Lint cotton opening device

A technology of opening device and lint, applied in fiber opening and cleaning machines, opening and cleaning with toothed tools, sustainable manufacturing/processing, etc., can solve the problems of high cotton fiber damage rate, small amount, low efficiency of lint opening speed, etc. problem, to achieve the effect of good preservation and little damage to cotton fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

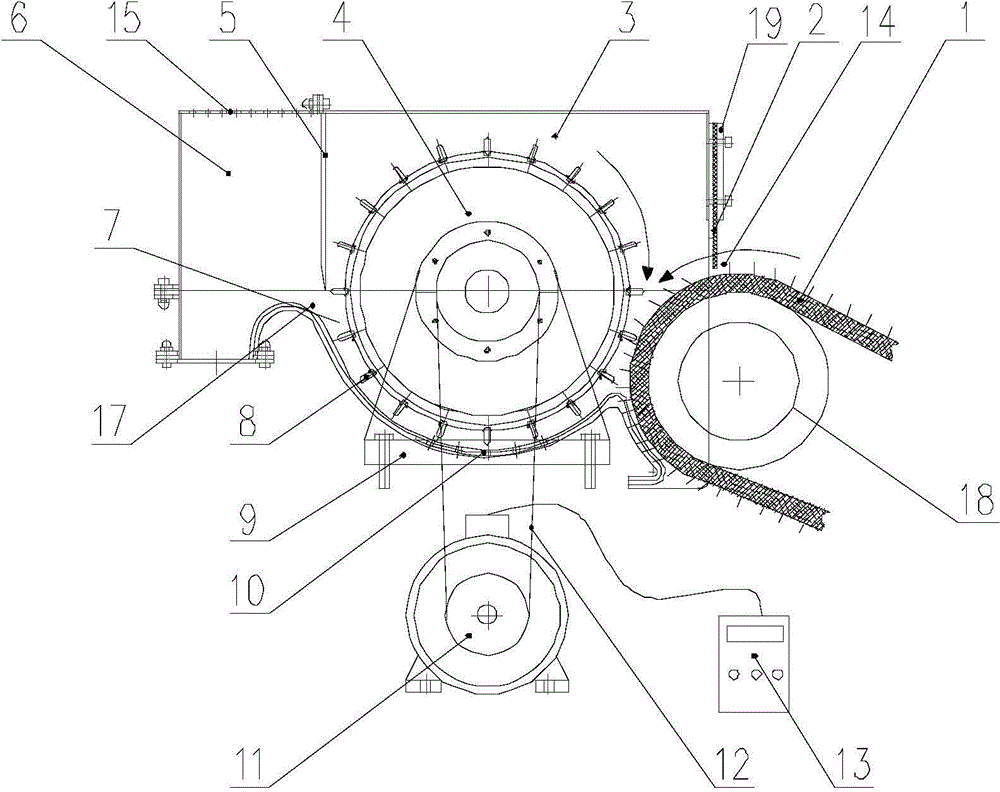

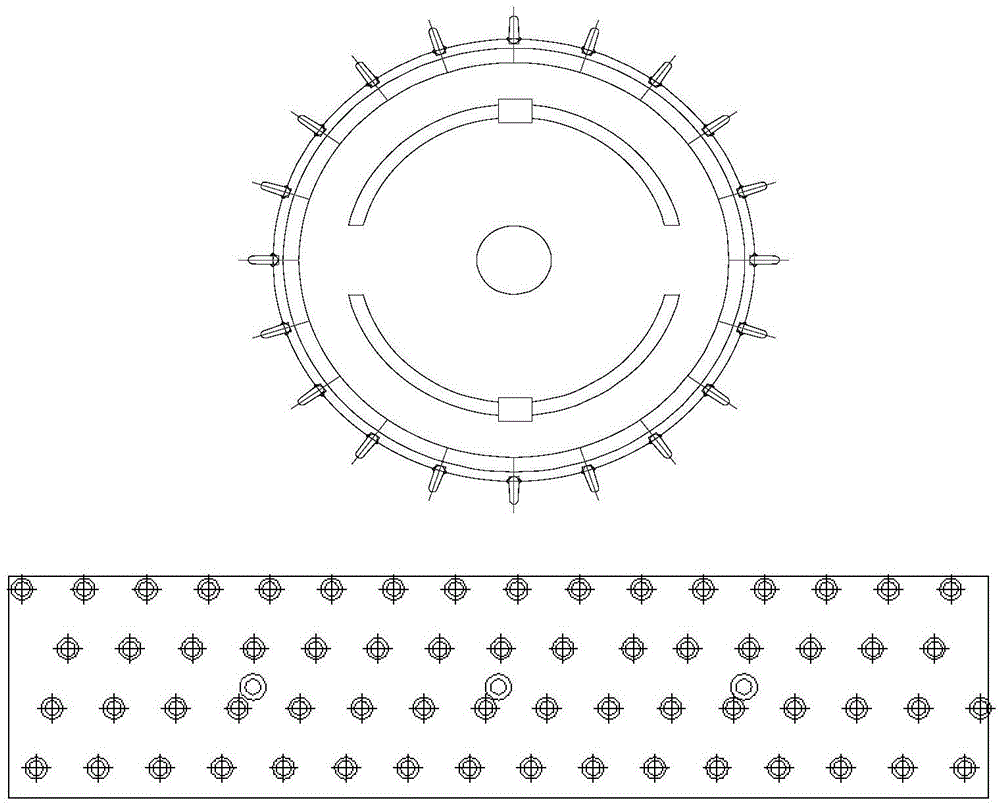

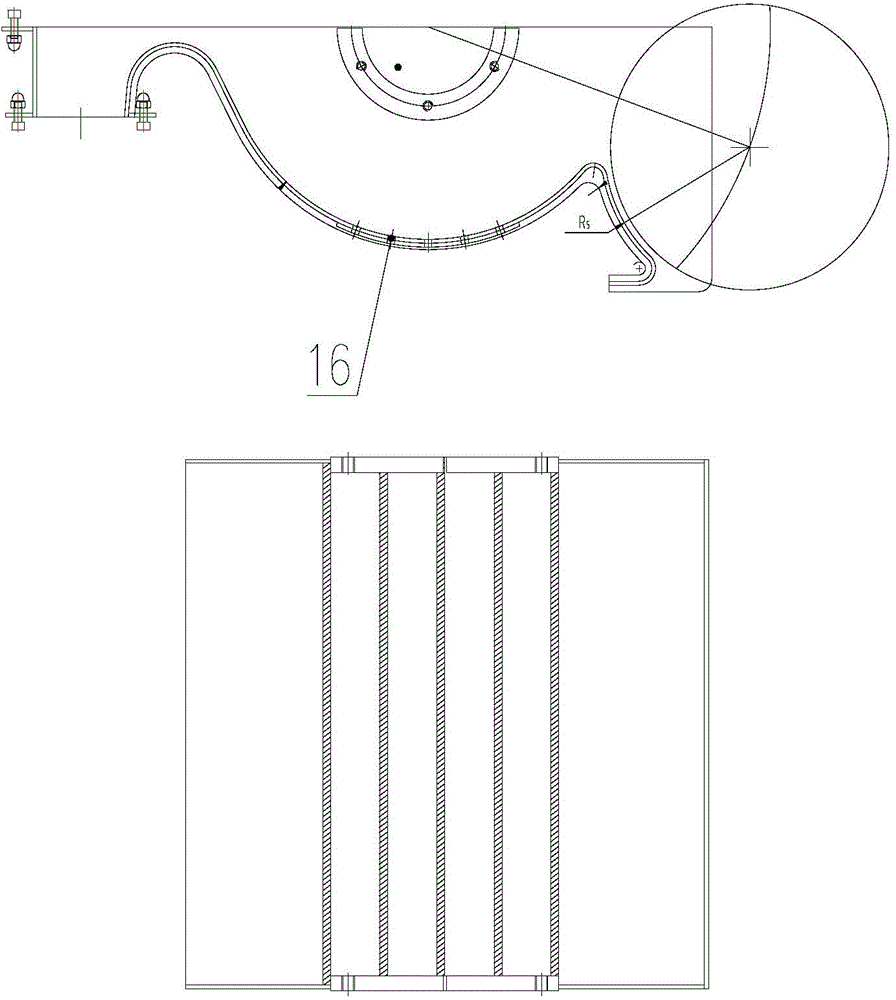

[0020] The upper opening shell 3 and the lower opening shell 7 are connected together with the perforated bolts of the sealing rubber pad to form the opening shell; the opening shell is a square shell composed of the upper opening shell and the lower opening shell. The ears on both sides are fixed on the frame; the throwing curve 6 is installed on the outlet side of the opening shell, the opening roller 4 is located in the middle part of the opening shell shell, one end of the opening roller is equipped with a pulley, the opening roller and the frequency conversion The motor 11 is connected through the belt 12, and the variable frequency motor is connected with the frequency converter 13; the opening roller is supported by the opening roller bearing seat 9 and connected on the frame; the nail conveyor belt 1 is installed on the inlet side of the shell opening; On the conveyor belt frame composed of the driving roller 18 and the driven roller; one end of the driving roller goes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com