Device for transporting track sections or mounted track connections

A track connection and pre-assembly technology, which is applied in the direction of transportation and packaging, track, transport passenger cars, etc., can solve the problems of high cost, inability to match or adjust low-platform vehicles, and inability to match or adjust existing flat-bed vehicles, etc., to achieve reliable Load bearing structure, effect of simple load bearing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

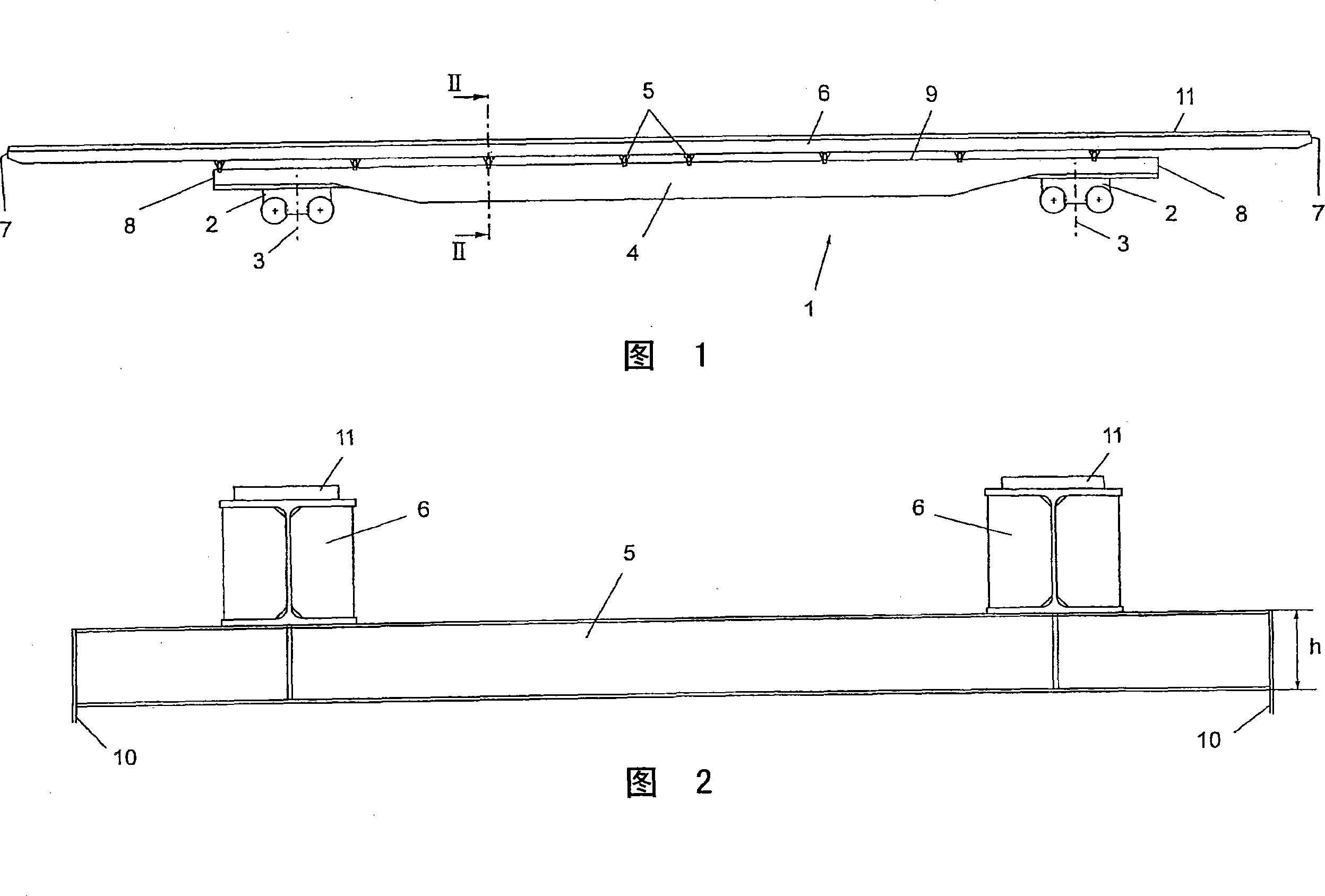

[0012] As shown in FIG. 1 , a chassis 2 of a flatbed vehicle 1 is connected to the platform in a manner that is rotatable about a vertical axis 3 . The support or support 5 is arranged on the platform 4 transversely to the flatbed vehicle 1, and the longitudinal beam 6 is fixed on the support or support. The free end 7 of the stringer protrudes forward beyond the corresponding end 8 of the flatbed vehicle 1, while the height of the support or bracket 5 ensures that the free end 7 of the stringer 6 does not collide with the upper surface of the adjacent flatbed vehicle platform 4. Edge 9 collides.

[0013] The load-bearing structure shown in FIG. 2 is composed of a support and a longitudinal beam, that is, an enlarged cross-sectional view cut along the section line II-II in FIG. 1 , in which h represents the height of the support 5 . This height must ensure that the protruding end 7 of the longitudinal beam 6 does not collide with the adjacent platform. move. A backing plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com