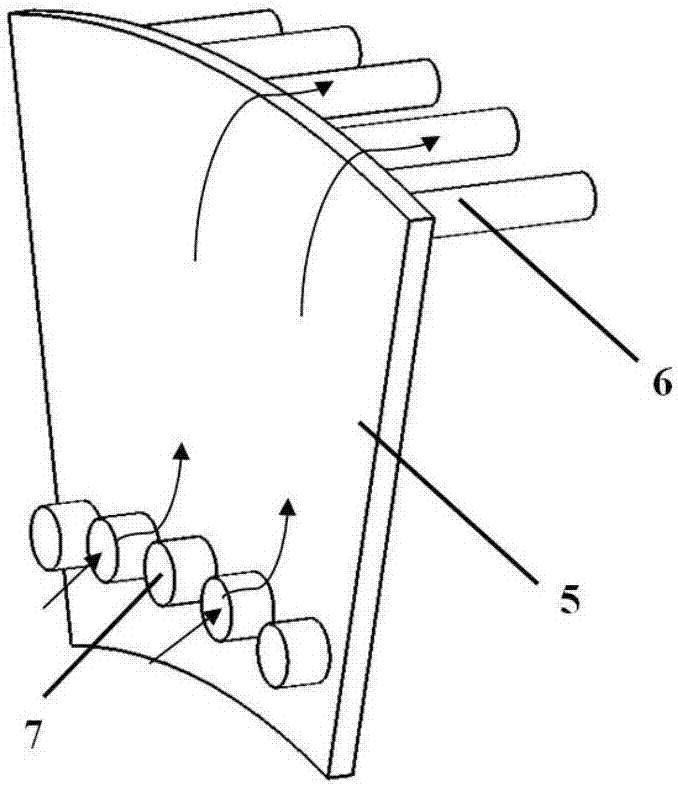

[0026] Example 1: figure 1 For the pre-rotation system structure. The pre-swirl system is composed of the air inlet chamber 1, the pre-swirl nozzle 2, the pre-swirl chamber 3, the receiving hole 4, the cover plate chamber 5 and the blade air supply hole 6. In the pre-rotation system, the inlet pressure of the air intake chamber 1 is the bleed air pressure of a certain stage of the compressor, which is basically a constant value; the outlet of the pre-rotation system is the blade air supply hole 6, and its pressure is basically a constant value. The air intake chamber 1 and the pre-rotating nozzle 2 are stationary parts, the receiving hole 4 and the blade air supply hole 6 are rotating parts; the pre-rotating chamber 3 is a rotary-static system, and the cover cavity 5 is a rotary-rotary system. The air inlet cavity 1, the pre-rotating nozzle 2, and the receiving hole 3 have the same radial position, and the air flow flows radially outward in the cover plate cavity 5 and flows ...

Embodiment 2

[0030]Embodiment 2: For a certain type of low-level cover plate type pre-rotation system, comparative analysis of the performance difference between the traditional axial straight-through receiving hole and the airfoil receiving hole; the geometric parameters of the pre-rotation system are shown in the following table.

[0031]

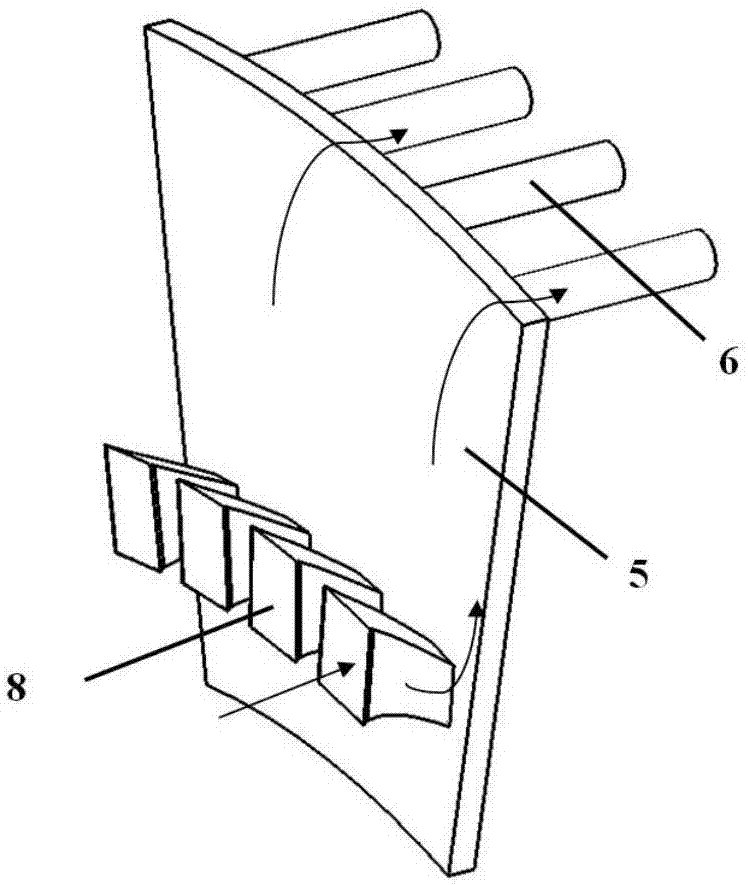

[0032] According to the CFD numerical simulation, the velocity streamline diagram of the axial straight-through receiving hole and the velocity streamline diagram of the airfoil receiving hole can be obtained. From Figure 7 It can be seen from the figure that the inlet of the axial straight-through receiving hole hinders the airflow, and an obvious vortex will be generated near the leeward side of the receiving hole, which will increase the flow loss inside the receiving hole and lead to a decrease in the flow coefficient. In the airfoil receiving hole, the proper air intake angle enables the air flow to flow into the receiving hole smoothly, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com