Crown turbine with margin plate step casing

A technology of edge plates and steps, which is applied in the field of shrouded turbines, can solve the problems of increasing the structural quality of the shroud, the control effect is small, and the blade stress is increased, so as to improve the negative impact, reduce the mixing loss, increase the The effect of flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be described clearly and completely below with reference to the accompanying drawings in the embodiments of the present invention.

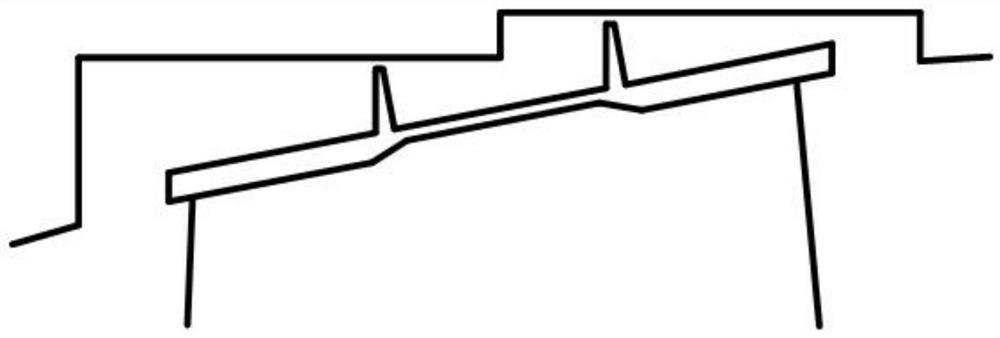

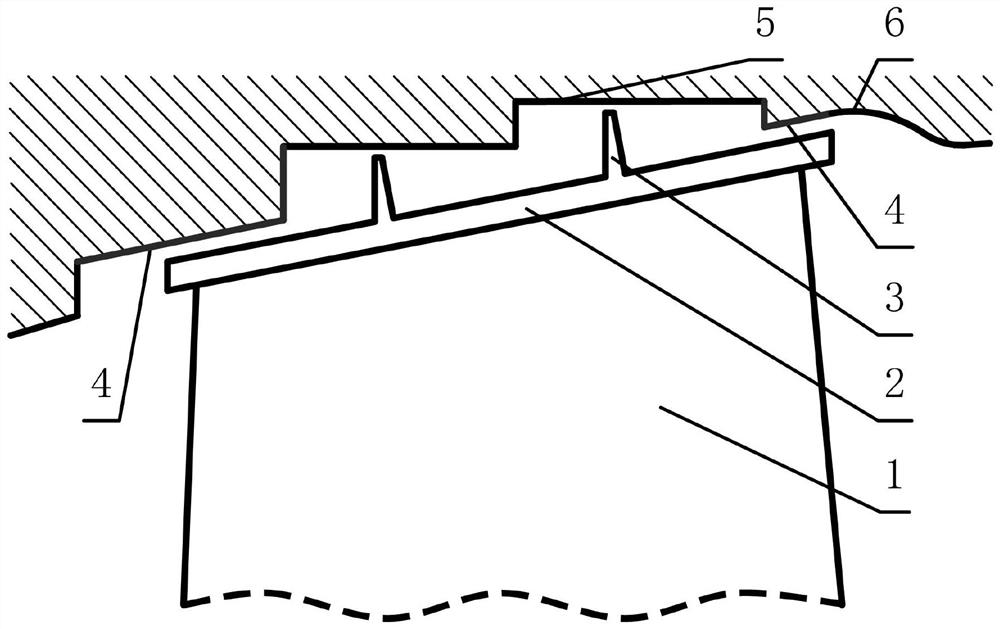

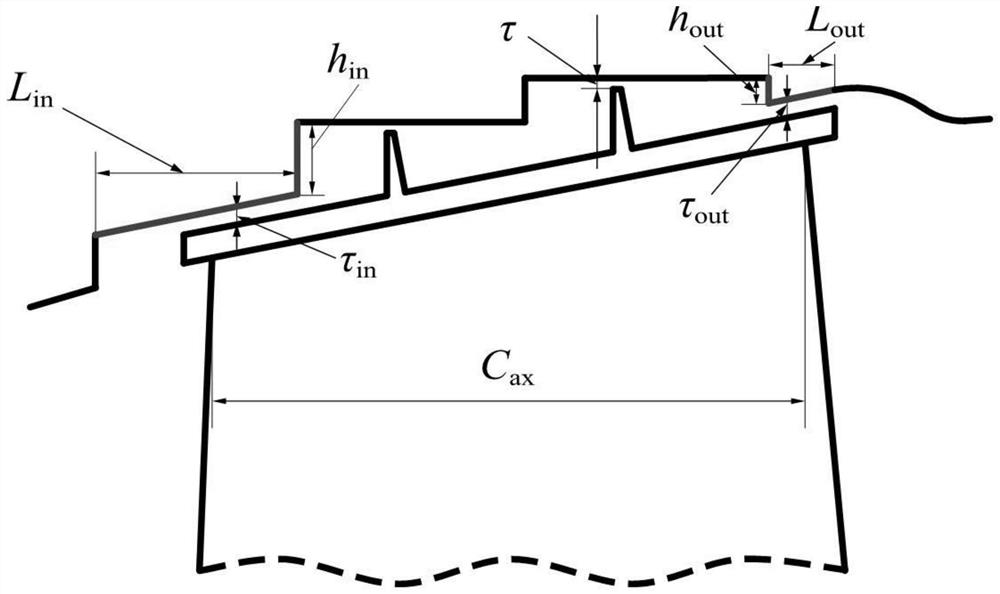

[0023] The research object of the present invention is a single-stage high aspect ratio low pressure crowned turbine. The rotor blade is provided with a double-grate blade crown structure, and the radial tooth tip clearance with the casing is 0.5mm. figure 1 A schematic geometrical representation of the shroud structure on a meridional section is given, this geometry is hereinafter referred to as the "prototype" shroud geometry.

[0024] Starting from reducing the leakage amount and adjusting the momentum distribution of the leakage flow, the present invention modifies the structure of the casing. like figure 2 As shown, the present invention includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com