Print head module and label printer

A printing head mold and printing head technology, which is applied in the field of printing head modules and label printers, can solve problems such as product reliability reduction, printing quality impact, user troubles, etc., achieve force balance, ensure deflection, and improve reliability and operability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

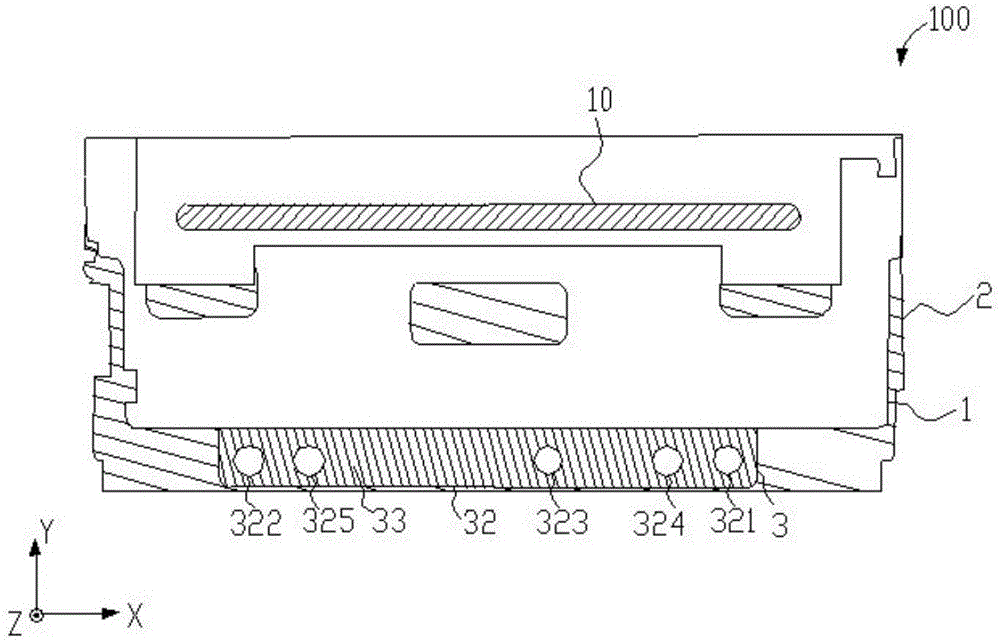

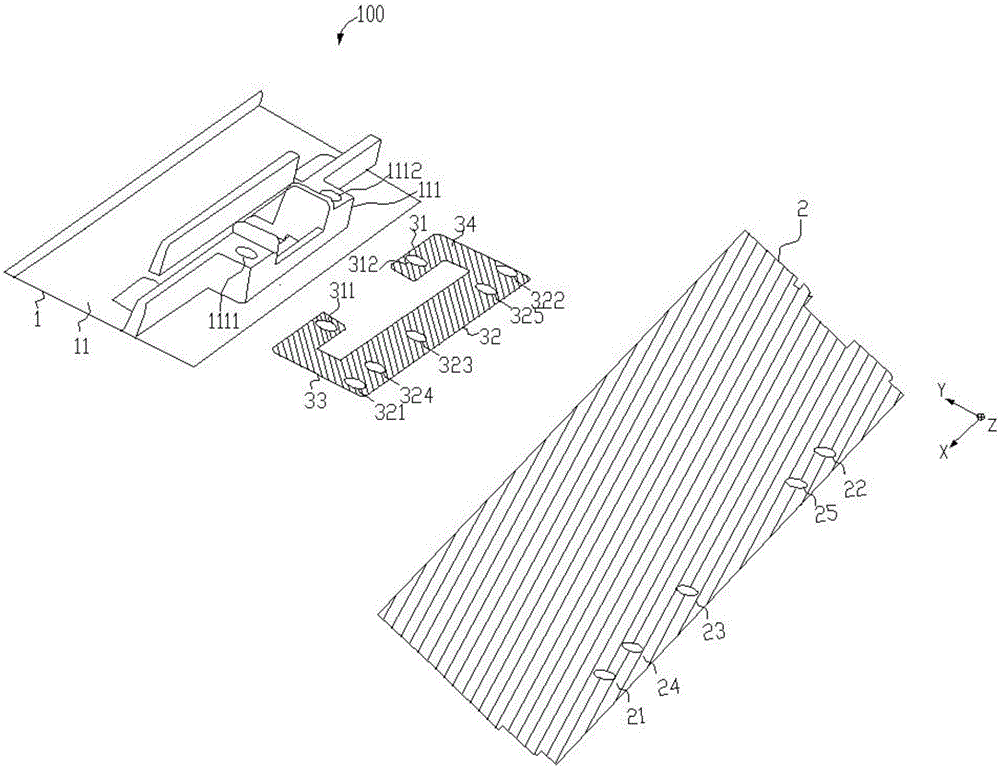

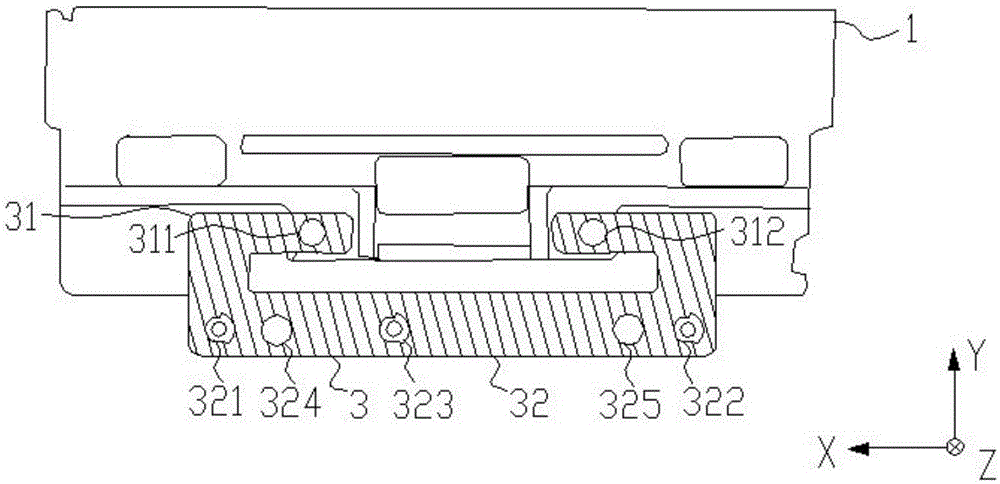

[0041] see Figure 1 to Figure 9As shown, a schematic structural diagram of the print head module 100 of the present invention is disclosed. The print head module 100 includes a flat plate 1 , a fixing frame 2 and an elastic piece 3 . The tablet 1 has a printing head 10 and a first surface 11 , the first surface 11 has a mounting portion 111 , and the printing head 10 is disposed on the surface of the tablet 1 away from the first surface 11 . The fixing frame 2 is used to be fixedly connected with the main body of the label printer. The print head 10 is preferably a thermal print head, but not limited thereto. The elastic piece 3 is disposed between the flat panel 1 and the fixing frame 2 for realizing the connection between the flat panel 1 and the fixing bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com